Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

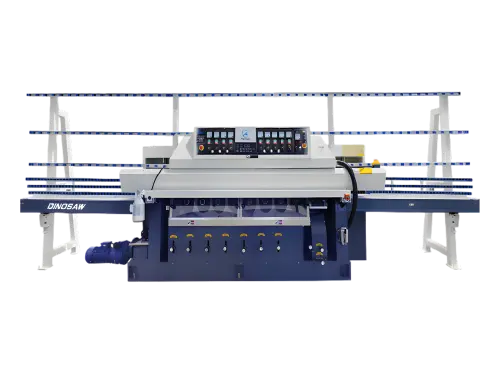

Bridge Single Head Automatic Stone Polisher

QDMJ-900/1200/1800/2000

Compatible Materials & Products

Precision Polishing for Premium Stone Products

▶ Product Demo

▶

▶

Granite > Tombstones

|

|---|

|

|

|

|

Memorial granite polishing equipment faces increasing demand in commercial fabrication markets worldwide. Granite tombstone manufacturing requires superior stone polishing machine precision to achieve lasting commemorative quality that families expect for generations.

DINOSAW bridge structure granite polishing equipment utilizes advanced diamond grinding head technology with programmable longitudinal movements for automated stone processing efficiency. The stone polishing machine system delivers precision granite countertop cutting capabilities through PLC-controlled pressure regulation, ensuring optimal material removal rates while maintaining dimensional accuracy across varying granite hardness levels.

Precision-calibrated grinding patterns achieve meticulous surface consistency through fine-tuned pressure distribution. This efficient granite processing methodology eliminates manual variations while delivering streamlined production workflows that optimize memorial stone fabrication.

Premium granite tombstone surfaces showcase commercial-grade mirror finishes essential for industrial applications. Professional monument fabricators achieve superior durability standards through automated granite memorial stone production, meeting demanding construction project specifications.

Advanced granite polishing equipment transforms traditional tombstone manufacturing through automated precision processing, establishing new industry benchmarks for commemorative stone excellence.

Marble > Kitchen Countertops

|

|---|

|

|

Luxury marble countertop fabrication demands sophisticated stone polishing machines for residential applications. Premium kitchen surface processing requires granite polishing equipment precision to preserve natural veining while achieving commercial construction standards.

DINOSAW automated stone processing technology employs variable-speed diamond grinding systems for marble kitchen countertop cutting precision. The granite polishing equipment utilizes controlled pressure algorithms through streamlined fabrication workflows, preventing thermal damage while optimizing surface texture through efficient marble tombstone shaping capabilities.

Meticulous temperature control ensures precision marble surface integrity through fine-tuned cooling systems. This accurate processing methodology delivers productive countertop manufacturing while maintaining rapid material handling for optimized kitchen project timelines.

High-grade marble countertop surfaces achieve professional kitchen standards for commercial fabrication projects. Superior residential installations demonstrate industrial-strength durability through premium marble kitchen surface quality that enhances property values.

Advanced automated stone profiling technology revolutionizes marble countertop production through precision fabrication processes, establishing premium standards for luxury kitchen applications.

Limestone > Architectural Panels

|

|---|

|

Architectural limestone processing requires specialized stone polishing machine precision for construction projects. Building facade applications demand granite polishing equipment accuracy to achieve consistent panel quality across large-scale commercial installations.

DINOSAW precision cutting technology delivers automated stone processing through programmable limestone grinding patterns. The stone polishing machine incorporates efficient granite countertop cutting methodologies with productive limestone surface texturing, optimizing architectural panel fabrication through streamlined manufacturing workflows.

Exact surface calibration maintains meticulous limestone panel uniformity through precision-engineered grinding sequences. This accurate architectural processing ensures productive building material preparation while delivering rapid project completion for optimized construction timelines.

Commercial-grade limestone architectural panels meet industrial construction specifications for professional building projects. Superior facade installations demonstrate high-performance structural integrity through premium limestone panel quality essential for large-scale developments.

Advanced precision stone cutting equipment transforms limestone panel manufacturing through automated architectural processing, establishing industry standards for commercial building applications.

Travertine > Bathroom Vanities

Premium travertine vanity fabrication demands delicate stone polishing machine handling for luxury bathroom applications. Natural stone surface processing requires granite polishing equipment sensitivity to preserve unique travertine characteristics while achieving residential quality standards.

DINOSAW controlled pressure systems deliver automated stone processing through specialized travertine grinding algorithms. The stone polishing machine employs precise granite countertop cutting techniques with gentle material handling, ensuring optimal surface preparation through efficient travertine bathroom surface manufacturing capabilities.

Careful surface preparation maintains exact travertine texture preservation through precision-controlled grinding pressures. This gentle processing methodology ensures productive vanity manufacturing while maintaining detailed natural stone characteristics for optimized bathroom installation quality.

Superior travertine vanity surfaces achieve luxury bathroom standards for high-end residential projects. Premium bathroom installations demonstrate exceptional aesthetic appeal through professional travertine surface quality that transforms residential spaces.

Advanced gentle stone processing technology revolutionizes travertine vanity production through precision fabrication methods, establishing premium standards for luxury bathroom applications.

Quartzite > Floor Tiles

|

|---|

|

|

Commercial quartzite flooring demands robust stone polishing machine performance for high-traffic applications. Durable floor surface processing requires granite polishing equipment strength to handle dense quartzite materials while achieving commercial durability specifications.

DINOSAW heavy-duty processing systems deliver automated stone processing through powerful quartzite grinding capabilities. The stone polishing machine utilizes robust granite countertop cutting methodologies with enhanced material handling, ensuring optimal surface preparation through efficient quartzite floor tile manufacturing processes.

Robust surface preparation achieves exact quartzite durability optimization through high-performance grinding systems. This powerful processing methodology ensures productive flooring tile manufacturing while maintaining superior wear resistance for optimized commercial installation performance.

Industrial-grade quartzite floor tiles meet demanding commercial specifications for professional flooring projects. Superior commercial installations demonstrate exceptional durability standards through premium quartzite surface quality essential for high-traffic environments.

Advanced heavy-duty stone processing equipment transforms quartzite tile production through automated manufacturing excellence, establishing industry benchmarks for commercial flooring applications.

Memorial Stone Production

Achieving Premium Granite Finishes at Scale

Leading monument manufacturers rely on DINOSAW's precision polishing technology to deliver consistent mirror finishes across varied granite types. The automated system processes multiple stone sizes while maintaining exacting quality standards.

Countertop Manufacturing

Elevating Kitchen Surface Standards

Premium countertop fabricators achieve superior surface quality through automated polishing sequences. The system's programmable parameters ensure consistent gloss levels across large marble and granite slabs for high-end residential projects.

Specs and options

Specifications customizable upon request.

| Model | Unit | QDMJ - 900 | QDMJ - 1200 | QDMJ - 1800 | QDMJ - 2000 |

|---|---|---|---|---|---|

| Main motor power | kw | 15 | 15 | 15 | 15 |

| Grinding speed | r/min | 560 | 560 | 560 | 450 |

| Grinding disc horizontal walking speed | mm/min | 0 - 5600 | 0 - 5600 | 0 - 5600 | - |

| Grinding disc longitudinal walking speed | mm/min | 0 - 4300 | 0 - 4300 | 0 - 4300 | - |

| User - prepared pressure | Mpa | 0.35 - 0.5 | 0.35 - 0.5 | 0.35 - 0.5 | - |

| Gas source equipment flow | m³/min | 0.15 - 0.3 | 0.15 - 0.3 | 0.15 - 0.3 | - |

| Work efficiency | m²/h | 2 - 2.5 | 2.5 - 3.0 | 3.0 - 3.5 | - |

| Maximum grinding size | mm | 3000×900×120 | 3000×1200×120 | 3000×1800×120 | 3000×2000×120 |

| Overall dimensions | mm | 6500×2200×2000 | 6500×2500×2000 | 6500×3100×2000 | 6500×4700×2000 |

| Water consumption | m³/h | 4 | 4 | 4 | 5 |

| Approximate weight | t | 2 | 2.5 | 3 | 5 |

| Diameter of grinding head | mm | - | - | - | 470 |

| Number of grinding head loading blocks | pcs | - | - | - | 6pcs |

Bridge design and PLC control for automated polishing

Master Every Stone Surface with Precision and Flexibility

Long Service Life & Accurate Movement

Bridge structure with oil-sealed linear guide rails ensures minimal vibration and extended equipment life

Versatile Processing Patterns

PLC control enables three grinding patterns with adjustable feed rates for different stone requirements

Powerful & Efficient Material Removal

15KW motor with 560 r/min rotation speed delivers fast processing while maintaining surface quality

One Machine Multiple Applications

Single machine processes granite and marble by changing heads, handling 3-120mm thickness materials

Lower Operating Costs

Optimized design achieves 2-3.5 m²/h output with only 4m³/h water consumption for cost efficiency

Safe & Consistent Results

Variable speed control with emergency stops and automated pressure regulation ensures safety

FAQs

Common Questions About Bridge Single Head Stone Polisher

What is a bridge single head stone polisher?

Bridge single head stone polisher uses 15KW motor with automated grinding head for precise stone surface finishing. The bridge structure provides stable platform for processing granite, marble, and natural stone slabs up to 3000×2000×120mm. PLC programming controls longitudinal, transverse, and wave grinding patterns automatically adjusting pressure and speed.

How does bridge granite polishing equipment work?

Granite polishing equipment operates through air cylinder-controlled grinding head with diamond tools rotating at 560 r/min. System automatically adjusts grinding patterns based on stone hardness, using 0.35-0.5 MPa pressure for optimal material removal. Integrated water cooling at 4m³/h prevents overheating while maintaining surface quality.

What materials can bridge stone polishing machines process?

Stone polishing machines handle granite, marble, limestone, travertine, and quartzite materials efficiently. Different stone types require specific grinding parameters - granite needs higher pressure, marble requires gentler speeds. Universal design accommodates varying hardness levels from soft limestone to dense quartzite through programmable settings.

What's the difference between single-head and multi-head polishers?

Single-head polishers excel at precision work and custom shapes, while multi-head systems optimize high-volume production. Bridge single head offers maximum flexibility for varied thicknesses and specialty applications. Multi-head machines suit continuous slab production, single-head handles monuments, countertops, and architectural elements requiring individual attention.

What are the technical specifications of the Bridge Single Head Stone Polisher?

QDMJ series offers four models: 900/1200/1800mm standard models and 2000mm heavy-duty version. All models feature 15KW main motor, 560 r/min grinding speed, and 3000mm processing length. Feed rates range 0-4300mm/min longitudinal and 0-5600mm/min transverse with 3-120mm thickness capacity.

What applications suit Single Head Stone Polisher best?

Machine excels at tombstone production, kitchen countertops, bathroom vanities, and architectural panels requiring precision finishing. Ideal for custom projects and medium-volume production where surface quality matters more than speed. Perfect for monuments, specialty stones, and detailed work needing individual attention.

What maintenance and support are DINOSAW provided for Single Head Stone Polisher?

Regular maintenance includes grinding head inspection, water system cleaning, and component lubrication every 200 operating hours. DINOSAW provides comprehensive technical support, spare parts availability, and installation training. Robust design minimizes downtime with easily accessible service points and 24/7 technical assistance.

How does pricing compare to alternatives?

Bridge single head offers lower initial investment than multi-head systems while delivering superior flexibility for custom applications. Operating costs average 30% less than comparable equipment due to efficient water usage and reduced maintenance. ROI typically achieved within 18-24 months for specialized stone processing operations.

Certifications & Standards

Master Every Stone Surface with Precision and Flexibility

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Transform Your Stone Polishing Operations?

Experience precision, efficiency, and quality with DINOSAW's advanced polishing technology

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Stone Polishing Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский