Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

Diamond Saw Blade for Granite

250mm-3000mm

Compatible Materials & Products

Precision Cutting for Natural Stone Slabs and Countertops

Granite Slabs > Countertop Fabrication

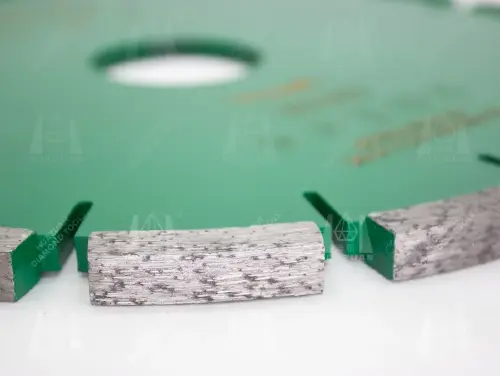

Fabricating granite countertops demands precision to avoid material waste. The challenge is achieving chip-free edges on this hard material, a key requirement for high-end projects. Our diamond saw blades excel in this with a specialized diamond matrix formulation and high-concentration diamond segments. The design ensures optimal cooling and debris removal for fast, clean cuts. This results in smooth edges that require minimal secondary polishing, accelerating production cycles.

Granite Blocks > Segments for Block Cutting

Cutting large granite blocks requires blades with high efficiency segments to maintain straight cuts over long distances. The main challenge is handling the material's high abrasiveness, which demands long life segments.

These blades feature a robust, tensioned steel core and wear-resistant bond. The hot-pressed or laser welded segments are formulated for cutting hard granite, ensuring consistent performance and long tool life in demanding factory environments.

The key benefit is high efficiency and yield, producing uniformly thick slabs while reducing downtime.

Granite Pavers > Sizing for Patios

Sizing granite pavers for patios requires consistent, fast cutting segments to keep projects on schedule. The work often involves repeatedly cutting dense, thick material.

With an aggressive segment design like M-shape or multi-layer segments, our blades deliver rapid cutting speeds. The formulation is optimized for various granite types, making it a reliable tool for landscaping and construction.

This provides installers with an efficient way to achieve clean, uniform pavers, speeding up installation time.

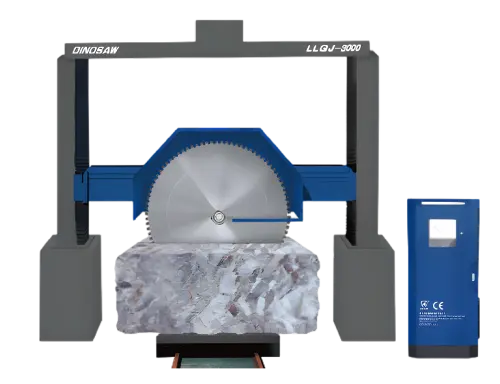

Bridge Saw > Blade Segments for Bridge Saw

Bridge saws are the workhorses of stone fabrication, requiring blade segments that offer a balance of speed and precision for applications from countertop making to architectural cutting.

Our blade segments for bridge saws, such as 400mm or 600mm blade segments, provide stable and precise cutting. The combination of a strong steel core and optimized diamond segments allows for clean cuts, reducing the need for extensive secondary finishing.

This enables workshops to achieve crisp edges and accurate shapes, boosting overall productivity and quality.

Specs and options

Specifications customizable upon request.

| Diameter | Segment Specification (Length/Width/Height) | Teeth No. | |||

| Inches | mm | Length/mm | Thickness/mm | Height/mm | pcs |

| 10" | 250 | 40 | 3 | 15 | 17 |

| 12" | 300 | 40 | 3 | 15 | 21 |

| 14" | 350 | 40 | 3.2 | 15/20 | 24 |

| 16" | 400 | 40 | 3.4 | 15/20 | 28 |

| 18" | 450 | 40 | 4 | 15/20 | 32 |

| 20" | 500 | 40 | 4.2 | 15/20 | 36 |

| 24" | 600 | 40 | 4.8 | 15/20 | 42 |

| 28" | 700 | 40 | 5.2 | 15/20 | 42 |

| 32" | 800 | 40 | 5.6 | 15/20 | 46 |

| 36" | 900 | 24 | 6/7 | 15/20 | 64 |

| 40" | 1000 | 24 | 6.5/7.5 | 15/20 | 70 |

| 48" | 1200 | 24 | 6.5/7.5 | 15/20 | 80 |

| 51" | 1300 | 24 | 7.5/8 | 15/20 | 88 |

| 56" | 1400 | 24 | 8.5/8.5 | 15/20 | 92 |

| 64" | 1600 | 24 | 8.4/9.2 | 15/20 | 108 |

| 72" | 1800 | 24 | 9.5/10.5 | 15/20 | 120 |

| 80" | 2000 | 24 | 9.5/10.5 | 20/30 | 128 |

| 88" | 2200 | 24 | 10.5/11.5 | 20/30 | 132 |

| 100" | 2500 | 24 | 11.5/12.5 | 20/30 | 140 |

| 120" | 3000 | 24 | 11.5/12.5 | 20/30 | 160 |

Granite Blades: Fast Cutting, Long Life.

Segmented rim for fast, chip-free granite cutting.

Fast Cutting Speed

Engineered with an aggressive segment design and optimal diamond concentration for rapid granite cutting.

Long Service Life

A wear-resistant metal bond matrix protects the diamonds, ensuring more cuts per blade and less downtime.

Clean and Straight Cuts

The tensioned steel core and segment geometry deliver precise, chip-free cuts with minimal vibration.

Optimized for Hard Granite

The bond formulation is tailored to prevent glazing when cutting dense, hard stones.

Stable and Precise Cutting

Features a tensioned steel core that minimizes vibration for straight, accurate cuts.

Standard and Silent Options

Available with standard or silent cores for noise reduction in sensitive work areas.

Segmented Rim Design

A non-continuous edge improves cooling and debris removal for faster, efficient cutting.

High Versatility

Effective across a wide range of granite types, from high to low density.

CE Certified Safety

Rigorously tested to meet European safety standards, guaranteeing operator protection.

FAQs

Common Questions About Diamond Granite Saw Blades

How do machine power and blade diameter affect selection?

Choosing the correct blade requires matching its diameter to your machine's power (kW/HP) and the arbor size. An underpowered machine will struggle to drive a large blade, leading to slow cutting and motor damage. For example, a standard bridge saw is typically suited for blade segments 400mm to 600mm.

Our diamond matrix formulation is optimized for a range of machine powers. Whether you need a blade for a 15kW bridge saw or a 45kW block cutter, we have a solution. Always consult your machine's manual to confirm its power rating and recommended blade diameter range.

Should I choose a taller segment height or a thinner kerf?

This depends on whether you prioritize blade lifespan or material savings. Taller segment height (e.g., 20mm) directly increases tool life. A thinner kerf (thickness) removes less material, enabling faster cuts and saving valuable stone. We offer multi-layer diamond segments and sandwich segments to balance these needs, providing both durability and efficiency.

For cutting high-value granite, a thin-kerf blade is ideal. For high-volume jobs where durability is key, a standard kerf with taller, customized diamond segments offers a better cost-per-cut.

What are the best practices for wet cutting granite?

For wet cutting segments, adequate water flow is critical; it cools the blade, flushes debris, and prevents dust. Ensure a steady stream of water is directed at both sides of the blade where it enters the cut. A common guideline is 10-15 liters (3-4 gallons) per minute for larger diameter blades on bridge saws.

Insufficient water can cause overheating and damage. While some small-diameter blades may be used for dry cutting, wet cutting is always recommended for granite to ensure the best performance and blade life.

What are the signs of blade glazing and how do I fix it?

Blade glazing occurs when the diamond particles become dull and the metal bond smears over them, causing the blade to rub instead of cut. Signs include a drop in cutting speed and a shiny segment edge. This can happen if the bond is too hard for the granite or the feed rate is too slow.

To fix a glazed blade, you need to "dress" it by making a few cuts into an abrasive material like a dressing stick. This wears away the smeared metal from the hot-pressed segments and exposes new, sharp diamond particles.

How do I troubleshoot common cutting problems?

To resolve common issues, check these points:

- Chipping:Often caused by an aggressive feed rate, unstable material, or a blade with a bond that is too hard. Check if M-shape segments, known for initial sharpness, could help.

- Blade Wobble:Can result from worn machine bearings, improper flange mounting, or a damaged blade. Inspect the blade core and sandwich segments if it's a silent blade.

- Burning Marks:Indicates insufficient cooling or excessive RPM. Ensure adequate water flow and verify the machine RPM matches the blade’s operating speed.

What is the proper procedure for blade break-in?

Properly breaking in a new diamond blade is essential for performance, as it exposes the diamonds in the segments. Make several shallow cuts (3-5 passes) in an abrasive material like soft granite. Start with a slow feed rate and gradually increase it with each pass.

This controlled wear gently removes the outer layer of the metal bond on the sintered segments, ensuring diamonds are evenly exposed without causing thermal shock. This simple step prevents glazing on the first real cut.

Can a used blade be re-tipped, and what is the lead time?

Yes, re-tipping with new diamond segments is a cost-effective practice if the steel core is in good condition. The process involves professionally laser welding new segments on, restoring cutting performance.

Lead times vary. Standard, in-stock replacement segments ship within a few business days. The re-tipping service itself takes additional time. For custom orders, please contact our team for an accurate delivery estimate.

Certifications & Standards

Segmented rim for fast, chip-free granite cutting.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Master Granite Cutting?

Equip your team with blades that deliver speed, precision, and safety. Contact us for a quote.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond Blade Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский