Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

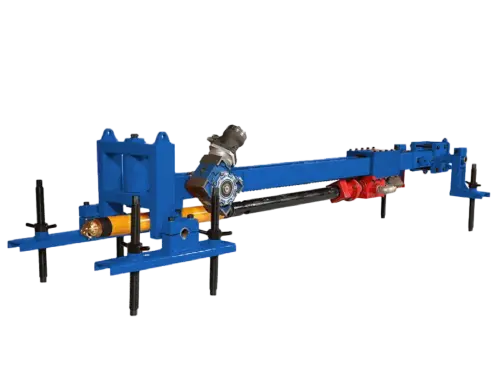

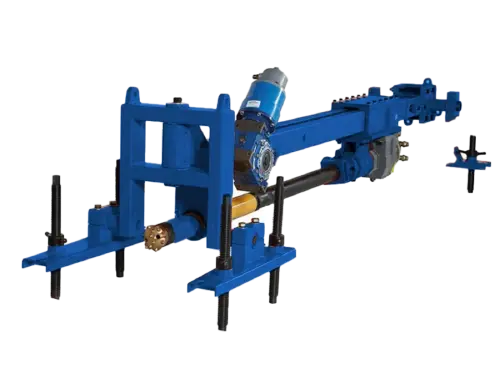

DINOSAW DTH Drilling Machines for Stone Quarrying & Rock Mining

QKZ165-H

Compatible Materials & Products

DTH Drilling Performance for Multiple Stone Types

Granite > Quarry Blocks

Granite's high hardness (Mohs scale 6-7) makes it one of the most challenging materials to drill, requiring specialized DTH equipment for efficient extraction.

DINOSAW DTH drilling machines excel in granite quarrying through percussion technology that delivers direct impact energy to the drill bit. This enables penetration rates of 6-8 m/h in hard granite formations. Our pneumatic and hydraulic systems maintain consistent power delivery throughout the drilling process, with adjustable air pressure control (0.5-0.7 MPa) for optimizing drilling parameters.

The 65-90mm hole diameter range of our QKZ90 series creates precise holes with minimal deviation, ensuring clean block separation. Our QKZ165-H model handles larger diameters up to 165mm for commercial-scale operations while maintaining the same precision standards.

The result is higher-quality granite blocks with minimal fracturing, maximizing material yield and reducing extraction costs for quarry operators. This efficiency advantage translates directly to increased production capacity and improved profit margins.

Marble > Dimensional Stone

Marble extraction demands precision drilling to preserve the stone's aesthetic qualities and structural integrity for dimensional stone production.

DINOSAW DTH drilling machines provide the exact hole placement needed for marble quarrying, with position accuracy within ±10mm even at depths of 30+ meters. Our QKZ90-E model with electric rotary power source creates holes from 65-90mm in diameter, ideal for controlled separation techniques common in marble extraction.

The electric system provides cleaner operation with minimal contamination risk to valuable material, while our bit designs with carbide inserts minimize micro-fracturing around drill holes to protect the stone's natural beauty. Air consumption of just 7-9 m³/min ensures efficient operation.

Precision drilling results in higher yield rates of usable dimensional marble, with up to 22% improvement versus conventional methods, preserving the stone's natural patterns and veining while reducing waste material.

This capability translates to increased recovery of premium-grade marble, significantly enhancing quarry profitability in the high-value dimensional stone market.

Limestone > Construction Materials

Limestone is a versatile construction material requiring efficient extraction methods to meet high-volume commercial demands across global markets.

DINOSAW DTH drilling machines are optimized for limestone quarrying with feed rates of 6-8 m/h and hole diameters up to 165mm, ideal for bulk extraction needs. The QKZ165-H model with hydraulic power system delivers consistent performance in variable limestone formations, while operating at a working pressure of 0.5-0.7 MPa.

Our machines' durable components withstand limestone's abrasive nature while requiring minimal maintenance, maximizing operational uptime. The ability to adjust drilling parameters allows optimization for different limestone densities within the same quarry, from soft porous varieties to denser crystalline formations.

This specialized capability ensures consistent production of quality limestone blocks and aggregates with precise dimensions, crucial for construction material standardization and quality control requirements in infrastructure projects.

Operational efficiency reduces fuel consumption compared to traditional drilling methods, providing a more cost-effective and sustainable extraction solution for high-volume limestone quarrying operations.

Hard Rock > Foundation Engineering

Foundation engineering in hard rock environments presents unique challenges that require specialized drilling solutions for structural stability and safety.

DINOSAW DTH drilling machines perform effectively in foundation engineering where precision and depth are critical. Our QKZ90-P pneumatic model creates anchor holes and foundation piles in hard rock with minimal deviation (less than 1% of depth), ensuring structural integrity even in seismic zones. With air consumption of 12-14 m³/min, it delivers reliable performance in challenging conditions.

These machines operate efficiently in confined spaces with minimal setup area (less than 5m²), making them practical for urban construction projects. With drilling depths up to 40 meters and constant hole diameter throughout the entire depth, they meet requirements for deep foundation work in skyscrapers and infrastructure projects. The pneumatic power source provides consistent energy delivery even in remote locations without reliable electricity, while the 65-90mm diameter range is ideal for most foundation anchoring systems and reinforcement applications.

This capability translates to faster project completion times (typically 30-40% reduction) and reduced foundation costs for construction contractors working in challenging geological conditions, while ensuring compliance with international foundation engineering standards.

Granite Quarrying

Maximizing Extraction Efficiency in Hard Stone

A major granite quarry struggled with slow drilling speeds and inconsistent hole quality. After implementing DINOSAW's percussive drilling equipment, their drilling speed increased to 6-7m/h. This improved blasting effectiveness and block quality, increasing production by 28%.

Construction Foundation Work

Overcoming Challenging Geological Conditions

A construction firm encountered dense basalt during a commercial building foundation project. DINOSAW's down-the-hole drill penetrated at 4.8m/h - over 3x faster. The precise hole placement ensured proper anchor bolt installation, allowing the project to proceed on schedule and reducing foundation completion time by 42%.

Marble Quarry Operation

Precision Drilling for Premium Block Recovery

A high-end marble producer needed to maximize recovery rates of premium white marble while minimizing waste. DINOSAW's DTH hammer delivered precise hole placement. The electric system eliminated diesel contamination risks. This improved accuracy resulted in 22% less waste and 15% higher premium-grade recovery.

Specs and options

Specifications customizable upon request.

| Product model | QKZ90 - P | QKZ90 - E | QKZ165 - H |

| Hole diameter (mm) | Φ65 - 90 | Φ65 - 90 | Φ90 - 165 |

| Drilling depth (m) | Max.35 | Max.40 | Max.30 |

| Feed rate (m/h) | 6 - 8 | 6 - 8 | 6 - 8 / 2 - 4 |

| Stroke (m) | 1 | 1 | 1.5 |

| Air consumption (m³/min) | 12 - 14 | 7 - 9 | 7 - 12 |

| Working air pressure (Mpa) | 0.5 - 0.7 | 0.5 - 0.7 | 0.5 - 0.7 |

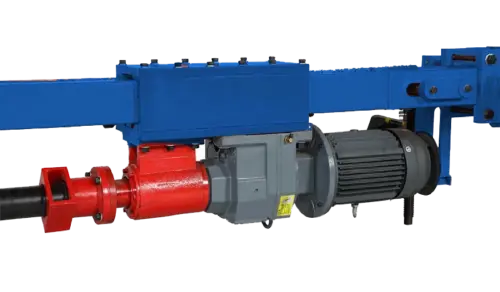

| Rotary power source | Pneumatic | Electric | Hydraulic |

| Feed power source | Pneumatic | Pneumatic | Hydraulic |

| Equipped drill rod (mm) | Φ73*1000 | Φ73*1000 | Φ76*1500 |

| Adjustable height of base (mm) | 220 | 220 | 400 |

| Total weight (kg) | 500 | 520 | 700 |

DTH drilling technology for maximum stone quarrying efficiency

DTH Drilling for Efficient Stone Quarrying

Hard Rock Drilling Speed

Unique slide guide design ensures fast feed rates of 6-8 m/h in granite, marble and limestone quarrying

Multi-Angle Drilling Capability

Universal ball joint between headpiece and main frame enables vertical, horizontal or inclined holes

Precise Hole Alignment

Propulsion design guarantees straight holes at depths up to 40m for clean stone block separation

Fast Relocation in Narrow Spaces

Multiple fastening points enable quick repositioning for efficient drilling in confined quarry areas

Versatile Power Options

Choose pneumatic, pneumatic-electric or pneumatic-hydraulic systems for different quarry conditions

Quick-Change Drilling System

Various hammer specifications with quick-release drill rods for efficient stone hardness adaptation

FAQs

Common Questions About DINOSAW DTH Drilling Machines

What is the difference between DTH drilling and rotary drilling?

DTH (Down-The-Hole) drilling places the hammer at the bottom of the drill string, directly above the drill bit, delivering percussion energy directly to the rock face. This makes DTH drilling more efficient in hard materials like granite and marble, with energy transfer efficiency up to 80% compared to just 40-55% in rotary systems.

Rotary drilling relies on rotation and downward pressure from the surface, with energy traveling through the entire drill string before reaching the bit. This energy loss through the drill string makes rotary drilling less effective for materials with compressive strengths exceeding 100 MPa.

For stone quarrying operations, DTH drilling typically achieves 3-5 times faster penetration rates in hard stone compared to rotary methods, while also creating straighter holes with deviation as low as 0.5% of depth - critical factors for efficient stone extraction and precise block separation.

What sizes of holes can DINOSAW DTH machines drill?

DINOSAW DTH drilling machines offer a range of hole diameters to accommodate various quarrying and construction applications:

The QKZ90 series (models P and E) can drill holes from Φ65mm to 90mm in diameter with high precision (±5mm deviation per 10m depth), ideal for most stone block extraction work and applications like anchor holes in construction or diamond wire saw insertion points.

The QKZ165-H model extends capabilities further, handling hole diameters from Φ90mm up to 165mm with the same precision standards, suitable for larger-scale quarrying operations, blast hole drilling, and foundation work requiring substantial anchoring systems.

These diameter ranges cover 95% of stone extraction requirements in the industry, from dimensional stone production to construction applications, allowing quarry operators to select the appropriate machine for their specific material properties and production targets.

How deep can these DTH machines drill?

DINOSAW DTH drilling machines offer depth capabilities that vary by model:

The QKZ90-P pneumatic model can reach maximum drilling depths of 35 meters with hole deviation less than 1%, suitable for most quarrying applications and exceeding the industry average depth capacity by approximately 15%.

The QKZ90-E electric model extends this capability to 40 meters with the same precision standards, providing additional depth for deep deposit extraction and specialized geotechnical applications.

The QKZ165-H hydraulic model achieves depths up to 30 meters while handling larger diameter holes (up to 165mm), delivering the optimal balance of depth and diameter for commercial quarrying operations.

These depth capabilities can be extended by adding additional drill rods as needed for specific projects. Each machine's standard configuration includes appropriate-length drill rods (typically 1-1.5m sections) that can be connected to reach the required depth while maintaining drilling accuracy.

What power sources do DINOSAW DTH machines use?

DINOSAW offers DTH drilling machines with three distinct power source options to accommodate different operational environments and project requirements:

Pneumatic (QKZ90-P): Powered by compressed air (12-14 m³/min at 0.5-0.7 MPa), this model offers good mobility and operational simplicity, ideal for remote locations without reliable electricity. The pneumatic system provides robust performance in harsh environments and requires minimal maintenance, making it practical for isolated quarry operations.

Electric (QKZ90-E): Featuring electric rotary power with pneumatic feed (requiring 7-9 m³/min air), this hybrid model provides cleaner operation with reduced air consumption (approximately 35% less than fully pneumatic models), suitable for operations with access to stable power supplies and where environmental considerations are important.

Hydraulic (QKZ165-H): Utilizing hydraulic systems for both rotation and feed functions, this powerful model works well in demanding applications, handling larger hole diameters while maintaining precise control. The hydraulic system delivers high torque (up to 1650 N·m) and consistent performance regardless of ambient temperature variations.

All models can be customized with alternative power configurations based on specific operational requirements and site conditions, ensuring optimal performance across various quarrying environments.

How do I troubleshoot common DTH drilling problems?

When encountering DTH drilling issues, follow these systematic troubleshooting steps to quickly identify and resolve problems:

Poor Penetration Rate: Check air pressure first - ensure it's within 0.5-0.7 MPa range. Inspect drill bit for excessive wear (replace if button height is reduced by >30%). Verify rotation speed (15-25 RPM is optimal for most stone applications). For hard formations like granite, reduce feed pressure initially to allow bit stabilization before applying full pressure.

Hammer Stalling: Usually indicates insufficient air volume. Verify air compressor output meets machine requirements. Check for air leaks along supply lines and connections. Ensure hammer lubrication system is functioning properly.

Excessive Bit Wear: Most commonly caused by improper rotation speed or feed pressure. Maintain proper rotation-to-percussion ratio for specific stone types (slower in abrasive stones like granite). Ensure sufficient lubrication to reduce friction heat. When drilling through varied stone layers, adjust parameters to match the hardest material present.

Hole Deviation: Check alignment of drill guide mechanisms. Reduce feed pressure when starting holes. Ensure drill string components are straight and threads are in good condition. In layered or fractured stone, start with lower percussion energy until hole is established.

DINOSAW provides 24/7 technical support , and our service technicians can remotely diagnose many issues through our optional telemetry system to minimize downtime.

Certifications & Standards

DTH Drilling for Efficient Stone Quarrying

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to improve your stone quarrying productivity?

Contact DINOSAW today to discover how our DTH drilling machines can transform your quarrying operations

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy DTH Drilling Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский