Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

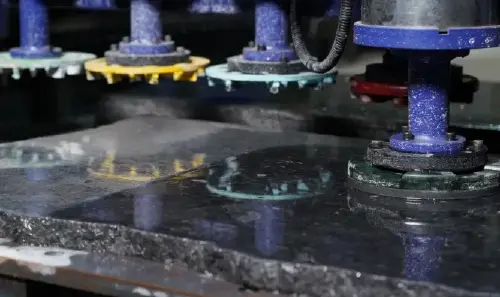

Granite slab polishing case study using automatic blade-changing CNC polishing machine, covering polished granite for memorials, monuments, and architectural stone applications.

▶

▶Case Snapshot

Material

Granite

Processing Method

CNC automated blade-changing stone polishing

Typical Application

Polished granite slabs for memorials, monuments, façades, flooring, and stone panels

Applicable Markets

Memorial and monument fabrication, architectural stone processing, exterior stone projects

Processing Focus

Stable polishing quality on both thick and thin granite slabs used in visible finished products

Associated Product

Dinosaw Automatic blade-changing CNC stone polishing machine

Granite Polishing Across Memorial and Architectural Applications

Granite is widely used in applications where long-term durability and surface stability are required.

In memorials and monuments, granite surfaces are viewed at close distance and often under direct sunlight, making polishing quality a defining factor of the finished piece.

In architectural use, granite slabs are applied to façades, floors, and exterior panels where consistency across large areas is essential.

Both thick and thin granite slabs are commonly polished in the same production environment.

Thicker slabs are often used for memorial stones, headstones, and monument bases, while thinner slabs are applied to walls, floors, and cladding systems.

Despite the difference in thickness, visual consistency remains a shared requirement.

Practical Challenges in Polishing Granite Slabs for Finished Products

Polishing granite presents challenges that go beyond surface appearance.

Granite’s hardness makes it sensitive to unstable tool contact.

Thick slabs require controlled material removal to maintain flatness.

Thin slabs are more affected by vibration and uneven support.

In memorial and monument production, even minor polishing marks remain visible after installation and cannot be hidden by later processes.

Managing multiple polishing stages while maintaining consistent results across different slab thicknesses is a common workshop challenge.

Workshop Insights from Granite Polishing Operations

What makes granite polishing particularly critical for memorial and monument work?

In memorial production, the surface is the product.

There is no secondary layer to hide polishing defects.

If the surface reflection is uneven or shows swirl marks, it stands out immediately, especially outdoors.

That’s why granite polishing for memorials is treated as a precision operation, not just a finishing step.

Why does automatic blade changing matter in granite polishing?

Granite polishing typically involves several grinding and polishing stages.

Automatic blade changing allows these stages to run in sequence without stopping the line.

This reduces human variation between stages and helps keep surface quality consistent, especially when polishing thick and thin slabs together.

What do operators pay the most attention to during granite polishing?

Operators focus on slab stability and surface response.

Thin slabs need proper support to avoid vibration, while thick slabs need steady pressure to prevent surface waves.

They also watch how the surface develops after each stage, not just the final gloss.

How is acceptable polishing quality judged on the workshop floor?

Quality is judged by uniform reflection, surface flatness, and the absence of visible polishing traces.

For memorial stones, slabs are often checked from multiple angles under light.

If slabs of different thicknesses appear visually consistent side by side, the polishing result meets workshop standards.

How the Granite Polishing Process Was Handled

Granite slabs were loaded and supported according to their thickness.

The CNC system controlled consistent polishing paths across all slabs.

Automatic blade changes enabled smooth progression from coarse grinding to fine polishing without interrupting the workflow.

Finished slabs were visually inspected before being sent to memorial fabrication, engraving, or architectural installation.

Observed Results in Granite Slab Polishing

Polished granite slabs showed stable surface quality across different thickness categories.

Reflection and gloss remained consistent on both memorial-grade thick slabs and architectural thin slabs.

Surface defects were minimized, reducing the need for rework.

The polishing process aligned well with both monument production and architectural stone workflows.

Who This Case Is Relevant For

If you are polishing granite slabs for memorials or monuments,

if your production line handles both thick and thin granite products,

if surface consistency directly affects acceptance in visible finished stone,

this case reflects a real-world granite polishing scenario common in professional stone workshops.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский