What Is an Industry Machine?

An Industry Machine is a specialized piece of manufacturing equipment designed for tasks like cutting, drilling, grinding, polishing, engraving, and shaping. These machines are vital in industries such as stone processing, construction, metal fabrication, and woodworking due to their ability to deliver high precision, efficiency, and automation.

Industry Machines can be categorized into the following types:

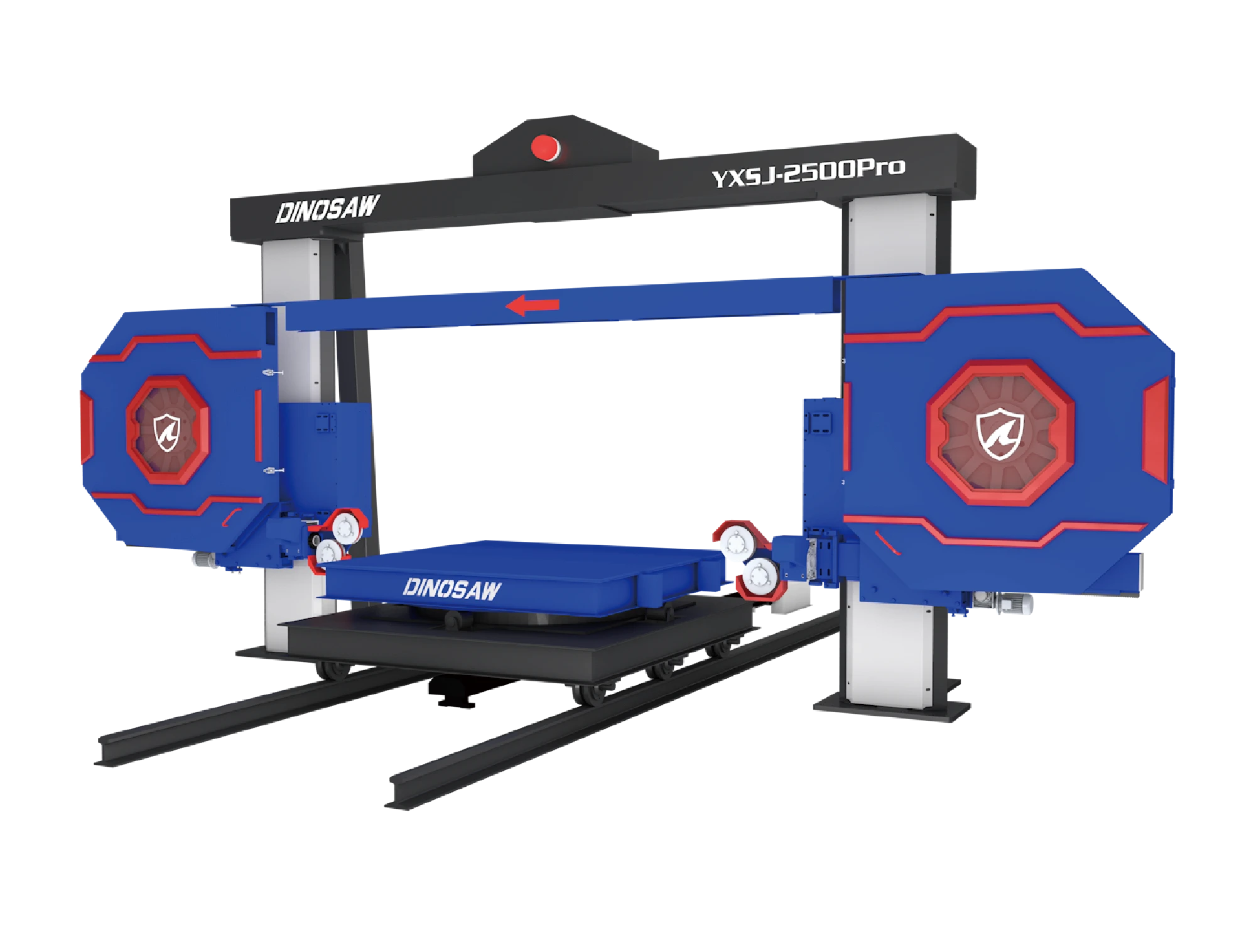

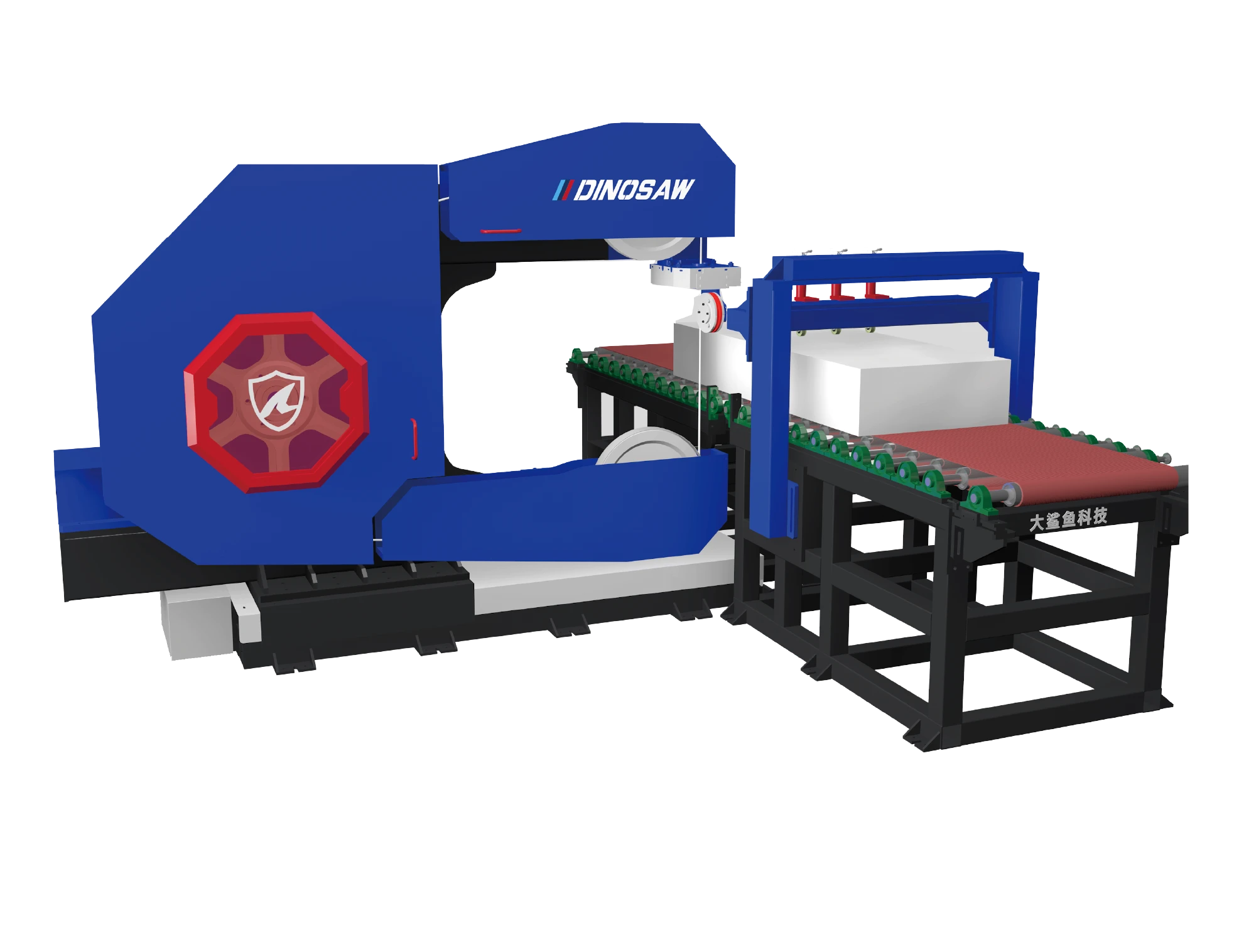

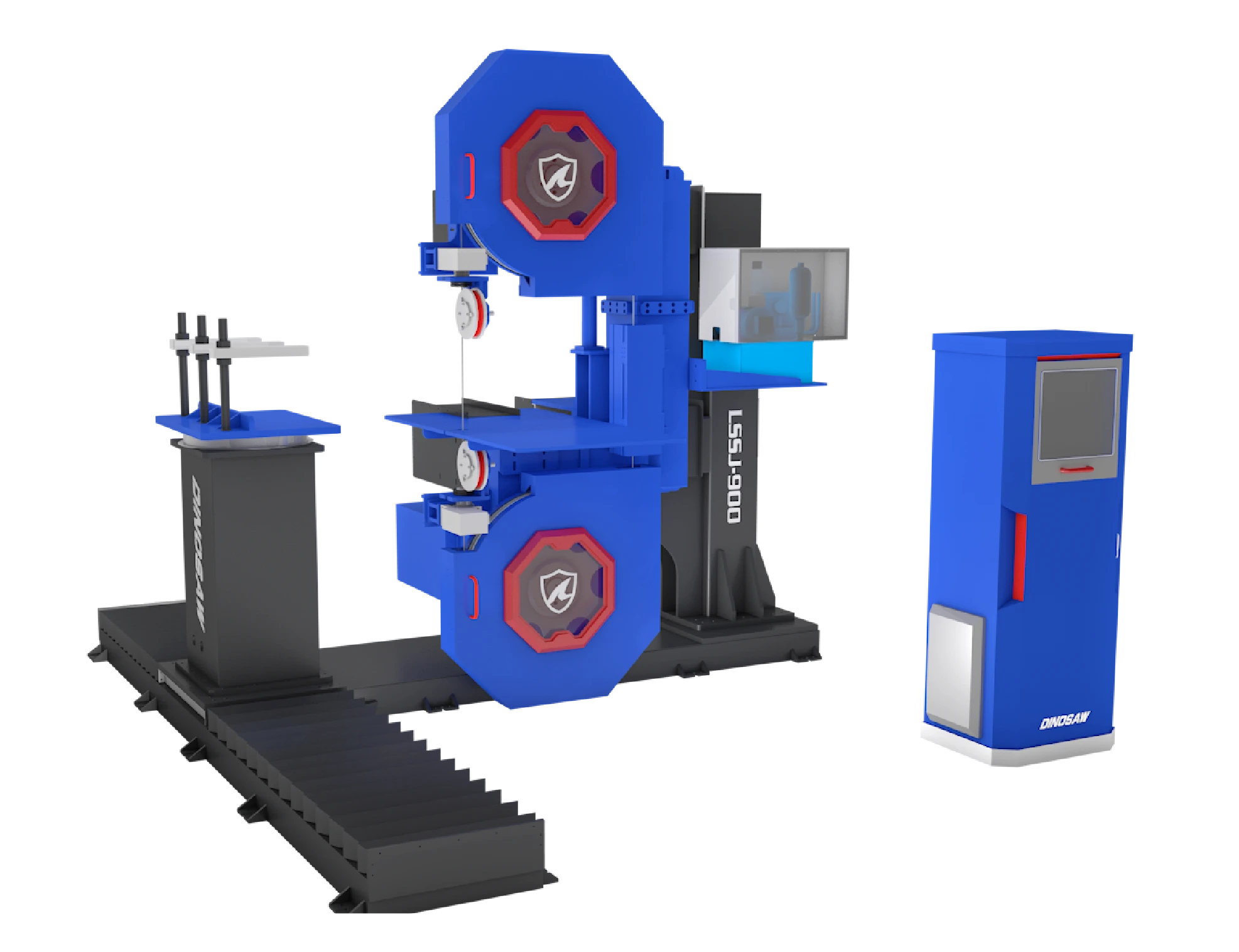

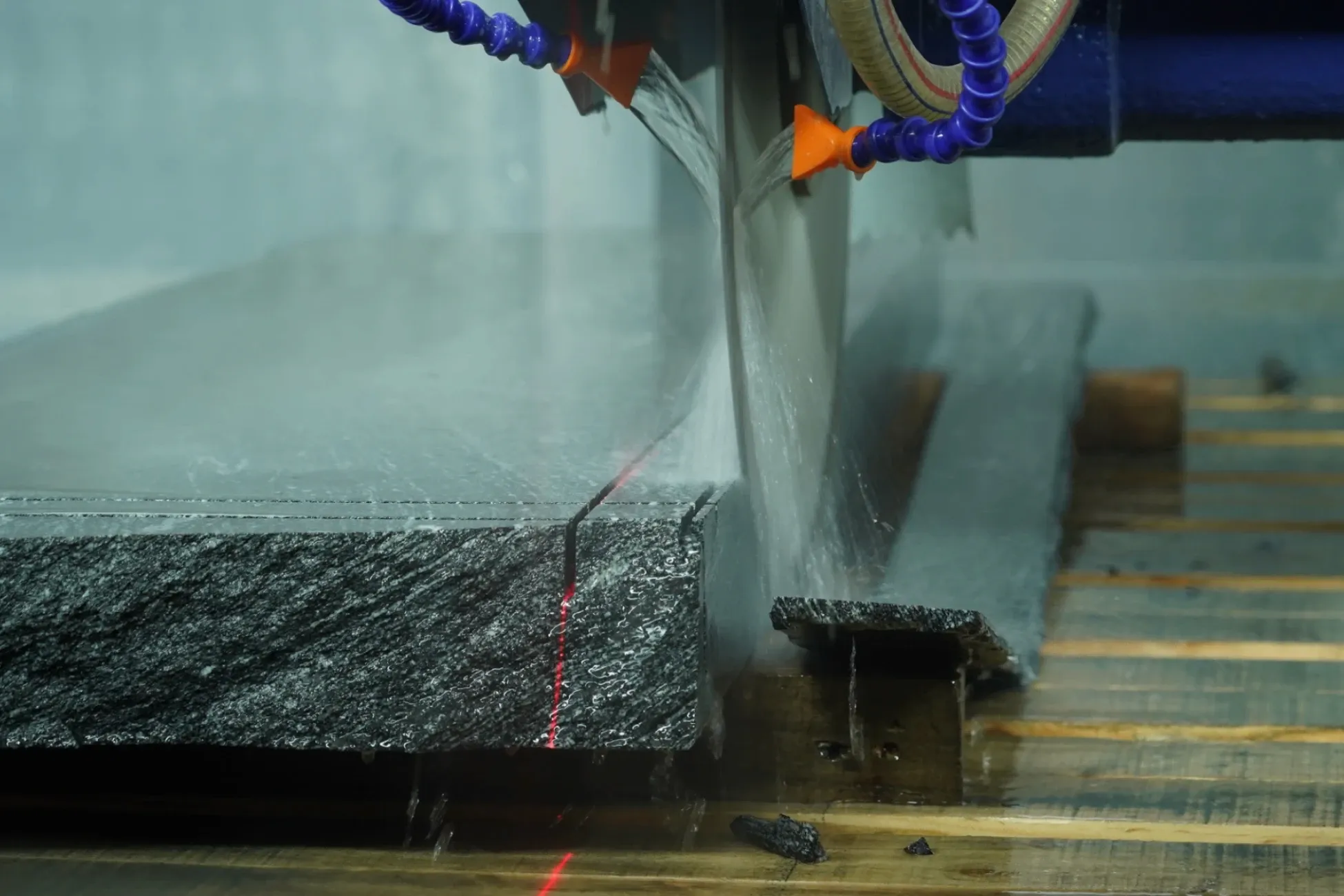

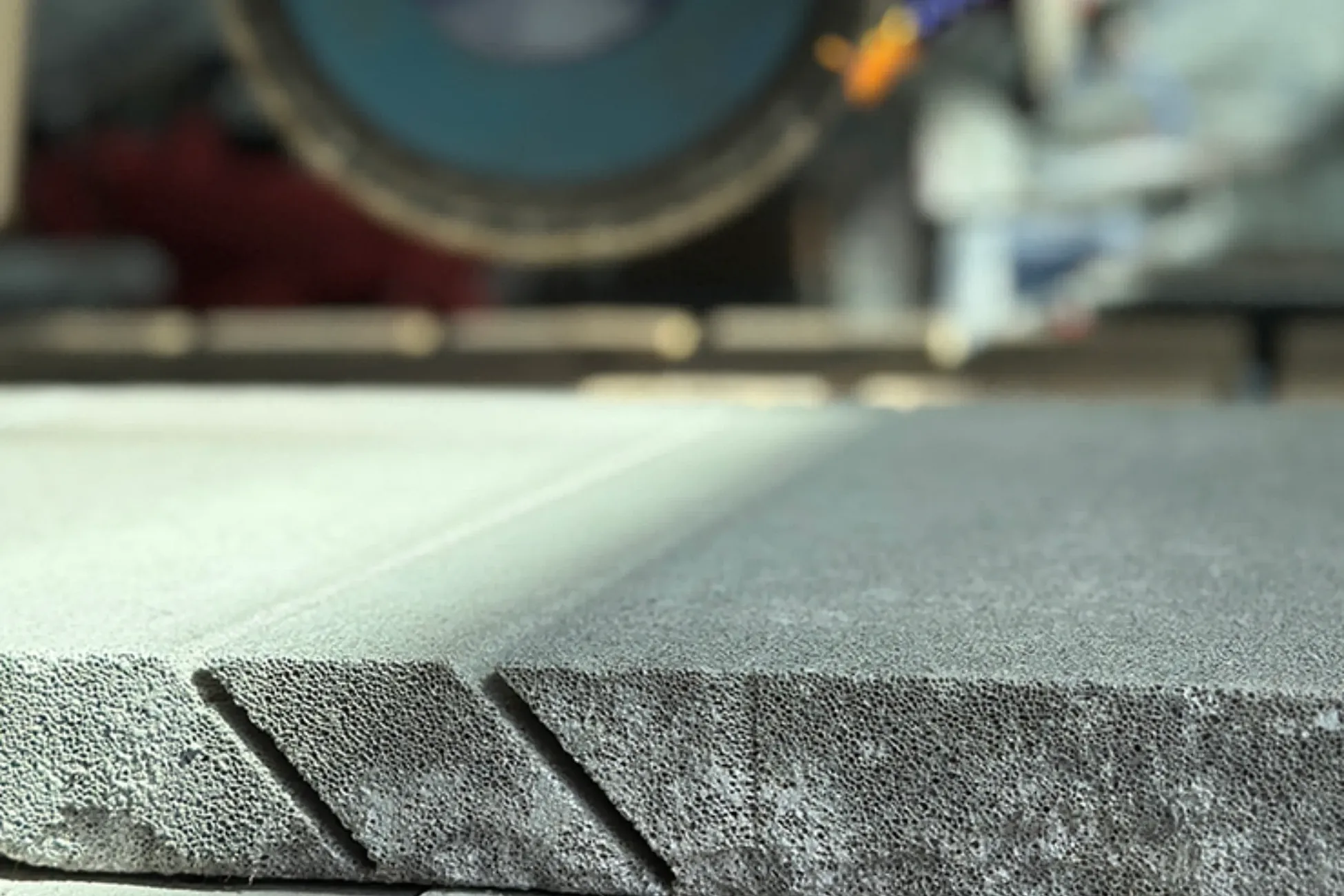

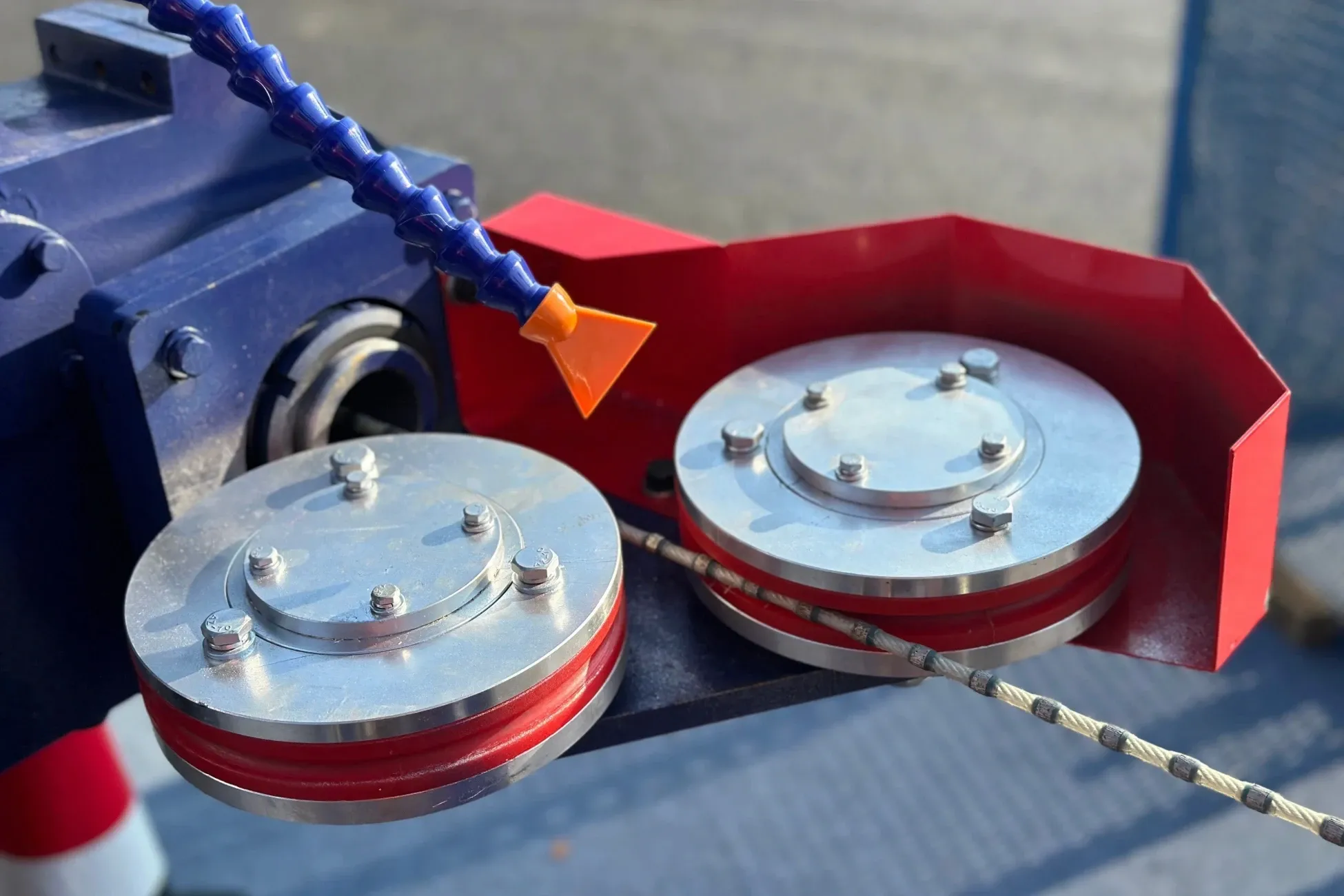

Wire Saw Machines

Mono wire saw and multi-wire saw machines for quarrying, precision cutting, trimming, and profiling.

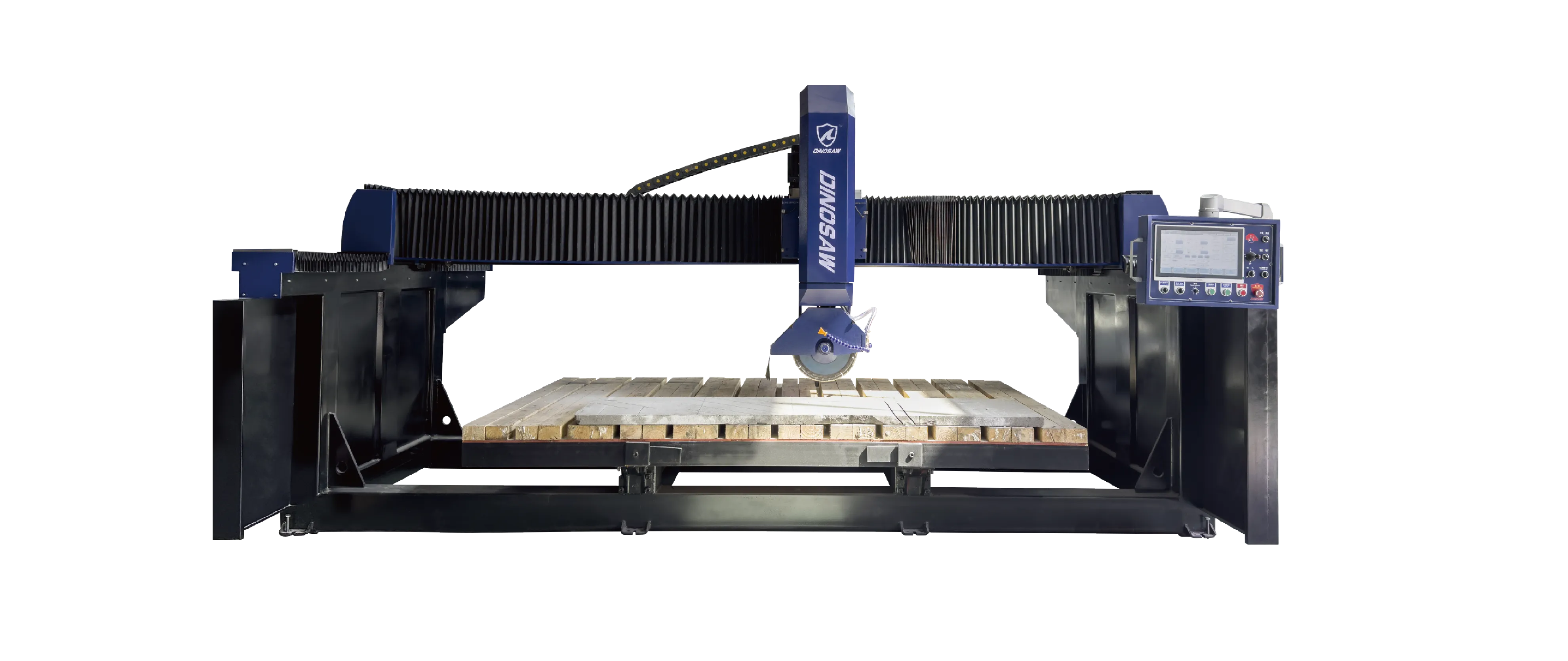

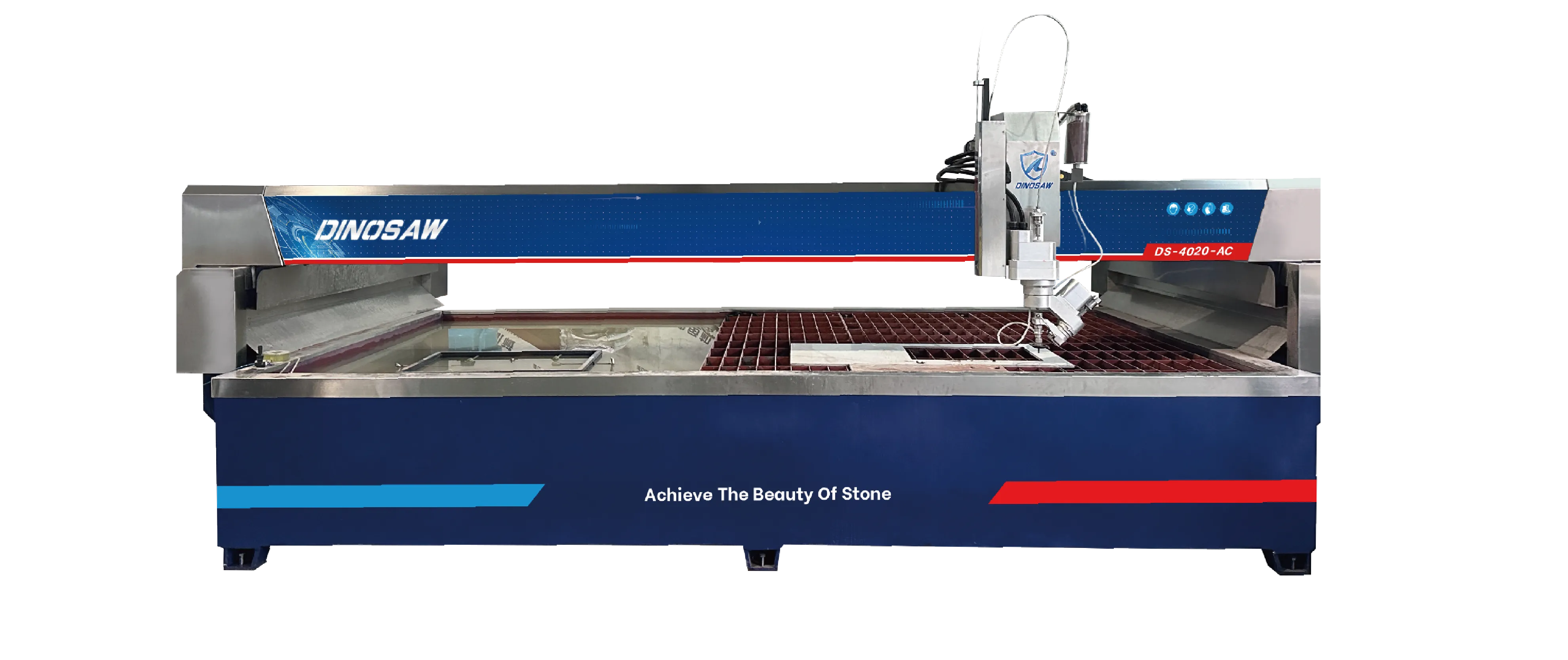

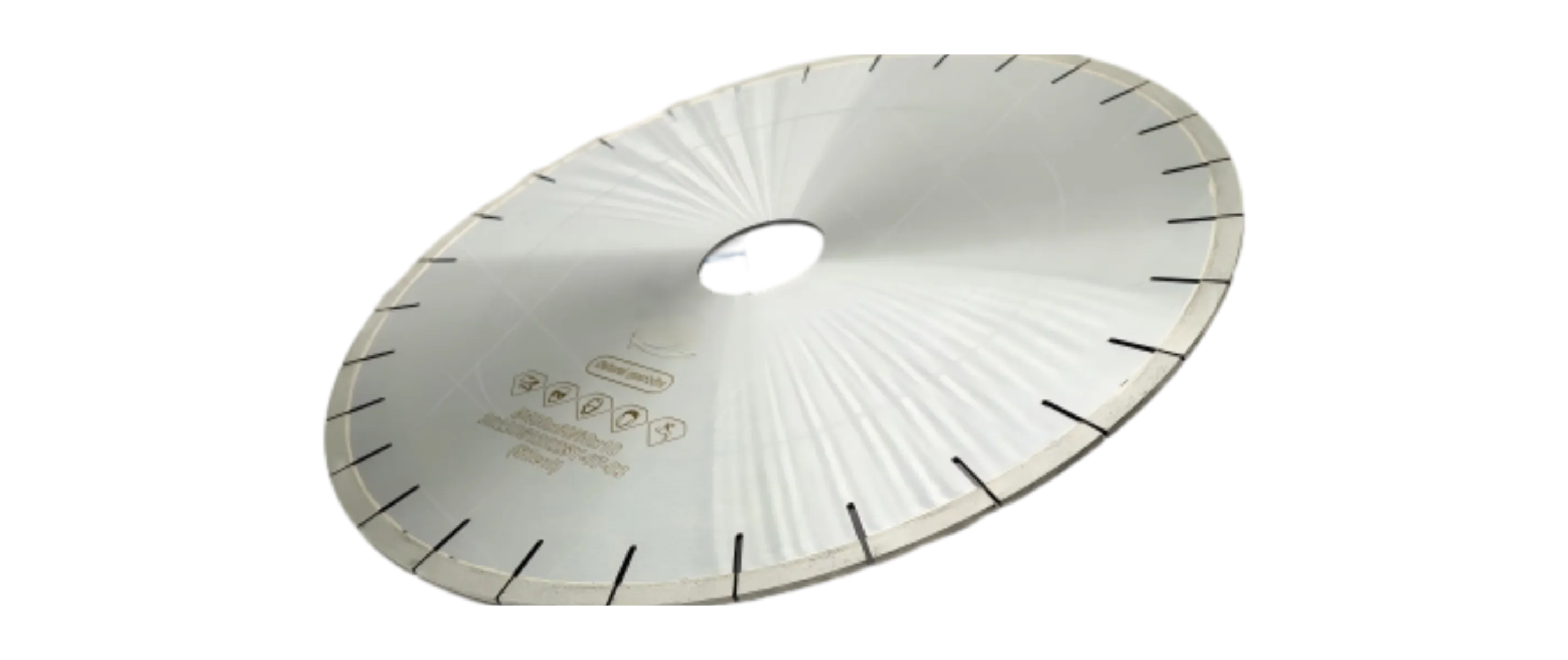

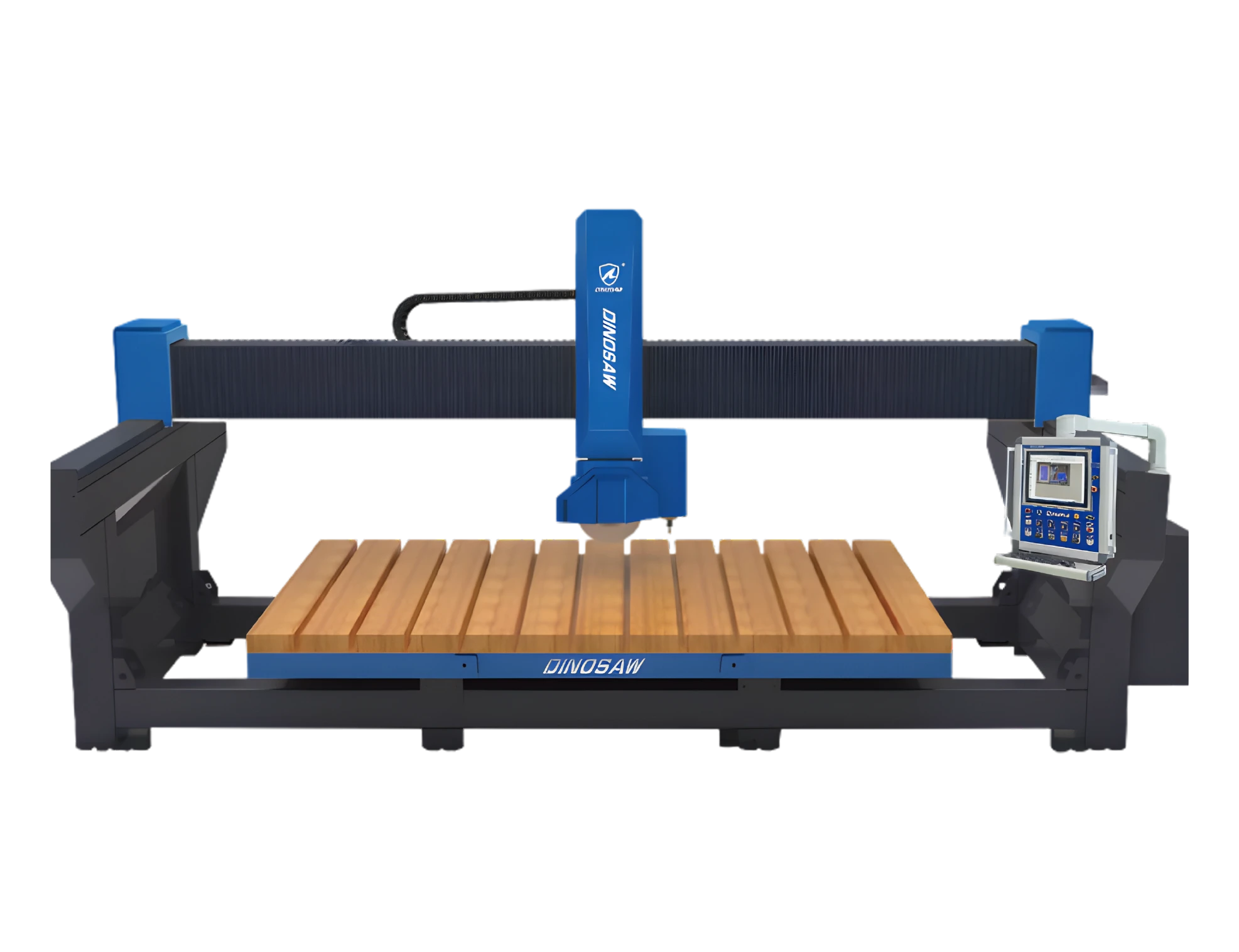

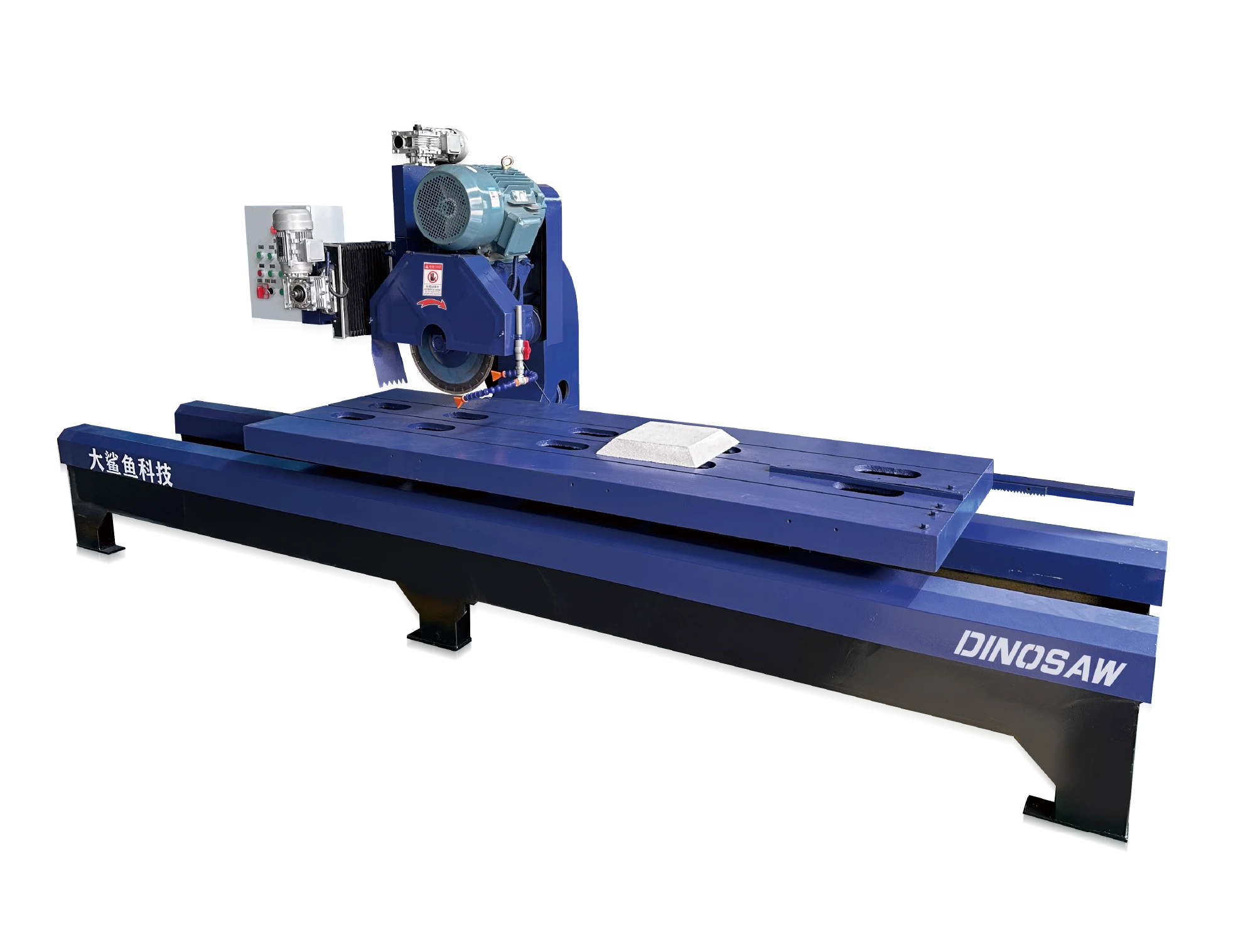

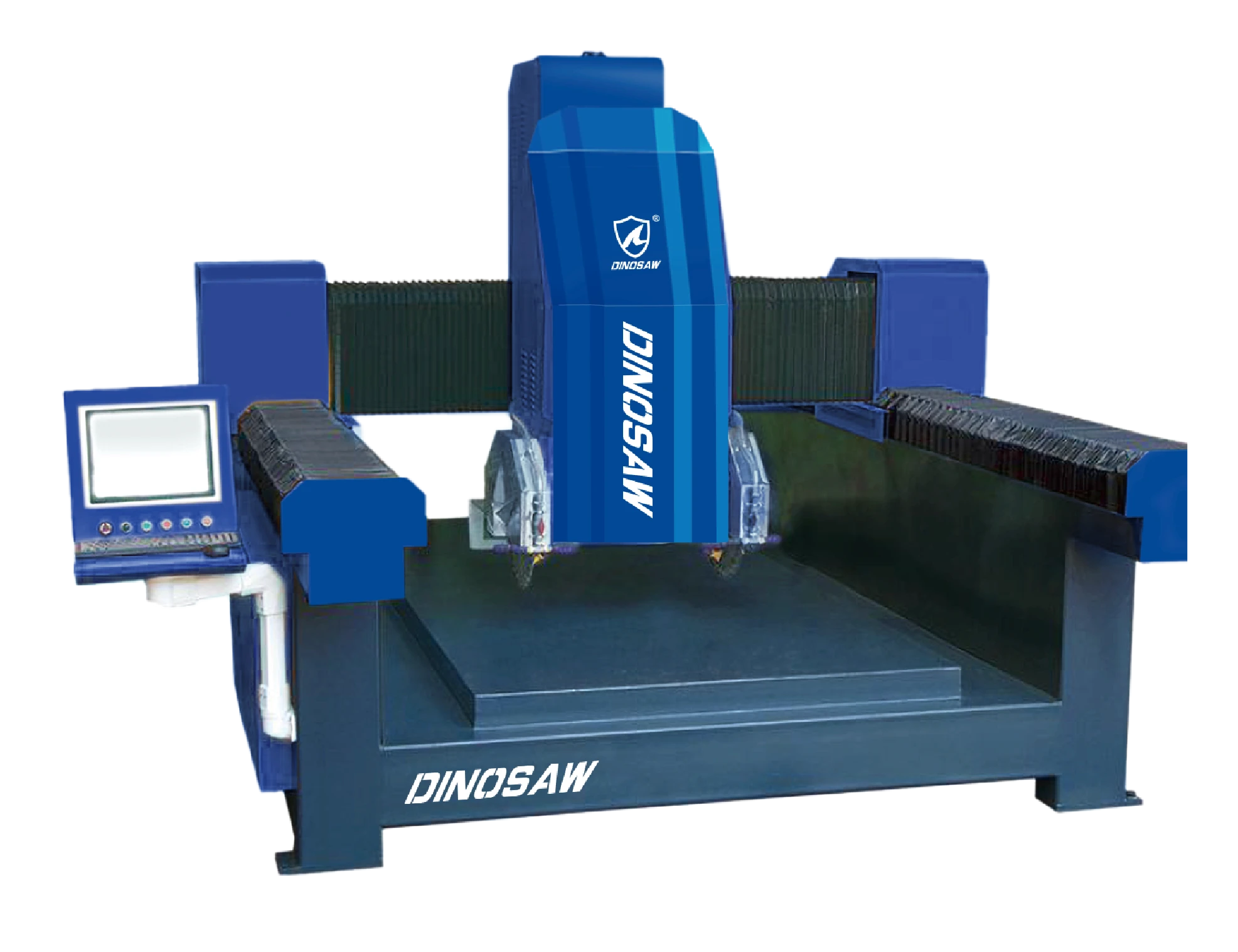

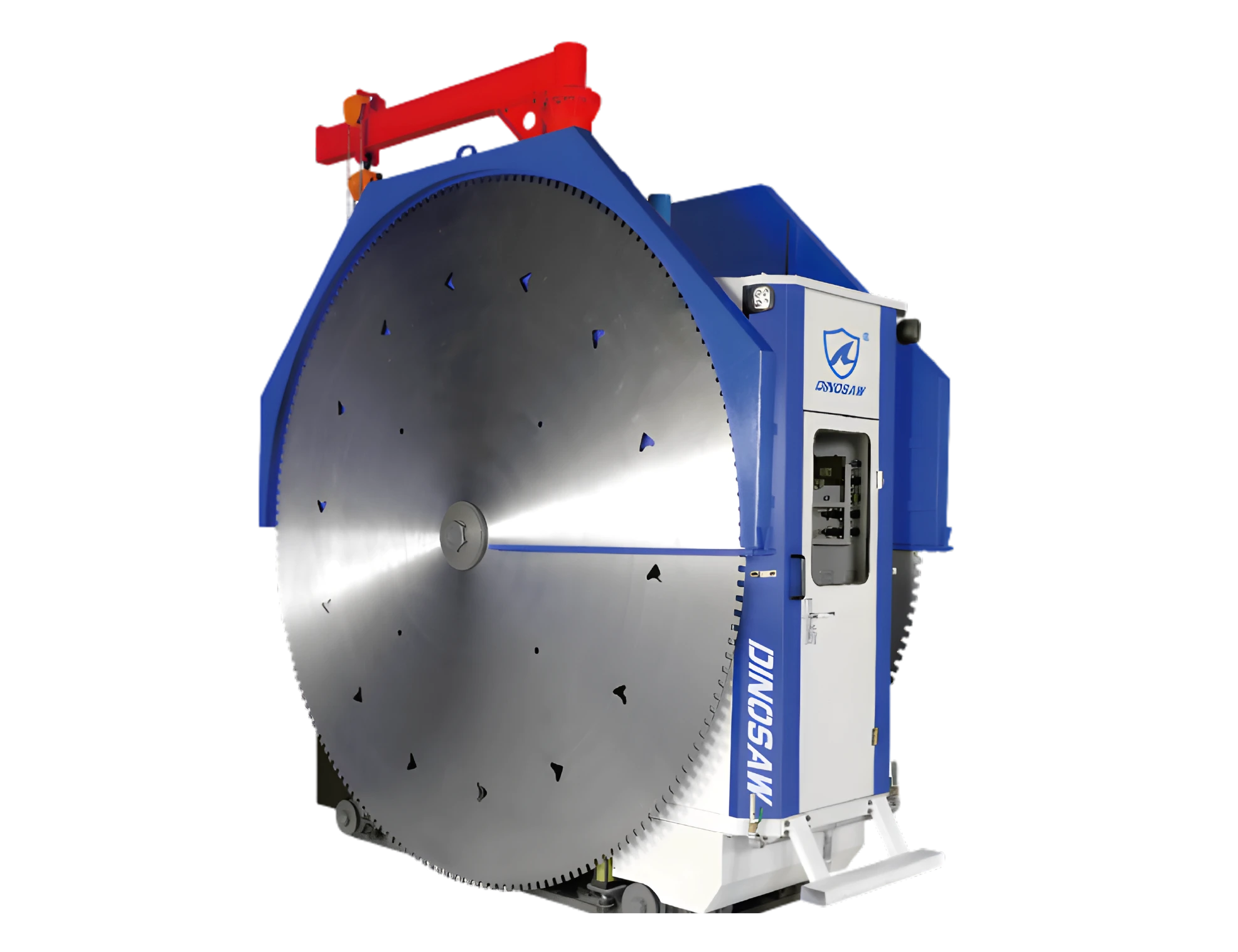

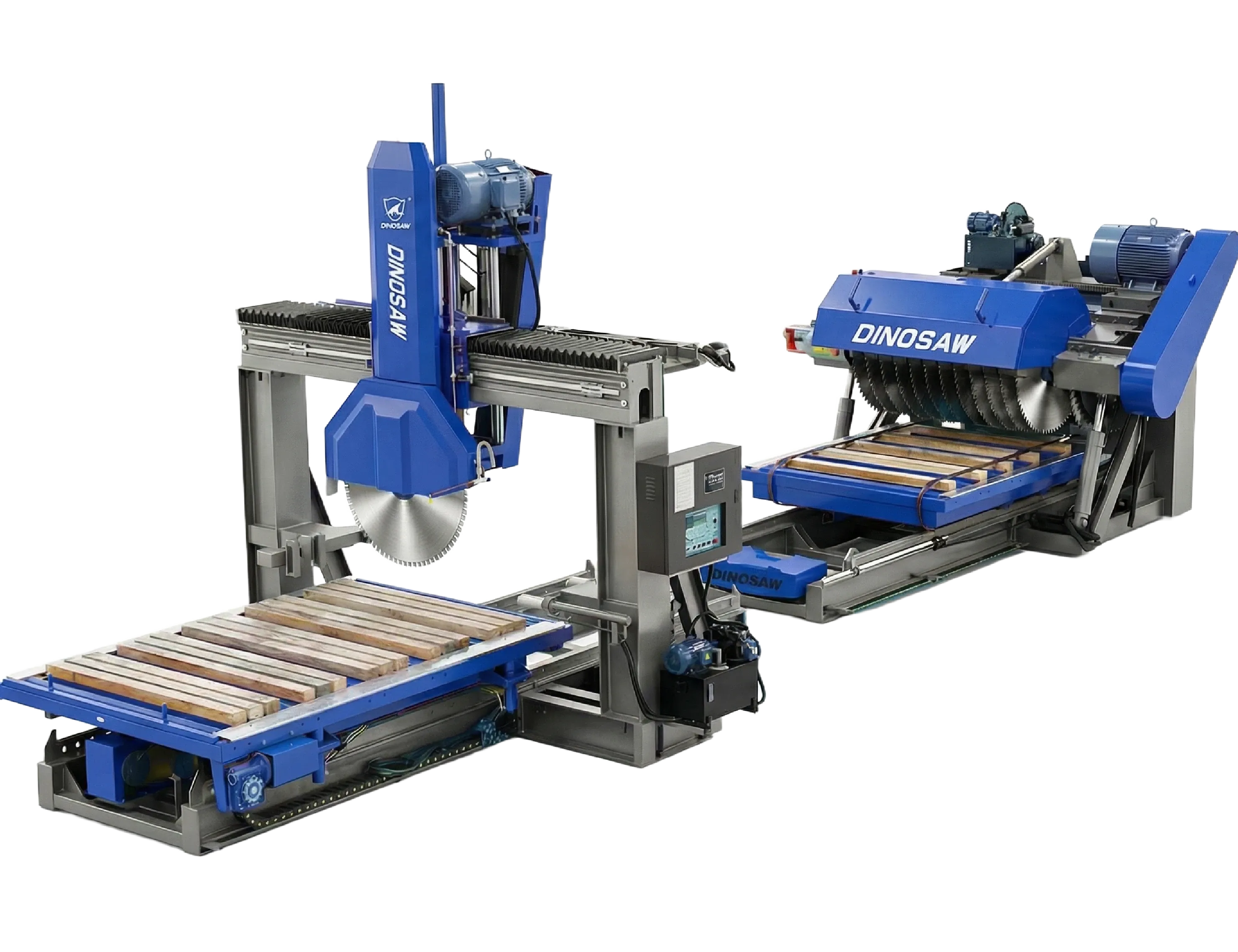

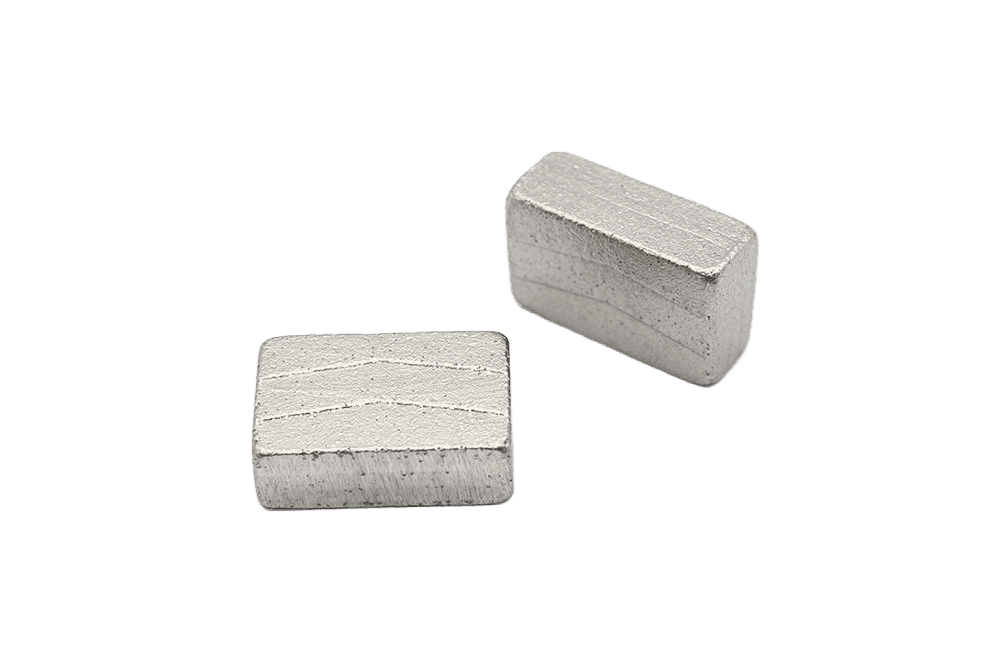

Circle Saw Machines

Includes bridge saws, block cutters, and manual cutting machines for diverse materials.

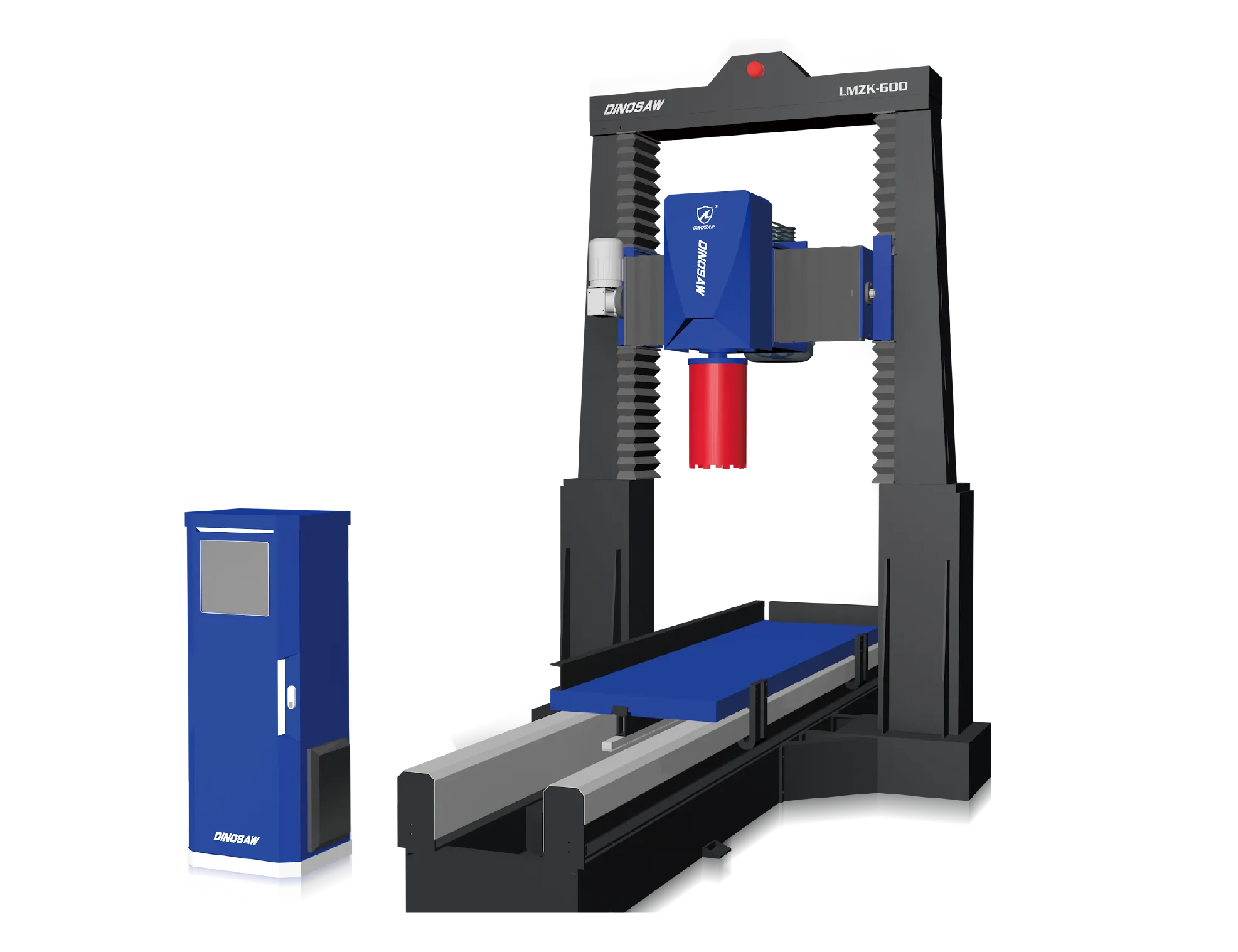

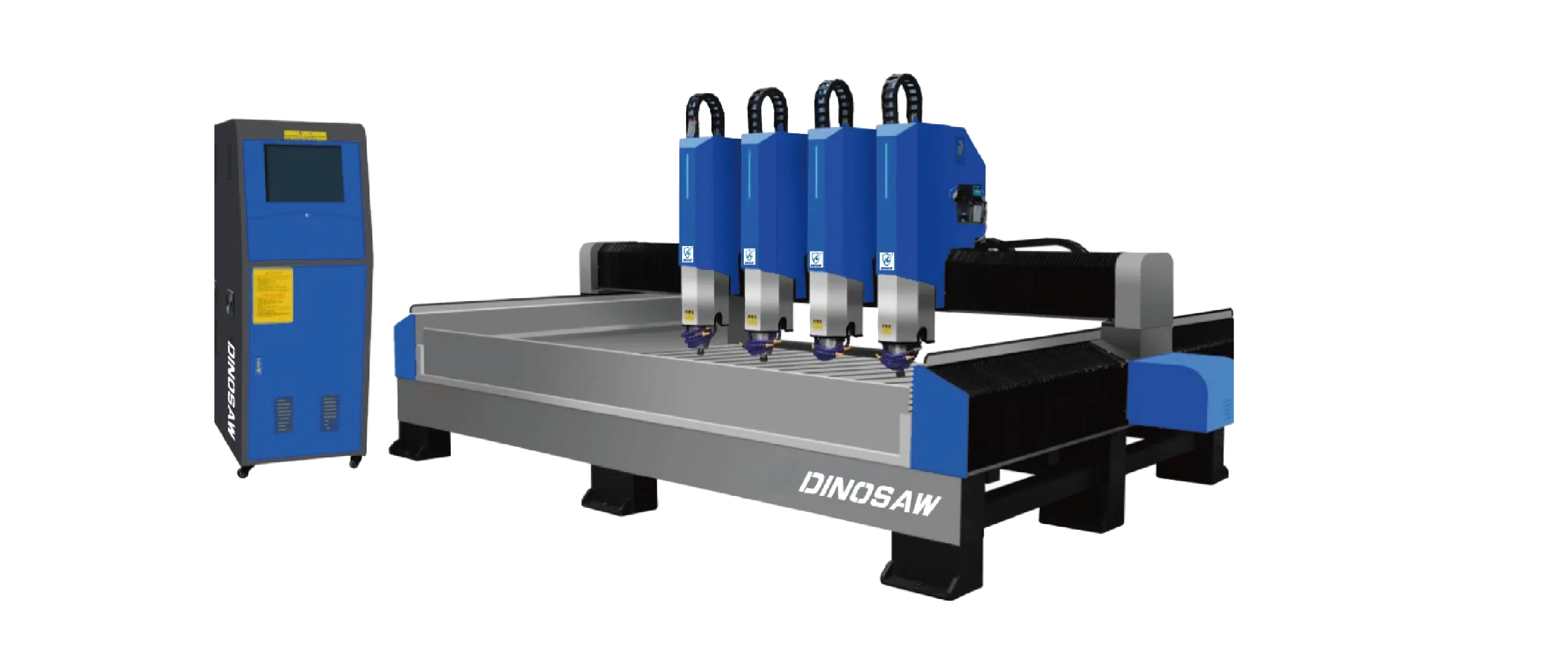

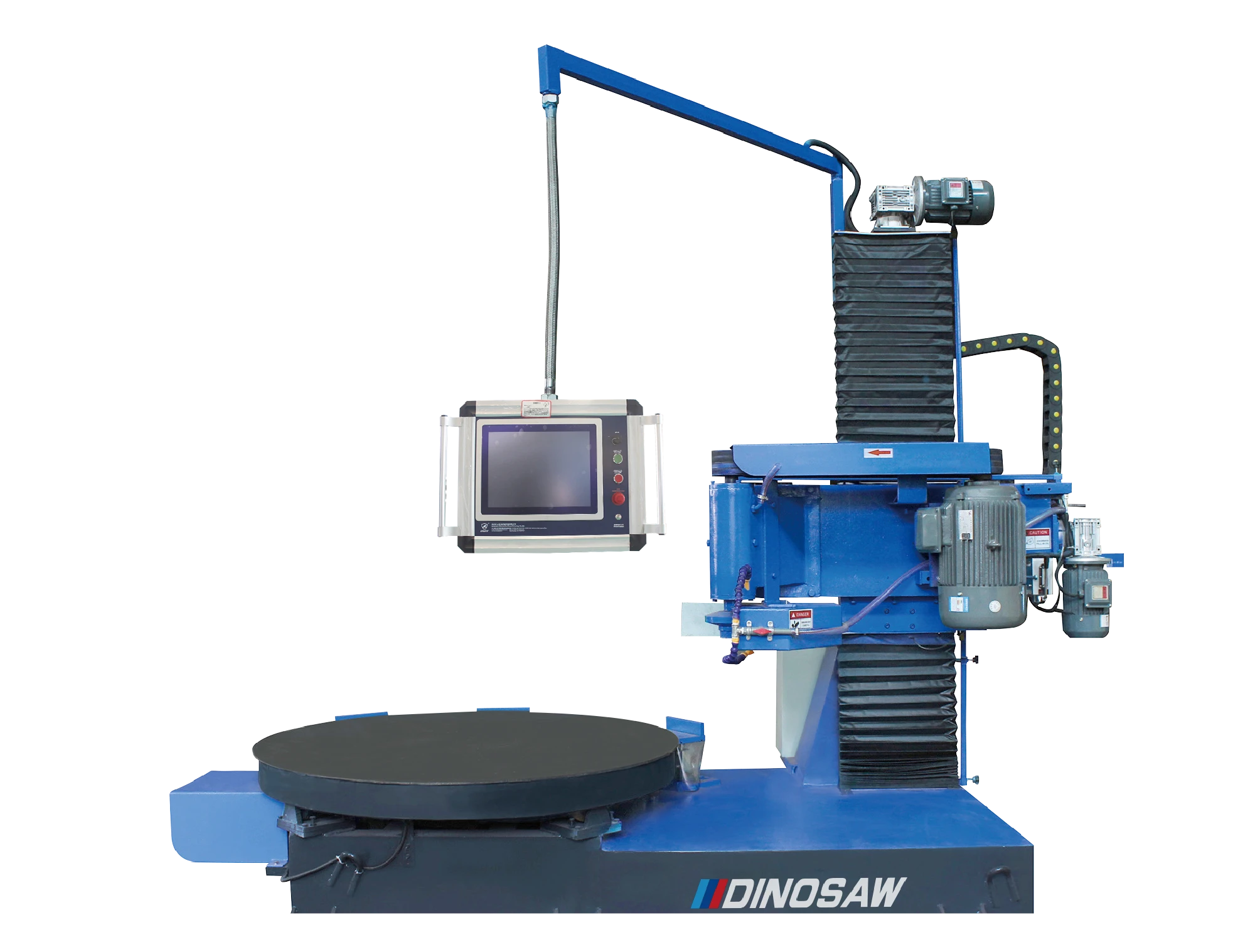

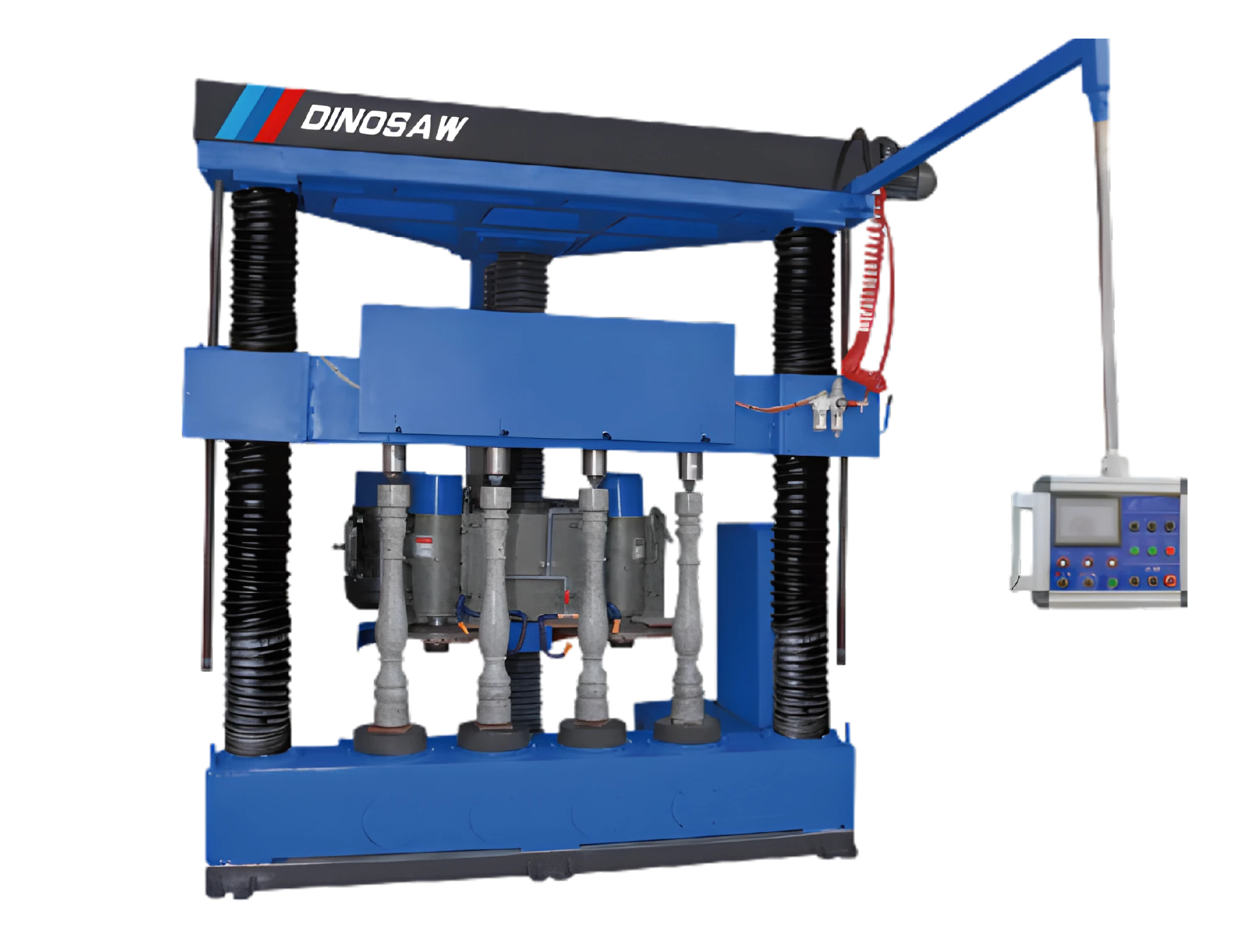

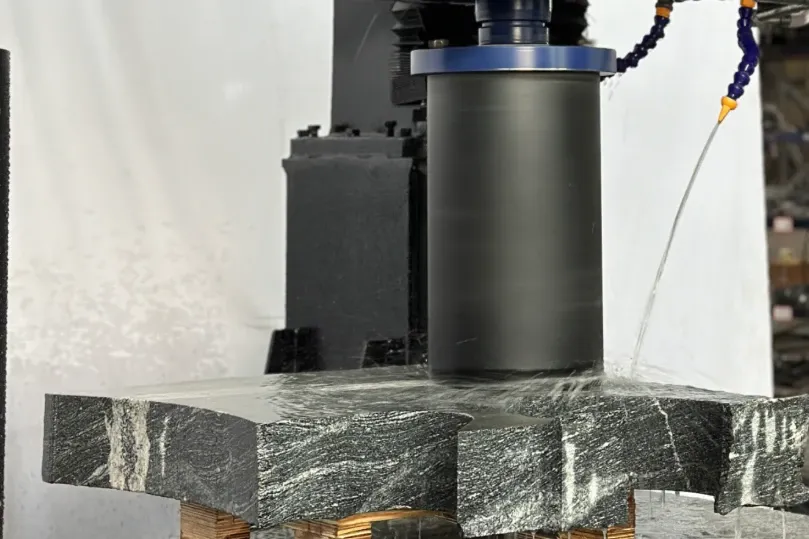

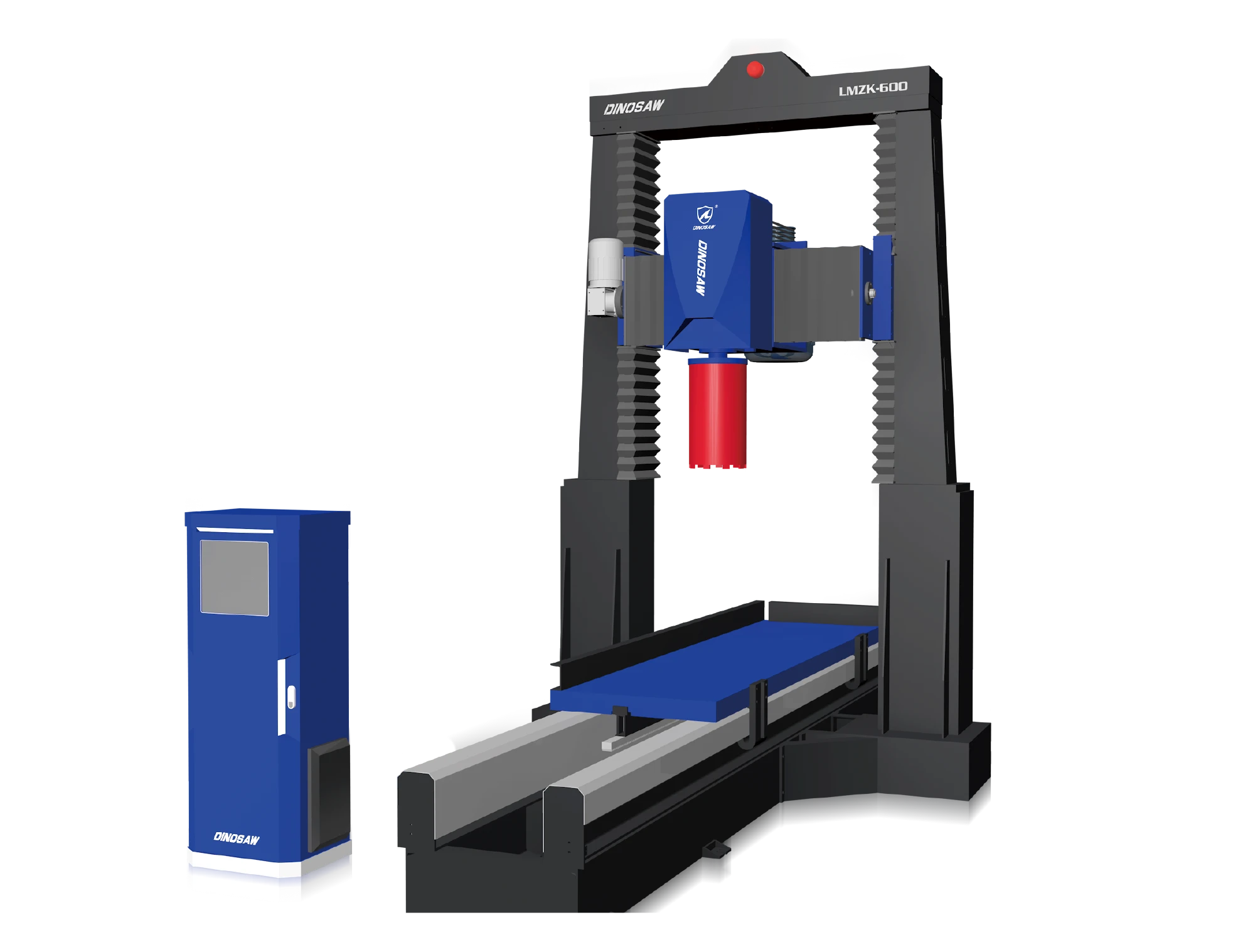

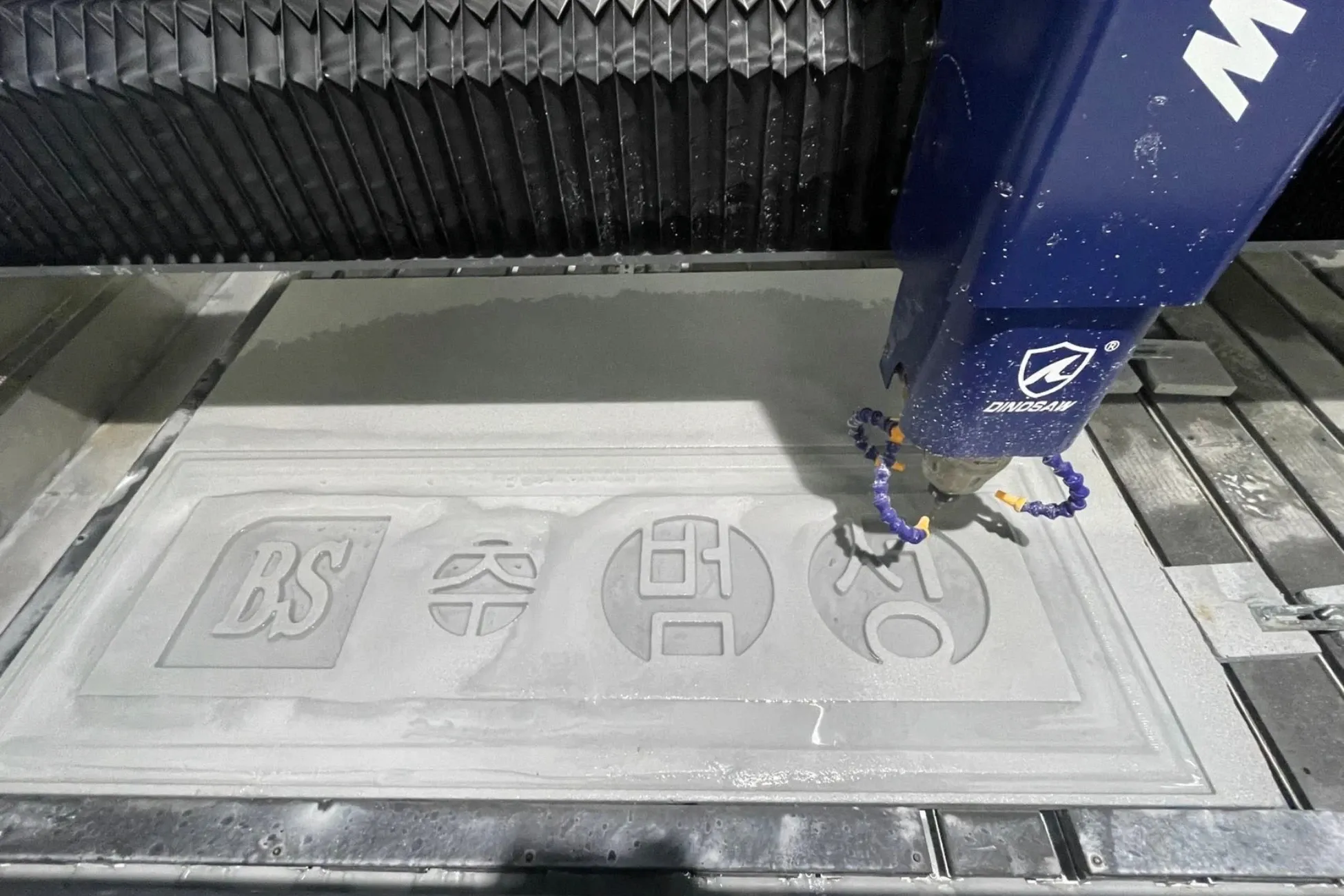

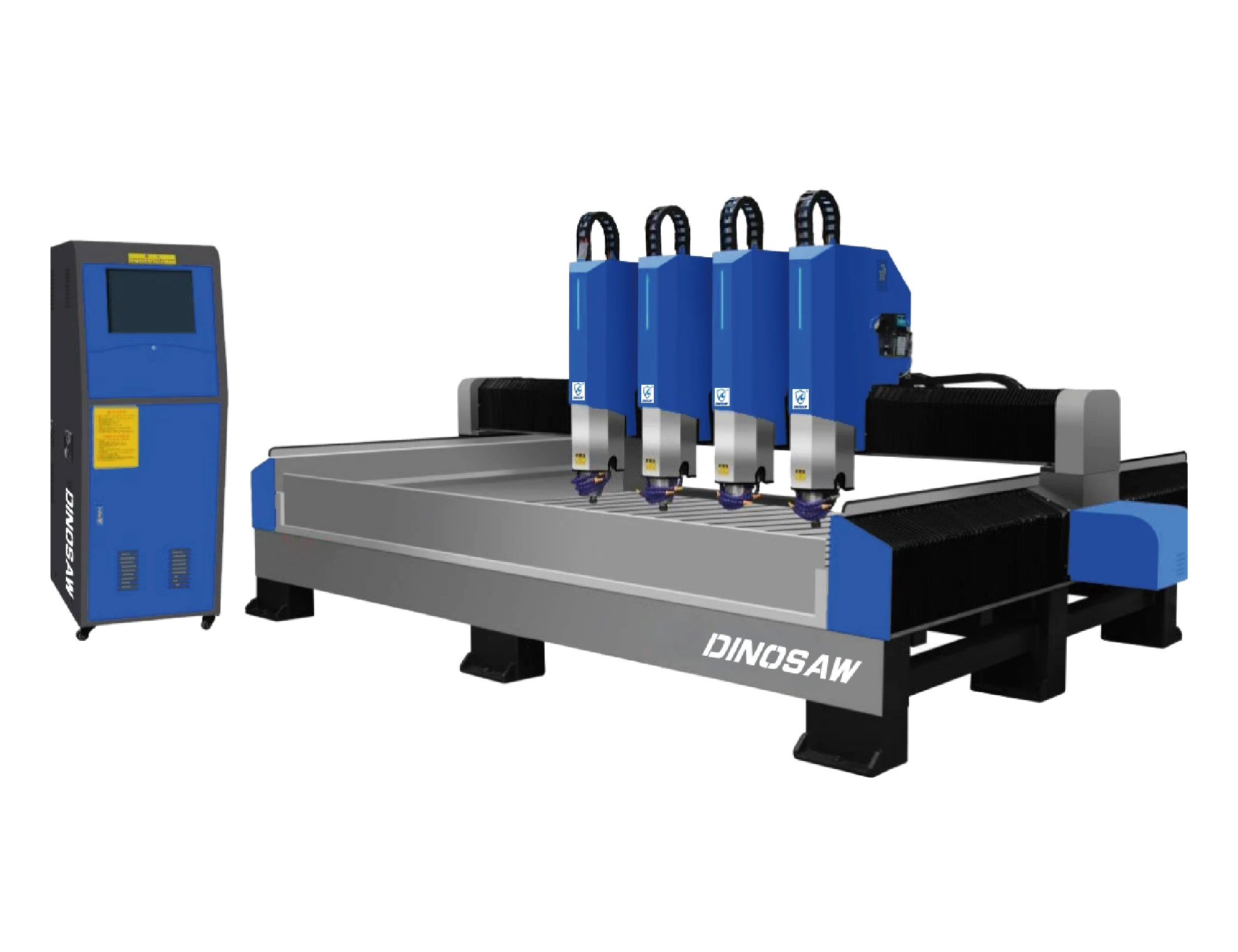

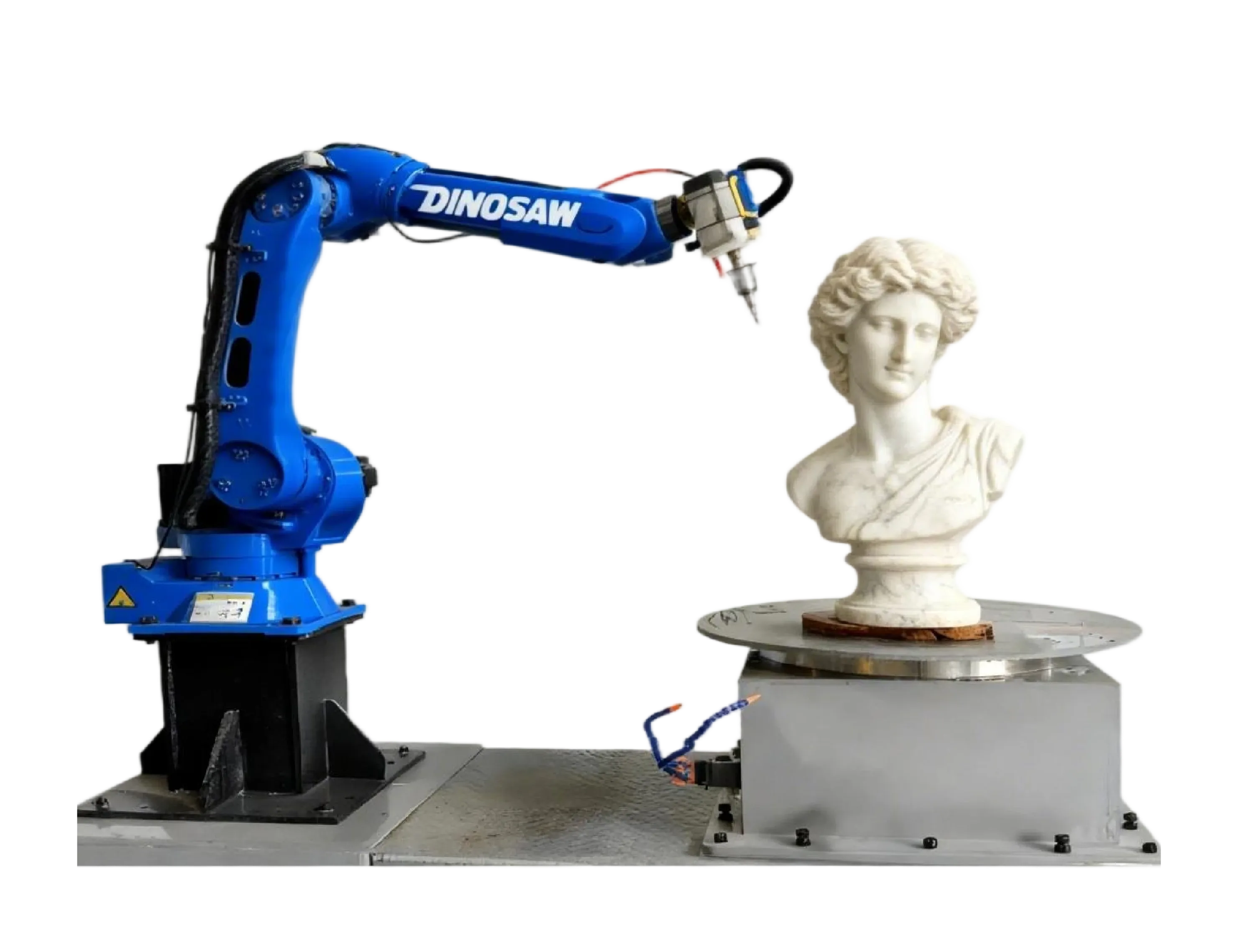

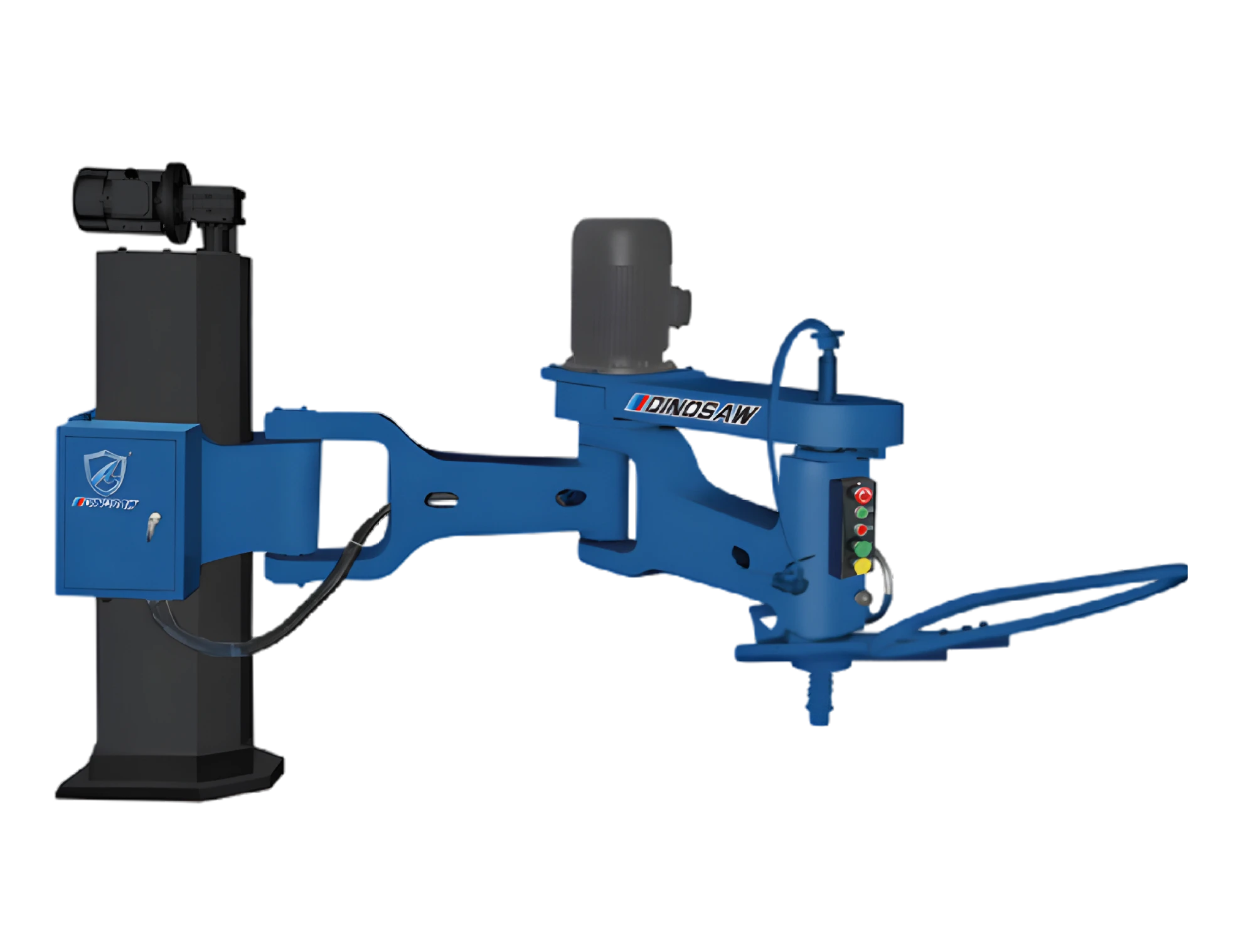

Drilling and Engraving Machines

Equipments and tools for creating holes or engravings on stone, metal, and glass.

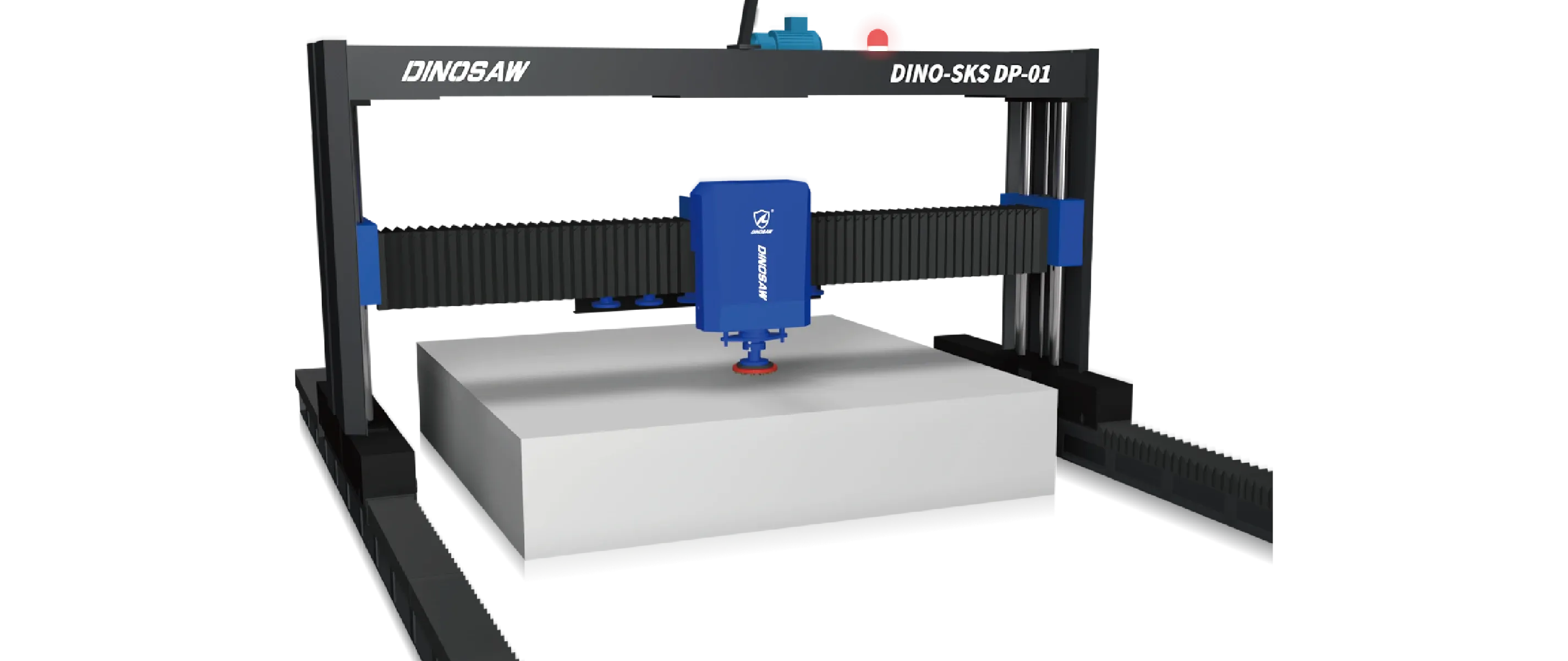

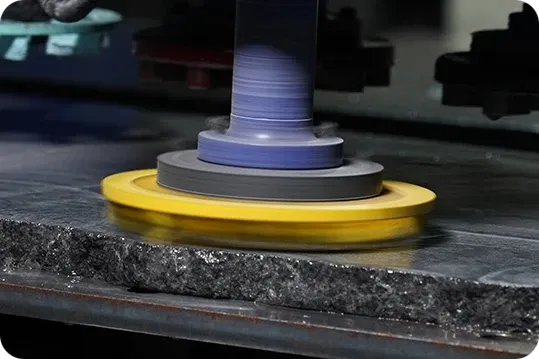

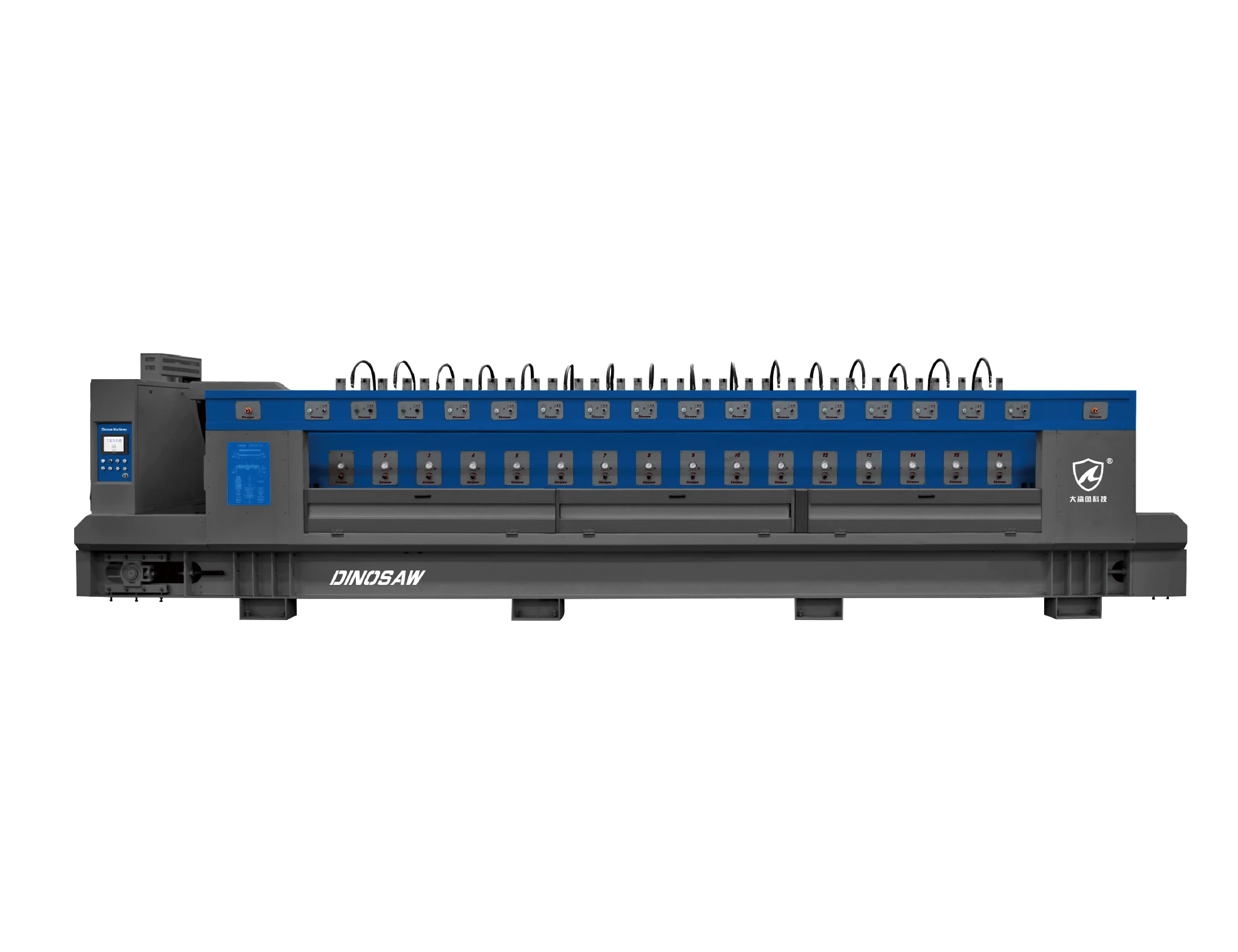

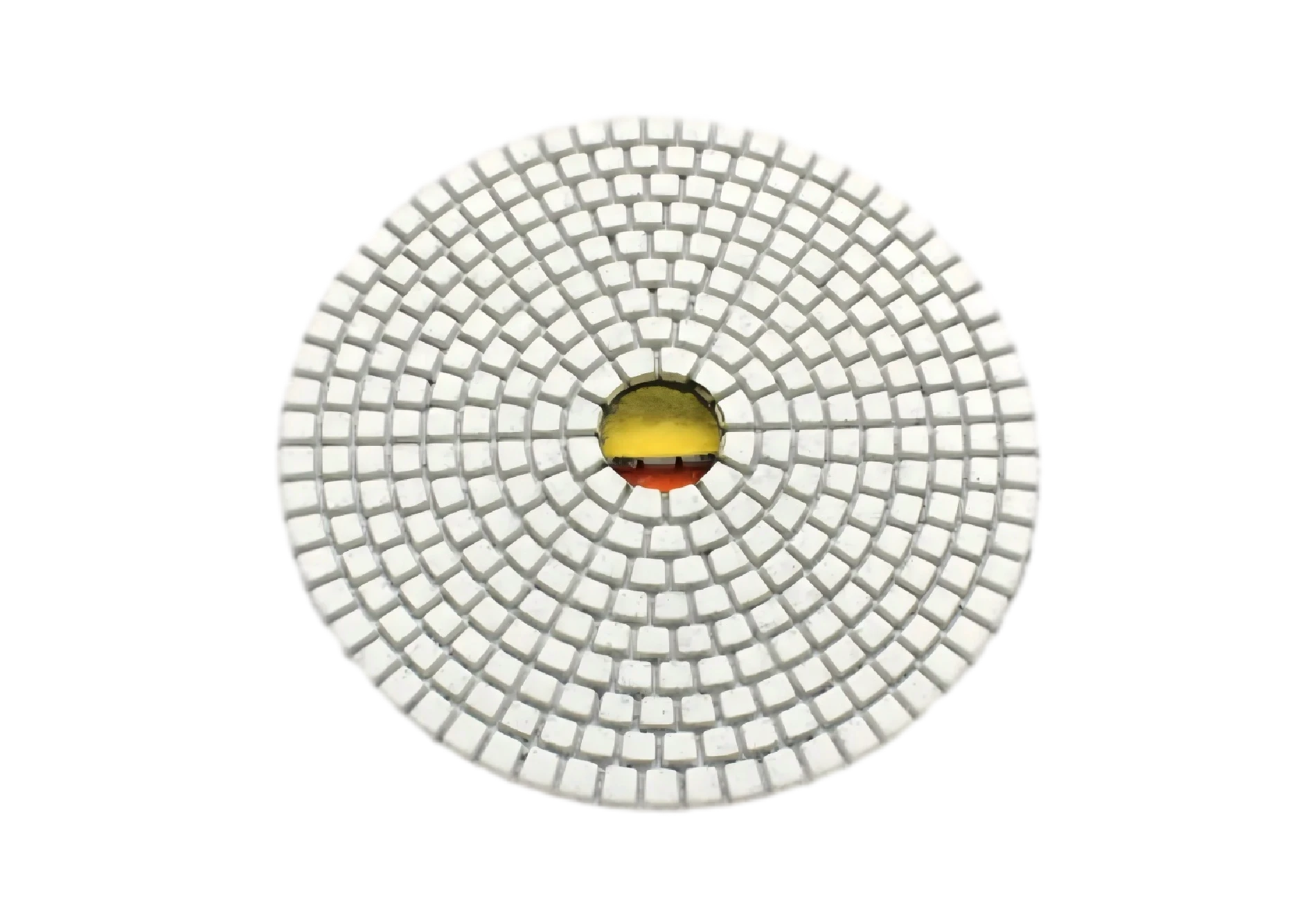

Grinding and Polishing Machines

Designed to enhance surface finishes with efficiency and precision.

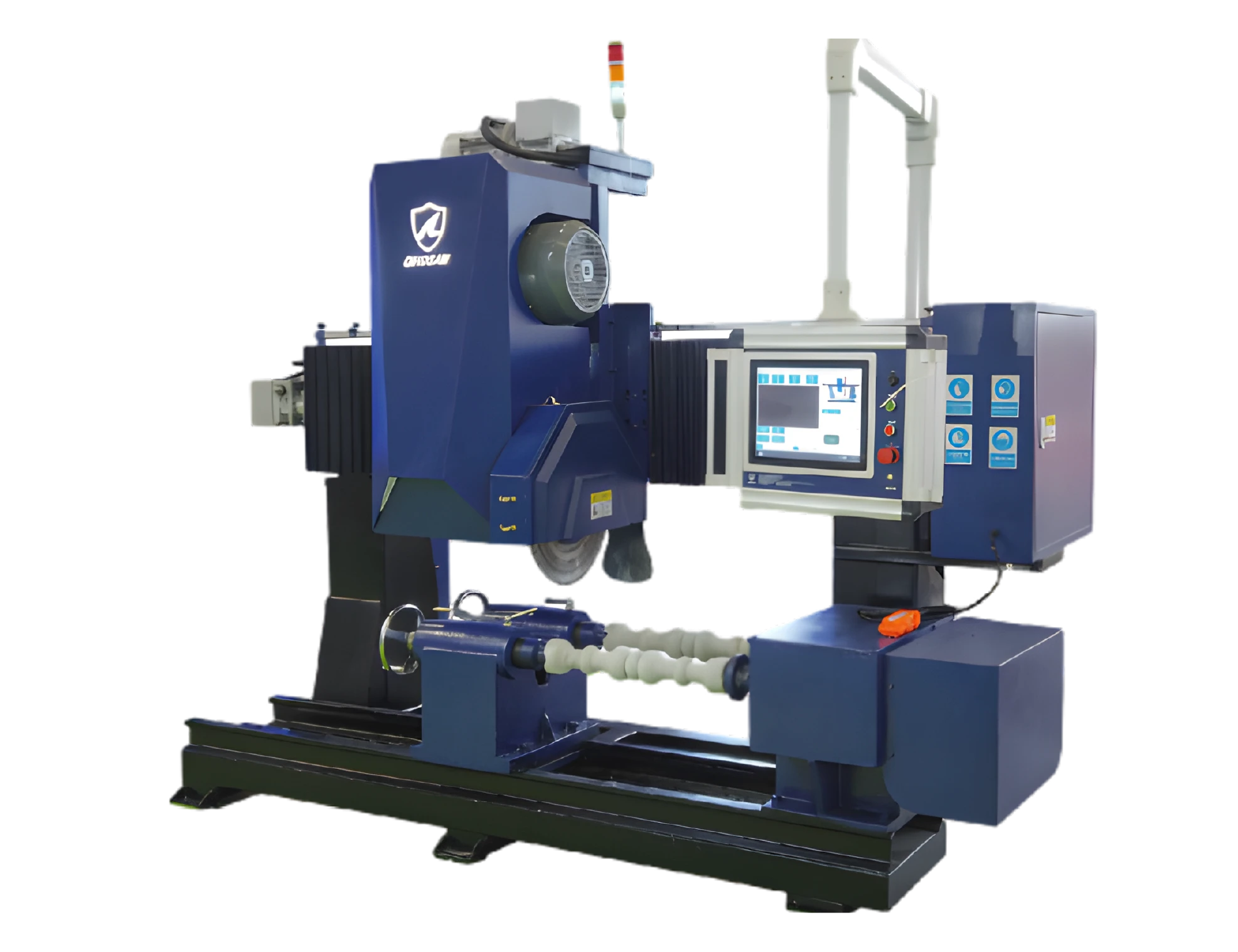

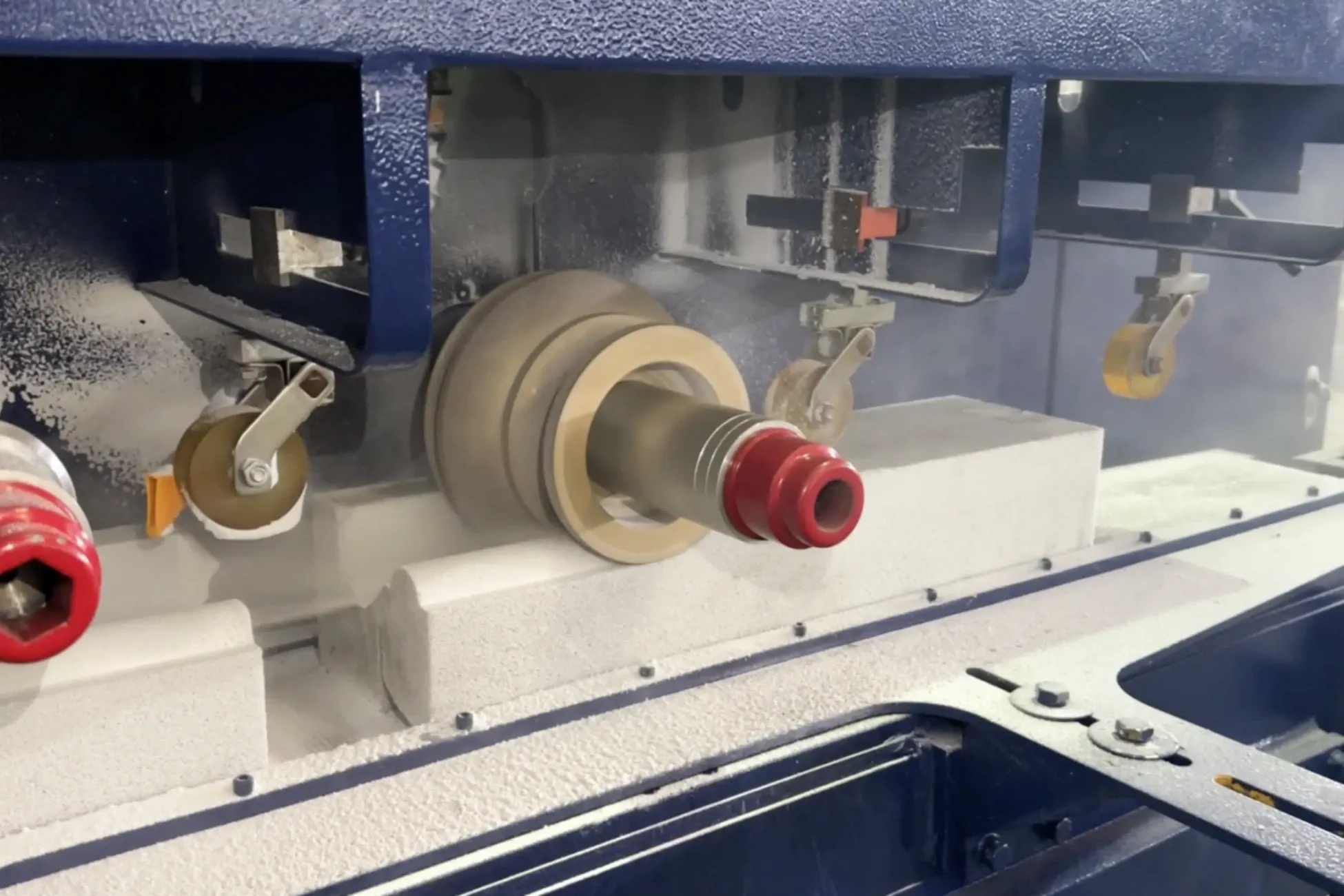

Profiling Machines

Used for shaping intricate architectural components and decorative elements.

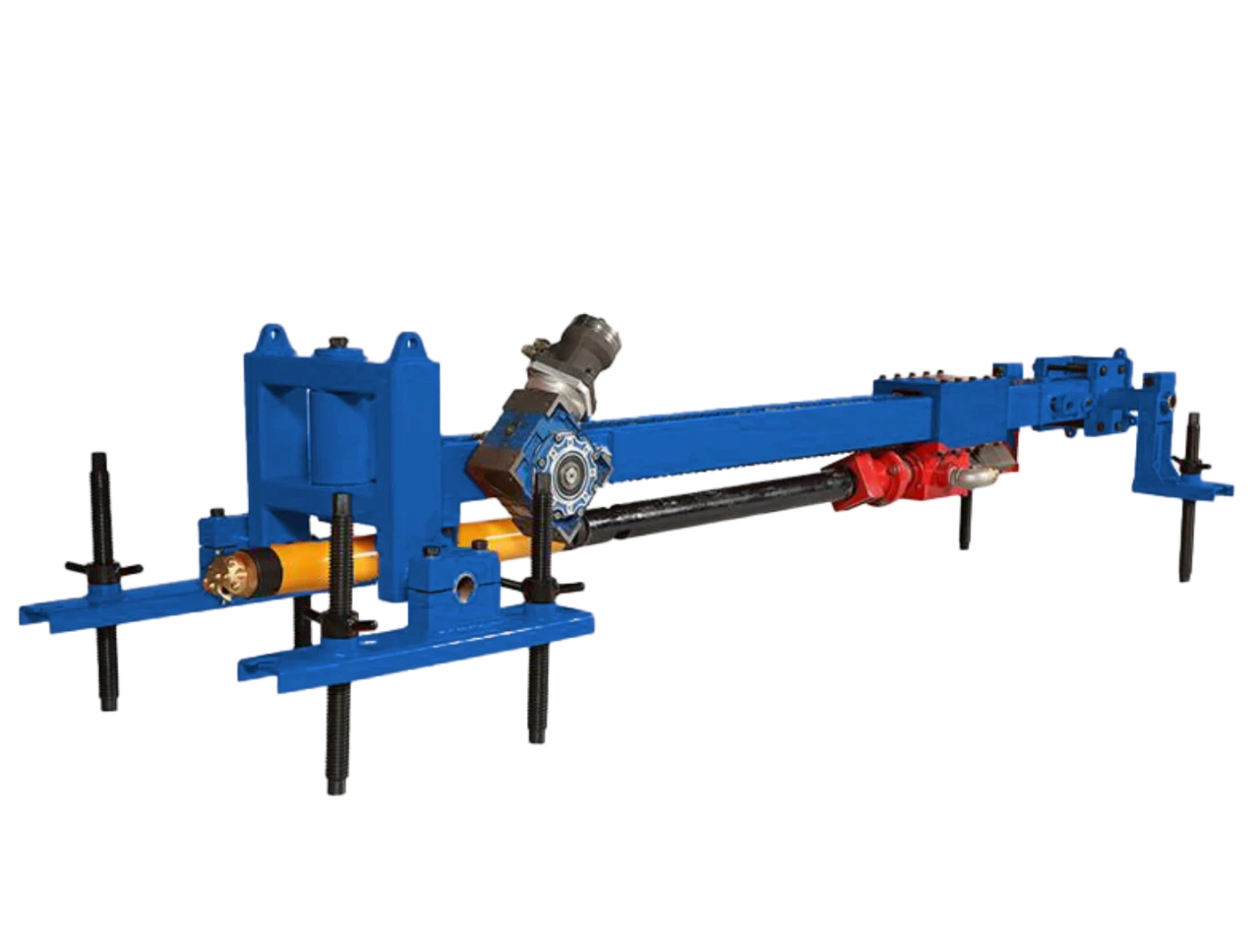

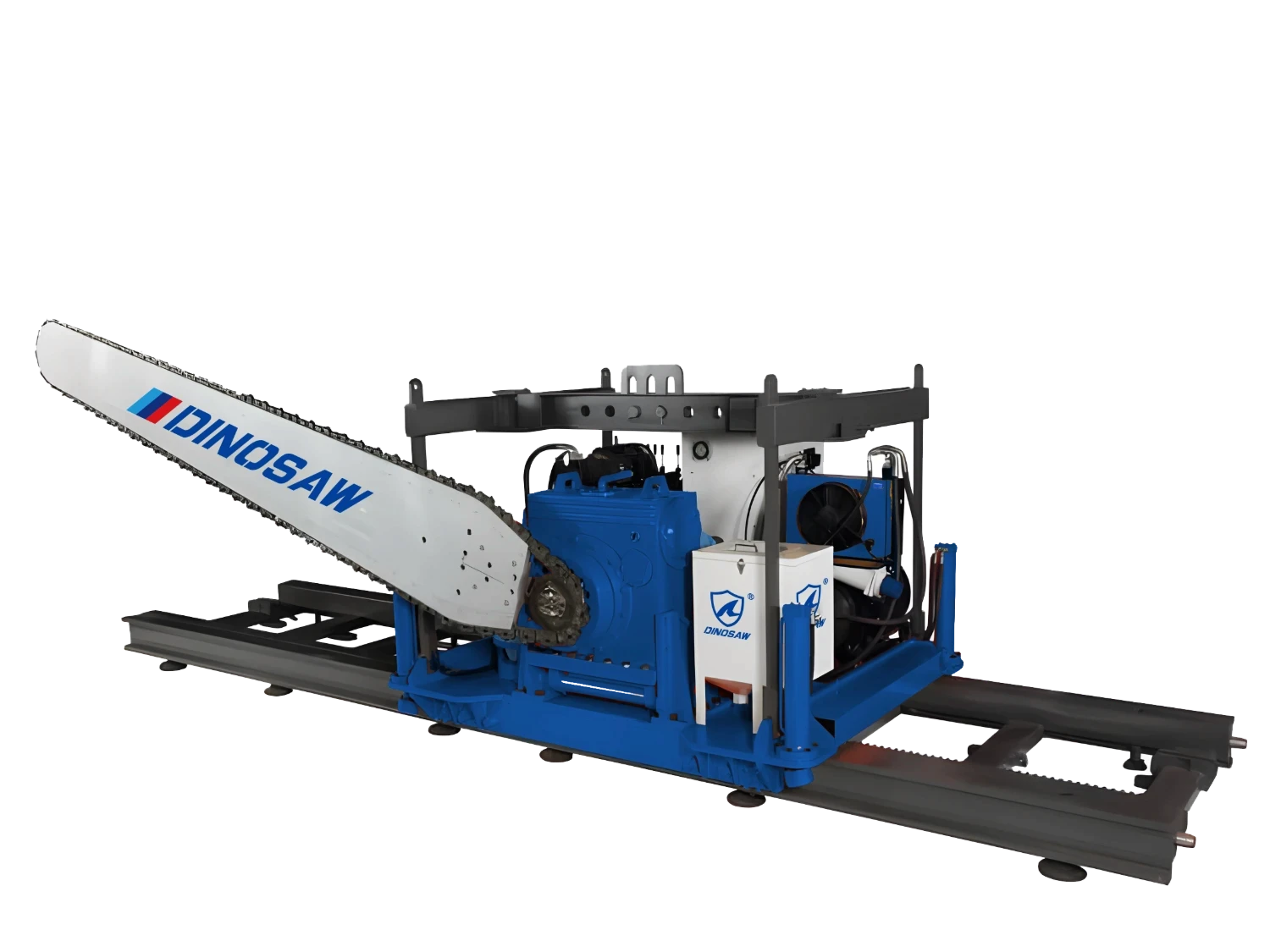

Mining and Quarry Machines

Includes diamond wire saws, double-blade cutters, and quarry chainsaw.

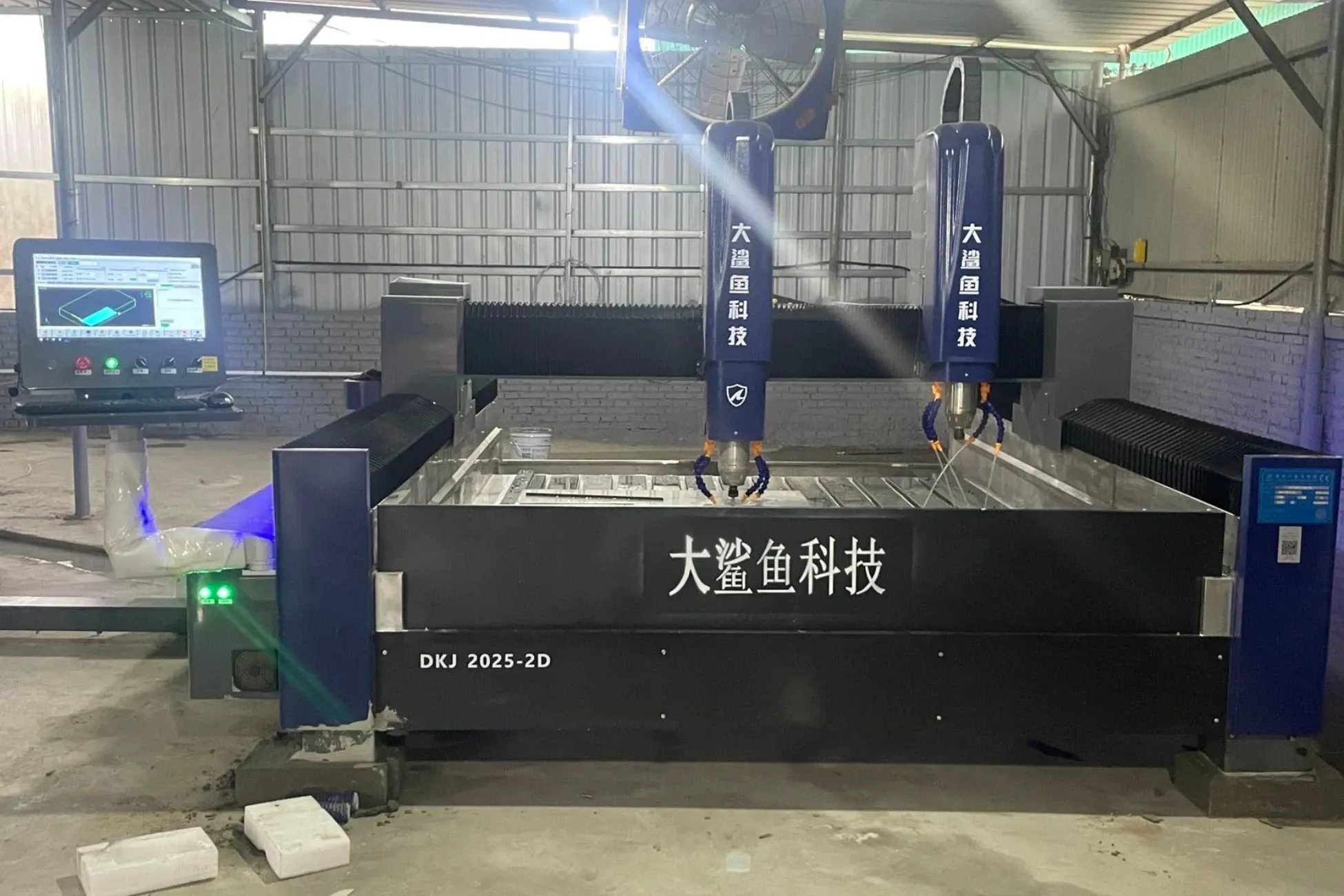

Other Industry Machines

Waterjet cutters, thicknessing machines, machining centers, and assembly line equipment.

Why Invest in an Industry Machine?

Investing in an industry machine can transform production processes and elevate business outcomes. Key advantages include:

Increased Productivity

Automates complex tasks, reducing manual intervention and expediting production cycles.

Enhanced Precision

Guarantees consistency in material processing with advanced technology.

Versatility

Adapts to a wide array of materials and applications.

Cost Efficiency

Saves labor costs and minimizes material wastage for long-term profitability.

Competitive Edge

Helps businesses meet market demands with cutting-edge capabilities.

Factors to Consider When Buying an Industry Machine

When selecting the ideal Industry Machine, consider these critical factors:

Material Compatibility

Match the machine with the materials you'll process (e.g., stone, metal, glass).

Functionality

Choose between CNC capabilities or manual operation based on production needs.

Size and Capacity

Ensure the machine's dimensions and workload align with factory space and production goals.

Automation Level

Evaluate the trade-off between fully automated and manual machines for efficiency or flexibility.

Customization Options

Look for equipment that can be adapted to specific operational requirements.

Budget

Balance upfront costs with potential ROI.

Brand Reputation

Opt for reputable brands known for quality and reliability.

After-Sales Support

Check for services like installation, maintenance, and training.

Market Feedback

Investigate customer reviews and case studies to assess real-world performance.

Steps to Buying Your First Industry Machine

Follow this step-by-step guide for a seamless buying experience:

Identify Needs

Analyze the materials and tasks required for your operation.

Research Suppliers

Compare brands, focusing on features, reliability, and customer feedback.

Request a Consultation

Engage with suppliers to clarify technical details and get tailored recommendations.

Schedule a Demonstration

Verify machine performance through on-site or video demonstrations.

Plan Your Budget

Select the most cost-effective solution that fits your financial plan.

Finalize the Contract

Confirm specifications, warranties, and delivery timelines before signing.

Install and Train

Arrange professional installation and ensure your team receives adequate training.

Monitor and Feedback

Start operations and communicate regularly with suppliers for continued support.

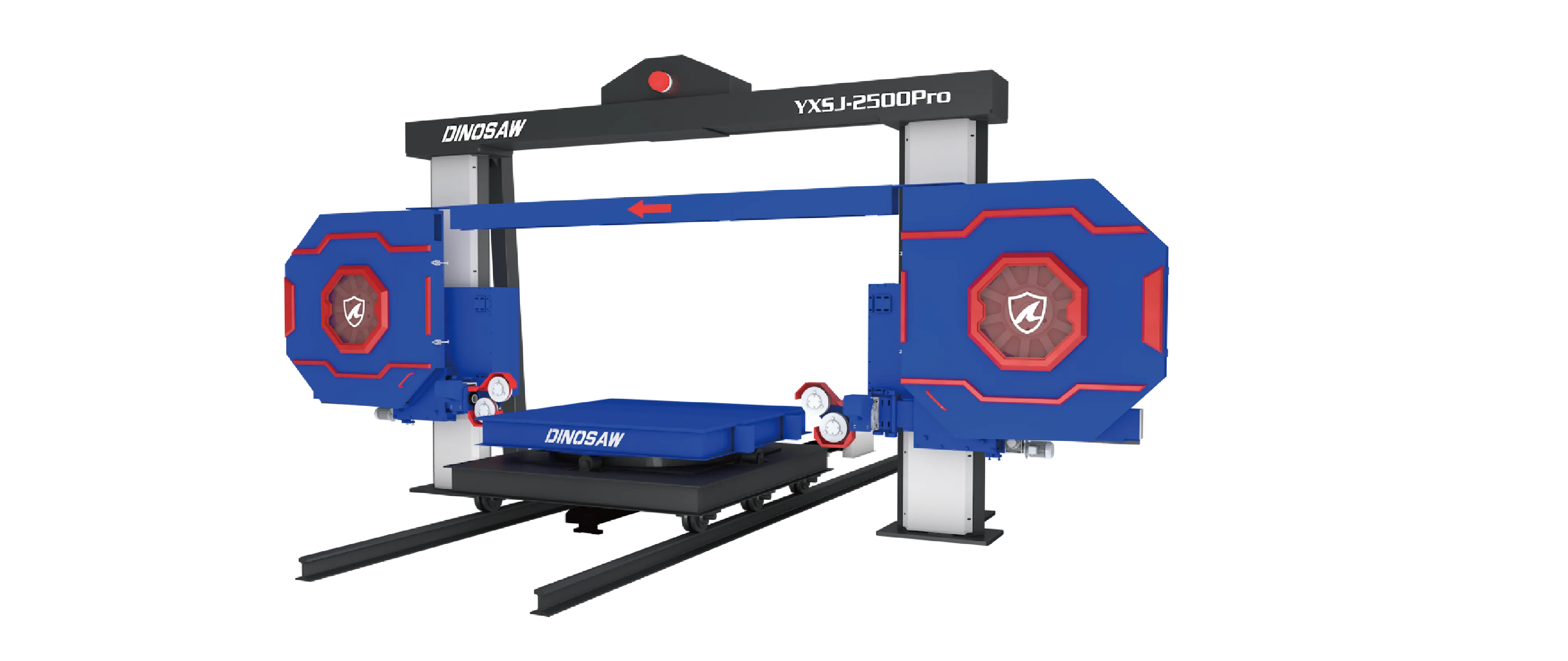

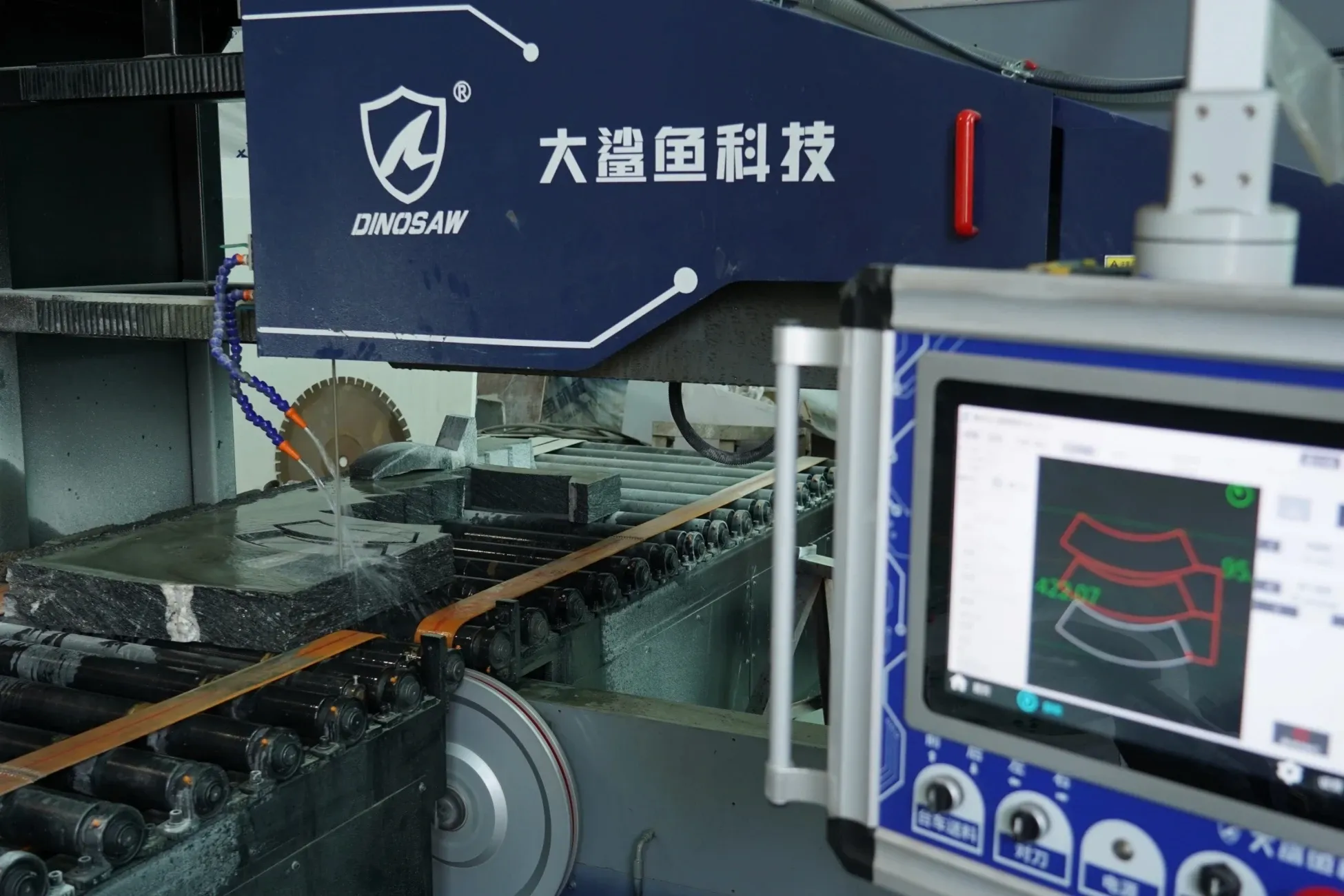

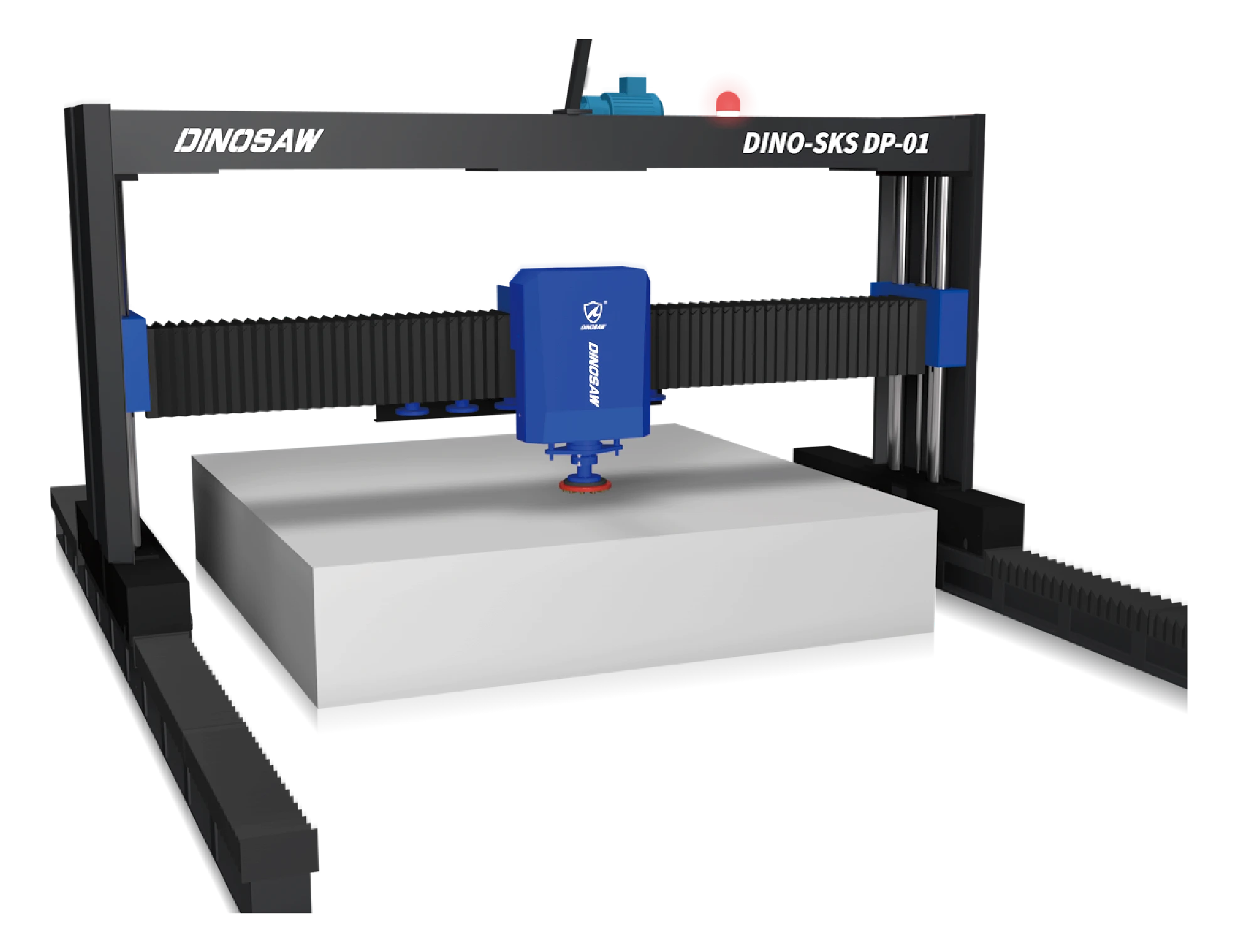

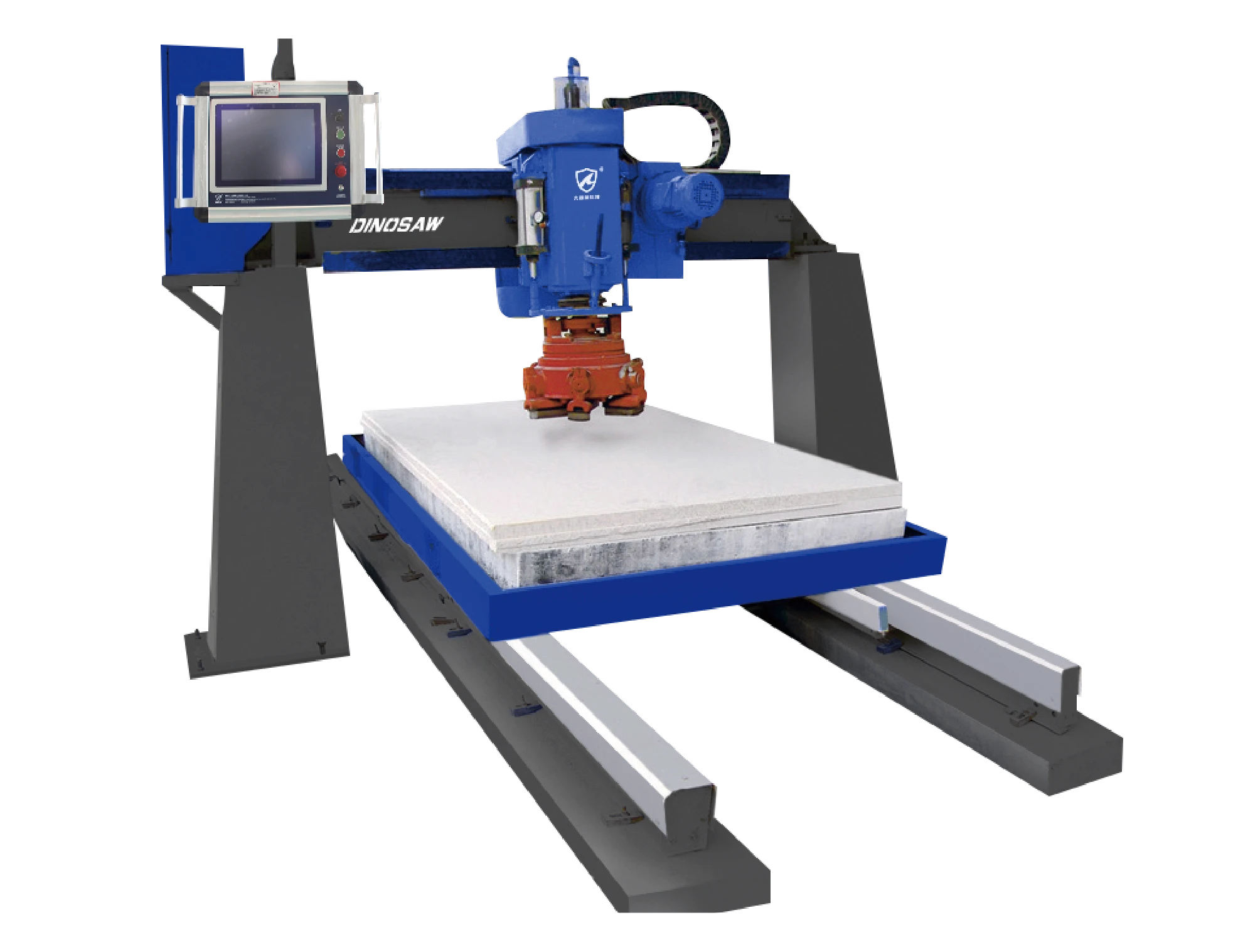

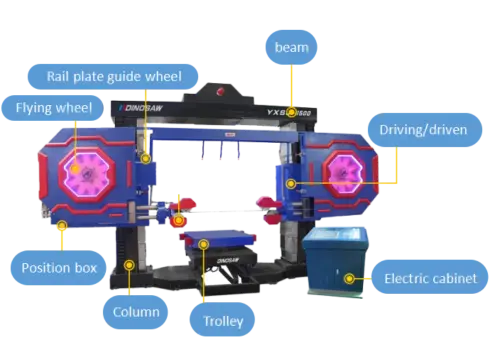

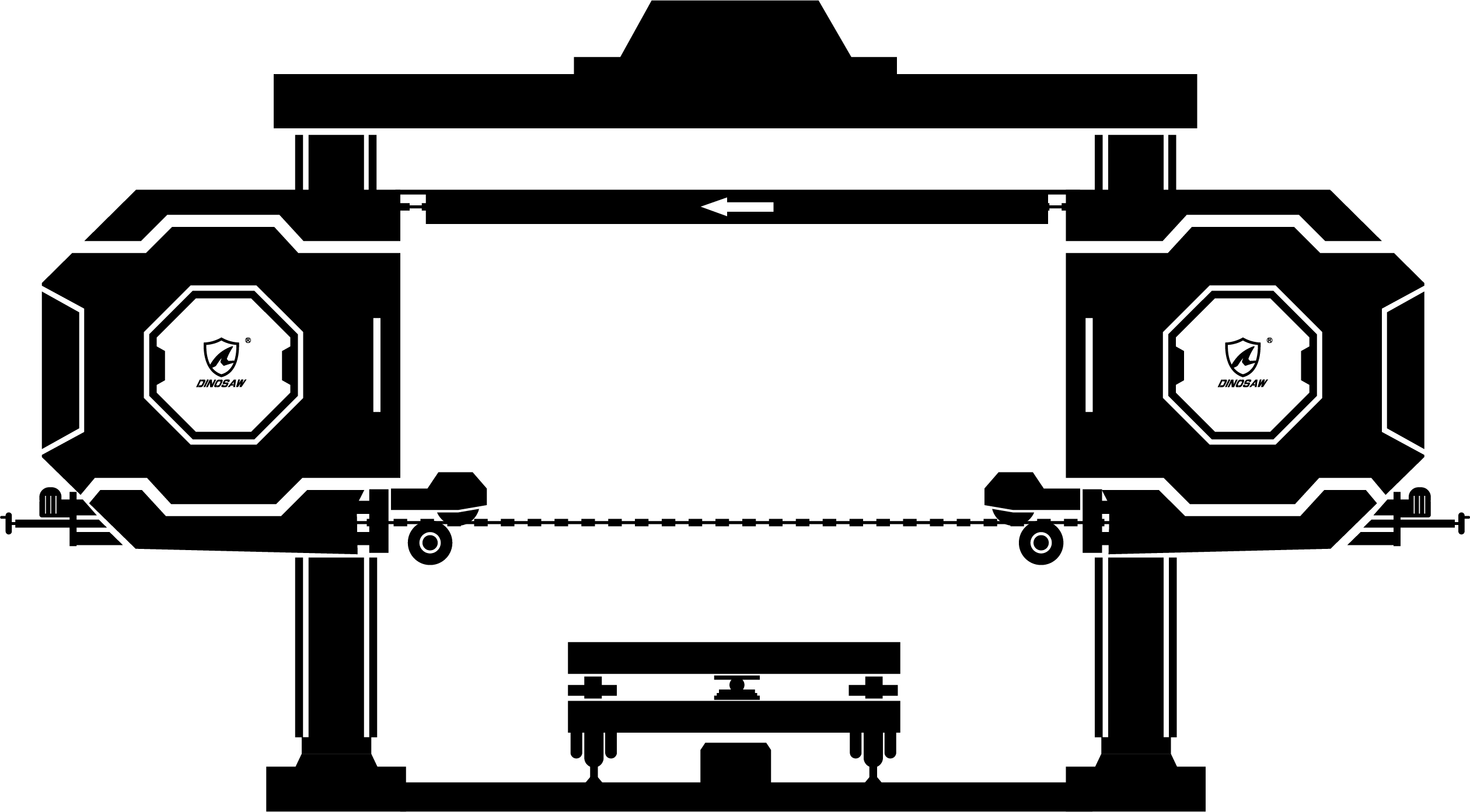

Why Choose Dinosaw?

Dinosaw is a trusted leader in industry machinery, offering high-performance wire saw cutting equipment. Here’s why Dinosaw stands out:

Intelligent Operating System

Simplifies operations with features like automatic diagram import, one-click drawing, and tool compensation.

Modular Customization

Flexible designs accommodate a wide range of application needs.

Rapid Iteration

Continuous innovation driven by customer feedback ensures adaptability to market trends.

Certifications

ISO, CE, and CCC certifications guarantee quality and safety.

Comprehensive Support

Offers global installation, maintenance, and spare part supplies.

With Dinosaw’s expertise, businesses achieve enhanced productivity and reduced costs, ensuring long-term success.

Conclusion

Purchasing an Industry Machine is a significant investment that requires careful consideration of your business needs, market research, and collaboration with a reputable supplier. By following this guide, you can confidently select a machine tailored to your requirements. Trust Dinosaw for state-of-the-art solutions that empower your business to thrive in today’s competitive landscape.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский