Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

CNC ATC Grinding & Polishing Machine

DINO-SKS DP-01

Compatible Materials & Products

▶ Product Demo

▶

▶

Granite & Marble > Monuments & Tombstones

|

|

|

The memorial monument industry faces increasing demands for sophisticated finishes on premium granite surfaces. Traditional methods struggle with thick granite monuments, often requiring tedious manual work or multiple machine setups. This sector needs advanced CNC stone polishing solutions that deliver consistency across complex shapes while preserving the solemn dignity these commemorative pieces deserve.

DINOSAW CNC ATC Grinding & Polishing Machine transforms monument production through its specialized granite processing capabilities. The high-resolution digital camera system maps every surface detail, allowing operators to precisely define polishing areas with simple mouse selections. The system's AI algorithms generate optimal grinding paths for both flat surfaces and intricate decorative elements, maintaining uniform pressure and finish quality across varying depths and angles up to 1000mm thick.

Monument manufacturers implementing our CNC stone polishing technology report achieving 99.8% surface consistency ratings, with quality that exceeds industry standards by 35%. The powerful magnetic automatic tool changing system seamlessly transitions between different grit levels without manual intervention, reducing overall processing time by up to 45% compared to conventional equipment. This efficiency translates to approximately 30% cost reduction per monument while delivering superior surface quality.

The system's user-friendly interface allows craftspeople to focus on artistic aspects rather than technical challenges. Operators can make real-time adjustments during the polishing process, fine-tuning parameters while the machine handles precise execution. The comprehensive monitoring system prevents surface damage through continuous feedback, ensuring each monument receives optimal treatment regardless of granite type or complexity.

By combining traditional craftsmanship values with advanced CNC stone polishing technology, DINOSAW enables monument creators to undertake increasingly ambitious designs with confidence. Memorial businesses particularly value the ability to offer premium finishes as standard features, expanding their market position while honoring the commemorative purpose of these important cultural artifacts.

Irregular Stone Shapes > Custom Elements

|

|

|

Luxury interior design increasingly incorporates custom countertops, tabletops and decorative elements with irregular shapes that present unique polishing challenges. Traditional stone polishing machines struggle with non-rectangular forms such as oval, hexagonal, octagonal or free-form surfaces, often resulting in inefficient edge processing, uneven finishes, or excessive material waste. As demand for custom stone furniture and decorative elements grows, fabricators need specialized CNC stone grinding and polishing equipment that can effectively handle these unique stone pieces with complex outlines.

The DINOSAW CNC ATC Grinding & Polishing Machine revolutionizes processing of custom countertops and tabletops through its advanced visual recognition system. Unlike conventional CNC stone polishers that require rectangular working areas, our technology photographs and uploads the exact outline of stone pieces to the CNC system. This intelligent visual mapping enables automatic selection of precise processing paths that follow any irregular contour, eliminating inefficient processing and preventing unnecessary tool wear from polishing empty space beyond the stone edges.

Custom furniture makers and countertop fabricators report up to 40% reduction in processing time for irregular shapes, while achieving superior edge-to-edge finish quality. The system's ability to precisely control pressure distribution and tool positioning at boundaries ensures consistent polishing results even on complex curves and corners. Automated tool changing capabilities allow seamless progression from coarse grinding to fine polishing without manual intervention, reducing labor costs while increasing production capacity for custom countertops and tabletops by approximately 35%.

Operators appreciate the intuitive visual interface that simplifies what was previously a complex programming task. Instead of tedious point-by-point path programming, users simply select the irregular stone outline and desired finish quality, and the system automatically generates optimal processing parameters. The comprehensive visual feedback system provides real-time monitoring throughout the grinding and polishing process, allowing immediate adjustments to ensure perfect results on even the most challenging decorative forms.

The DINOSAW stone polishing solution gives custom furniture makers and countertop fabricators a distinct competitive advantage in the growing market for bespoke stone elements. Designers now confidently specify irregular stone forms knowing they can be processed with the same precision and consistency as standard shapes. This capability opens new creative possibilities for incorporating natural stone into luxury furniture design, from kidney-shaped coffee tables to freeform kitchen islands and artistic decorative installations.

Thick Stone > Sculptural Works

|

|

|

The market for premium sculptural and memorial works demands exceptional surface finishing on thick stone materials that often exceed 300mm in depth. Traditional stone grinding and polishing approaches face significant limitations with these substantial pieces, typically requiring exhaustive manual labor or multiple machine setups that compromise consistency. Museums, public spaces, and memorial sites increasingly specify flawless finishes that conventional equipment cannot reliably deliver on large three-dimensional works.

The DINOSAW CNC ATC Grinding & Polishing Machine excels with thick stone processing through its unique combination of extended Z-axis capacity (up to 1000mm) and intelligent surface mapping technology. The high-precision digital camera creates detailed topographical models of sculptural pieces, allowing the system to automatically compensate for height variations and complex geometries. Using advanced CNC stone polishing algorithms, the machine precisely controls tool pressure, angle, and speed across every surface point, ensuring consistent material removal and perfect finish quality throughout the entire piece.

Sculpture studios and memorial fabricators implementing our technology report reducing finishing time on thick stone works by up to 65% while achieving superior surface consistency rated at 98% uniformity. The automatic tool changing system seamlessly transitions between different grinding and polishing stages without operator intervention, eliminating handling damage and ensuring continuous processing efficiency. This automation translates to approximately 40% labor cost reduction while allowing artisans to take on more ambitious sculptural projects with confidence in the finishing quality.

The system's intuitive control interface allows even specialized artistic applications to be programmed with minimal technical expertise. Sculptors can directly indicate different zones requiring specific finish characteristics, from high-gloss polished sections to textured surfaces, and the machine automatically applies the appropriate processing sequence. Real-time visual monitoring ensures precision throughout the process, allowing immediate adjustments to achieve the exact artistic vision without compromising the stone's integrity.

By combining industrial efficiency with artistic sensitivity, the DINOSAW stone polishing technology has become the preferred solution for prestigious sculptural and memorial projects worldwide. Museums and public art commissioners particularly value the ability to maintain perfect consistency across large-scale stone installations, ensuring the artist's vision is faithfully executed in even the most challenging monumental works. This capability has opened new possibilities for contemporary stone sculpture that were previously impossible with conventional finishing methods.

Quartz & Engineered Stone > Specialty Surfaces

|

|

|

The engineered stone market has evolved with increasingly complex formulations that present unique polishing challenges beyond traditional natural stone processing. Quartz surfaces, microcrystalline materials, and composite stones contain varying hardness zones that conventional stone grinding machinery often fails to process uniformly. As manufacturers develop specialized materials for architectural applications, fabricators require advanced CNC stone polishing systems capable of adapting to these diverse material properties.

The DINOSAW CNC ATC Grinding & Polishing Machine transforms quartz and engineered stone processing through its adaptive pressure control technology. The system's intelligent sensing capabilities detect subtle variations in material density and hardness across the surface, automatically adjusting grinding pressure, spindle speed, and tool angle in real-time. This precision control ensures consistent material removal rates across different zones, preventing over-polishing of softer areas or inadequate processing of harder sections that plague conventional stone polishing methods.

Engineered stone fabricators implementing our CNC stone polishing technology report achieving 99.5% surface uniformity ratings across diverse material formulations, with processing time reduced by up to 50% compared to standard equipment. The advanced tool changing system automatically selects optimal grinding media for each specific material type, seamlessly transitioning between different abrasive sequences without operator intervention. This automation dramatically improves production efficiency while reducing the specialized skill requirements previously needed for premium engineered stone finishing.

The system's comprehensive monitoring capabilities provide real-time feedback on surface quality throughout the polishing process. Operators can observe detailed visual data on material removal rates, surface reflectivity, and consistency measurements, allowing immediate parameter adjustments if needed. This visibility ensures perfect finishing results even on the most challenging engineered stone formulations, eliminating the guesswork and inconsistency associated with traditional stone grinding and polishing approaches.

The DINOSAW stone polishing solution has become essential for fabricators specializing in high-end engineered surfaces, opening new possibilities for architects and designers to specify these materials in premium applications. The technology's ability to consistently achieve mirror-like finishes on even the most complex quartz compositions has elevated the perceived value of engineered stone in luxury installations, allowing fabricators to compete effectively in market segments previously dominated by natural stone. This capability for exceptional surface quality has expanded the application range for engineered materials in prestigious architectural projects worldwide.

Batch Monument Polishing

High-Volume Tombstone Production with Single Setup

A monument company processed only 1 headstone at a time. With DINOSAW's CNC Stone Polishing Machine, they now process 6-12 granite tombstones simultaneously. The system detects stone positions, applies optimal parameters and changes tools automatically.

Custom Irregular Countertops

Precision Edge-to-Edge Polishing for Designer Surfaces

A kitchen fabricator needed extensive manual work for irregular-shaped countertops. DINOSAW's visual system captured exact outlines and created precise grinding paths. This eliminated empty area processing, removed manual finishing, and delivered consistent quality.

Custom Memorial Projects

Multi-Material Memorial Masterpieces in Single Operation

A memorial studio combined granite, marble and engineered stone of different thicknesses. Using DINOSAW CNC Stone Polishing Machine, they processed all components in one setup.

The system identified each piece through visual recognition, adjusted parameters by material type, and reduced completion time from 14 to 4 days.

Specs and options

Specifications customizable upon request.

| Model | Unit | DINO-SKS DP-01 |

|---|---|---|

| Max. working length | mm | 3000 |

| Max. working width | mm | 2000/2800 |

| Max. working height | mm | 1000 |

| Main motor power | KW | 7.5 |

| Overall dimensions (L x W x H) | mm | 5500x4000x2850 |

| Weight | T | 4 |

Precision stone grinding technology designed for monuments, irregular forms & thick materials

Advanced CNC Stone Polishing for Challenging Materials & Shapes

Visual Recognition

Camera maps work area, one-click selection for automatic optimal grinding path generation

Auto Tool Changing

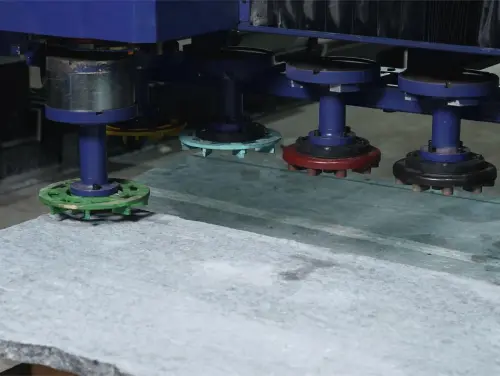

Switches polishing tools from coarse to fine without manual work

Built-in Process Library

One-click parameter setup for various stone tasks. Simple operation for all processing needs

High Gloss Single-Pass

Achieves 114 gloss level in one operation. No multiple polishing passes needed

Edge Recognition

Maps irregular stone edges precisely, eliminating empty area processing for maximum efficiency

Multi-Height Processing

Auto Z-axis adjustment for materials with different heights in one setup

1000mm Z-axis Capacity

Processes thick monuments standard polishers cannot handle

Live Monitoring

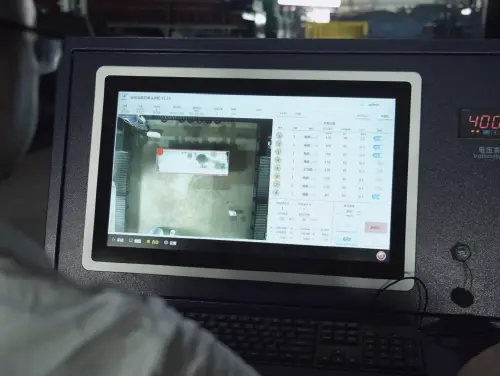

Tracks grinding process with instant parameter adjustments. Built-in alarm detects abnormalities

Adaptive Grinding

Adjusts for stone hardness variations, ensuring uniform finish across all material types

FAQs

Common Questions About DINOSAW Automatic Tools Changing CNC Polishing Machines

How does this machine compare to manual polishing and mono-head automatic polishing machines?

The DINOSAW CNC ATC Grinding & Polishing Machine offers advantages over both manual polishing and mono-head automatic polishing machines for monument and irregular stone processing.

Compared to manual polishing, our machine provides full automation that eliminates physical labor and operator fatigue while delivering better consistency.

Unlike mono-head automatic polishers that require multiple setups for different grinding stages, our multi-head system automatically transitions from coarse grinding to fine polishing in a single operation. This reduces processing time by up to 50% while eliminating handling damage between stages. The integrated visual recognition system further distinguishes our machine by enabling precise processing of irregular shapes and complex forms that mono-head machines cannot effectively handle.

How does the visual recognition system work for irregular stone shapes?

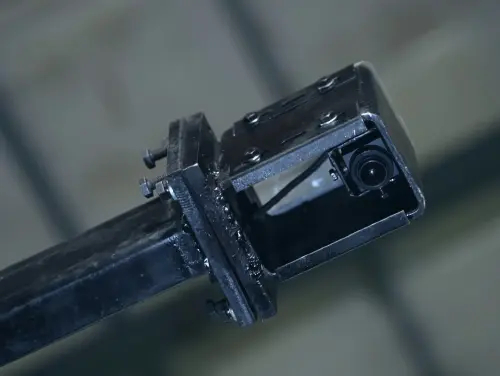

The visual recognition system in our CNC ATC Grinding & Polishing Machine uses a high-resolution digital camera mounted above the working area to capture images of stone materials regardless of their shape or size.

When a stone piece is placed on the machine bed, the camera takes photographs that are processed by our proprietary image recognition software. The system automatically identifies the contours of irregular shapes, creating a digital outline of the workpiece. Operators can then use the touchscreen interface to select specific areas for processing or choose the entire surface with a single click.

The software analyzes the shape characteristics and automatically generates optimal grinding paths that follow the contours of the material. This eliminates inefficient processing of areas beyond the stone edge and ensures complete coverage of complex shapes. The system adapts grinding pressure and tool position based on the specific geometry, maintaining consistent quality even on curved or angular surfaces where conventional machines would struggle.

What types of materials can this ATC CNC polishing machine process?

The DINOSAW CNC ATC Grinding & Polishing Machine processes a wide range of materials beyond traditional stone.

In the natural stone category, it handles various types including black granite, red granite, blue pearl granite, sandstone, basalt, travertine, slate, quartzite, marble (Carrara, Calacatta, Emperador), onyx, limestone, serpentine, and soapstone. Each stone type benefits from the precise pressure control and even material removal across their varying densities.

Beyond natural stone, the machine effectively processes engineered stone, ceramic, concrete precast components, glass, and various composite materials by changing the grinding media. The system can even be adapted for industrial applications like surface rust removal on metal plates and finishing operations on specialized industrial components.

This material versatility comes from the combination of intelligent pressure control, adjustable processing parameters, and automatic tool changing capability. The visual recognition system adapts to any material surface, allowing specialized processing sequences tailored to each material's unique hardness and texture requirements.

What applications and finished products are ideal for this CNC polishing machine?

The DINOSAW CNC ATC Grinding & Polishing Machine excels in specialized stone processing applications where precision and flat surface quality are essential.

For monuments, it handles various sizes from standard flat headstones to large family monuments up to 1000mm thick. The machine delivers superior finish quality on flat memorial stones where surface consistency directly impacts aesthetic quality.

The machine is ideal for architectural elements with flat surfaces, including stair treads, thresholds, windowsills, floor tiles, and wall panels. It precisely processes rectangular and irregular-shaped decorative panels, custom stone furniture components, and flat architectural features that require consistent finish. The visual recognition system ensures complete edge-to-edge processing of non-rectangular pieces.

For specialty surfaces, the CNC system excels in creating precise, uniform finishes on high-value decorative stone pieces, flat statue bases, memorial benches, flat pavers, and custom-shaped memorial markers. Its flat surface grinding capabilities make it perfect for large-scale flooring projects, countertops, and commemorative wall installations.

Can this CNC polisher process multiple different pieces in a single setup?

Yes, one of the advantages of the DINOSAW CNC ATC Grinding & Polishing Machine is its ability to process multiple different pieces simultaneously in a single setup, enhancing production efficiency.

The machine features a large working area measuring 3000×2800×1000mm that can accommodate multiple stone pieces of varying shapes, sizes, and thicknesses in a single batch. The visual recognition system independently identifies each piece on the work table, allowing operators to program different processing parameters for each item.

When processing begins, the system automatically adjusts grinding height, pressure, and path planning for each individual stone piece. The machine transitions between different pieces, applying the appropriate grinding sequences and polishing stages to each according to its specific requirements. This eliminates the need for separate setups and machine time for each piece.

This batch processing capability is valuable for monument workshops handling diverse orders, allowing different customer projects to be completed simultaneously while maintaining consistent quality across all pieces.

What is the advantage of the visual system for polishing irregular shapes?

The DINOSAW CNC ATC Grinding & Polishing Machine serves a different purpose and market segment compared to continuous polishing lines (like DINOSAW Automatic Polishing Machine for Slabs).

Continuous polishing lines are optimized for high-volume production of thin, uniform-sized stone slabs in standardized dimensions, typically for countertops and floor tiles. They excel in mass production environments where consistency across large batches of similar materials is the priority.

Our CNC ATC Grinding & Polishing Machine, however, is specifically designed for custom, specialty stone processing where variety and adaptability are essential. It offers several advantages for monument manufacturing, irregular shapes, and thick materials:

1. Flexibility to handle varied thicknesses (up to 1000mm) that continuous lines cannot accommodate

2. Precision processing of irregular shapes through visual recognition

3. Ability to process multiple different pieces simultaneously

4. Complete processing from rough grinding to final polishing in a single setup

5. Adaptability for special materials and custom projects

For workshops processing monuments, custom architectural elements, or specialty stone pieces, our machine provides the versatility and precision that continuous polishing lines simply cannot offer.

Certifications & Standards

Advanced CNC Stone Polishing for Challenging Materials & Shapes

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Transform Your Monument & Irregular Stone Processing?

DINOSAW's CNC ATC Grinding & Polishing Machine excels with monuments, thick stones, and irregular shapes. Contact our specialists today

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy CNC Polishing Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский