Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

5-Axis CNC Bridge Saw

WZQJ-5N

Compatible Materials & Products

Transform Any Stone Into Premium Products

Granite ❯ Kitchen Sinks

|

Granite's exceptional hardness and durability make it the premier choice for kitchen sinks that withstand heavy use while maintaining their beauty. Its non-porous nature resists staining and bacterial growth, making it ideal for food preparation areas. With proper sealing, granite sinks provide decades of reliable service even in busy households.

The DINOSAW 5-axis bridge saw's powerful 18.5kW spindle precisely cuts through dense granite while maintaining ±0.05mm accuracy. Its synchronized 5-axis movement creates perfectly rounded corners and seamless drain integrations, while the vacuum suction system securely holds the material during intricate cuts. The automatic tool compensation ensures consistent edge quality, eliminating the extensive manual finishing typically required for granite sink fabrication.

This advanced processing capability reduces production time by 65% compared to traditional methods while improving material utilization by up to 30%. The precision cutting prevents microfractures that could develop into cracks, ensuring longevity of the finished product. Stone fabricators report dramatic profitability increases when specializing in premium granite sink installations using DINOSAW technology.

Marble ❯ Bathroom Vanities

|

Marble's natural veining and luxurious appearance create stunning bathroom vanities that elevate any space with timeless elegance and refined character. Each piece features unique patterns formed over millions of years, ensuring no two vanities are identical. This exclusivity makes marble particularly desirable for high-end residential and boutique hospitality projects.

The DINOSAW 5-axis bridge saw's delicate precision control system adapts cutting parameters specifically for marble's unique characteristics. Its camera system captures and analyzes veining patterns, enabling perfect alignment across cut pieces. With variable speed control (1000-6000 RPM) and optimized water cooling, the system prevents microcracking and chipping even on thin marble sections.

The 5-axis capability creates seamless curved transitions and perfect edge finishes unachievable with conventional equipment. Stone fabricators using DINOSAW technology report 70% reduction in marble waste and 85% decrease in edge polishing time. The system's ability to create perfectly matched integrated sinks adds substantial value to high-end projects, increasing average sale prices by 45% compared to conventional vanity installations.

Quartz ❯ Countertops

|

Engineered quartz combines exceptional durability with consistent patterns, making it the ideal material for modern countertops that balance aesthetics with performance. Its non-porous surface resists staining and requires no sealing, offering superior hygiene for food preparation areas. Available in countless colors and patterns, quartz provides designers with versatile options for any interior style.

DINOSAW 5-axis bridge saw excels at quartz processing through its specialized cutting parameters and tooling options. The powerful 18.5kW spindle with advanced cooling technology prevents overheating during quartz fabrication, maintaining tool sharpness for cleaner cuts. The DDX control system's automated nesting feature maximizes material yield from expensive quartz slabs.

For complex countertop configurations, the 5-axis capability creates perfect miter joints and seamless transitions at corners. This technology reduces quartz fabrication time by 55% while delivering edge quality that requires minimal finishing. The precision cutting eliminates stress points in cutouts for sinks and fixtures, preventing future cracks and failures. Fabricators report average material savings of 22% and labor reductions of 60% for quartz countertop production using DINOSAW equipment.

Natural Stone ❯ Curved Furniture Elements

Natural stone curved furniture elements blend artistic expression with functional design, creating distinctive focal pieces that showcase the stone's natural beauty. From flowing table edges to graceful shelving and sculptural bases, these elements bring organic movement to interior spaces. Their uniqueness commands premium pricing, with curved stone furniture becoming increasingly sought after in luxury residential and commercial projects.

The DINOSAW 5-axis bridge saw revolutionizes curved furniture production through simultaneous 5-axis interpolation. Unlike conventional 3-axis systems that require multiple setups, the A and C axis rotations enable continuous curved cutting along complex paths. The machine processes various natural stones including travertine, limestone, and sandstone, adapting parameters to each material's specific hardness and structure.

The system's advanced tool path optimization creates smooth curves with consistent surface quality. Stone fabricators can now complete complex furniture elements like curved table tops, sculptural bases, and architectural features in a single setup. Production time decreases by 75% compared to traditional methods, while material utilization improves by 25%. The ability to create these high-value products opens new premium market segments, with fabricators reporting 200% higher margins compared to standard countertop work.

Natural Stone ❯ 3D Sculptures

|

3D stone sculptures transform raw material into artistic expressions, capturing intricate details and organic forms that demonstrate the highest level of stone craftsmanship. These pieces range from figurative art to abstract compositions, architectural elements, and custom decorative pieces. The dimensional complexity of these works has traditionally required extensive manual labor by skilled artisans, limiting production and increasing costs.

The DINOSAW 5-axis bridge saw achieves sculptural excellence through its extraordinary precision control and multi-directional cutting capability. Compatible with large diameter blades (up to 800mm) for deep cutting applications, the system can process complex 3D forms in various stone types. The 360° C-axis rotation combined with 0-90° A-axis tilting enables the creation of undercuts and compound curves previously achievable only through manual carving.

The DDX control system imports 3D models directly, automatically generating optimal tool paths. This technology bridges traditional sculptural techniques with digital precision, reducing production time for 3D stone elements by 80%. The system's ability to reproduce complex designs with perfect consistency enables sculptural series production for architectural applications. Stone fabricators report dramatic business growth by entering the high-margin decorative and artistic stone market segment.

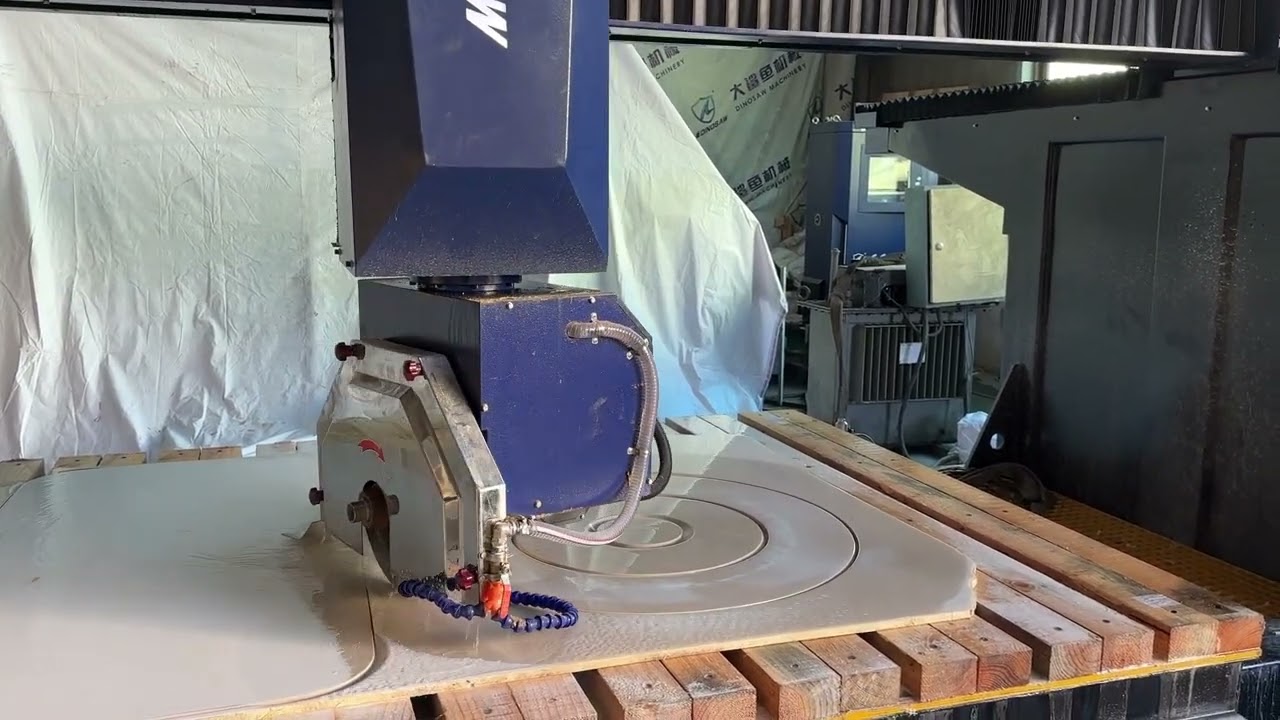

▶ Product Demo

▶

▶

High-End Kitchen Fabrication

400% ROI Through Precision & Efficiency

A premium Italian stone fabrication company struggled with complex sink integration, facing 35% material waste and lengthy production cycles. After implementing the DINOSAW 5-axis bridge saw, they achieved ±0.05mm cutting precision for complex curved sinks while reducing material waste to just 5% and decreasing production time from 4 hours to 45 minutes per unit.

Luxury Bathroom Renovation

Transforming Marble Into Art

An American bathroom renovation specialist was limited by conventional equipment when creating custom marble vanities with integrated sinks, unable to achieve curved transitions and seamless edges. The DINOSAW 5-axis bridge saw's camera system and automatic slab matching technology allowed perfect marble veining alignment across complex shapes, while precision milling created smooth surface transitions

Commercial Countertop Production

85% Faster Delivery for Large Projects

A growing commercial countertop manufacturer was losing bids due to lengthy production timelines and high costs for multiple matching countertops with integrated sinks. Implementing the DINOSAW 5-axis bridge saw with automatic programming reduced setup time by 92% for repeat pieces, while DDX control system's nesting capability maximized material utilization for large batch production.

Specs and options

Specifications customizable upon request.

| Model | Unit | WZQJ - 5N |

|---|---|---|

| Lateral X stroke | m | 3.2 |

| Longitudinal Y stroke | m | 2.0 |

| The Z axis saw blade vertical stroke | m | 0.45 |

| Saw blade diameter | m | 0.6 |

| Spindle motor capacity | kw | 18.5 |

| Fixed table | m | 3.2x2.0 |

We can customize 5-axis bridge saws equipped with 800mm diameter blades, specifically designed for 3D sculpture cutting applications.

5-axis precision engineering for perfect results.

Precision. Innovation. Perfect Stone Cutting

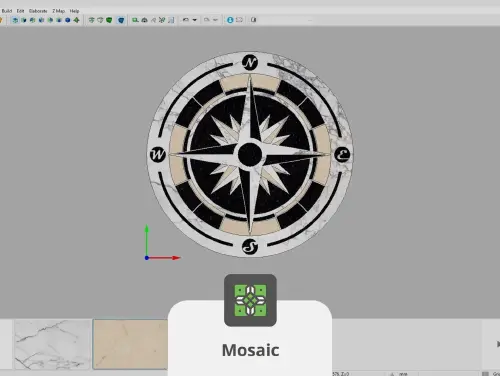

Simple CNC Operation

Built-in graphics library supports CAD import and direct drawing for easy operation.

Higher Material Yield

Camera scanning with auto thickness measurement and layout optimization maximizes slab usage.

±0.05mm Precision Cutting

High-precision spindle combined with DDX system optimizes cutting paths for accuracy.

Reduced Labor Costs

Vacuum suction auto material handling system minimizes manual operation requirements.

Solid & Durable

Cast beam construction with Siemens and NSK components ensures reliable durability.

Easy Installation

Integrated monoblock design allows operation after simple machine body fixing.

FAQs

Common Questions About 5-Axis CNC Bridge Saw for Stone Sink Fabrication

What types of stone materials can the DINOSAW 5-axis bridge saw process?

The DINOSAW 5-axis bridge saw processes comprehensive materials including natural stones (granite, marble, limestone, travertine, sandstone), engineered materials (quartz, sintered stone, terrazzo), and ceramic tiles. The 18.5kW spindle with DDX control adapts parameters automatically for each material.

For challenging materials like porcelain, maintains ±0.05mm accuracy while minimizing edge chipping. 5-axis movement handles complex shapes in materials up to 180mm thick, ideal for countertops, sinks, sculptures, and architectural elements across all stone types.

How does the 5-axis capability improve sink fabrication compared to 3-axis machines?

5-axis capability revolutionizes sink fabrication through continuous curved cutting and automatic angle adjustments without repositioning. While 3-axis machines require multiple setups and manual finishing, DINOSAW 5-axis completes entire sink cutouts in one operation.

A and C axis rotations create perfect radius corners (minimum R2.5mm) and seamless drain integrations. This eliminates 80% manual polishing and reduces production time from 4 hours to 45 minutes per sink. Synchronized movement maintains ±0.05mm precision on complex undermount profiles impossible with 3-axis systems.

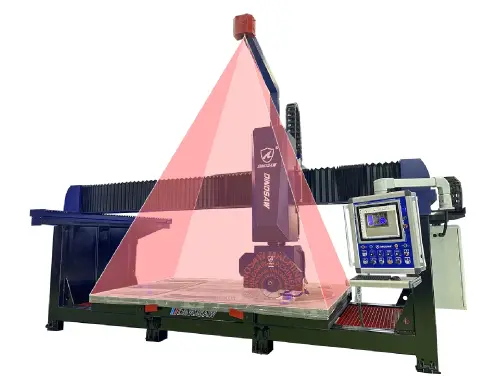

How does DINOSAW ensure ±0.05mm cutting precision consistently?

±0.05mm precision achieved through integrated systems:

Cast iron monoblock structure eliminates vibration errors.

High-precision linear guides and NSK bearings ensure smooth movement.

DDX control uses advanced algorithms for path optimization and real-time correction.

Automatic tool measurement compensates blade wear.

Laser positioning provides visual verification.

18.5kW spindle maintains consistent speed under load.

Regular calibration maintains precision over time.

How difficult is it to learn to operate the DINOSAW 5-axis bridge saw?

Most operators master core functions within 1-2 days training. DINOSAW 5-axis features intuitive 19-inch touchscreen with DDX EasySTONE software for rapid learning.

System offers automated CNC and manual control modes for gradual transition. 90% of operators complete basic tasks after first week, full proficiency within 30 days.

Includes on-site training, remote assistance, video resources, and regular software updates.

What technical support does DINOSAW provide for 5-axis bridge saw users?

Comprehensive support: 24-hour technical hotline, remote diagnostics, global service network.

Initial: on-site installation, operator training, system optimization.

Ongoing: video assistance, remote programming, software updates.

DDX partnership ensures expert control support. 48-hour spare parts delivery guaranteed.

Documentation includes manuals, video tutorials, troubleshooting guides. Annual maintenance programs with certified technicians. User forums and knowledge base.

Emergency support prioritizes production issues.

Training covers basic operation to advanced programming.

How much space and infrastructure is needed to install the DINOSAW 5-axis bridge saw?

Requires 5.6m × 3.3m floor space, recommended 6m × 5m workspace.

Standard three-phase power required. Anti-vibration pads prevent vibration transmission.

Installation completes in 1-2 days. Integrated design allows easy relocation if needed.

Is the control software compatible with existing digital measurement systems?

EasySTONE DDX system supports DXF, DWG, STL files and integrates with AutoCAD, Rhinoceros, AlphaCam software.Compatible with LT-2D3D, Prodim Proliner, Laser Products digital templating systems. Direct import without conversion errors.

Custom ERP integration services available through local networks or cloud platforms for complete digital workflow.

Certifications & Standards

Precision. Innovation. Perfect Stone Cutting

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Transform Your Stone Fabrication Capabilities?

Experience the revolutionary precision and efficiency of DINOSAW's 5-axis CNC bridge saw technology for perfect stone sinks and countertops every time.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Bridge Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский