Multi‑Wire Saw Boosts Marble Yield 20%+, Ultra‑Thin Cuts

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

Countries Served Worldwide

Innovative technology patents

Industry machinery expertise

Quanzhou DINOSAW Machinery Technology Co., Ltd. is a high-tech enterprise jointly established by Huada Superhard Materials, Huazuan Diamond Tools, and Wuhan University partners. With over 20 years of industry experience, we focus on intelligent and automated machinery R&D and manufacturing for hard material processing applications.

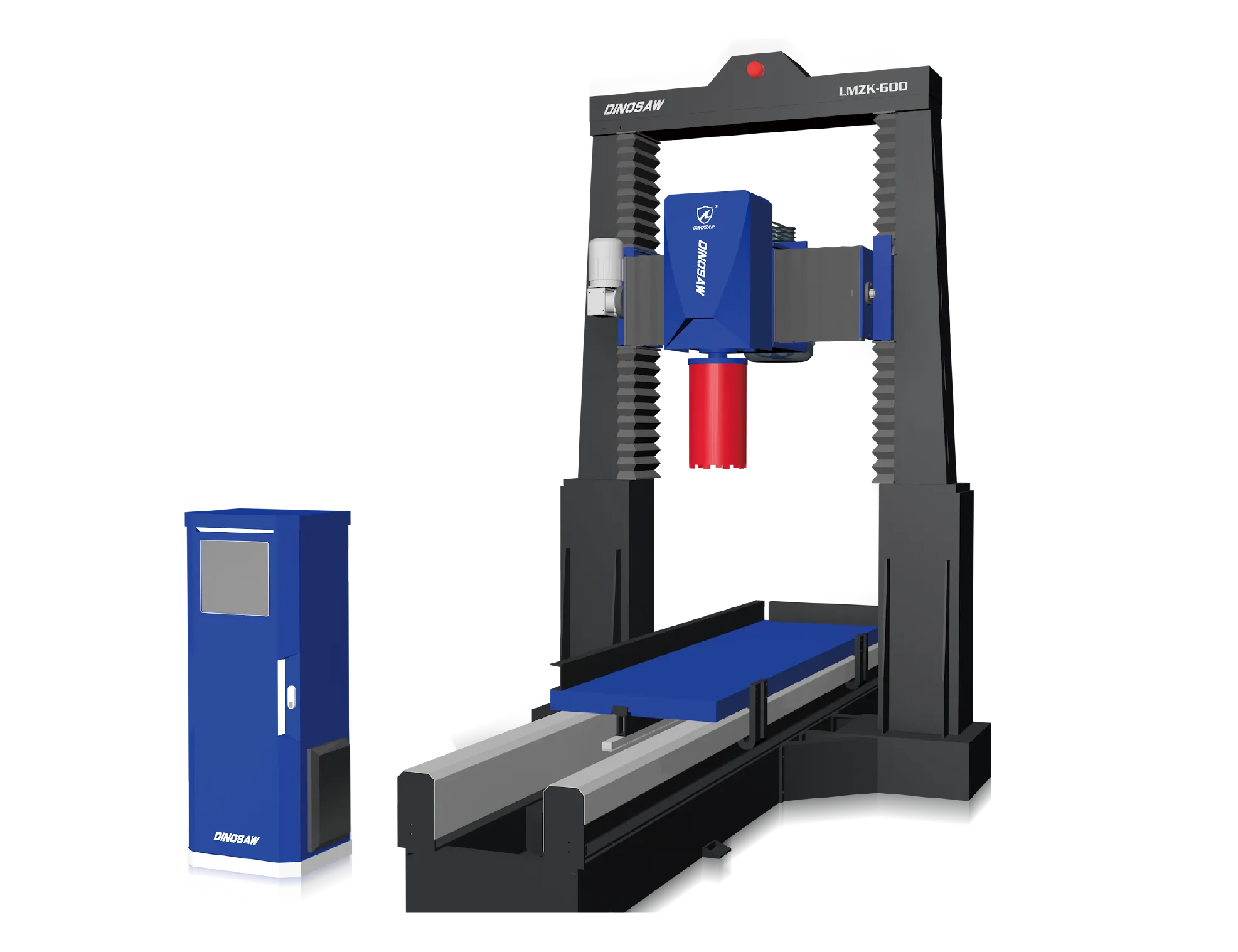

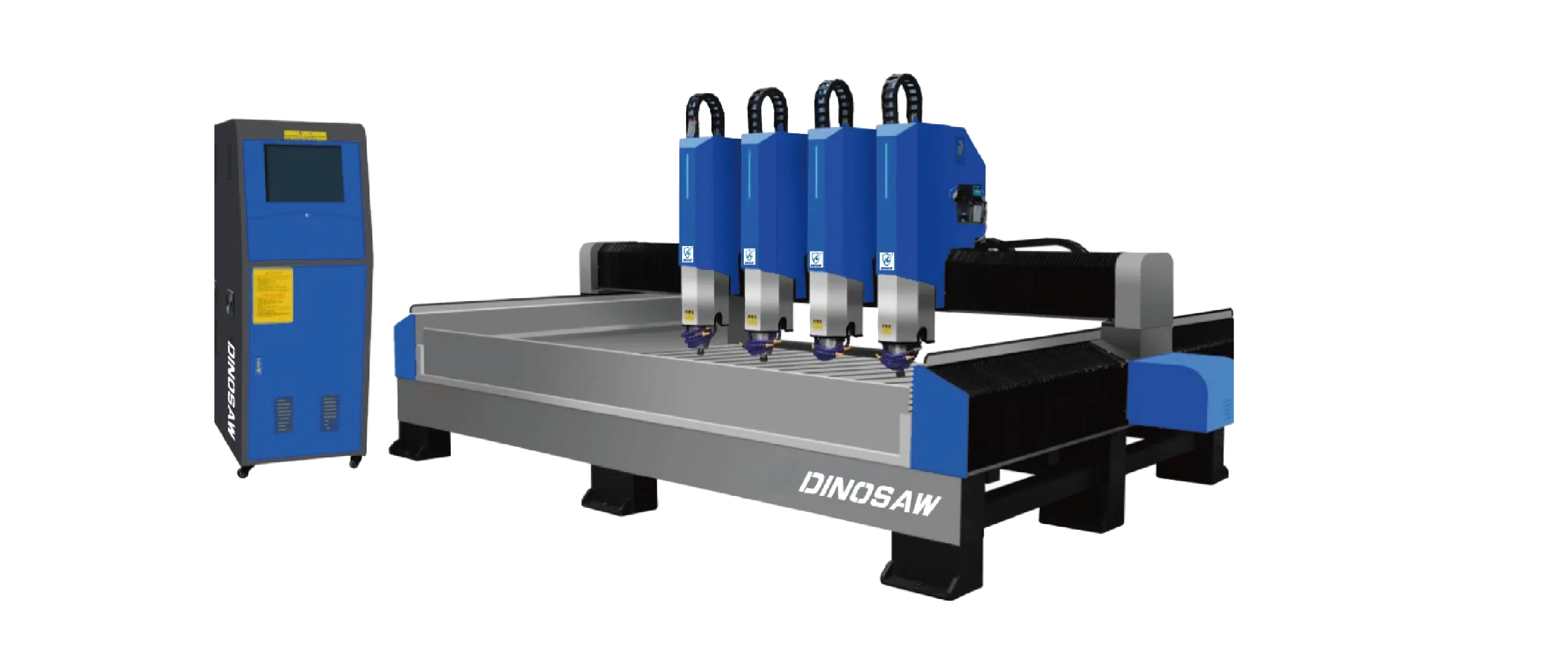

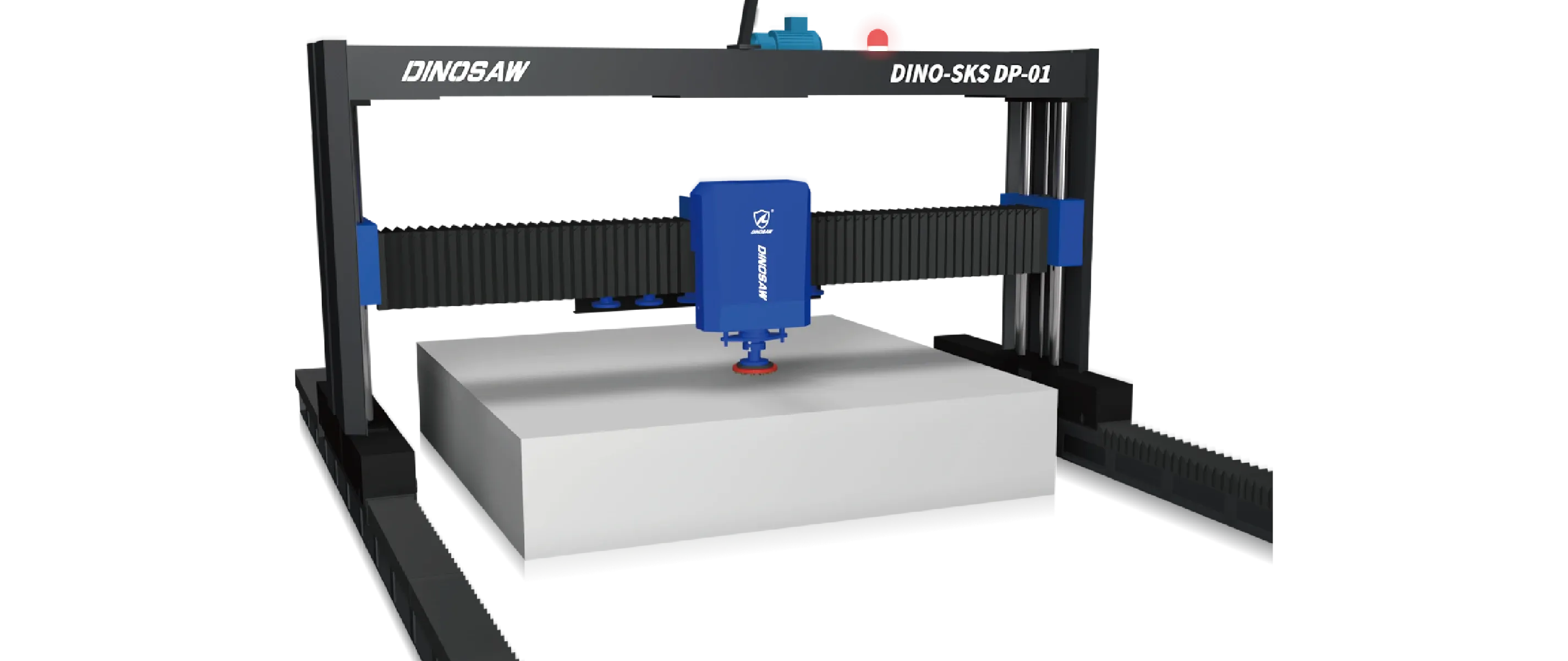

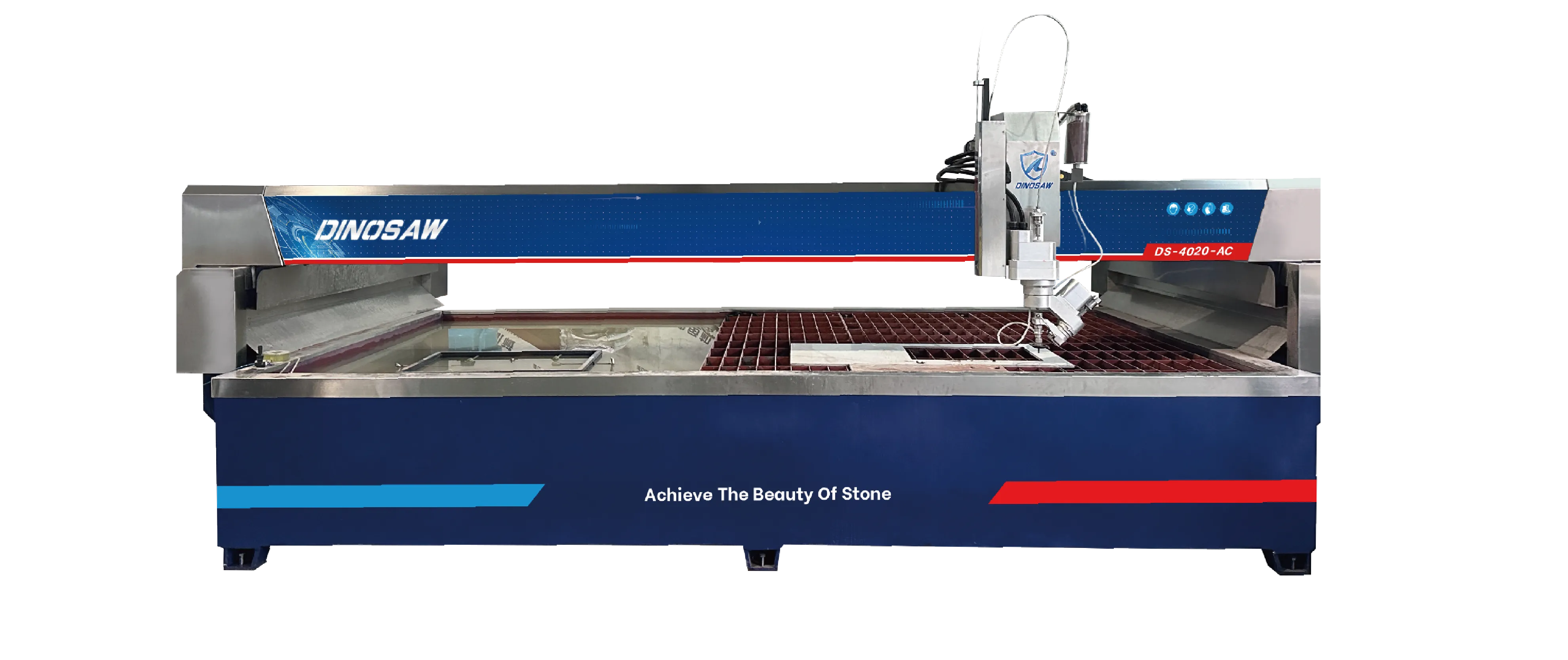

Our comprehensive product portfolio includes CNC wire saws, bridge saws, polishing machines, engraving machines, drilling machines, quarrying machines, and diamond tools. Originally specializing in stone processing, we've strategically expanded into diverse industries including building materials, railway equipment, semiconductor, photovoltaic, and nuclear power sectors. This industry expansion allows us to develop specialized processing solutions for various materials such as concrete, quartz glass, refractory materials, semiconductors, graphite, and metals, delivering customized solutions that meet precise technical requirements across multiple applications.

Our commitment to excellence is validated through international certifications such as ISO and CE standards. With an intellectual property portfolio exceeding 100 patents, we provide professional services and technical solutions to customers in over 75 countries worldwide, establishing DINOSAW as a trusted global partner in hard material processing technology.

High-Tech Enterprise

National Certification

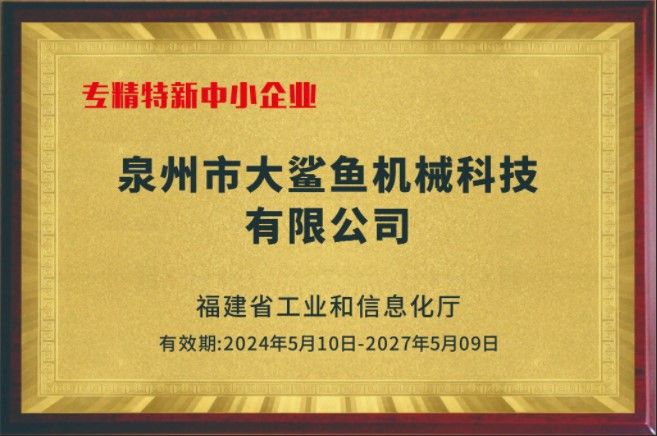

Specialized & Innovative Enterprise

Technical Innovation Certification

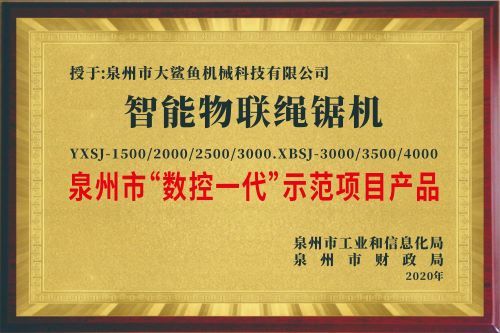

CNC Demonstration Project

Wire Saw Product Certification

CE Certification

EU Market Access

100+ Patents

Technical Innovation & IP Protection

ISO Certification

International Quality

Integrated development of mechanical design, electrical control, and AI algorithms to continuously enhance equipment intelligence. 100+ patented technologies covering multiple high-end applications.

Proprietary digital systems enable transparent production processes, providing real-time visualization service experience, ensuring high quality and on-time delivery.

Custom design drawings submitted within 7 days, leveraging technology from international partner DDX to quickly respond to special processing needs across industries.

24-hour online support, 30-minute response time, and 4-hour on-site service. After-sales mini-program for online diagnostics and quick problem resolution.

Embedded and AI development experts. Intelligent operating systems and AI process research center shorten equipment training cycles, improving production efficiency and technical capabilities.

Service coverage in 120+ countries, providing equipment lifecycle support. Partnerships with Siemens, Schneider, SKF and other top international suppliers ensure global quality standards.

Continuously improve productivity for user

DINOSAW provides global customers with intelligent equipment for the entire industrial chain from mining to deep stone processing, meeting various hard material processing needs.

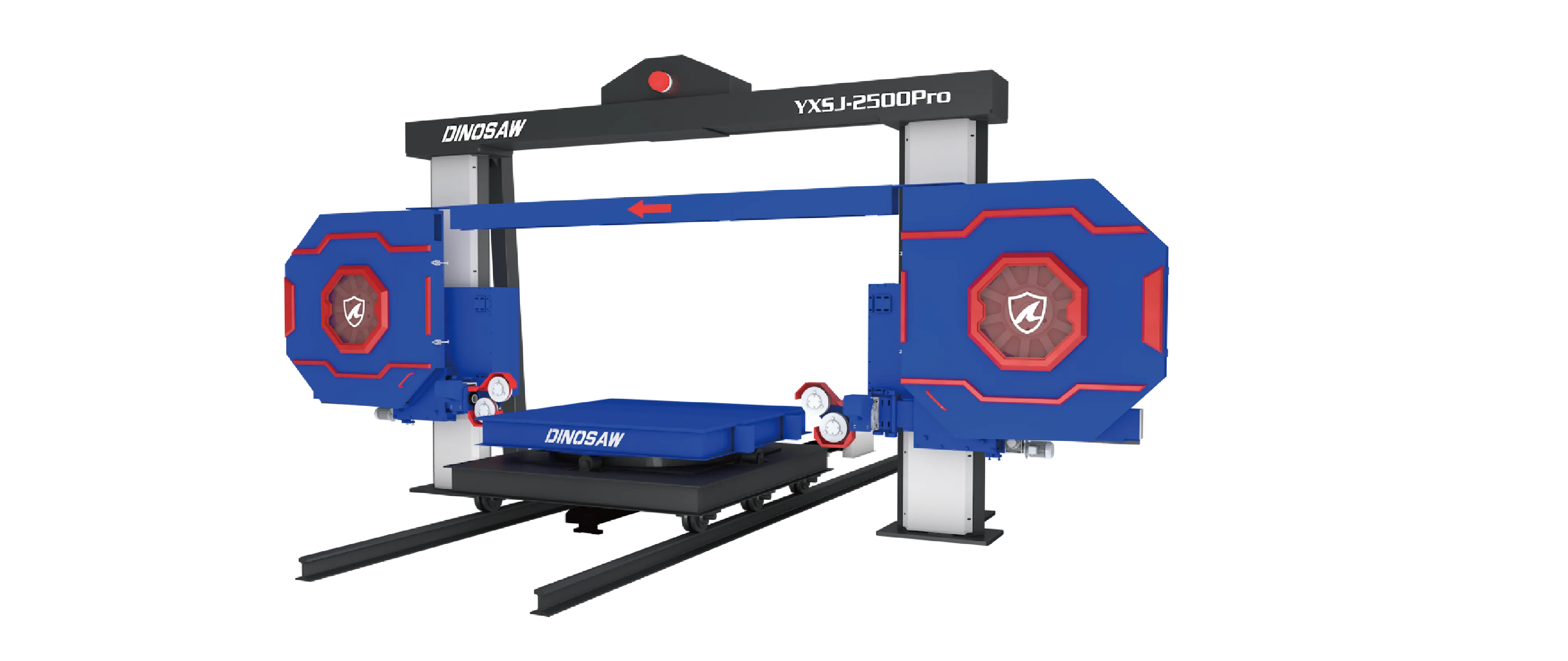

Single and multi-wire saw equipment for batch cutting of thin plates, profiling, and special material cutting, providing efficient stone processing solutions.

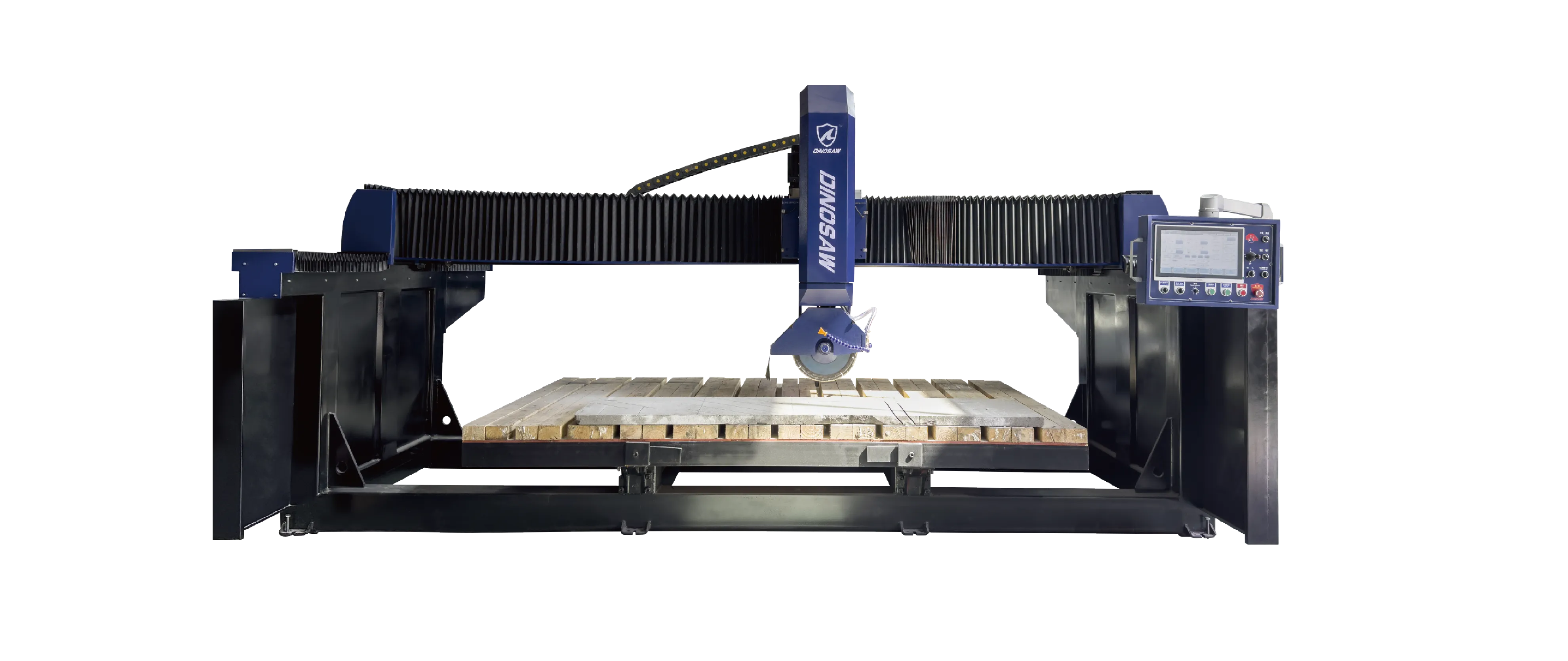

Bridge cutting machines and stone cutting equipment for precise and rapid cutting of various stone materials, suitable for countertop processing and building decoration material production.

Intelligent profiling equipment for processing complex shaped products such as railings and vases, applicable to building decoration and artistic sculpture creation.

Efficient grinding and polishing equipment to enhance surface quality, meeting high-end building and decoration requirements.

Specialized mining equipment, including diamond wire saws, double-blade cutting machines, and quarry chain saws.

Advanced equipment such as water jet cutting machines and machining centers, suitable for special material processing and innovative applications across multiple fields.

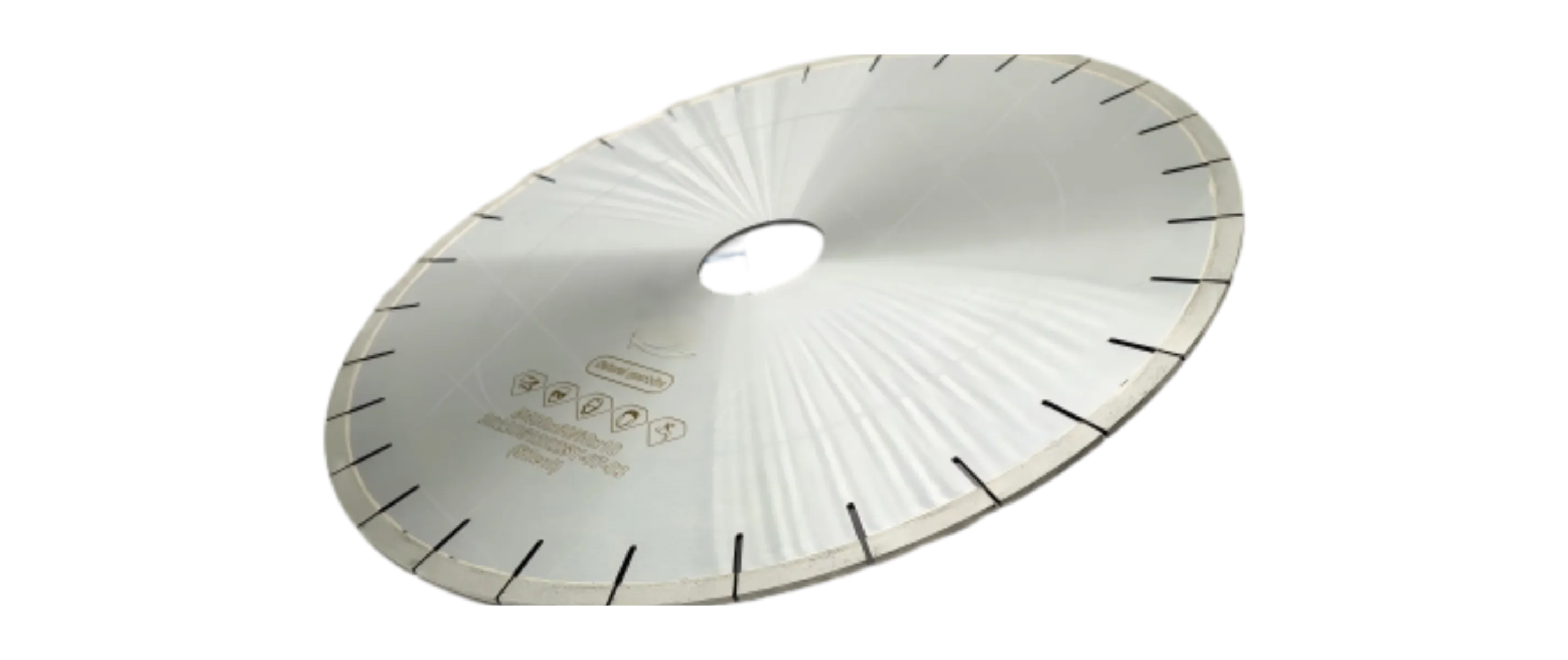

Professional diamond tools for cutting, grinding, and drilling, providing efficient and durable solutions for processing various stone and hard materials.

English

English

Get A Easy Solution

Chat Online

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Hello 👋 How can we help?