Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

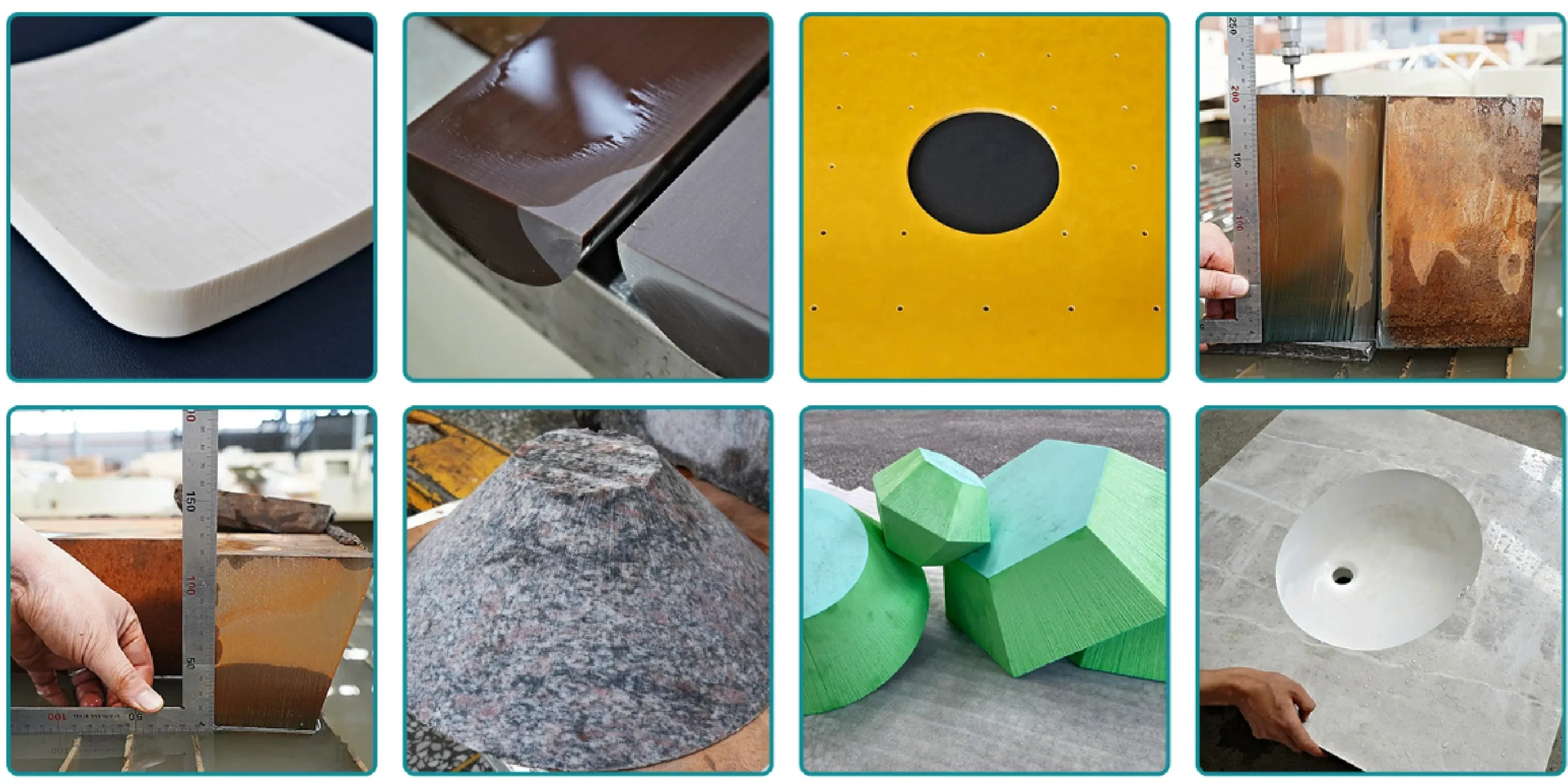

Explore 5 axis waterjet applications for mosaics, sinks, and countertops in granite, quartz, and ceramic. Achieve clean edges and tight tolerances.

For stone fabrication shops, achieving intricate designs and flawless cutouts in hard, brittle materials like granite, quartz, and ceramic is a constant challenge. A 5-axis waterjet delivers clean edges, tight tolerances, and complex geometries without creating heat-affected zones (HAZ)—making it the ideal solution for high-value applications like stone mosaic patterns and sink cutouts, where traditional saws often fall short.

