Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

Diamond Segment for Core Drill Bit

25-356mm

Compatible Materials & Products

Materials & Applications from Concrete to Porcelain

Concrete > HVAC openings

Intro: For HVAC openings in cast‑in‑place concrete, you need fast, low‑spalling diamond core drilling that keeps dust down and layout accurate.

Process: Rooftop/turbo crowns with balanced metal bond and wet coring improve cooling, slurry/chip evacuation and hole straightness; laser‑weldable geometry supports re‑tipping and stable RPM/line speed.

Benefits: The payoff is faster penetrations, clean entry/exit edges and less patching, reducing downtime across shafts and sleeves.

Recommended segment: Roof Type for fast feed and clean entry.

Reinforced concrete > Structural coring

Intro: In RC walls/slabs, rebar introduces impact, heat and deflection.

Process: Tougher bond segments with chip‑breaker notches and wider slurry channels stabilize through‑bar drilling; wet coring controls temperature and silica dust, improving safety and cut quality.

Benefits: You get steady progress, longer segment life and safer structural penetrations for anchors, sleeves and services.

Recommended segment: Straight Groove or Arix for cooling and balanced force under wet coring.

Masonry/brick > Utility pass‑through

Intro: Abrasive masonry/brick wears tools quickly while indoor work may limit water.

Process: Softer‑bond segments deliver fast cutting and reliable chip removal under dry coring; choose geometry that clears swarf without glazing, and use gentle feed for neat holes.

Benefits: The result is swift pass‑throughs with cleaner walls and fewer stoppages on utility routes.

Recommended segment: M‑Shape Pit for swift cooling and chip ejection.

Asphalt > Core sampling

Asphalt coring prioritizes cylindrical integrity for lab testing and QA.

Process: Open‑structure segments with efficient slurry paths reduce bit drag and keep cores intact; wet coring further improves cooling and segment life.

Benefits: Expect accurate samples, smoother extraction and better economy on pavement investigations.

Recommended segment: Groove Dot for large chip space and strong removal.

Porcelain/ceramic > Small‑dia coring

Intro: Brittle porcelain/ceramic chips easily under heat and high feed.

Process: Fine‑grit segments and gentle feed rates, preferably wet coring, keep edges clean and hole position precise; crown or dot‑tip geometries help start and guide small diameters.

Benefits: Benefits include low chipping, tight tolerances and premium finishes around fixtures.

Recommended segment: Crown type or Dot Tip for clean small‑diameter holes.

Specs and options

Specifications customizable upon request.

| Diameter | Specification | Teeth No. | Diameter | Specification | Teeth No. | ||

|---|---|---|---|---|---|---|---|

| Inches | mm | mm | pcs | Inches | mm | mm | pcs |

| 1" | 25 | 16×3.5×10 | 3 | 4-1/2" | 114 | 24×4.0×10 | 10 |

| 1-1/8" | 29 | 16×3.5×10 | 4 | 4-3/4" | 120 | 24×4.0×10 | 10 |

| 1-1/4" | 32 | 16×3.5×10 | 4 | 5" | 127 | 24×4.0×10 | 10 |

| 1-1/2" | 38 | 16×3.5×10 | 4 | 5-1/2" | 140 | 24×4.0×10 | 11 |

| 1-5/8" | 42 | 16×3.5×10 | 5 | 5-3/4" | 146 | 24×4.0×10 | 11 |

| 1-3/4" | 45 | 16×3.5×10 | 5 | 6" | 152 | 24×4.5×10 | 12 |

| 1-7/8" | 48 | 16×3.5×10 | 5 | 6-1/4" | 159 | 24×4.5×10 | 12 |

| 2" | 51 | 24×3.5×10 | 5 | 6-1/2" | 165 | 24×4.5×10 | 12 |

| 2-1/4" | 57 | 24×3.5×10 | 5 | 7" | 178 | 24×4.5×10 | 13 |

| 2-1/2" | 63 | 24×3.5×10 | 6 | 8" | 203 | 24×4.5×10 | 14 |

| 2-3/4" | 70 | 24×4.0×10 | 7 | 9" | 229 | 24×4.5×10 | 16 |

| 3" | 76 | 24×4.0×10 | 7 | 10" | 254 | 24×4.5×10 | 16 |

| 3-1/4" | 82 | 24×4.0×10 | 7 | 11" | 280 | 24×5.0×10 | 18 |

| 3-1/2" | 89 | 24×4.0×10 | 8 | 12" | 305 | 24×5.0×10 | 24 |

| 4" | 102 | 24×4.0×10 | 9 | 13" | 330 | 24×5.0×10 | 24 |

| 4-1/4" | 108 | 24×4.0×10 | 9 | 14" | 356 | 24×5.0×10 | 24 |

Precision Coring, Longer Life.

Diamond segments for concrete/RC coring with re‑tipping advantage.

Faster Penetration, Cleaner Edges

Rooftop/turbo crowns and balanced bonds speed coring while controlling chipping for smoother hole walls.

Longer Life via Re‑tipping

Segment geometry supports reliable re‑tipping to extend tool life and reduce downtime.

Stable Through‑Rebar Coring

Tough bonds and chip‑breakers enhance stability under rebar impacts, especially in wet mode.

Versatile Across Materials

One segment family covers concrete, RC, masonry, asphalt and ceramics.

Lower Total Cost of Ownership

Maintenance‑friendly crowns and re‑tipping path reduce lifecycle cost.

Certified Quality & Safety

ISO 9001 and CE marking are declared across the range.

FAQs

Common Questions About Diamond Segments for Core Drill Bits

What is the diamond segment for core drill bits?

A diamond segment is the cutting tooth (or coring head) of a core bit. It consists of industrial diamonds sintered within a metal bond matrix and is typically laser-welded to the bit's crown. The specific geometry of the segment is designed to guide coolant for wet coring and efficiently manage chip/slurry evacuation.

When selecting segments, match the shape and bond to your specific material and application. Always verify that the products carry the necessary safety and quality certifications, such as EN 13236,oSa, and CE.

Can diamond segments core concrete, RC, masonry, asphalt, porcelain?

Yes. Our segments are engineered for high performance across various materials, including:For reinforced concrete and deep holes, we recommend wet coring.

Pick diamond segment shapes per job: use Roof/Turbo for concrete HVAC; Straight Groove/Arix for RC (wet); M‑pit for masonry; Groove Dot for asphalt; and Crown/Dot Tip for small‑diameter tiles.

Wet vs dry coring—how to choose?

The choice between wet and dry coring depends on site constraints, the material being drilled, and the required depth.

- Wet Coring:This method uses water to cool the bit and flush debris. It's cleaner, reduces heat, and extends segment life, making it ideal for reinforced concrete and deep holes—and supports diamond coring productivity.

- Dry Coring:This offers faster setup and is suitable for indoor or light-duty tasks where water is impractical. However, it generates more dust and typically results in a shorter tool life.

Which segment shape for each coring job?

The segment's geometry directly impacts drilling speed, entry quality, and the final finish. Here is a quick guide for matching segment shapes to applications:

- Roof/Turbo: For fast, clean entry for concrete diamond coring.

- Straight Groove/Arix: For balanced cooling and force distribution for RC wet coring.

- M-pit: For efficient chip evacuation in abrasive masonry.

- Groove Dot: For large chip space for asphalt coring.

- Crown/Dot Tip: For precise, low-chipping holes for small-diameter porcelain/ceramic coring.

Always verify the core bit's interface (threads/adaptors) for compatibility with your rig and check for CE compliance. It's good practice to perform a test on an off-cut piece before starting production drilling.

How to balance coring speed and segment life?

Diamond coring speed vs segment life: optimizing performance requires balancing the penetration rate (speed) with the segment's wear rate (life). The key is in the formulation:

- Bonds: Softer bonds wear faster to expose new diamonds, ideal for hard, non-abrasive materials. Harder bonds resist wear, suitable for abrasive materials like masonry.

- Grit: Finer diamond grit is used for brittle materials like ceramics to minimize chipping. Coarser grit allows for faster cuts in materials like concrete.

A typical segment height is 8–12 mm, providing substantial operational life. Monitor for glazing (a sign the bond is too hard) and dress the segment to re-expose diamonds. Track the number of holes drilled per segment to manage your Total Cost of Ownership (TCO) and schedule timely re-tipping based on your target RPM/line speed.

Will my rig and threads fit these core bits?

Ensuring core drill rig compatibility, including the connection thread and diameter range, is crucial for safety and performance.

Customization supported—no compatibility worries; standard coring head diameters: Ø25–356 mm.After re-tipping, it's important to check for proper balance and minimal runout.

Before ordering, confirm CE labelling and any specified torque settings for the connection. Share your target RPM and line speed with your supplier to ensure the segment bond is correctly matched.

What specs, lead time, and MOQ should I expect?

- Diamond segment specs: Segment height and other specs are defined by product series; customization available on request.

- Lead Time: Typically 7–15 days; in‑stock items ship immediately (confirm before order).

- Minimum Order Quantity (MOQ): Generally 10 pieces; varies by specification.

Do these segments have ISO 9001 and CE?

We provide robust assurance through:We provide all necessary documentation, including a link to the CE Declaration of Conformity (DoC). Upon delivery, verify the CE mark on product/packaging and file the ISO 9001 documentation with your project records.

When should I dress or re‑tip the core bit?

Recognizing wear signs and acting promptly is key to maintaining cutting efficiency and avoiding damage. Look for these two common signs:

- Glazing:If the segment surface becomes smooth and shiny, it needs to be "dressed" or resharpened to expose new diamonds.

- Loss of Speed:A significant drop in cutting speed indicates the segments are worn out and it's time to re-tip the core bit.

Establish scheduled dressing cycles based on your application. Keep spare segments on hand to minimize downtime. Log maintenance actions and track the number of holes drilled to help with future planning.

What RPM and feed should I run for different diameters?

Setting the correct rotational speed (RPM) is vital for safety, efficiency, and tool life. Recommended RPM varies by diameter. Use these ranges as a starting guide:

- Small Diameter (e.g., <50mm):1000–2500 RPM

- Medium Diameter (e.g., 50-150mm):500–1200 RPM

- Large Diameter (e.g., >150mm):300–700 RPM

For reinforced concrete, always prefer wet coring and monitor the temperature and slurry.

Always start at a lower RPM and gradually increase to the optimal speed, avoiding chatter and vibration. Ensure your RPM setting aligns with the recommended surface speed (line speed) for the material.

Certifications & Standards

Diamond segments for concrete/RC coring with re‑tipping advantage.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

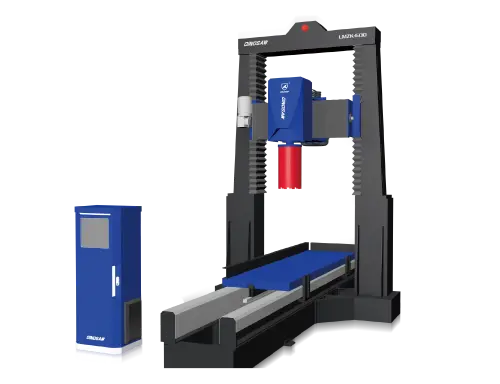

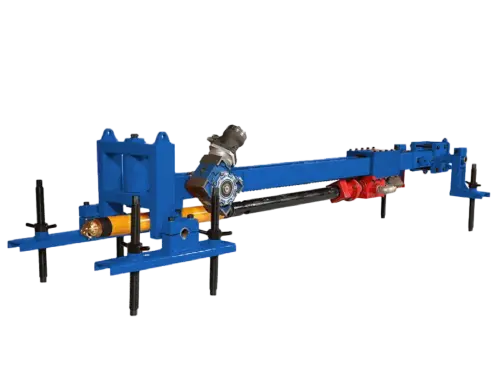

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Upgrade Your Coring with Re‑tippable Segments

Extend tool life, cut downtime, achieve cleaner coring in concrete, RC, masonry, asphalt, porcelain.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond Segment Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский