Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

Diamond Core Drill Bits for Precision Drilling

干/湿式金刚石取芯钻头

Compatible Materials & Products

Advanced Core Drilling for Stone Quarrying, Testing & Industrial Use

Core Drill Bits for Natural Stone

|

|---|

|

|

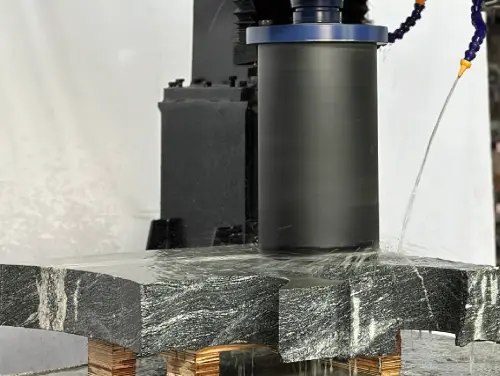

Natural stone materials like marble, granite, sandstone, limestone, and quartz require specialized drilling solutions that preserve material integrity while achieving precise extraction. DINOSAW diamond core bits for natural stone feature optimized diamond concentration and bonding matrix specifically formulated for these demanding quarrying applications.

Our stone-specific bits create clean, chip-free cores thanks to carefully calibrated diamond exposure and cutting angles. The specialized segment design minimizes vibration and prevents material cracking, ensuring valuable stone remains intact during the extraction process and when used alongside quarry wire saw machines for marble extraction.

Quarry operators and fabricators benefit from reduced waste and rework, while achieving the exact specifications required for geological assessment, stone block qualification, and preparation for further processing in high-end stone applications.

Core Drill Bits for Dekton

Dekton and other ultra-compact surfaces require exceptional precision drilling to prevent breakage or damage. DINOSAW core bits for Dekton feature specialized ultra-thin edge sintered drill bit technology specifically engineered for these dense, hard materials.

Our sintered drill bits deliver fast drilling speeds while maintaining smooth surface finish even on Dekton's challenging composition. The specialized diamond matrix provides controlled cutting action that minimizes edge stress even on premium countertop installations.

Fabricators working with Dekton achieve consistently clean holes without micro-fractures or edge chipping, ensuring perfect installation of fixtures, anchors, and service penetrations in premium countertops, wall panels, and decorative applications.

Core Drill Bits for Concrete

|

|---|

|

Concrete is the foundation of modern construction, demanding reliable drilling solutions for structural installations and anchoring systems. DINOSAW diamond core bits are engineered specifically for concrete applications, featuring reinforced diamond segments that easily cut through aggregate and rebar without compromising structural integrity.

Our concrete core bits utilize precision-engineered cooling channels that effectively remove debris while maintaining optimal cutting temperature. This advanced design prevents bit overheating and extends tool life even during continuous operation on reinforced concrete.

Contractors achieve faster project completion and superior hole quality, reducing labor costs and minimizing material waste. The precise, clean holes create stronger anchor points for installations, ensuring long-term structural stability.

Core Drill Bits for Glass

Glass drilling applications require exceptional precision and control to prevent cracking and chipping. DINOSAW sintered thin-wall diamond core bits feature specialized diamond matrix technology that creates perfect, chip-free holes in sea glass, tempered glass, sheet glass, and decorative glass products.

Our glass-specific bits utilize precision-engineered 1mm thin walls with 10mm diamond height, delivering optimal performance while maintaining cool cutting temperatures with proper water cooling. The specialized design provides low noise, zero vibration, and clean edge finish even on delicate or thin glass materials.

Jewelry makers, glass fabricators, and installation professionals achieve consistently clean, precise holes without material damage, ensuring professional results in architectural glass installations, display cases, artistic creations, and decorative applications.

Core Drill Bits for Ceramic Tiles

Ceramic tiles require precise drilling solutions for countertop installations, bathroom fixtures, and decorative applications. DINOSAW ceramic tile core bits feature vacuum brazed diamond coating technology that creates perfect, chip-free holes in all tile types.

Our tile-specific bits deliver razor-sharp cutting edges and can be used in both dry and wet conditions for convenient drilling in any installation environment. The specialized diamond coating prevents tile cracking even on delicate or thin materials, while maintaining fast cutting speeds throughout the bit's extended lifespan.

Tile installers and contractors achieve clean, precise holes without damage to expensive materials, ensuring professional results in bathroom renovations, kitchen backsplashes, and decorative tile applications.

Commercial Construction

Accelerating Multi-Story Building Installations

A construction company struggled with utility installations through reinforced concrete floors. DINOSAW core bits delivered 40% faster drilling while maintaining precise holes for plumbing and electrical conduits. Longer bit life helped complete the project ahead of schedule.

Stone Fabrication Workshop

Transforming Countertop Production

A stone fabrication shop needed precise holes for sink and faucet installations in granite and quartz countertops. DINOSAW core bits created chip-free, round holes even in brittle materials. This reduced material waste by 25% and eliminated customer callbacks for imperfections.

Road Maintenance Crew

Streamlining Infrastructure Sampling

A municipal road department needed consistent core samples for quality testing across pavement types. DINOSAW asphalt core bits extracted clean samples from both new and aged roadways. The team reduced sampling time by 35% while collecting more accurate data for analysis.

Specs and options

Specifications customizable upon request.

DINOSAW offers a comprehensive range of core drill bits for different materials, applications, and drilling methods. Available in both dry and wet drilling options with various diameters and lengths to meet your specific requirements. Contact us directly for detailed specifications and customized solutions.

Compatible Accessories: Drill bit segments, Drill bit connectors, Extension rods, Hilti quick-connect adapters

Compatible Core Drilling Brands: Hilti, Husqvarna, Makita, Bosch, Dewalt, Weka, CS Unitec, DINOSAW and more

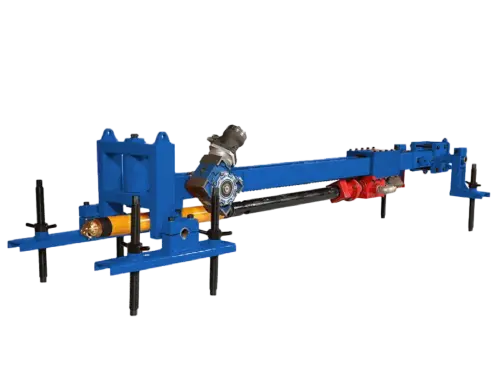

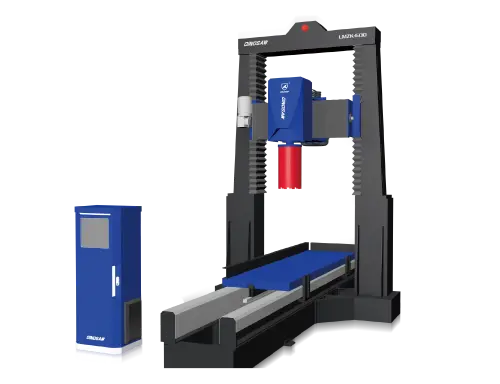

Related Drilling Machine: Gantry stone drilling machine, DTH (Down-The-Hole) drill

Core bit technology for perfect extraction in any material

Diamond Core Precision: Mastering Every Drilling Challenge

Faster Cutting Speed

Diamond segments with controlled exposure cut efficiently through marble, granite and concrete.

Precision Hole Accuracy

Stable design creates precise round holes with exact dimensions, reducing material stress.

Extended Tool Life

Water channels prevent overheating during operation, extending diamond segment life.

Material-Specific Performance

Matrix formulations balance diamond retention and wear for different material hardness, improving efficiency.

Universal Equipment Compatibility

Universal connection system fits all drilling machines, eliminating equipment compatibility issues.

Minimized Downtime

Modular design enables quick segment replacement, reducing downtime and project delays.

FAQs

Common Questions About Diamond Core Drill Bits

What is a core drill bit?