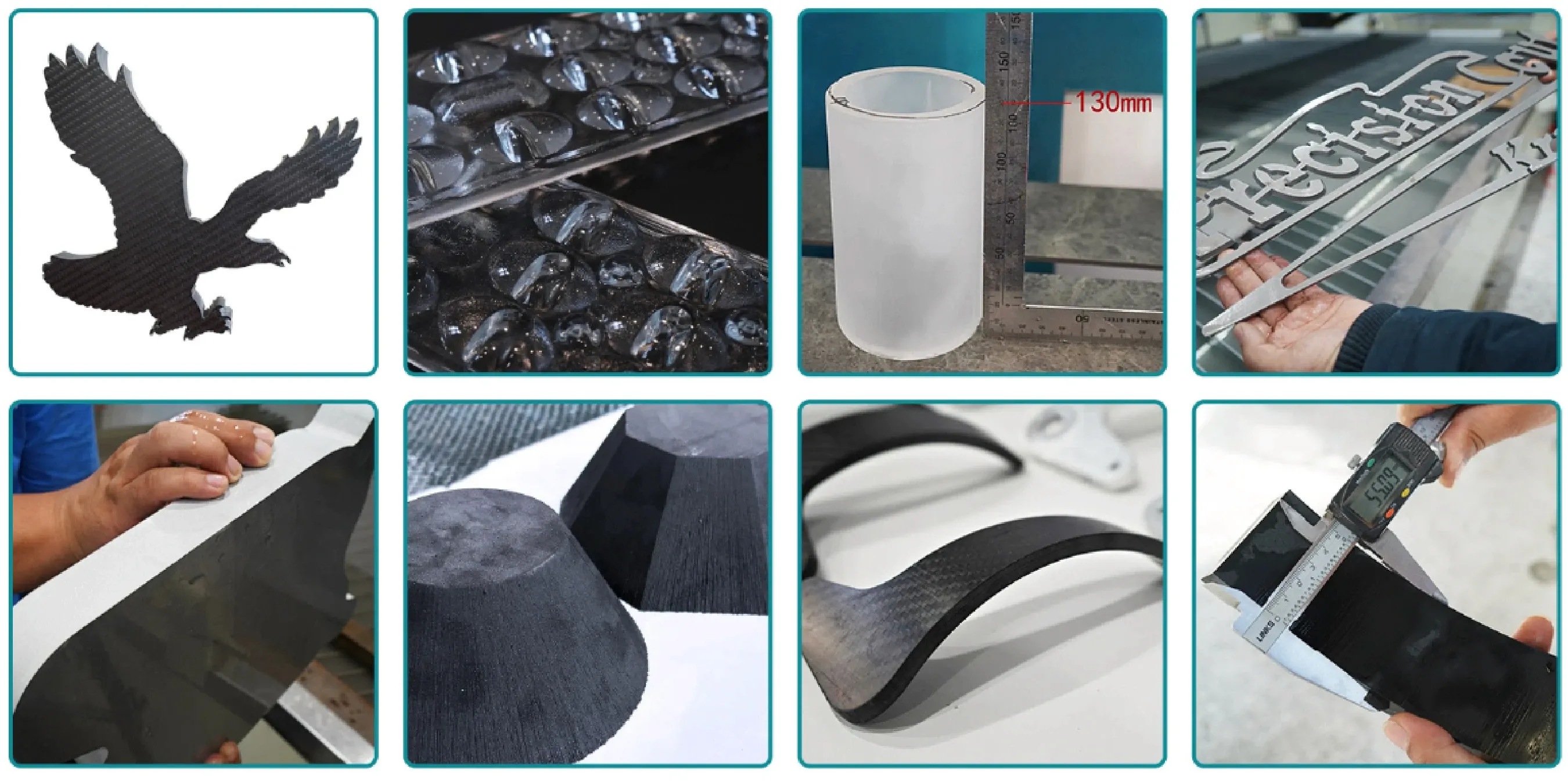

The DINOSAW 5-Axis CNC Waterjet Machine is a precision system designed for cutting stone mosaics, countertop sinks, sintered slab vanities, and other advanced materials like metals, carbon fiber, and quartz glass.

Talk to our application team to validate your mosaic or sink cutout recipe.

5 Axis Waterjet Cutting for Intricate Mosaics

Creating detailed stone mosaics requires cutting complex shapes and sharp corners without chipping or causing micro-fractures. The cold-cutting process of an abrasive waterjet is perfectly suited for this task, preserving the integrity of materials like marble and granite.

Tight Radii & Clean Edges without Heat

Unlike saws that generate heat and friction, a waterjet uses a high-velocity stream of water and abrasive to erode the material. This eliminates thermal stress, preventing discoloration and structural weakness. The fine cutting stream allows for extremely tight radii and sharp internal corners that are impossible to achieve with a bridge saw, enabling fabricators to produce detailed logos, lettering, and artistic inlays.

Sink Cutouts on Granite/Quartz/Ceramic with Waterjet

Sink cutouts are a critical part of any Countertop Fabrication Workflow. Waterjet cutting provides a superior method for producing smooth, precise openings for undermount and top-mount sinks in granite, quartz, and ceramic slabs. The process minimizes the risk of cracking the slab, a common issue with mechanical cutting methods, especially near the edges.

5-Axis Bevels vs 3-Axis Profiles

While a 3-axis waterjet can produce a clean vertical cut, a 5-axis machine adds the ability to create beveled edges for seamless sink integration or unique design features. The articulating head can tilt to cut at various angles, providing a finished edge that requires little to no secondary grinding or polishing, saving significant time and labor.

Sintered Slab Vanity Tops: Abrasive vs Pure Water

Sintered stone and ultra-compact surfaces are notoriously difficult to cut due to their hardness and brittleness. An abrasive waterjet is the go-to solution, as pure water alone cannot cut such dense materials. The key is to balance abrasive flow, pressure, and cutting speed to achieve a chip-free edge.

Low-Pressure Pierce Strategies

A critical technique for brittle materials like sintered slabs and glass is the use of a low-pressure piercing cycle. Instead of starting at full pressure, the machine pierces the surface at a lower pressure to create a starting hole without causing blow-outs or cracking. Once the material is pierced, the system ramps up to full cutting pressure to complete the profile, ensuring a safe and clean start to the cut.

Mini-Cases: Real-World Applications

- Marble Mosaic Logo: A hospitality client required a complex company logo inlaid into a marble floor. A 5-axis waterjet was used to cut the intricate marble pieces with tight tolerances, ensuring a perfect fit with minimal grout lines.

- Granite Sink Cutout with Tight Radii: A kitchen countertop fabricator used a waterjet to execute a custom sink cutout in a 3cm granite slab, featuring tight corner radii of 8mm. The result was a smooth, chip-free edge that required no additional hand finishing.

- 12mm Sintered Slab Vanity Top: A bathroom vanity top made from a 12mm sintered slab required cutouts for the faucet and sink. A low-pressure pierce followed by a standard abrasive cut prevented chipping and delivered a flawless finish, a task too risky for conventional saws.

Summary of Capabilities

| Capability | Details & Boundaries | |

|---|---|---|

| Supported Materials | Granite, marble, engineered stone, sintered slab metals (stainless steel, aluminum), carbon fiber (CFRP), glass, and quartz glass. | |

| Material Limitations | For very thick slabs (e.g., over 15 cm / 6 inches), multiple passes or reduced cutting speeds are typically required. An unknown interlayer may cause delamination. | |

| Risks & Prerequisites | Ensure secure material fixturing to prevent movement. For porous stones, water ingress can be a risk; post-cut sealing may be required. For glass, pierce blow-out is a risk without a proper low-pressure strategy. Consistent abrasive quality and pump pressure calibration are essential for reliable results. | |

Frequently Asked Questions

How do you choose between abrasive and pure waterjet cutting?

Abrasive waterjet is used for hard materials like stone, metal, and glass. Pure waterjet is only suitable for soft materials like foam, rubber, and thin plastics.

What is the best piercing strategy for brittle glass?

Always use a low-pressure pierce. This starts the cut gently to avoid thermal shock and cracking before the machine switches to high pressure for the main cut.

Can a waterjet cut sintered slabs without chipping?

Yes, a waterjet is one of the most reliable methods for cutting sintered slabs chip-free. Success depends on a correct low-pressure pierce, proper abrasive flow, and an optimized feed rate.

What is a typical cutting tolerance for a 5-axis waterjet?

A well-maintained machine can achieve tolerances of ±0.1mm (±0.004 inches), with a repeated precision of ±0.02mm, though this depends on material thickness and cutting speed.

When should I use a 5-axis waterjet instead of a 3-axis?

Use a 5-axis machine for any job requiring beveled edges, countersinks, or complex 3D contours. For simple 2D profiles and straight cuts, a 3-axis machine is sufficient.

Should I seal porous stone after waterjet cutting?

It is a recommended best practice. Although the cutting process is fast, some porous stones like certain marbles or limestones can absorb water. Sealing after cutting protects against potential staining.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский