CNC Stone Bridge Saw for Precision Cutting

QSQJ-400/600/800

Compatible Materials & Products

Versatile CNC Bridge Saw Processing for Premium Stone Materials

▶ Product Demo

▶

▶

|

|---|

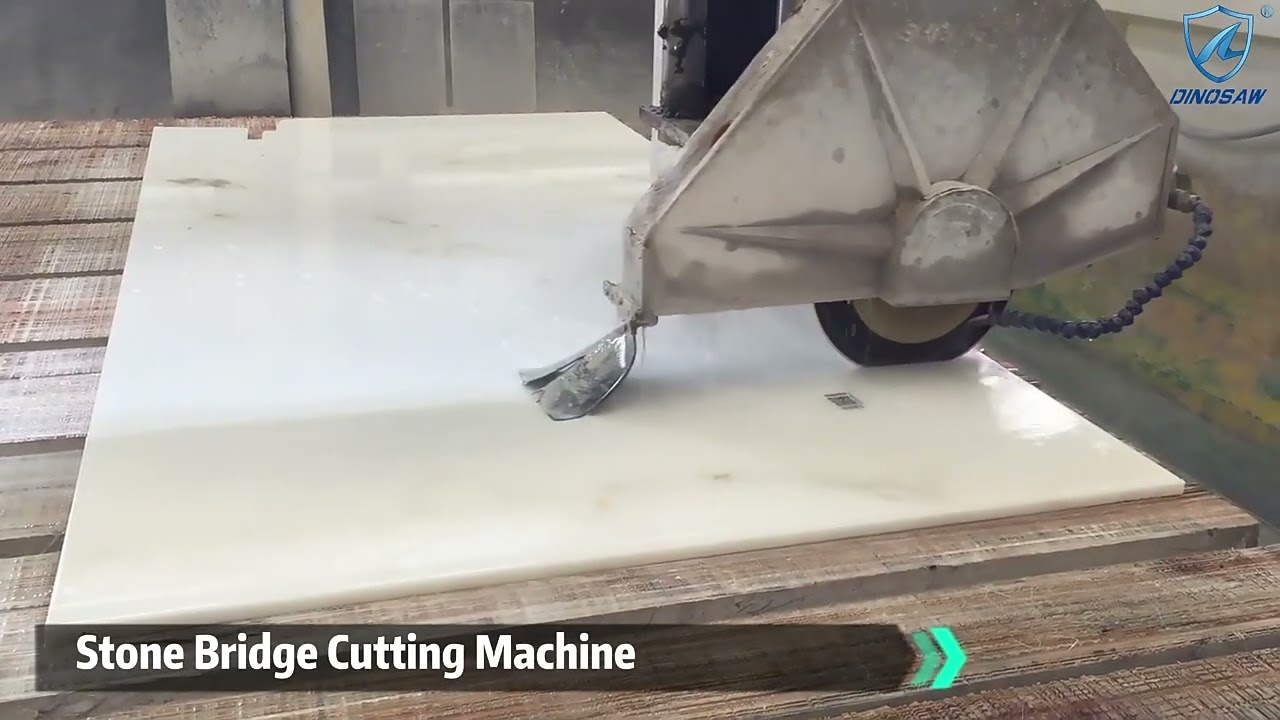

| Stone Bridge Cutting Machine Demo: Show how it cuts jade slabs |

▶

▶

|

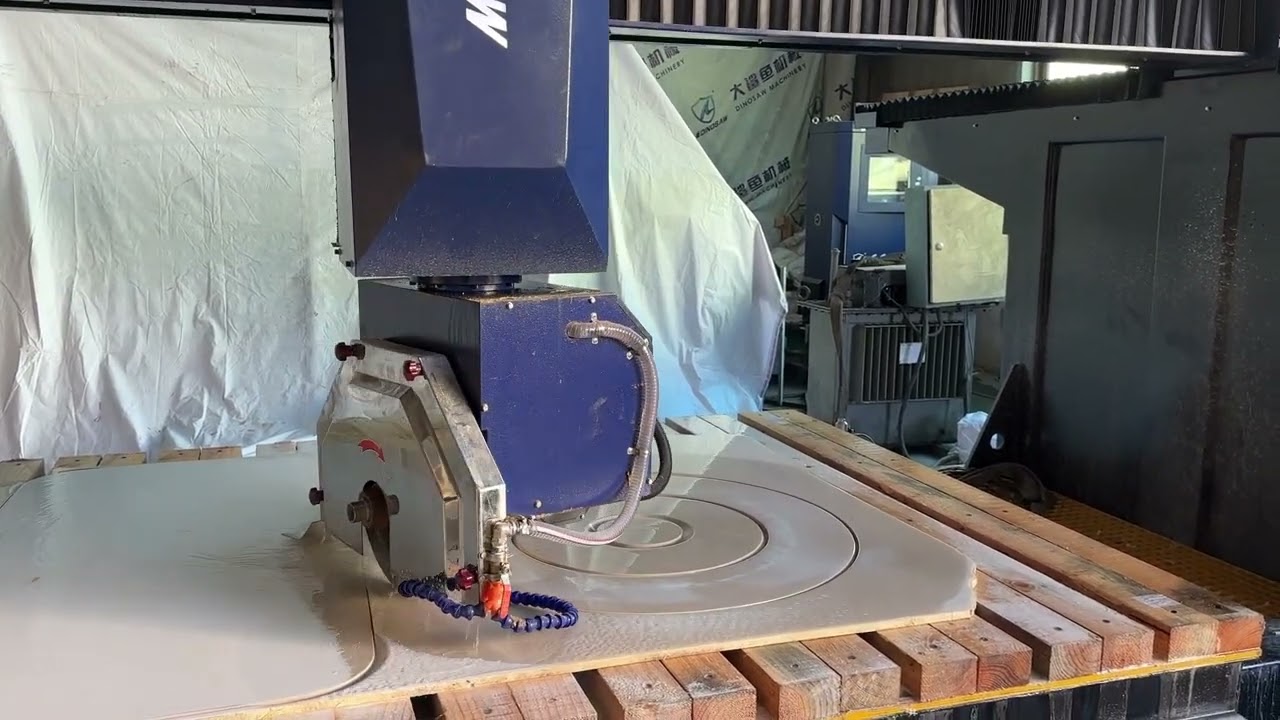

| DINOSAW 5 Axis Bridge Saw Cuts tiles, countertops,circle |

▶

▶

|

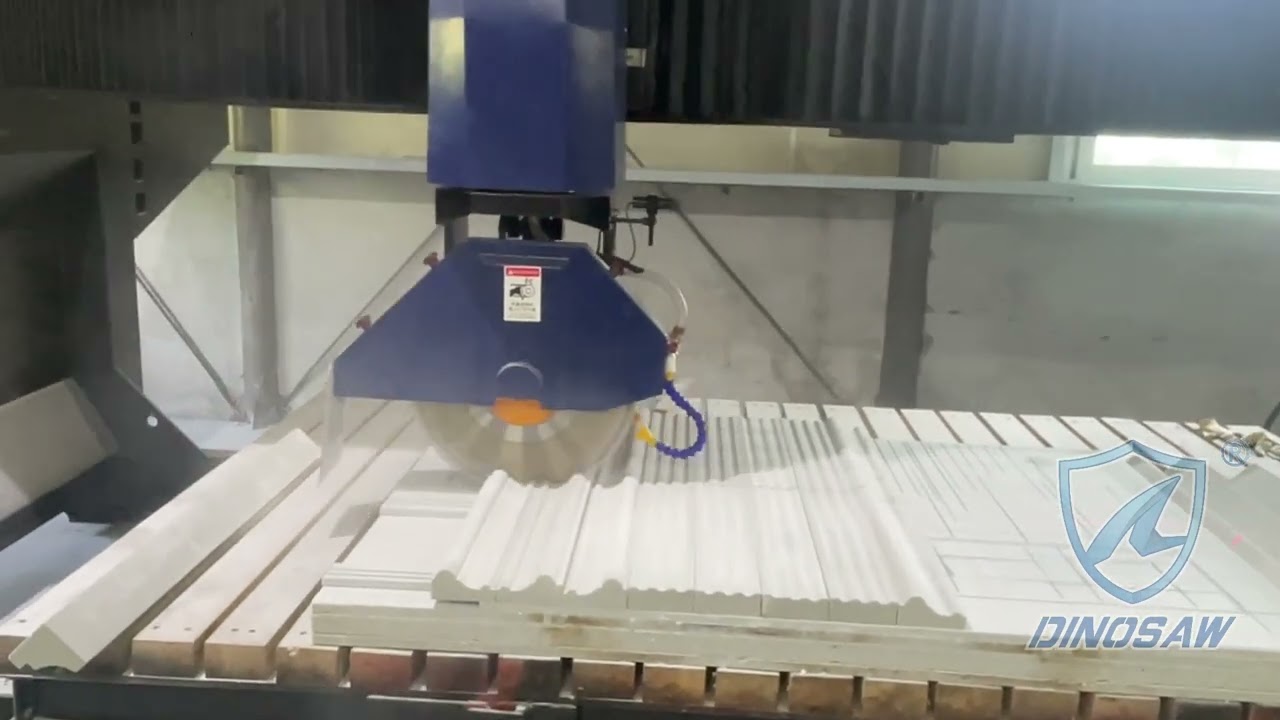

| DINOSAW bridge cutting machine cuts foamed ceramic lines |

▶

▶

|

| DINOSAW Bridge Saw Machine Cuts Slabs Automatically |

Marble ❯ Bathroom Vanity Tops

|

|

|

Marble bathroom vanity tops epitomize luxury and sophistication, with natural veining patterns and lustrous finish creating spa-like environments that transform ordinary bathrooms into elegant retreats, making marble the preferred choice for high-end projects worldwide.

DINOSAW bridge saws utilize specialized diamond blade technology and precision water cooling designed for marble's crystalline structure, cutting without thermal stress to preserve natural beauty and prevent micro-cracks. Advanced CNC programming enables complex edge profiles, sink cutouts, and decorative details in single operations, while variable cutting speeds accommodate different marble densities.

Professional fabricators achieve 50% faster production cycles while maintaining flawless surface finishes that enhance marble's luxury appeal, reducing installation time by 30% through precise measurements and eliminating extensive on-site modifications, delivering vanity tops that showcase marble's timeless elegance.

Engineered Stone ❯ Commercial Surfaces

|

|

|

Engineered stone surfaces dominate commercial applications due to consistent composition, superior durability, and resistance to staining and scratching, making them ideal for high-traffic environments like reception desks, conference tables, and retail counters where performance and aesthetics coexist.

DINOSAW bridge saws feature optimized cutting parameters and specialized tooling for quartz-based materials, utilizing diamond blades with modified bond matrices preventing chipping while ensuring clean edges. Multi-axis CNC capabilities handle large format slabs up to 3200x1600mm with precise accuracy, while automated material handling reduces labor and improves safety.

Commercial fabricators reduce material waste by 25% while achieving consistent quality across large projects, with automated cutting reducing labor costs by 30-40% and enabling faster completion times that meet demanding deadlines, delivering surfaces combining aesthetic appeal with intensive commercial durability.

Ceramic Tile ❯ Floor Tiles

|

|

|

Ceramic floor tiles require precision cutting to maintain structural integrity and achieve perfect installations, with fired clay composition demanding specialized techniques to prevent edge chipping and ensure dimensional accuracy for seamless floor layouts.

DINOSAW bridge saws incorporate adjustable cutting speeds and specialized blade configurations for ceramic materials, featuring diamond segments with optimized bond formulations minimizing edge chipping while maintaining efficiency. Automated measurement systems enable batch processing with consistent dimensions, while programmable cutting patterns accommodate various tile sizes.

Tile manufacturers increase production efficiency by 40% while maintaining tight tolerances for seamless installations, with automated processing reducing labor requirements and improving consistency across large runs, enabling faster project completion and reducing installation costs while delivering tiles meeting professional standards.

Granite ❯ Kitchen Countertop

|

|

|

Granite kitchen countertops represent durability and natural beauty in modern home design, with crystalline structure and unique mineral patterns creating installations that withstand decades of use while maintaining exceptional aesthetic appeal.

DINOSAW bridge saws employ high-torque motors generating 22KW cutting power, paired with diamond blades calibrated for granite's dense structure. Our DDX CNC control ensures ±0.05mm precision while integrated water cooling prevents thermal stress and micro-fractures. Multi-axis capabilities enable complex edge profiling, sink cutouts, and decorative beveling in single setups, with automated measurement systems guaranteeing consistent dimensions.

Professional fabricators achieve 45% faster throughput while maintaining exact measurements for perfect installations, reducing material waste by 20-25% and eliminating costly rework, delivering superior kitchen countertops that combine natural granite beauty with precision engineering excellence.

Natural Stone ❯ Monuments

|

|

|

Natural stone monuments demand exceptional precision and craftsmanship to honor lasting memories, with granite and marble blocks requiring specialized cutting techniques to create memorial shapes with intricate details and smooth finishes that withstand weathering while preserving dignity.

DINOSAW bridge saws combine powerful motors with precise CNC control to cut dense granite and marble blocks into complex memorial shapes, utilizing variable cutting speeds accommodating different stone hardness while maintaining dimensional accuracy for perfect joints and inscriptions. 5-axis capabilities enable three-dimensional carving and detailed relief work.

Monument fabricators achieve superior surface quality and reduce finishing time by 35% compared to traditional methods, with CNC precision enabling intricate details and perfect fits enhancing visual impact while reducing installation complexity, delivering monuments combining traditional craftsmanship with modern precision manufacturing.

Kitchen Countertop Fabrication

Transforming Production Efficiency for Custom Designs

A leading countertop fabricator increased daily output by 65% after implementing DINOSAW 4+1 axis bridge saw.

The integrated cutting, drilling, and edge finishing eliminated workflow bottlenecks while reducing labor costs by 30%.

Sink & Integrated Vanity Fabrication

Seamless 5-Axis Precision for Complex Cutouts

Advanced 5-axis systems create flawless sink cutouts and integrated vanity tops without visible joints.

Automated tool changes handle drilling, profiling, and edge finishing in single setups, eliminating manual assembly steps.

Architectural Cladding Projects

Meeting Demanding Specifications on Schedule

Architectural projects require precise dimensional tolerances and surface finishes. DINOSAW 5-axis systems process complex geometries for curtain walls and decorative panels, ensuring perfect fit during installation.

产品型号与参数表

参数可根据需求定制。

| Model | Unit | QSQJ-400 | QSQJ-600 | QSQJ-800 |

|---|---|---|---|---|

| Max.diameter of blade | mm | 400 | 600 | 800 |

| Main motor power | KW | 15 | 18.5 | 22 |

| Table dimensions (LxW) | mm | 3200x2000 | 3200x2000 | 3200x2000 |

| Table tilting degree | n° | 0 - 85° | 0 - 85° | 0 - 85° |

| Table rotating degree | n° | 90° / 360° | 90° / 360° | 90° / 360° |

| Max. cutting size (LxWxH) | mm | 3200x2000x80 | 3200x2000x180 | 3200x2000x280 |

| Overall dimensions (LxWxH) | mm | 6000x5000x3000 | 6000x5000x3200 | 6000x5000x3400 |

| Water consumption | m³/h | 3 | 3 | 3 |

| Approximate Weight | t | 5 | 5.3 | 5.5 |

Bridge design maximizes processing efficiency

Bridge Excellence for Stone Fabrication

Superior Stone Precision

±0.05mm accuracy via precision motors, bearings, DDX CNC system

Maximum Cutting Efficiency

25㎡/h speed via 18.5kw high-performance main motor

Easy Automation Operation

CNC system with CAD import and one-click processing

Reduced Material Waste

Camera imaging enables automatic layout optimization to maximize stone utilization

Automated Workpiece Handling

Automated suction cup workpiece positioning system eliminates labor-intensive material movement

Stable and Durable

Siemens, NSK brand components with cast iron bridge beam provide exceptional structural durability

Reduced Energy Costs

Advanced motor control and standby modes optimize power consumption for up to 40% energy savings

Quick Setup & Installation

One-piece frame structure design enables quick deployment with plug-and-play connectivity

Multi-Language Support

6+ UN languages default configuration with custom language support for international usability

FAQs

Common Questions About DINOSAW Bridge Saw Machines

What materials can a CNC bridge saw cut effectively?

DINOSAW CNC bridge saws effectively cut granite, marble, engineered stone, ceramic tiles, and natural stone materials. Our specialized diamond blades and optimized cutting parameters handle materials up to 280mm thickness with precision.

The advanced water cooling system prevents thermal damage while maintaining clean edges across all stone types. Whether processing kitchen countertops, bathroom vanities, commercial surfaces, or monuments, our bridge saws deliver consistent results with minimal material waste.

How does bridge saw accuracy compare to traditional cutting methods?

DINOSAW bridge saws achieve ±0.05mm cutting accuracy, significantly superior to manual methods typically limited to ±0.5mm. CNC control eliminates human error while maintaining consistent dimensional tolerances.

Automated measurement systems ensure repeatable results across production runs, reducing waste and improving material utilization efficiency by up to 15% compared to traditional methods.

What axis configuration should I choose for my applications?

Choose 3-axis for batch cutting of specification boards and chamfering, 4-axis for countertop cutting and curved cuts, or 5-axis for complex 3D shapes and integrated sink cutouts. Our 4+1 axis configuration adds milling capabilities for edge profiling and decorative work.

For high-volume production with varied requirements, 5-axis systems offer maximum flexibility and automation. Our technical team provides consultation to match axis configuration with your specific production needs and material types.

What safety features are included with DINOSAW bridge saws?

DINOSAW bridge saws include emergency stop buttons, safety guards around cutting areas, and automatic blade protection systems. Our machines feature enclosed cutting zones with dust collection, reducing operator exposure to debris.

What maintenance is required for optimal performance?

Daily maintenance includes cleaning stone debris, checking hydraulic fluid levels, and lubricating moving parts according to the manual. Weekly tasks involve inspecting diamond blades, testing emergency stops, and calibrating electronic components.

Monthly maintenance requires professional inspection of motorized spindles, servo drives, and hydraulic systems. Our comprehensive maintenance schedule extends machine life to 15+ years while ensuring consistent cutting quality and minimizing unexpected downtime.

How user-friendly is the DINOSAW bridge saw's software interface?

DINOSAW bridge saws feature intuitive touch-screen interfaces with CAD import capabilities and one-click processing functions. The DDX CNC system supports multiple languages and provides visual programming for complex cuts.

Operators can easily create cutting programs, monitor progress, and adjust parameters in real-time. Our comprehensive training program ensures your team can efficiently operate the system within days, maximizing productivity from day one.

Can bridge saws handle custom or irregular shapes?

Yes, DINOSAW 5-axis bridge saws excel at cutting custom shapes, curves, and complex geometries. Our CNC programming handles CAD files for precise reproduction of architectural elements, decorative panels, and artistic designs.

Multi-axis capabilities enable sink cutouts, beveled edges, and 3D profiling in single setups. Variable cutting speeds and specialized tooling accommodate intricate details while maintaining surface quality. Perfect for custom countertops, monuments, and architectural stonework.

What power requirements are needed for bridge sawinstallation?

DINOSAW bridge saws require 3-phase power supply with 380V-480V voltage depending on your location. Main motor power ranges from 15KW to 22KW based on model selection.

Total power consumption includes auxiliary systems like water pumps, hydraulics, and control electronics. Our technical team coordinates with local electricians to ensure proper power installation and can provide voltage conversion solutions if needed. Detailed electrical specifications are provided with each machine order.

荣誉认证

Bridge Excellence for Stone Fabrication

CE认证

100+项技术专利

ISO 9001:2015

大鲨鱼产品线全面符合国际工程标准,通过严格的第三方质量认证,确保所有工业设备在高负载环境下表现卓越、经久耐用。

全球服务与经验

75+

服务国家和地区

20+

年行业经验

大鲨鱼科技为硬脆材料机械设备及金刚石工具提供全生命周期质量追溯与技术支持,涵盖切割、钻孔、雕刻、抛光及各行业精密加工需求。

我们的产品服务于传统行业(矿山、石材加工、建材)、高精制造(石英玻璃、半导体)、先进材料(石墨、碳纤维复合材料)及特殊应用(核退役、铁路工程机械)。

配套产品推荐

根据您的产品需求选择设备组合,打造高效自动化生产线,最大化盈利。

Ready to revolutionize your stone processing?

Transform efficiency and precision with DINOSAW CNC bridge saw technology today

联系大鲨鱼

与大鲨鱼专家沟通,找到适合您材料及生产需求的最佳加工解决方案。

DINOSAW: Trustworthy Bridge Saw Machine Manufacturer

了解大鲨鱼如何助力您的项目。我们为您提供定制化产品线、前沿研发、强大制造、全流程服务、全球支持及行业认证。

其他设备或工具

您在寻找更多新型设备或工具信息吗?

中文

中文您好 👋 需要什么帮助?

English

English Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский