Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

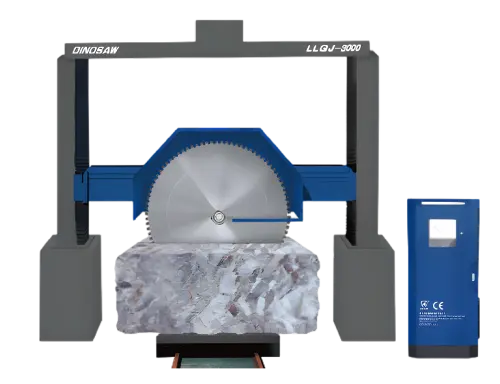

Gantry Stone Block Cutting Machine for Granite, Marble & Bluestone

LLQJ-2200/2500/3000

Compatible Materials & Products

Versatile Stone Block Cutting for Premium Slab Products

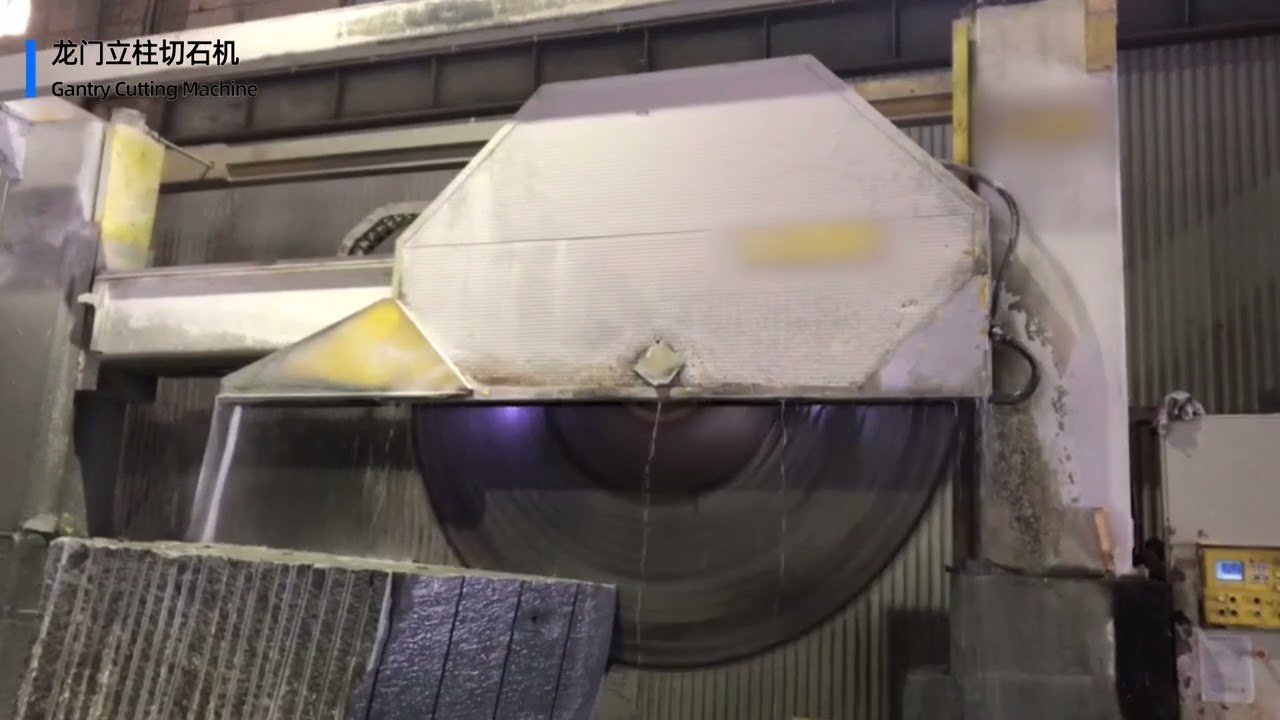

▶ Product Demo

▶

▶

Granite ❯ Tombstone Cutting

Tombstone Industry Applications: Granite stands as the gold standard for tombstone manufacturing due to its exceptional hardness (6-7 Mohs scale) and superior weather resistance. The global memorial industry processes over 200,000 tons of granite annually, with premium varieties commanding high prices for their durability and prestige value. What makes granite particularly valuable for tombstone production is its ability to maintain detailed engravings and polished surfaces for decades without deterioration, making it the material of choice for 80% of modern memorial installations.

Precision Tombstone Processing: Our gantry cutting machine excels at processing granite blocks into tombstone blanks using diamond-tipped circular saw blades specifically designed for granite's dense 2.6-2.8g/cm³ structure. The V-shaped crossbeam structure ensures stable cutting performance essential for creating the precise rectangular and custom-shaped blanks required in memorial stone fabrication. The multiple cutting frames stationed on horizontal tracks enable even processing of workpieces, and due to their efficiency and precision, gantry block cutting machines have become the industry standard in stone cutting. PLC-controlled hydraulic systems provide smooth operation while water cooling prevents thermal stress that could compromise stone integrity during the cutting process.

Memorial Industry Benefits: This automated tombstone cutting system eliminates manual measurement errors that can result in costly material waste, reduces granite waste by 15%, and delivers precisely dimensioned tombstone blanks ready for engraving and finishing. The consistent cutting quality ensures uniform thickness essential for professional memorial fabrication, while the reliable processing enables monument producers to meet growing demand with superior quality standards. Furthermore, the automated operation significantly reduces labor costs compared to traditional cutting methods, enabling memorial stone manufacturers to maintain competitive pricing while improving their production consistency and profitability in the specialized tombstone market.

Marble ❯ Monument Production

Monument Industry Applications: Marble's natural beauty and workability make it the premium choice for monument and tombstone production, with the global memorial industry processing over 150,000 tons annually. Premium varieties like Carrara marble command high prices in memorial applications due to their fine grain structure and superior carving properties for detailed engravings and sculptural elements.

Precision Block Processing: Our gantry machine's hydraulic lifting system provides vibration-dampened cutting essential for preserving marble's delicate veining patterns during monument block preparation. The programmable control system and hydraulic transmission feature reliable performance and high cutting efficiency, while diamond blades slice through marble's 3-4 Mohs hardness with minimal stress generation. The frequency converter enables stepless speed adjustment for different marble densities (2.5-2.8g/cm³).

Production Excellence: Multi-blade configurations allow simultaneous processing of multiple monument blocks, increasing production efficiency by 200% while maintaining surface quality essential for memorial applications. This reliable cutting system reduces subsequent finishing time by 35%, enabling monument producers to meet growing demand with superior quality and faster delivery times for custom memorial projects.

Limestone ❯ Kerb Stone Cutting

Infrastructure Market Demand: Limestone's durability and workability drive the $25 billion global infrastructure market, with kerb stone applications requiring precise dimensional accuracy for road construction and urban development projects. Different stone processing machines enable work on specific materials including limestone because each type needs its own particular cutting method. Modern infrastructure projects demand standardized kerb stone dimensions for efficient installation and long-term performance.

Specialized Kerb Cutting: Our gantry machine's automated control system processes limestone blocks (2-6 Mohs hardness, 2.2-2.8g/cm³ density) using programmable cutting sequences optimized for kerb stone production. The four-column hydraulic locking structure provides good overall rigidity and small clearance, reducing shaking during stone cutting. The touchscreen PLC interface allows operators to input standard kerb dimensions directly, ensuring consistent 200x100x1000mm specifications for road construction applications.

Infrastructure Efficiency: Water jet cooling prevents limestone's carbonate structure from thermal damage, preserving natural texture integrity essential for weathering resistance in outdoor applications. This automated kerb stone manufacturing reduces installation complications by 50%, eliminates costly dimensional variations, and enables infrastructure contractors to complete road projects 30% faster while meeting stringent municipal specifications for urban development.

Sandstone ❯ Standard Slab Cutting

Standard Slab Market Value: Sandstone's natural texture and consistent properties drive standardized slab production for construction industry applications, with growing demand for 600x300x20mm and 400x400x25mm standard formats. Gantry block cutting machines process various types of stone - whether natural or artificially created, ranging from sandstone to limestone. The construction industry increasingly relies on standardized dimensions for efficient building processes and cost-effective installation.

High-Volume Slab Processing: Our machine's frequency converter technology adjusts cutting parameters to accommodate sandstone's variable density (1.8-2.6g/cm³) and composition variations, ensuring consistent slab thickness across production runs. The robust steel frame construction with multi-blade configuration enables simultaneous cutting of 6-10 standard slabs, dramatically increasing production capacity. The multi-blade stone cutting machine is designed for heavy use with the latest technology for cutting stone blocks into slabs.

Standardization Benefits: Advanced programmable controls ensure dimensional consistency essential for modern construction applications, reducing installation time by 40% compared to custom-cut alternatives. This standardized slab production enables stone suppliers to achieve economies of scale, reduce inventory complexity by 60%, and offer competitive pricing while maintaining quality standards required for commercial construction projects.

Travertin ❯ Block Cutting

Architectural Block Processing: Travertine's unique cellular structure and warm aesthetics make it a premium choice for luxury architectural applications, with growing demand for decorative wall panels, flooring tiles, and facade elements. Gantry block cutting machines process various types of stone - whether natural or artificially created, ranging from sandstone to limestone to even synthetic stones used for specific construction demands, and this adaptability means they cater to distinct customer needs across multiple industries. The natural porosity (15-25%) and distinctive banded texture of travertine require specialized block cutting techniques to preserve the stone's inherent beauty while creating dimensionally accurate slabs for downstream processing into architectural products.

Advanced Block Cutting Technology: Our gantry machine's water cooling system delivers precisely controlled flow rates essential for processing travertine's calcium carbonate structure (2.3-2.7g/cm³ density) without thermal damage to its delicate pore structure. The programmable blade positioning system automatically compensates for travertine's natural void distribution and density variations, maintaining consistent cutting performance while preserving the stone's structural integrity. The steel frame structure adds stability through its design characteristics and diamond blades allow precise cutting of hard materials, while the electronic control system enables automated processing with efficient operation. This sophisticated approach ensures clean block cuts that preserve travertine's natural character essential for high-end architectural applications.

Architectural Market Advantages: PLC-controlled block cutting operations automatically adjust cutting parameters based on material density variations throughout each travertine block, ensuring consistent dimensional accuracy without compromising the stone's unique aesthetic qualities. This specialized processing eliminates 60% of manual handling traditionally required for travertine preparation, produces installation-ready blocks with clean, sealed surfaces, and delivers architectural-grade material ready for further processing into premium building products. The automated block cutting reduces project timelines by 5-7 days while maintaining the superior appearance standards demanded by luxury construction projects, enabling stone suppliers to command premium pricing in competitive architectural markets.

Specs and options

Specifications customizable upon request.

| Model | Unit | LLQJ - 2200 | LLQJ - 2500 | LLQJ - 3000 |

|---|---|---|---|---|

| Max. diameter of blade | mm | 2200 | 2500 | 3000 |

| Max. No. of blades | pc | 3 | 1 | 1 |

| Recommended Blade Combination | mm | 2200 1600 940 | 2500 | 3000 |

| Recommend saw blade thickness | mm | 6.5 | 8.0 | 8.0 |

| Main motor power | kw | 30 | 30 | 37 |

| Table dimensions (L x W) | mm | 2000x2000 | 2000x2000 | 2000x2000 |

| Max. cutting size (L x W x H) | mm | 3000x2000x950 | 3000x2000x1100 | 3400x2000x1350 |

| Overall dimensions (L x W x H) | mm | 6600x6000x4800 | 6600x6000x4800 | 7000x4700x6000 |

| Water consumption | m³/h | 10 | 10 | 10 |

| Approximate weight | t | 9 | 9 | 12 |

Transform stone blocks into profitable slabs efficiently.

Gantry Structure. Block Cutting. Mass Production.

Consistent Cutting Results

Heavy-duty steel frame structure ensures stable operation with minimal vibration for reliable slab quality

Fast Cutting Speed

High-power motor system delivers rapid processing, completing blocks efficiently without delay

Automated Cost Reduction

PLC controls reduce labor needs by 60% while minimizing material waste

Variable Speed Control

Frequency converter adjusts cutting speed for different stone hardness

Enhanced Safety Design

Safety interlocks and emergency stops protect operators during operation

No Foundation Required

Self-supporting design eliminates concrete foundation needs, saving installation costs and space

FAQs

Common Questions About Gantry Stone Block Cutting Machines

What is a gantry stone block cutting machine used for?

A gantry stone block cutting machine is designed for processing large stone blocks into slabs with precise thickness. The machine features a crossbeam and composite drag board system that moves up and down for longitudinal feeding, while the beam moves horizontally for transverse feeding.This equipment is commonly used in stone industry for cutting marble, granite, bluestone, and tombstone materials. The automated system handles various stone types efficiently through programmable controls and hydraulic transmission.

Its simple structure, compact design, low cost, and high efficiency make it ideal for mass production of stone slabs in quarries and fabrication facilities. The equipment delivers consistent results while maintaining cost-effectiveness for commercial stone processing operations.This equipment is commonly used in stone industry for cutting marble, granite, bluestone, and tombstone materials. Its simple structure, compact design, low cost, and high efficiency make it ideal for mass production of stone slabs in quarries and fabrication facilities.

What can gantry stone block cutting machines cut?

Gantry cutting machines excel at processing various natural and engineered stones. Primary materials include granite, marble, limestone, sandstone, travertine, and bluestone. The machines can handle both soft and hard stone varieties with appropriate blade selection.

Material thickness capacity ranges from 950mm to 1350mm depending on machine model. The equipment effectively processes blocks into slabs, tiles, countertops, and architectural elements through precision cutting sequences. Advanced hydraulic systems ensure consistent cutting performance across different stone densities.

Advanced models also process engineered quartz and composite materials for modern construction applications. This versatility makes gantry machines essential equipment for stone processing facilities requiring diverse material handling capabilities and consistent production quality.The machines can handle both soft and hard stone varieties with appropriate blade selection. Material thickness capacity ranges from 950mm to 1350mm depending on machine model. The equipment is particularly effective for creating slabs, tiles, countertops, and architectural elements. Advanced models also process engineered quartz and composite materials for modern construction applications.

How does PLC control improve gantry cutting machine performance?

PLC (Programmable Logic Controller) automation significantly enhances cutting precision and operational efficiency. The system enables precise control of blade movement, cutting speed, and feed rates through programmable parameters. Operators can preset cutting dimensions and automatically control blade elevation with real-time monitoring.

PLC systems reduce human error, ensure consistent slab thickness, and optimize cutting sequences for maximum material utilization. The automated controls eliminate manual measurement inconsistencies while maintaining steady production quality throughout extended operations.

Advanced models feature touch screen interfaces for user-friendly operation and data logging capabilities for quality control and maintenance scheduling. This integration creates comprehensive operational control that enhances both productivity and production reliability.The system enables precise control of blade movement, cutting speed, and feed rates through programmable parameters. Operators can preset cutting dimensions, automatically control blade elevation, and monitor cutting progress in real-time. PLC systems reduce human error, ensure consistent slab thickness, and optimize cutting sequences for maximum material utilization. Advanced models feature touch screen interfaces for user-friendly operation and data logging capabilities for quality control and maintenance scheduling.

What maintenance is required for gantry stone cutting machines?

Annual maintenance requires professional inspection of the crossbeam structure, gantry rails, and safety systems. Proper maintenance prevents costly breakdowns and maintains cutting accuracy essential for quality stone production. This systematic approach maximizes equipment longevity and operational reliability.

Weekly maintenance involves inspecting cutting blades for damage, checking hydraulic fluid levels, and calibrating PLC settings.

Monthly procedures include deep cleaning of electrical components, replacing worn segments, and verifying structural alignment.

Annual maintenance requires professional inspection of the crossbeam structure, gantry rails, and safety systems. Proper maintenance prevents costly breakdowns and maintains cutting accuracy essential for quality stone production.

How many blades can a gantry cutting machine accommodate?

Standard gantry machines accommodate 1-3 blades for basic operations. For multi-blade applications, we strongly recommend multi-blade bridge stone block cutting machines instead.

Bridge Stone Block Cutting Machines provide superior stability and rigidity compared to traditional gantry designs, safely supporting 15-20 blades for maximum production capacity. The key structural difference: traditional gantry machines use overhead crossbeam movement, while bridge cutting machines feature fixed bridge frameworks offering enhanced stability and precision during cutting operations. This superior engineering enables higher blade loads with better cutting accuracy and consistency. Bridge machines excel in high-volume standardized slab production, making them ideal for commercial stone processing facilities requiring reliable output and maximum operational efficiency.

What safety features are included in modern gantry cutting machines?

Modern gantry machines incorporate comprehensive safety systems for operator protection. Emergency stop buttons are strategically placed for immediate machine shutdown. Safety guards protect operators from blade contact and stone debris while automatic water systems prevent blade overheating and dust generation.

PLC systems include safety interlocks preventing operation with open guards or improper setup. Warning lights and alarms alert operators to potential hazards, while hydraulic systems feature pressure relief valves preventing over-pressurization. Regular safety training and proper maintenance ensure all protective systems function correctly for safe stone processing operations. This multi-layered safety approach creates secure working environments while maintaining high productivity standards.

Safety guards protect operators from blade contact and stone debris. Automatic water systems prevent blade overheating and dust generation. PLC systems include safety interlocks preventing operation with open guards or improper setup. Warning lights and alarms alert operators to potential hazards. Hydraulic systems feature pressure relief valves preventing over-pressurization. Regular safety training and proper maintenance ensure all protective systems function correctly for safe stone processing operations.

How do you choose the right gantry cutting machine size?

Machine selection depends on block sizes, production volume, and facility space. Common models include LLQJ-2200, LLQJ-2500, and LLQJ-3000 with cutting capacities of 950mm, 1100mm, and 1350mm respectively. Consider maximum block dimensions your quarry produces and desired slab thickness range.

Larger machines handle bigger blocks but require more facility space and power consumption. Evaluate daily production targets as multi-blade systems on larger frames increase output significantly. The cost-benefit analysis should include installation requirements and operational efficiency gains.

Factor in future expansion plans and material types when making your selection. Professional consultation helps determine optimal machine specifications for your specific stone processing requirements and operational constraints. This ensures long-term investment value and operational success.Consider maximum block dimensions your quarry produces and desired slab thickness range. Larger machines handle bigger blocks but require more facility space and power consumption. Evaluate daily production targets - multi-blade systems on larger frames increase output significantly. Factor in future expansion plans and material types. Professional consultation helps determine optimal machine specifications for your specific stone processing requirements and operational constraints.

Certifications & Standards

Gantry Structure. Block Cutting. Mass Production.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Transform Your Stone Block Cutting Efficiency?

Experience gantry stone block cutting technology that maximizes output and quality.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Stone Block Cutting Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский