Manual Industrial Stone Cutting Machine

Oct 29, 2025

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

Bridge saws are a core stone cutting machine type for slab and countertop work, built for repeatable accuracy and clean edges. Depending on axis configuration and table setup, they support straight cuts, 45° bevel cuts (mitre), and more complex patterns for fabrication workflows.

If you need help choosing a bridge saw configuration, share your material, max slab size, and daily output—we’ll recommend the right axis setup and options and provide a quote.

Block cutting machines are designed to process large stone blocks into consistent slabs and tiles with stable throughput. They’re the right category when you run batch production and care most about output, reliability, and smooth cutting under heavy loads.

Choose this type for granite, marble, limestone, and other natural stones—especially when block size and daily capacity are the key constraints. Tell us your block dimensions, material, and target output, and we’ll recommend the appropriate machine layout and blade options.

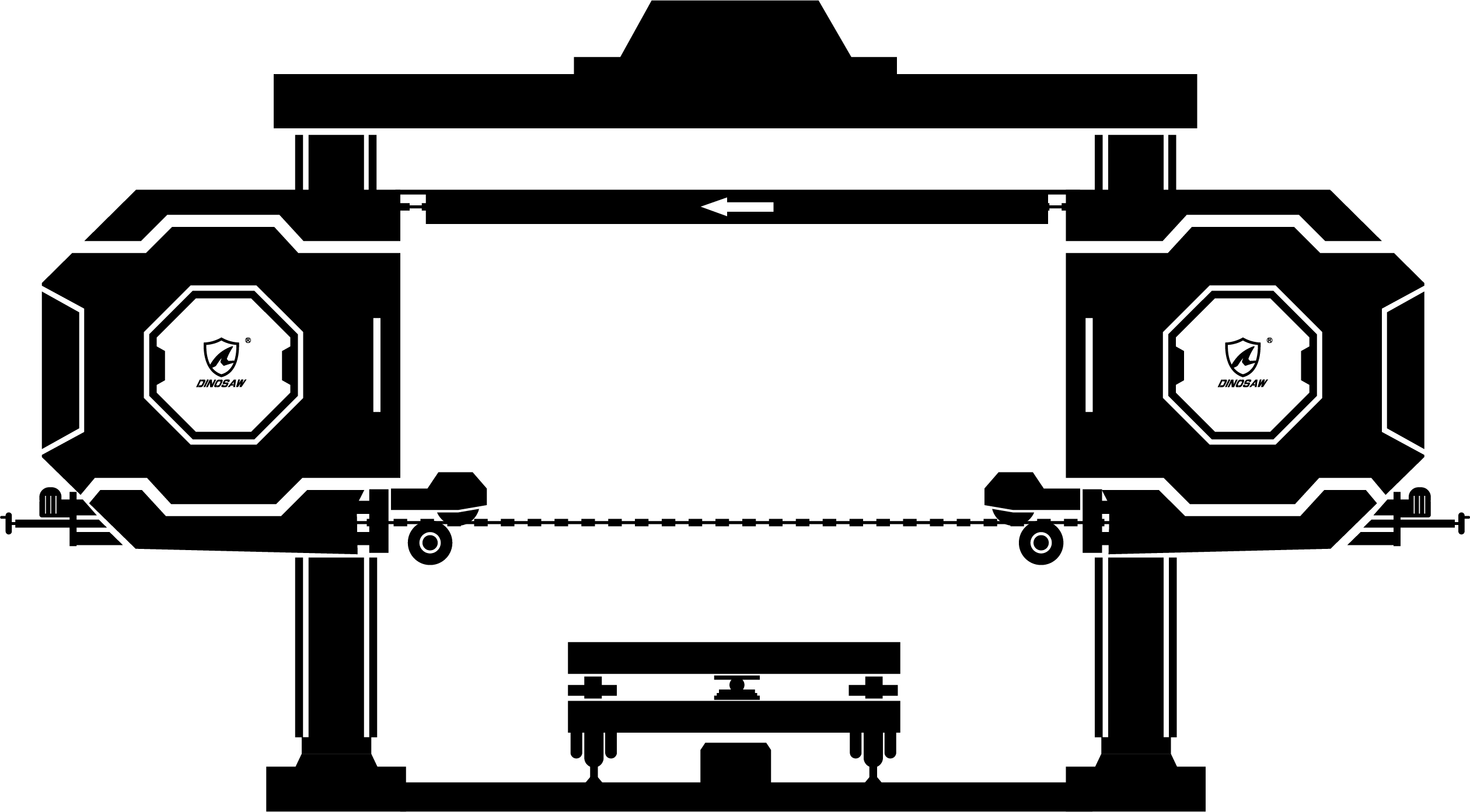

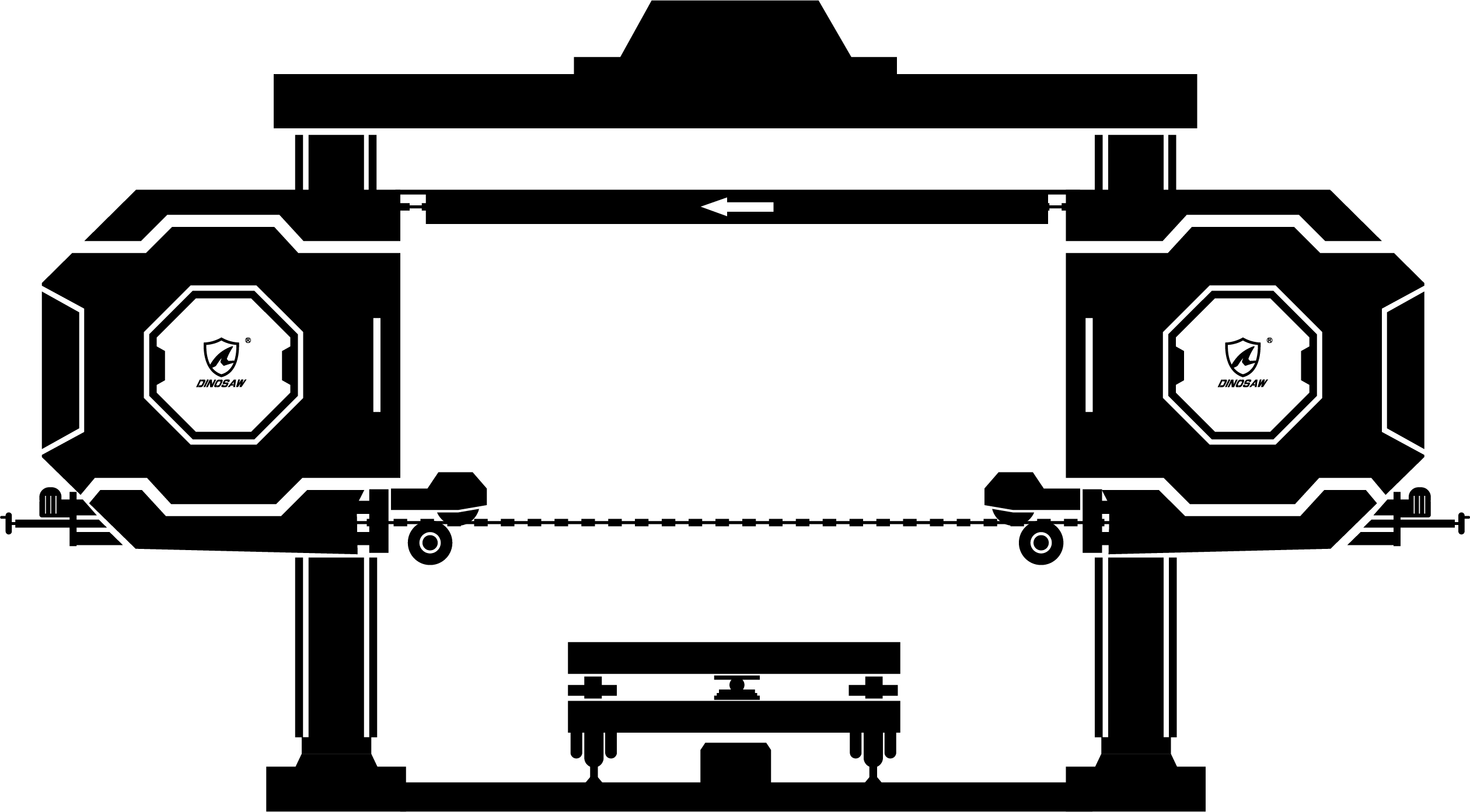

Manual stone cutting machines are compact solutions for small to medium operations that need flexible cutting without CNC automation. They’re widely used for tiles, ceramics, limestone, sandstone, and decorative stone where quick setup, footprint, and cost efficiency matter.

For straight and 45° bevel cutting in workshops or on-site projects, manual machines offer practical control and dependable results. If you share your material, max cutting size, and typical cut type, we’ll recommend the best fit and provide a quote.

Stone cutting machines are industrial machines used to cut stone and other hard materials with controlled accuracy and efficiency. In practical production, they’re typically grouped by application into CNC bridge saws, block cutting machines, and manual stone cutting machines—the same three categories shown on this page.

CNC Bridge Saws: best for slabs and countertop blanks where edge quality, repeatability, and bevel cutting matter.

Block Cutting Machines: designed for high-throughput processing of large blocks into slabs and tiles.

Manual Stone Cutting Machines: compact and flexible for workshops, small batches, and on-site jobs.

To choose the right machine type, focus on three inputs: material & hardness, max workpiece size, and daily output target. Once the type is clear, you can compare the specific models above and request the configuration that fits your workflow.

Choosing the right stone cutting machine is less about picking a “bigger” model and more about matching your workpiece, material, and output target to the right machine type. In most stone-processing workflows, stone cutting machines fall into three practical categories: CNC bridge saw machines (bridge cutting machines) for slab and fabrication work, stone block cutting machines (block cutters) for high-volume block processing, and manual stone cutting machines for workshops and flexible on-site jobs. Use the guide below to narrow down the right category first, then compare configurations within that category.

Your maximum workpiece size is the fastest way to avoid buying the wrong machine.

Slabs / countertop blanks (fabrication)

Choose a CNC bridge saw (often searched as a CNC bridge saw machine or bridge cutting machine). This category is built for repeatable accuracy, clean edges, and efficient straight and bevel cutting on slab-sized materials.

Large stone blocks (batch production)

Choose a stone block cutting machine (also called a block cutting machine or stone block cutter). This category is designed for high-throughput processing—turning blocks into slabs and tiles with stable feeding and heavy-duty mechanical structure.

Tiles, small pieces, workshop tasks, and on-site cutting

Choose a manual stone cutting machine (manual stone cutter). It’s the practical option when footprint, budget, and quick setup matter more than CNC automation.

If you’re unsure, ask one question: “Is my main job slab fabrication, block-to-slab production, or flexible workshop cutting?” The answer usually determines the category.

Material hardness and edge behavior decide how much stability, power, and cooling you need.

Granite / quartz / engineered stone

These are demanding materials. Prioritize a stable frame, reliable drive, and consistent water cooling to protect blade life and reduce chipping. If your daily output is high, choose configurations that stay stable under continuous load.

Marble / limestone / sandstone

Softer stones can still be edge-sensitive. Prioritize smooth cutting behavior, stable feeding, and finish quality—especially if the parts are decorative or visible surfaces.

Ceramics / porcelain / sintered stone

These often require careful control to avoid edge damage. Stable feed, consistent cooling, and the right blade setup matter more than “raw power.” If your workflow includes frequent bevels or finishing cuts, plan for configurations that keep edges clean.

A simple way to think about materials: harder materials require more cutting stability and cooling discipline; edge-sensitive materials require smoother feeding and better finish control.

Many buyers focus on “can it cut?” but the real cost comes from edge quality and rework.

Straight cuts (most common)

All categories can handle straight cuts, but output and repeatability differ dramatically. For repeated production, CNC bridge saws and heavy-duty block cutters tend to reduce labor and rework.

45-degree bevel cuts / 45° miter cuts

If bevel cutting is frequent (countertops, architectural parts, edge finishing), treat it as a primary requirement. A bridge saw configuration is typically the most efficient approach for slab fabrication bevel work, while manual machines can handle bevel cutting for smaller-scale workshop applications.

Pattern work / complex operations (depends on configuration)

Some bridge saw setups support more complex operations depending on axis configuration and table design. If pattern cutting is a real need, define it upfront so the right configuration is selected.

Output is not just “how many pieces per day.” It’s the deciding factor for reliability and labor cost.

Low-volume / mixed jobs

Choose flexibility and quick setup. Manual machines often win on cost efficiency when jobs change frequently.

Medium-volume production

Prioritize repeatability and stable throughput. CNC bridge saws reduce labor and help keep edge quality consistent.

High-volume / continuous production

Prioritize heavy-duty structure, serviceability, and stable feeding. For block processing, this usually points to a robust stone block cutting machine configuration built for long shifts.

A practical rule: if labor time and rework cost are already a bottleneck, automation pays for itself faster than most buyers expect—especially in slab fabrication workflows.

Once you’ve chosen the category, compare models using production-critical checkpoints. These are also the fields you should request in a quotation.

A) Cutting capacity (non-negotiable)

Max slab/block size (length/width)

Cutting height / max thickness

Table size and usable travel (for bridge saws)

B) Blade system and drive power (matched to material)

Blade diameter range

Motor power appropriate for material hardness and thickness

Stability under load (especially for granite/quartz)

C) Accuracy and repeatability (fabrication workflows)

Repeatable positioning matters more than “one-time accuracy”

Edge quality and reduced chipping reduce rework and polishing time

D) Cooling and water management (often underestimated)

Consistent water cooling affects finish quality and blade life

For long production shifts, water handling and filtration influence uptime and operating cost

E) Automation level / axis configuration (mainly for CNC bridge saws)

Higher automation improves repeatability and reduces operator dependency

Choose the configuration based on your cut types (straight, bevel, repeated trimming, pattern work)

F) Maintenance access and service support (uptime)

Easy access to wear parts reduces downtime

Spare parts availability and after-sales response directly affect total cost of ownership

If two machines look similar on paper, the real differentiator is often: stability under continuous work, edge quality consistency, and how quickly you can maintain it.

If you want a quick confirmation, use this checklist:

I cut mainly slabs/countertops → I should compare CNC bridge saw machines

I cut mainly blocks for batch production → I should compare stone block cutting machines

I cut mainly tiles/small jobs/on-site → I should compare manual stone cutting machines

My material is granite/quartz → I should prioritize stability, power, and cooling

I need frequent 45° bevel cuts → configuration must support repeatable miter cutting

My goal is higher daily output → reliability and serviceability matter as much as speed

To recommend the right stone cutting machine type and configuration, share:

Material (granite / marble / quartz / ceramics / sintered stone)

Workpiece (slab / tile / block) + max size + thickness

Main cut type (straight / 45° bevel / repeated trimming)

Daily output target and your current bottleneck (speed, labor, edge quality, rework)

We’ll match the best machine category and configuration for your workflow and provide a quote.

A stone cutting machine is an industrial machine that cuts stone and other hard materials into slabs, tiles, blocks, and fabrication blanks with controlled accuracy and efficiency.

What it’s used for: straight cutting, sizing, trimming, and (depending on configuration) 45° bevel (miter) cutting

Common materials: granite, marble, quartz, limestone, ceramics/porcelain, sintered stone

How it’s typically categorized (buyer-friendly):

CNC bridge saw machines / bridge cutting machines (slabs & fabrication)

Stone block cutting machines / block cutters (block-to-slab/tile throughput)

Manual stone cutting machines (workshops & flexible jobs)

Most production workflows fall into three practical types:

CNC bridge saw (bridge cutting machine): best for slabs, countertops, and fabrication blanks where repeatability and edge quality matter

Stone block cutting machine (block cutter): best for large blocks and batch processing into slabs/tiles

Manual stone cutting machine: best for small shops, tiles, decorative work, and on-site jobs where footprint and budget matter

Tip: choose the type first (by workpiece), then compare models within that type.

Use a 3-input decision rule:

Workpiece: slab / tile / block (max length, width, thickness, cutting height)

Material: granite/quartz vs marble/limestone vs ceramics/sintered stone

Output target: daily capacity + whether jobs are repetitive or mixed

Then validate with:

cut type (straight vs 45° bevel/miter)

finish requirement (edge chipping tolerance)

shop constraints (footprint, utilities, maintenance)

In practice, buyers use them interchangeably.

“Stone saw machine” often emphasizes the cutting method (blade saw), while “stone cutting machine” is broader and includes different workflows (slab, tile, block).

For SEO and clarity on a hub page:

Treat stone cutting machine(s) as the umbrella term

Use stone saw machine / stone cutting saw machine as supporting language when relevant (e.g., circular blade, saw-based cutting)

A bridge cutting machine (CNC bridge saw) is mainly used for slab cutting and fabrication—countertop blanks, architectural parts, and repeatable precision cuts.

Best for: slabs, countertops, sink cutouts (depending on setup), repeated sizing

Strengths: repeatability, consistent edge quality, efficient straight and bevel cutting

Key selection factors: slab size capacity, table design/travel, automation level, accuracy needs, bevel/pattern requirements

Choose by your main workpiece:

Pick a CNC bridge saw if you cut slabs and care about fabrication accuracy, clean edges, and repeatable processing

Pick a stone block cutting machine if you cut large blocks and your priority is batch throughput and stability under heavy load

A simple test:

If your raw input is mostly slabs → bridge saw

If your raw input is mostly blocks → block cutter

Focus on production-critical specs, not marketing terms:

Capacity: max slab size, cutting travel, cutting height/thickness

Accuracy & repeatability: whether positioning stays consistent in daily work

Bevel capability: stable 45° miter performance if you use it often

Blade system: blade diameter compatibility + motor power matched to material/thickness

Automation/axis configuration: choose based on your actual cut types (straight, bevel, repeated trimming, pattern work)

Water cooling & management: finish quality + blade life + operating cost

Yes—if the configuration is designed for it. Bevel cutting quality depends on stability and repeatability, not just “having a bevel function.”

To evaluate bevel reliability:

how stable the positioning is under load

whether bevel cutting is repeatable across a shift

whether edge chipping is controlled (material-dependent)

whether cooling is consistent during bevel operations

If bevel cuts are frequent, treat them as a primary requirement when selecting configuration.

A stone block cutting machine is used to process large stone blocks into slabs and tiles with stable throughput.

Best for: block-to-slab production, batch cutting, high-volume sizing

Strengths: heavy-duty stability, consistent throughput, production-oriented design

Key selection factors: max block size, cutting height, blade arrangement, feeding stability, maintenance accessibility

Choose based on block size + hardness + output target:

For granite/quartz: prioritize cutting stability, robust drive, and cooling discipline; match blade diameter and power to thickness/hardness

For marble/limestone: prioritize stable feeding and finish quality; reduce edge damage through proper setup and cooling

For high output: uptime and serviceability become as important as speed—downtime cost usually dominates total cost

What to prepare for a correct quote:

block dimensions + thickness range

material type

daily output target and shift pattern

Edge chipping usually comes from a mismatch between material behavior and cutting stability.

Common causes:

unstable feeding under load

blade selection not matched to material/thickness

insufficient or inconsistent water cooling

excessive vibration or worn components

too aggressive cutting parameters for edge-sensitive materials

How to reduce it:

ensure stable feed and rigid structure appropriate for hardness

keep cooling consistent (water flow/cleanliness matters)

match blade diameter and setup to the job

prioritize repeatability over “max speed” for chipping-sensitive work

Choose a manual stone cutting machine when you need flexibility and cost efficiency more than automation.

Best for: workshops, small batches, tile/decorative cuts, on-site jobs

Typical users: small fabrication shops, contractors, installers

Why it wins: compact footprint, easier setup, lower upfront cost, good ROI for mixed jobs

It’s also a practical entry option if your workload is variable and you want to keep operating cost predictable.

It can—but capacity and stability limitations matter more on harder materials.

If you plan to cut granite/quartz with a manual machine:

confirm cutting capacity and thickness range

prioritize stability and consistent cooling

expect slower throughput compared to CNC/production machines

set realistic expectations on edge finish and rework time based on hardness and cut type

If hard materials and daily output are high, a production-oriented category (bridge saw or block machine) usually becomes more cost-effective long term.

Decide by repeatability and labor cost:

Choose CNC when jobs are repetitive and edge quality/repeatability directly affect production efficiency and rework

Choose manual when jobs change frequently, output is lower, and the shop values flexibility and smaller footprint

A practical metric:

If operator time + rework is a visible bottleneck, CNC tends to pay back faster.

For sintered stone / porcelain, edge quality and stability are critical—these materials can be sensitive to edge damage.

Selection priorities:

stable feeding and controlled cutting behavior

consistent water cooling and clean water supply

configuration that supports your main cut type (straight vs bevel)

realistic throughput targets (avoid chasing speed at the expense of edge quality)

The best category depends on the workpiece:

slabs/fabrication → CNC bridge saw category

workshop sizing/smaller pieces → manual category (within capacity constraints)

Buyers often underestimate capacity constraints. Use these:

Max workpiece size: length/width and cutting height/thickness (non-negotiable)

Typical thickness range: not just the maximum once a month

Cut type: bevel cuts often require more stability and can affect effective throughput

Output target: pieces/day or meters/day, and how consistent that demand is

A safe method:

size the machine to your 90th percentile jobs, not rare extremes

avoid buying “just enough” capacity if you plan growth; upgrades often cost more than sizing correctly once

For a correct recommendation and quote, provide:

material (granite/marble/quartz/ceramics/sintered stone)

workpiece type (slab/tile/block) + max size + thickness range

main cut type (straight / 45° bevel)

daily output target and shift pattern

your current bottleneck (speed, labor, edge chipping, rework)

This allows a vendor to match category + configuration instead of guessing.

The highest ROI maintenance topics are the ones that prevent downtime and quality drift:

consistent water cooling and water quality management

inspection of wear parts that affect stability (feed components, alignment-sensitive parts)

keeping cutting behavior stable (reducing vibration and parameter drift)

planning for service access and spare parts so downtime doesn’t dominate production cost

If you run continuous production, uptime is often the biggest hidden cost—maintenance strategy should reflect that.

English

English

Get A Easy Solution

Chat Online

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Hello 👋 How can we help?