Automatic Stone Drilling Machines for Stone Core Drill

Jul 24, 2024

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

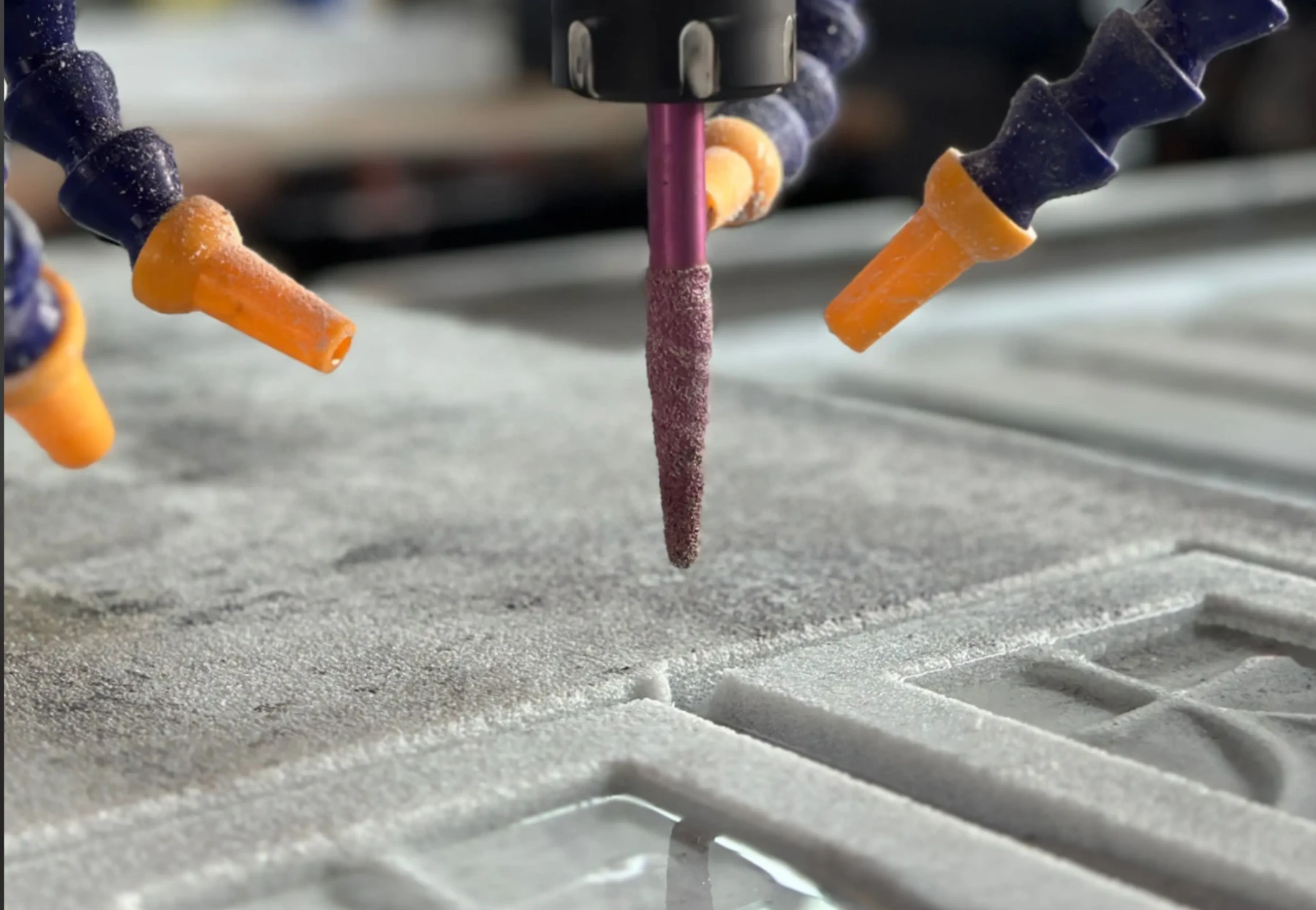

This category includes CNC stone drilling machines designed for factory and workshop environments. The machines are used for drilling stone slabs, blocks, and processed workpieces, supporting applications such as slab drilling, block drilling, positioning holes, and core drilling.

In factory production, these machines are commonly used for core extraction, structural holes, and installation holes in stone components. Typical finished products include stone columns, balustrades, railings, stone bases, decorative blocks, and prefabricated stone parts used in architectural and interior projects. Core drilling is also widely used for material testing, quality inspection, and preparation of cylindrical stone components.

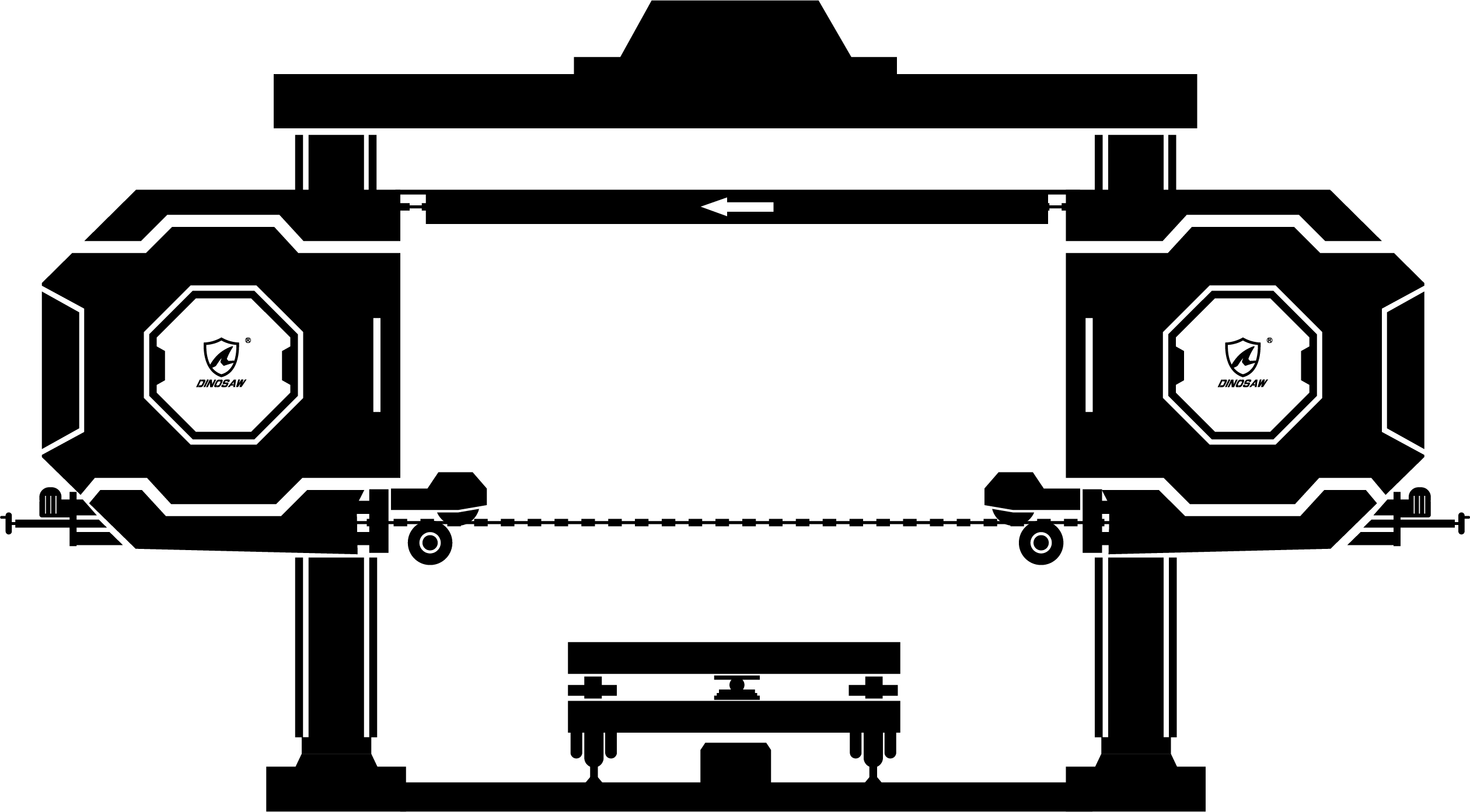

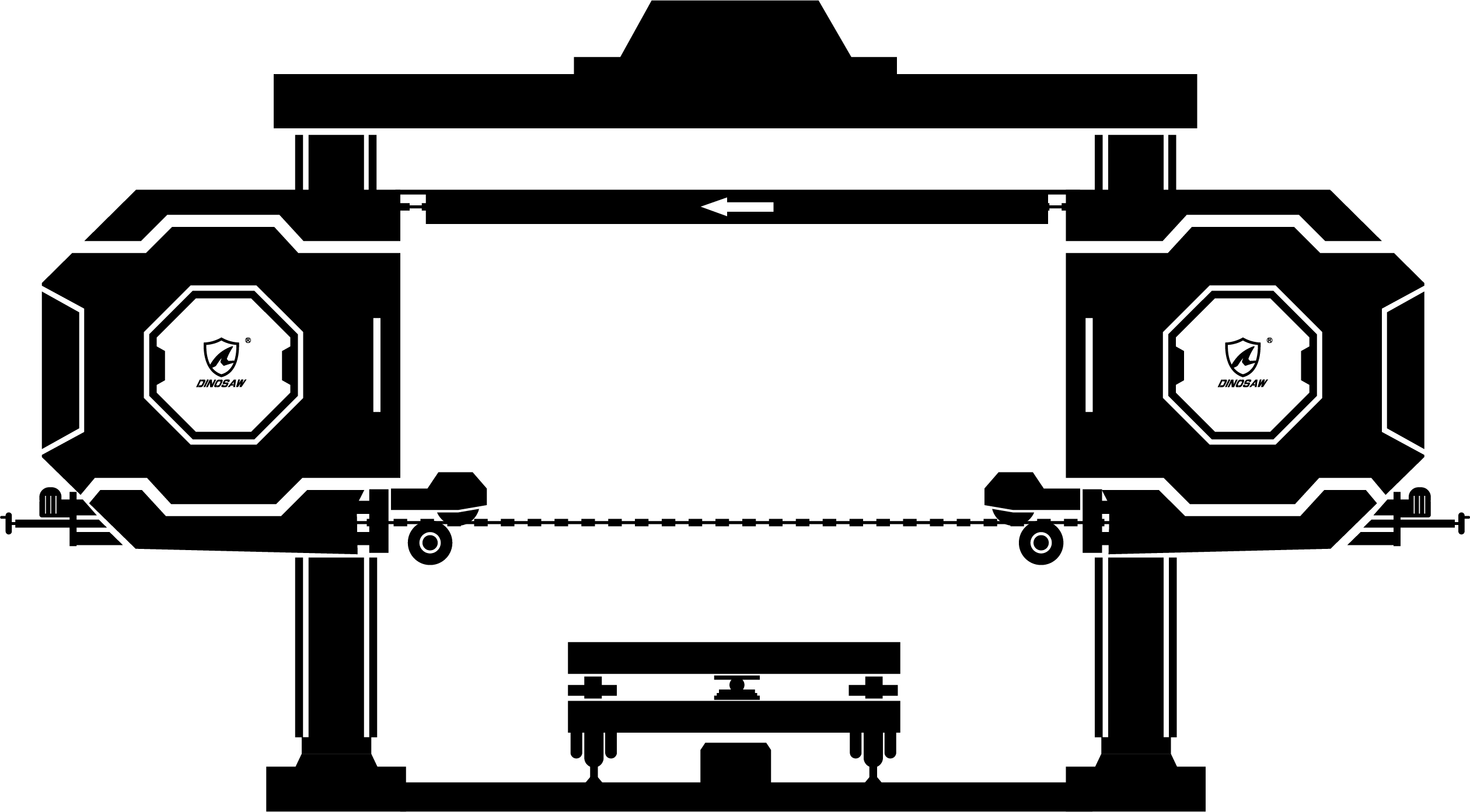

Gantry-type drilling machines provide higher stability, larger drilling depth, and wider working ranges, allowing multiple holes to be completed automatically by adjusting the lower trolley and upper beam system. Compact fixed-position drilling machines are suitable for simpler drilling tasks, where materials are manually repositioned between operations.

DTH (Down-The-Hole) drilling machines are used for drilling operations in quarry sites, mining areas, and construction environments. They are commonly applied for deep hole drilling and large-diameter holes in natural stone, rock, and concrete.

Typical applications include quarry block extraction, blasting holes, foundation drilling, anchoring holes, and on-site construction drilling. Drilled materials are often used for building stone, road stone, foundation structures, and large outdoor stone components. DTH drilling machines are suitable for granite, limestone, concrete, and other hard rock materials, where mobility and adaptability to uneven terrain are required.

These machines are widely used in stone quarries, infrastructure projects, and construction sites where drilling is performed directly on raw materials or in outdoor conditions.

A stone drilling machine is a specialized machine used to create holes in stone, concrete, and other hard or brittle materials. It is designed for drilling operations on stone slabs, blocks, and raw materials, supporting applications such as slab drilling, block drilling, positioning holes, and core extraction.

In stone processing factories, drilling machines are commonly used for producing installation holes, structural holes, and core samples in stone components. Typical applications include drilling stone columns, railings, balustrades, bases, and prefabricated stone parts used in architectural and interior projects. Core drilling is also used for material testing, quality inspection, and preparation of cylindrical stone elements.

For quarry and construction environments, stone drilling machines are applied to on-site drilling tasks such as foundation holes, anchoring holes, blasting preparation, and block extraction. Depending on the working environment, factory-based CNC drilling machines and mobile DTH drilling machines are used to meet different production and site requirements.

English

English

Get A Easy Solution

Chat Online

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Hello 👋 How can we help?