A core drill bit is a specialized drilling tool with these key characteristics:

• Design: Hollow cylindrical shape that creates circular holes while preserving the central core

• Function: Allows intact material samples to be collected during drilling

• Construction: Features diamond-embedded segments that provide cutting power and durability

• Applications: Ideal for geological exploration, stone quarrying, engineering inspection, and core sampling

• Best Materials: Especially effective for moderately hard materials like marble, granite, concrete, glass and engineered stone with Mohs hardness between 4-6

What's the difference between core vs non-core drill bits?

Core and non-core drill bits differ in fundamental design and application purposes:

• Core Drill Bits:

- Hollow center design that preserves material samples

- Material fills the central void during drilling - Ideal for material testing and sample collection

- Recommended for harder materials (Mohs hardness 4-6)

• Non-Core Drill Bits:

- Solid center with cutting blades

- Completely pulverizes material during drilling

- Debris removed by water flushing

- Highly efficient for softer materials (Mohs hardness below 4.5)

• Selection Guidance: Choose based on material hardness and whether sample preservation is required

How do I choose the right core drill bit for my material?

Selecting the right core drill bit involves these key considerations:

Starting Point:

• Begin with a 25-degree matrix hardness bit as baseline

• Observe performance during initial drilling

Adjustment Guidelines:

• If diamond particles don't expose properly → Switch to a softer matrix bit

• If diamonds fall out too quickly → Use a harder matrix bit

Material-Specific Selection:

• Hard materials (granite) → Use soft matrix bits

• Softer materials (limestone, marble) → Use harder matrix bits

Other Factors: Consider machine type, rotation speed, pressure, water flow, and operator technique

Are core drill bits reverse threaded?

Core drill bit threading varies based on specific applications:

Threading Types:

• Some core drill bits use reverse (left-hand) threading

• These are primarily designed for machines where rotation might loosen standard threads

General Guidelines:

• Handheld core drills → Typically use standard right-hand threads

• Larger machine-mounted core bits → May use reverse threading for operational security

Identification Methods:

• Check manufacturer's specifications

• Look for markings on the bit connection

• When unsure, try turning counterclockwise first when attempting to loosen the bit

How to properly change core drill bits?

To safely change core drill bits, follow this systematic process:

Preparation:

1. Ensure the machine is completely stopped and disconnected from power

2. Allow the bit to cool if recently used

Removal & Installation:

3. Use appropriate wrenches - one to hold the spindle and another for the bit

4. Check for reverse threads (refer to manufacturer specifications)

5. Clean mounting threads before installing the new bit

6. Hand-tighten first, then secure with wrenches without over-tightening

Final Safety Checks:

7. Verify alignment before starting

8. Test with minimal pressure initially to ensure proper installation

How to sharpen or maintain core drill bits?

Diamond core drill bits require specialized maintenance rather than traditional sharpening:

Regular Maintenance:

1. Clean thoroughly after each use to remove debris

2. Store in a dry environment to prevent corrosion

3. Inspect water ports and clear any blockages

Performance Restoration:

4. Core bits are typically not sharpened - instead, replace worn segments while preserving the core body

5. Professional segment replacement involves re-welding new diamond segments (cutting heads) to the existing bit body

6. For minor wear, "dress" the bit by drilling into abrasive material to expose fresh diamonds

Operational Best Practices:

7. Maintain proper cooling during operation to extend segment life

This segment replacement approach is more cost-effective than replacing entire bits while ensuring optimal cutting performance.

How to remove a stuck core drill bit?

When a core drill bit becomes stuck, follow this procedure:

Immediate Actions:

1. Stop the machine immediately and disconnect power

2. Apply penetrating oil around the bit where it enters the material

3. Use reverse rotation if your drill supports it

4. Gently tap the bit with a rubber mallet while applying reverse pressure

For Severe Cases:

5. Use specialized extraction tools or seek professional assistance

Prevention Tips:

• Maintain adequate water flow during drilling

• Use appropriate speed and pressure for the material

• Ensure the bit is suitable for the material being drilled

Certifications & Standards

Diamond Core Precision: Mastering Every Drilling Challenge

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Transform Your Drilling Efficiency?

DINOSAW core drill bits deliver precision, durability, and performance for your toughest material challenges

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond Core Drill Bits Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский