CNC Stone Engraving Machine for Precision Carving

Jan 15, 2026

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

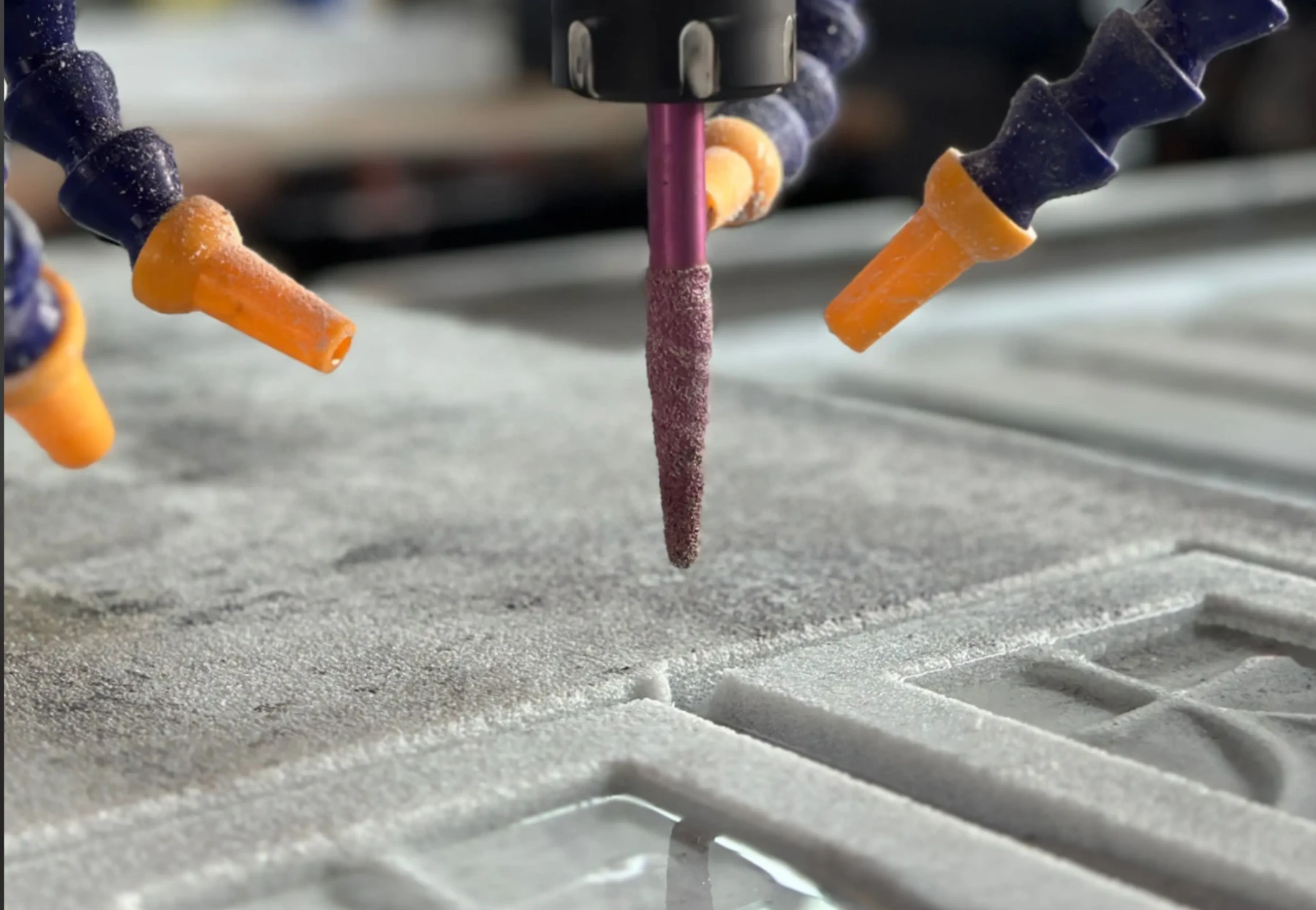

This category includes CNC stone engraving machines designed for flat engraving and relief carving on stone surfaces. These machines are used for engraving text, patterns, logos, and relief designs with controlled depth and angles, while the overall machining logic remains surface-based.

Typical applications include decorative wall panels, stone cladding, signage, nameplates, relief artworks, architectural details, and customized stone elements used in interior and exterior projects. They are commonly applied to marble, granite, quartz, engineered stone, and ceramic slabs in factory and workshop environments.

Flat and relief CNC engraving machines are suitable when engraving accuracy, repeatability, and production consistency are required. They are widely used in architectural stone processing, decoration projects, and batch production where engraving results need to remain consistent across multiple workpieces.

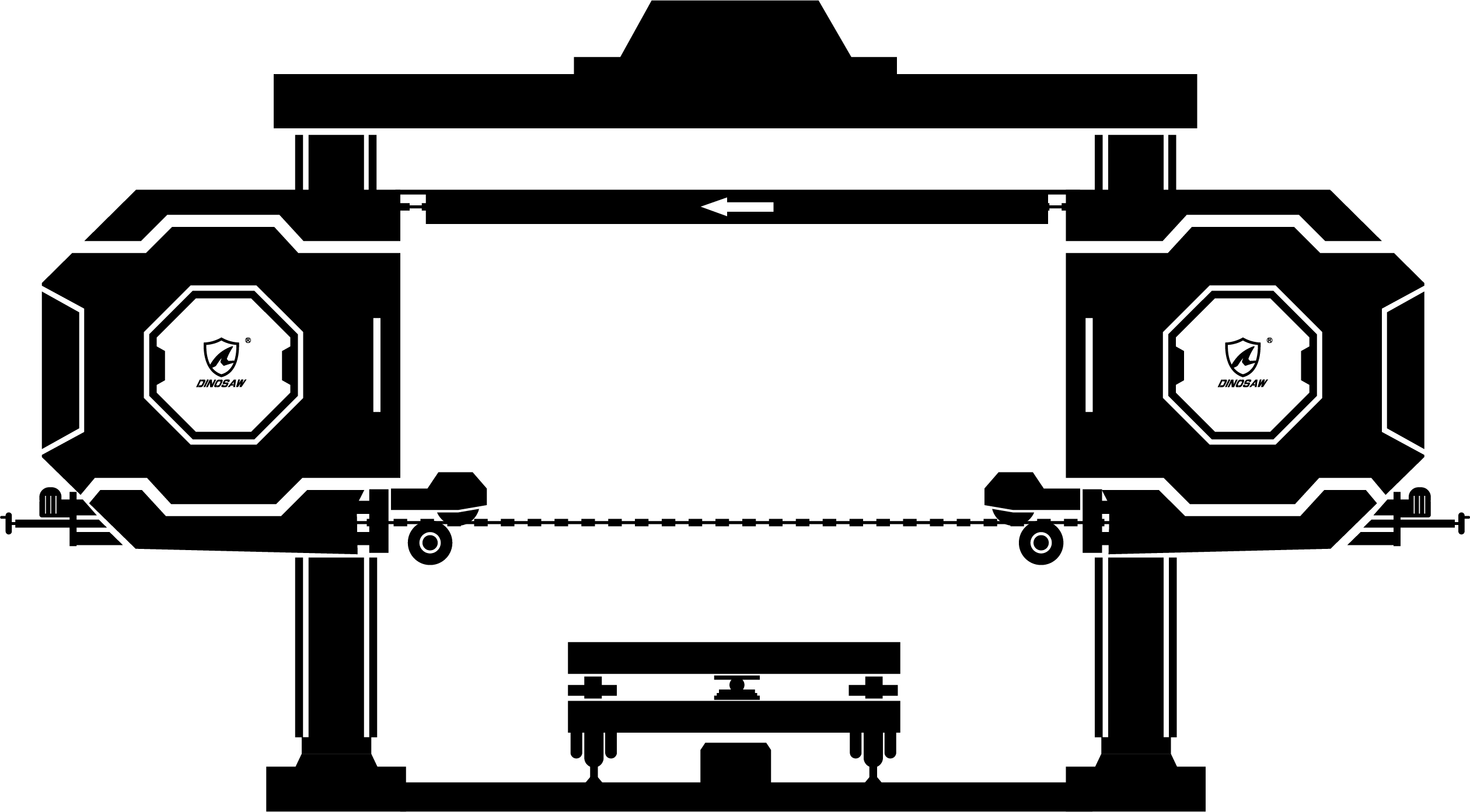

Robotic and multi-axis stone engraving systems are designed for carving tasks beyond flat surfaces. These systems are used for engraving complex shapes, curved surfaces, and multi-sided stone workpieces that cannot be processed efficiently with conventional flat CNC machines.

Typical applications include cylindrical engraving, free-form 3D carving, sculptural elements, columns, balusters, stone vessels, and custom artistic stone components. By combining CNC control with robotic movement, engraving paths can follow complex geometries while maintaining consistent carving depth and surface quality.

These systems are suitable for workshops and factories handling customized projects, large-scale decorative works, or non-standard stone shapes. They also provide a flexible foundation for future expansion into more advanced three-dimensional and automated stone engraving applications.

A stone engraving machine is used to carve text, patterns, and decorative or functional details into stone surfaces. Unlike cutting or drilling machines, engraving machines focus on shaping the surface of the material, controlling engraving depth, angles, and toolpaths to create visible designs and textures.

In real production, stone engraving machines are commonly used on marble, granite, quartz, engineered stone, and ceramic slabs. Typical engraving work includes logos, lettering, relief patterns, decorative panels, wall cladding details, stone signs, and customized architectural elements used in interior and exterior projects.

Most modern stone engraving is done with CNC engraving machines, where engraving paths are digitally controlled to ensure accuracy and repeatability. For more complex workpieces—such as curved surfaces, columns, or sculptural forms—multi-axis CNC systems and engraving robots are used to follow three-dimensional shapes and non-flat geometries.

In simple terms, a stone engraving machine is chosen when the goal is not to separate material, but to shape the surface of stone into a finished visual or functional form.

English

English

Get A Easy Solution

Chat Online

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Hello 👋 How can we help?