Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

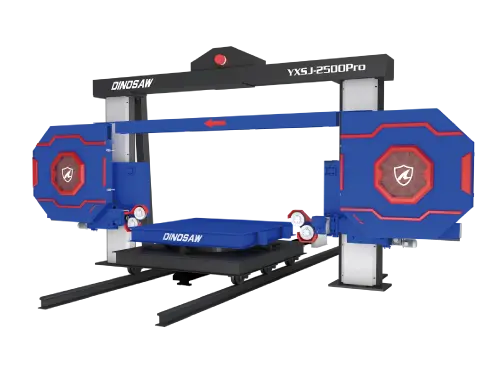

DINOSAW Diamond Wire Saw Cutting Machine

YXSJ-2500/3000/3500-16pro

Compatible Materials & Products

Wire Saw Machine Specifications customizable upon request

▶ Product Demo

▶

▶

|

|---|

| DINOSAW CNC wire saw cutting machine Video |

Granite ❯ Tombstones

|

|

| granite tombstone cutting with DINOSAW wire saw machine |

|

| DINOSAW CNC wire saw for granite tombstone cutting |

|

| Granite hradstone cutting with CNC wire saw machine |

|

| DINOSAW cnc diamond wire saw cutting machine |

|

| DINOSAW diamond wire saw cutting machine for granite |

|

Granite's exceptional durability and timeless elegance make it the premier choice for memorial stonework, demanding precision cutting technology that preserves both aesthetic appeal and structural integrity.

The DINOSAW CNC diamond wire saw cutting machine excels in granite tombstone fabrication through its advanced multi-axis control system. The diamond-embedded wire creates clean, precise cuts with minimal material waste while maintaining consistent pressure through servo-controlled tension systems. This technology allows for intricate designs, beveled edges, and perfect symmetry in memorial stones without the chipping or micro-fractures common with traditional cutting methods.

Stone fabricators benefit from reduced processing time, higher material yield, and enhanced precision that meets the exacting standards of memorial artistry. The machine's ability to execute complex curves and angles in a single setup significantly reduces production time while ensuring dimensional accuracy to within ±1mm – essential for creating dignified, lasting tributes.

Operators can easily program custom shapes through the intuitive touchscreen interface, allowing for personalized memorial designs from simple rectangular tablets to elaborate shaped monuments with consistent quality.

The combination of DINOSAW's precision engineering and diamond wire technology results in immaculate surface finishes that require minimal additional grinding, streamlining the production process while honoring the significance of memorial craftsmanship.

Granite & Marble ❯ Curved Slabs

|

|

| Granite curved slab cutting wire saw machine |

|

| DINOSAW CNC wire saw cutting stone curved slabs |

|

| DINOSAW cnc wire saw machine cutting marble slabs |

|

Granite and marble's enduring popularity in luxury interior and exterior applications demands innovative cutting solutions for creating curved slabs that maintain the material's natural beauty while achieving the architectural precision required for modern curved surfaces and radius elements.

The DINOSAW CNC diamond wire saw cutting machine excels in curved slab fabrication through its advanced 4-axis control system and proprietary curve-tracking technology. The diamond-embedded wire moves with exceptional precision along programmed arcs and complex curved paths, maintaining consistent material removal rates even as radii change. This dynamic adjustment capability ensures uniform cutting quality throughout variable curves, while the servo-controlled wire tension system automatically compensates for internal stresses within stone that typically cause deviation in curved cutting applications.

Fabricators benefit from the machine's ability to produce perfectly smooth radius cuts with tolerances of ±1mm, eliminating the extensive grinding and finishing traditionally required for curved stone elements. The significant reduction in material waste compared to segmented cutting methods translates to higher yield from premium stone blocks, while the elimination of micro-fractures ensures structural integrity throughout curved sections—critical for load-bearing architectural applications. Production time for curved elements is reduced by up to 70% compared to manual methods, dramatically improving project economics.

Operators easily program complex curved paths through the intuitive touchscreen interface, which offers both parametric curve generation and freeform drawing capabilities. The visual simulation feature allows verification of cutting paths before execution, ensuring accuracy in high-value materials. Multi-stage curved cutting sequences can be programmed and saved as templates, enabling consistent reproduction of common radius elements across multiple projects.

The combination of DINOSAW's precise curve-following technology with the diamond wire's narrow kerf width creates opportunities for innovative curved designs previously impractical with traditional stone cutting methods. The superior surface finish quality on curved sections significantly reduces secondary processing time, allowing fabricators to deliver complex curved elements with exceptional aesthetic quality and dimensional accuracy while maintaining competitive pricing even for custom radius applications.

Natural Stone ❯ Columns & Cylinders

|

|

|

Natural stone columns and cylindrical elements represent some of the most challenging and prestigious applications in architectural stone fabrication, requiring exceptional precision to achieve the perfect symmetry and surface consistency demanded in classical and contemporary architectural designs.

The DINOSAW CNC diamond wire saw cutting machine transforms column and cylinder production through its specialized rotational cutting capabilities. The machine's synchronized 4-axis control enables the diamond wire to follow precise helical paths around rotating stone blocks, creating perfectly uniform cylindrical forms without the seams or inconsistencies common in traditional segmented fabrication methods. The continuous cutting action produces seamless cylindrical surfaces with dimensional variations of less than ±1mm even on columns exceeding 3 meters in length. The wire's constant tension system, maintained through servo-controlled dynamic adjustment, ensures consistent cutting pressure throughout the entire circumference, eliminating the tapering effects often seen with conventional methods.

Stone fabricators experience dramatic efficiency improvements with production times reduced by up to 60% compared to traditional column fabrication techniques. The precision cylindrical cutting eliminates excessive material waste by maintaining optimal proximity to the final form throughout the cutting process. This significantly improves material yield from valuable stone blocks, particularly important for rare or premium stone varieties. The superior surface quality achieved through continuous wire cutting substantially reduces secondary finishing requirements, allowing for faster project completion and reduced labor costs. The ability to produce fluted columns, tapered designs, and complex profile variations in a single cutting operation further enhances production efficiency for architectural projects.

Operators benefit from dedicated column-specific programming interfaces that simplify the creation of both standard and custom cylindrical forms. The intuitive parameter-based controls allow for easy specification of column dimensions, taper ratios, fluting patterns, and decorative elements without requiring advanced CAD expertise. Visual simulation tools enable verification of column design before cutting begins, ensuring optimal results on high-value stone materials. The automated cutting sequence handles the complete column shaping process with minimal operator intervention, allowing skilled personnel to focus on other tasks during production.

The combination of DINOSAW's precision cylindrical cutting technology and the diamond wire's smooth cutting action enables the creation of architectural columns with exceptional aesthetic quality and structural integrity. The elimination of visible seams, consistent surface texture throughout the column's circumference, and perfect symmetry elevate the final product quality while ensuring accurate alignment during installation. This technical capability allows stone fabricators to expand their offerings to include premium architectural elements for high-end construction and restoration projects where authentic stone columns deliver both aesthetic impact and historical authenticity.

FRP ❯ Pipe Cutting

|

|

| Fiberglass reinforced plastic pipes cutting DINOSAW wire saw machine |

|

| DINOSAW CNC diamond wire saw machine for FRP pipes cutting |

|

Fiber Reinforced Polymer (FRP) pipes have revolutionized industrial fluid transport systems with their exceptional corrosion resistance, lightweight properties, and extended service life, creating demand for precision cutting solutions that preserve the material's structural integrity and specialized layered composition.

The DINOSAW CNC diamond wire saw cutting machine excels in FRP pipe processing through its vibration-minimizing cutting action and specialized material handling system. Unlike conventional cutting methods that can delaminate composite layers or generate harmful dust, the diamond wire's continuous cutting motion with controlled pressure prevents fiber separation between layers while maintaining dimensional accuracy. The water-cooled cutting process eliminates heat-affected zones that could compromise the resin matrix or create micro-fractures in fiber reinforcement. The machine's specialized pipe rotation system enables perfectly perpendicular end cuts on pipes ranging from 100mm to 3000mm in diameter, with angular precision within 0.5 degrees essential for creating reliable high-pressure connections.

Industrial pipe fabricators achieve significant quality improvements with perfectly clean, burr-free cut surfaces that require no secondary finishing—eliminating a labor-intensive process typically required with conventional cutting methods. The precision end cuts ensure optimal joint integrity in critical applications such as chemical processing, offshore installations, and high-pressure systems where connection failures can have severe consequences. Production efficiency increases dramatically with cutting times reduced by up to 75% compared to manual methods, allowing fabricators to meet demanding project timelines while maintaining exceptional quality standards. The ability to execute angled cuts, precise notches, and custom end preparations in a single operation further streamlines manufacturing processes for specialized FRP piping systems.

Operators benefit from the machine's dedicated pipe-cutting interface with automated diameter recognition and cut parameter optimization. The specialized pipe fixturing system accommodates various pipe diameters without complex changeovers, reducing setup time between different pipe specifications. Programmable cut sequences allow operators to process multiple identical pipe sections with consistent quality, ideal for large-scale industrial projects requiring numerous pipe sections with identical specifications. The automated material handling system reduces the physical demands on operators when working with large-diameter pipes, improving workplace safety and reducing fatigue-related quality issues.

The combination of DINOSAW's precision cutting technology with specialized FRP handling features enables manufacturers to deliver higher-quality piping components while reducing production costs. The elimination of delamination, edge fraying, and thermal damage ensures the full structural integrity of the composite material is preserved throughout its service life. This capability is particularly valuable in critical applications such as chemical processing, offshore installations, and infrastructure projects where FRP pipe systems must maintain their performance characteristics under demanding environmental conditions for decades of service.

Refractory Materials ❯ Block Cutting

|

|---|

|

|

|

|

Refractory materials are the backbone of high-temperature industrial applications, from steel furnaces to ceramic kilns. As industries demand more precise, custom-shaped refractory components for enhanced thermal efficiency, traditional cutting methods struggle with the extreme hardness and specialized requirements of these materials.

DINOSAW Diamond Wire Saw Machine revolutionizes refractory component manufacturing through advanced multi-axis cutting technology. Our specialized diamond wire cutting system handles the extreme hardness of refractory materials while maintaining precision across massive workpieces. The machine's dual-mode operation supports both dry cutting for minimal material contamination and wet cutting for enhanced surface finish, adapting to specific refractory composition requirements.

The extended worktable design accommodates oversized refractory blocks up to several meters in length, width, and height, far surpassing traditional refractory cutting limitations. The servo-controlled hydraulic tensioning system maintains consistent wire pressure throughout the cutting process. This ensures uniform cutting quality across the entire workpiece, critical for refractory components that must withstand extreme thermal cycling. The CNC multi-axis control enables complex angular cuts and custom geometries essential for modern furnace designs, from tapered furnace linings to intricate kiln furniture shapes.

Our precision cutting technology achieves ±1mm accuracy. The diamond wire's consistent cutting action produces mirror-smooth surfaces that eliminate secondary grinding operations, preserving the material's structural integrity crucial for high-temperature performance.

Transform your refractory manufacturing efficiency with up to 100% faster production speeds, zero secondary finishing requirements, and the capability to create complex custom shapes that traditional methods cannot achieve, ultimately reducing material waste and enhancing your competitive edge in specialized refractory applications.

Complex Memorial Shapes

Breaking Traditional Cutting Limits for Memorial Stones

Traditional blade saws can only cut straight lines and basic curves. DINOSAW CNC wire saw cuts intricate heart shapes, Celtic crosses, and custom memorial designs directly from CAD files. Wire flexibility enables complex internal cuts impossible with rigid blades.

Architectural Profiling

Simplified Operations, Maximum Material Efficiency

Import CAD drawings directly into CNC system. Visual cutting path preview shows exact material usage before cutting starts. Optimized nesting reduces stone waste by 25-40% compared to manual layout. One operator handles multiple complex profiles simultaneously.

Specs and options

Specifications customizable upon request.

| Model | Unit | YXSJ - 2500 - 16pro | YXSJ - 3000 - 16pro | YXSJ - 3500 - 16pro |

|---|---|---|---|---|

| Max Working dimensions | m | 2.5x1.5 | 3.0x1.5 | 3.5x1.5 |

| Worktable size | m | 2.5x1.4 | 2.5x1.4 | 2.5x1.4 |

| Wire length | m | 14.75 | 15.75 | 16.75 |

| Wire diameter | mm | 7.6 - 11 | 7.6 - 11 | 7.6 - 11 |

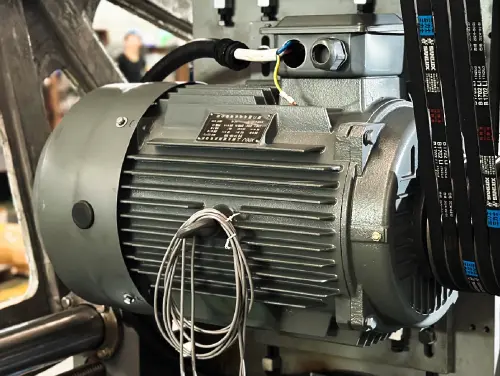

| Main motor power | kw | 15 | 15 | 15 |

| Water consumption | m³/h | 3 | 3 | 3 |

| Overall dimensions | m | 6.3x7.9x4.0 | 6.3x8.4x4.0 | 6.3x9.0x4.0 |

| Approximate weight | t | 6.8 | 7.6 | 8.5 |

If lt Exists, We Can Cut lt

Global Leader in Industrial Machinery & Diamond Tools Manufacturing

20% Energy Savings

High-efficiency permanent magnet synchronous motor

Remote Operation

OTA technology for remote updates and maintenance support

Versatile Cutting

Multi-axis control enables straight, curved, and custom-shaped cuts

Robust Construction

Cast iron columns with Siemens and NSK components ensure durability

Comprehensive Safety Protection

Software alerts + hardware safeguards with protective covers and limit switches

Reduced Maintenance

Dust/water-resistant design with automatic lubrication system

FAQs

Common Questions About DINOSAW Diamond Wire Saw Cutting Machines

What is a CNC diamond wire saw cutting machine and how does it work?

A CNC diamond wire saw cutting machine is a precision stone cutting tool that uses a thin, flexible wire embedded with industrial diamond particles to cut through hard materials. The wire is guided by computer numerical control (CNC) systems along predetermined paths with multiple axis movements. As the diamond wire moves at high speed (typically 20-40 m/s), it gradually abrades through materials while water cooling systems maintain optimal cutting conditions and remove cutting debris.

The machine operates using a continuous loop of diamond wire that runs around a series of pulleys and guide wheels, with one end connected to a motor drive system. The CNC control system precisely positions the workpiece relative to the wire or moves the wire itself through computer-programmed cutting paths. This technology allows for cutting complex shapes with exceptional precision (±1mm) without the heat damage, vibration issues, or large kerf width associated with traditional blade cutting methods.

What materials can be cut with a CNC diamond wire saw machine?

CNC diamond wire saw machines are exceptionally versatile and can cut through a wide range of hard materials including:

- Natural stones: granite, marble, limestone, sandstone, travertine, onyx, quartzite

- Engineered stones: quartz surfaces, sintered stones, terrazzo, concrete products

- Industrial materials: graphite, ceramics, glass, reinforced concrete, tungsten carbide

- Advanced materials: semiconductor materials, technical ceramics, carbon fiber composites

The diamond wire cutting technology is particularly effective for materials that are brittle, have varying densities, or are prone to thermal damage when cut using conventional methods. The water-cooled cutting process prevents overheating and maintains material integrity even in thermally sensitive materials. Additionally, the low-stress cutting action makes this technology ideal for materials with internal tensions that might crack under the higher-force impacts of blade cutting.

Does the CNC wire saw cutting machine require programming or CAD experience?

No, the diamond wire saw stone cutting machine is designed with user-friendliness as a priority:

- The intuitive touchscreen interface uses simple, graphical controls that operators can master quickly, unlike traditional CNC machines requiring complex programming knowledge

- No CAD programming is required for standard cutting operations

- Most operators can complete basic setup within 5 minutes after initial training, and a single operator can efficiently manage multiple machines simultaneously

- For complex shapes, our optional pattern library allows quick selection from pre-configured cutting paths

We provide comprehensive training for operators of all experience levels as part of our implementation package.

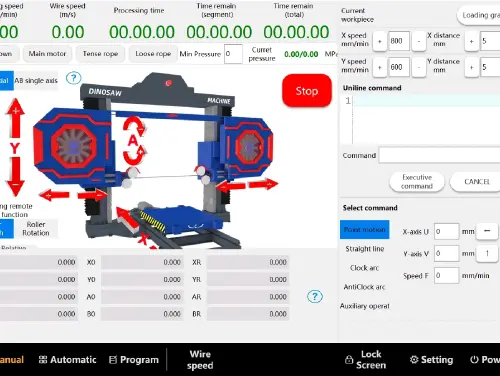

How does the CNC wire saw control system work, and what level of expertise is required to operate it?

The DINOSAW CNC diamond wire saw cutting machine features an intuitive control system designed to balance sophisticated functionality with user-friendly operation. Key aspects of the control system include:

- User Interface: Touch-screen interface with visual programming options and multi-language support

- Programming Methods: Multiple options including direct drawing on-screen, importing CAD files, or using preset shape libraries

- Multi-Axis Control: Complex 3d cutting capabilities

- Adaptive Cutting: Intelligent systems that automatically adjust wire speed, tension, and feed rate based on material properties

- Remote Operation: Wireless control options allowing operators to monitor cutting from a safe distance

Operator expertise requirements are intentionally minimized through our user-centric design approach. New operators typically require only 1-2 days of training to become proficient with basic operations, compared to weeks or months with traditional G-code based CNC systems. The interface eliminates the need for complex programming knowledge, using intuitive visual tools instead of manual coding.

Our remote assistance capability enables direct support from DINOSAW technicians who can access the system (with permission) to troubleshoot issues or optimize settings without requiring on-site expertise.

What safety features are incorporated into modern CNC diamond wire saw machines?

Safety is a paramount concern in the design of DINOSAW CNC diamond wire saw cutting machines. Our systems incorporate multiple layers of protection to ensure operator safety and prevent equipment damage:

Physical Barriers: Enclosed cutting area with transparent impact-resistant shields and safety interlocks that prevent operation when guards are open

Emergency Systems: Multiple emergency stop buttons positioned at strategic locations and foot pedal emergency stops for hands-free activation

Wire Break Detection: Instant shutdown system that detects wire breakage or excessive tension within milliseconds

Overload Protection: Automatic systems that prevent motor overload, hydraulic pressure excess, or mechanical strain

Intelligent Monitoring: Continuous monitoring of critical parameters with automatic shutdown if unsafe conditions develop

Remote Operation: Wireless control options allowing operation from a safe distance during high-risk cutting operations

Safety Certification: Compliance with international safety standards including CE, ISO, and regional safety requirements

Beyond physical safety features, our machines include operational safeguards such as two-stage confirmation for critical operations, password-protected access to advanced settings, and visual/audible warnings before motion begins. The control system maintains detailed safety logs and requires acknowledgment of safety protocols during startup.

We also provide comprehensive safety training with each machine, including detailed manuals, safety demonstration videos, and in-person instruction on proper operating procedures. Regular safety updates are made available through our service network to address emerging safety considerations as technology evolves.

What types of projects and industries benefit most from CNC diamond wire sawmachine?

CNC diamond wire saw technology offers exceptional benefits across various industries and project types where precision cutting of hard materials is required:

Stone Fabrication:

- Kitchen and bathroom countertop manufacturers requiring complex shapes and cutouts

- Custom furniture producers creating stone tables, desks, and decorative elements

- Architectural element fabricators producing columns, balusters, and ornamental features

Monument Industry:

- Memorial and tombstone manufacturers requiring shaped monuments and custom designs

- Public art and sculpture studios working with stone and composite materials

- Historical restoration specialists recreating period architectural elements

Construction and Renovation:

- Specialty contractors handling precision modification of existing concrete structures

- Historic building restoration requiring minimal vibration cutting techniques

- Custom home builders creating bespoke architectural features

Industrial Applications:

- Graphite electrode manufacturers

- Advanced ceramics producers requiring precision cutting

- Semiconductor and electronics industry cutting specialized materials

Projects that particularly benefit from CNC diamond wire saw technology include those requiring complex curved shapes, thick material cutting, preservation of material integrity, and applications where minimal material waste is economically important. The technology is especially valuable for high-value materials where precision cutting directly impacts the final product value and quality.

What future developments are expected in CNC diamond wire saw technology?

CNC diamond wire saw technology continues to evolve rapidly, with several key innovations on the horizon that will further enhance capabilities and performance. DINOSAW remains at the forefront of these developments:

- Advanced Material Science: Next-generation diamond wires with nano-structured diamond particles and enhanced matrix compositions will increase cutting speed by up to 30% while extending wire life

- Artificial Intelligence Integration: Machine learning algorithms are being developed to dynamically optimize cutting parameters in real-time based on material variations, cutting patterns, and environmental conditions

- Automation and Robotics: Enhanced integration with robotic material handling systems for fully automated production lines capable of 24/7 operation with minimal human intervention

- Digital Twin Technology: Creating virtual replicas of physical cutting operations to simulate and optimize processes before actual cutting begins, reducing waste and improving outcomes

- Ultra-thin Wire Technology: Development of sub-1mm diamond wires that reduce kerf width by 30%, maximizing material yield for precious stone applications

- Augmented Reality Interfaces: AR systems that overlay cutting paths, material information, and operational guidance directly onto the work surface for enhanced operator precision

- Sustainable Innovations: Zero-waste water systems and energy-neutral operation through renewable power integration and advanced energy recovery

DINOSAW's research and development program actively pursues these technological frontiers while maintaining our focus on practical, reliable solutions that deliver measurable benefits to our customers. Our user-centric innovation approach ensures that advanced technologies are implemented in ways that enhance productivity and quality without compromising ease of use or maintenance.

As the industry evolves, we anticipate CNC diamond wire saw technology will continue expanding into new materials and applications, including advanced composites, engineered building materials, and specialized industrial components where precision cutting of hard materials is essential.

Certifications & Standards

Global Leader in Industrial Machinery & Diamond Tools Manufacturing

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to upgrade your cutting solution?

Use DINOSAW Diamond Wire Saw Cutting Machine to transform production efficiency and precision.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский