Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

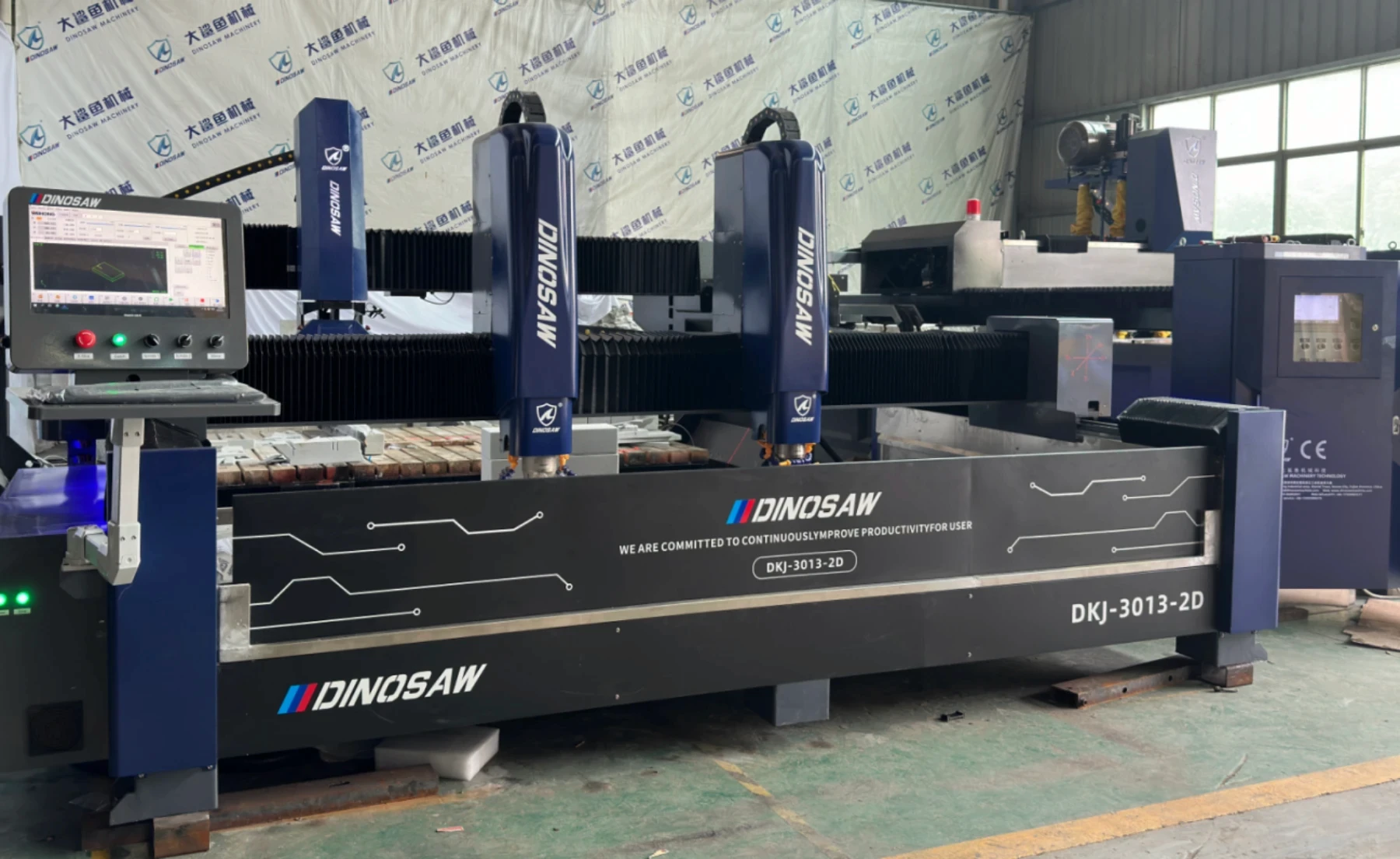

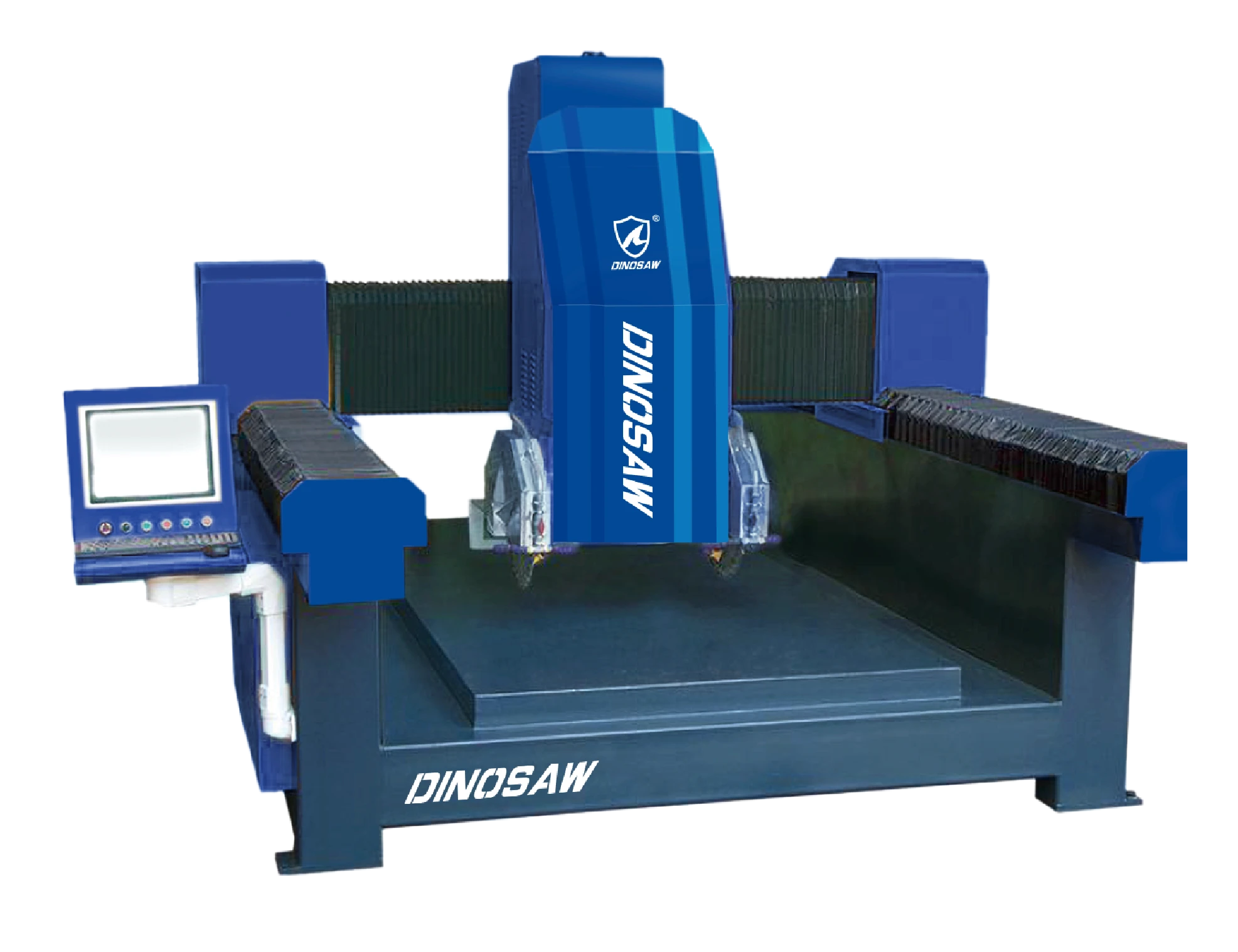

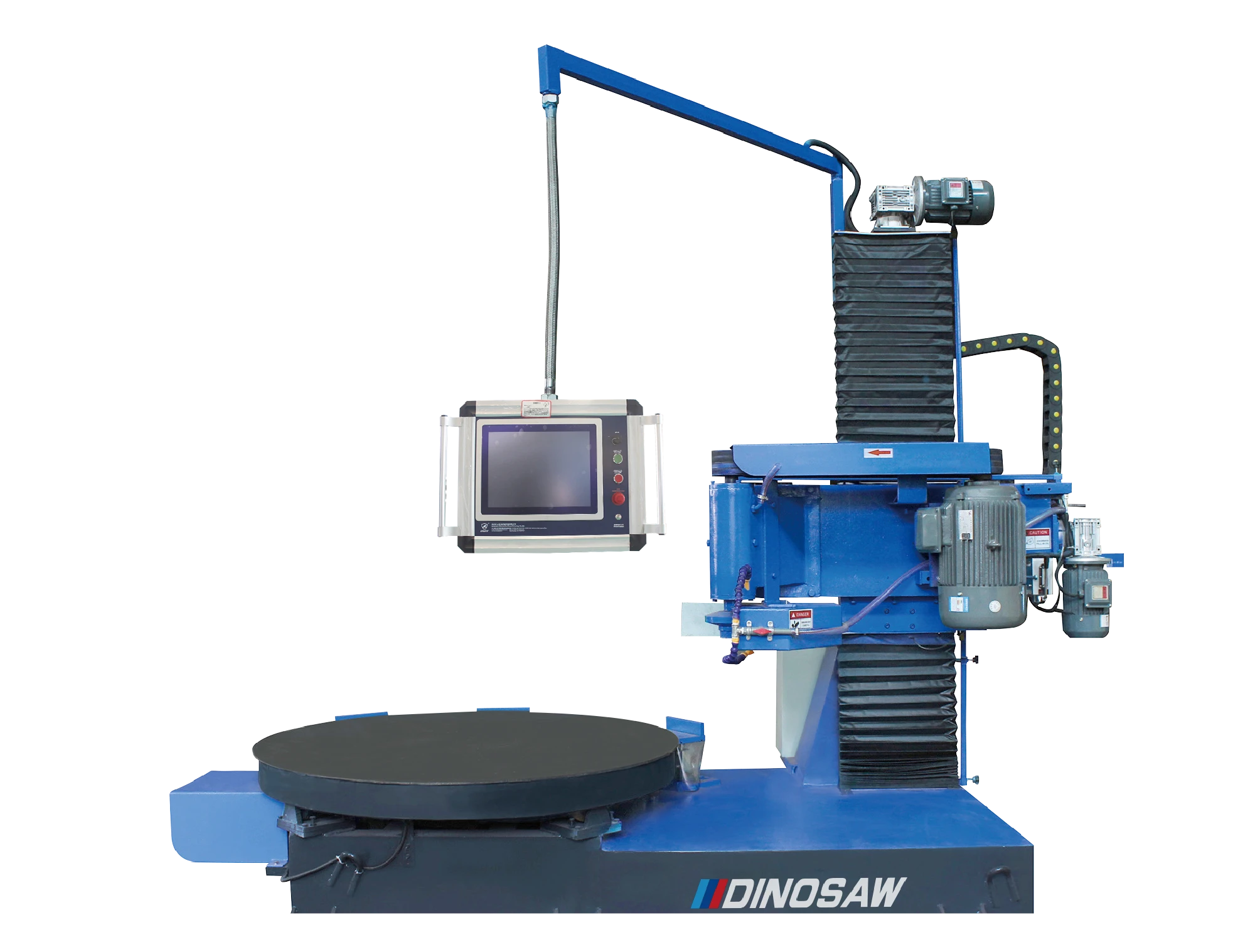

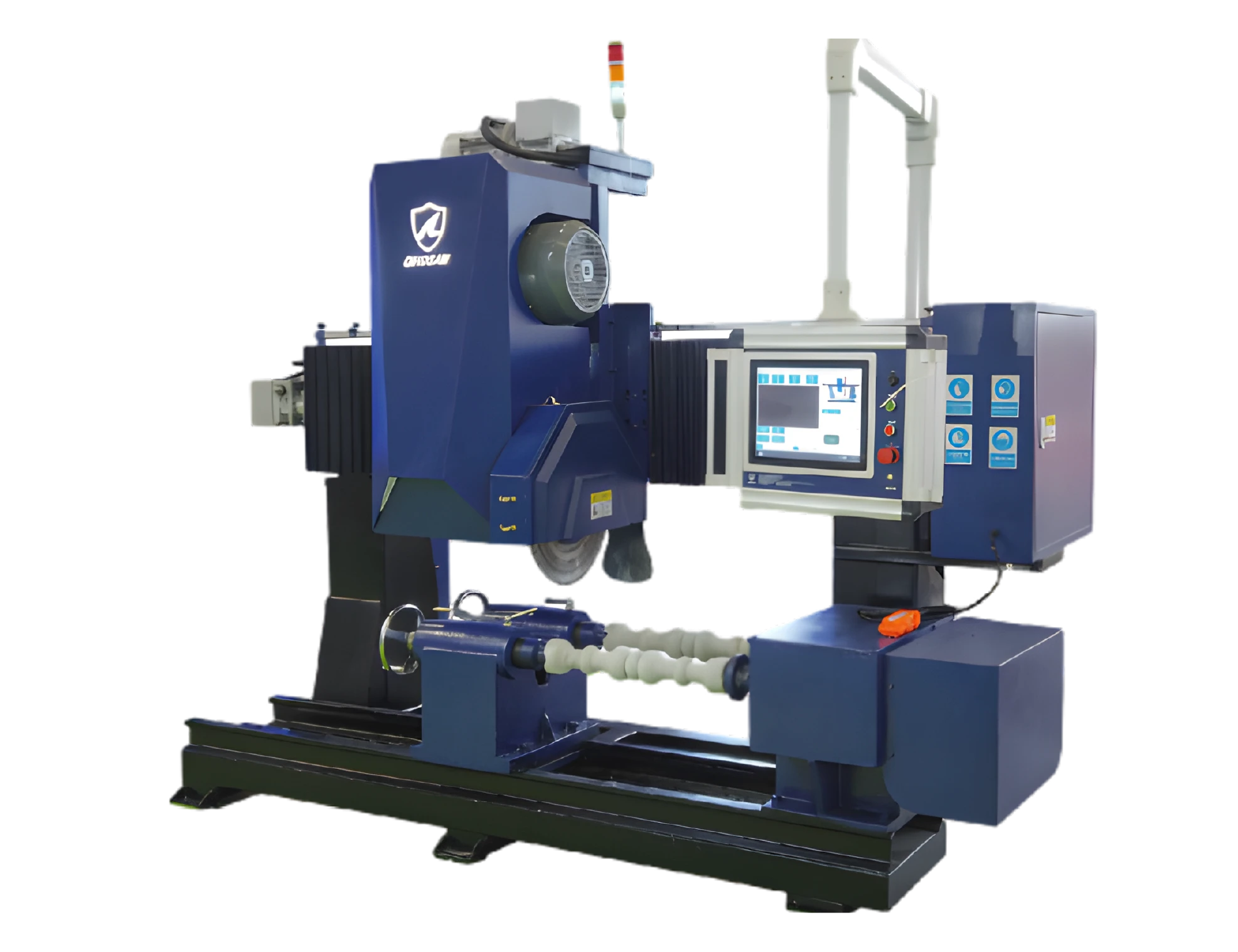

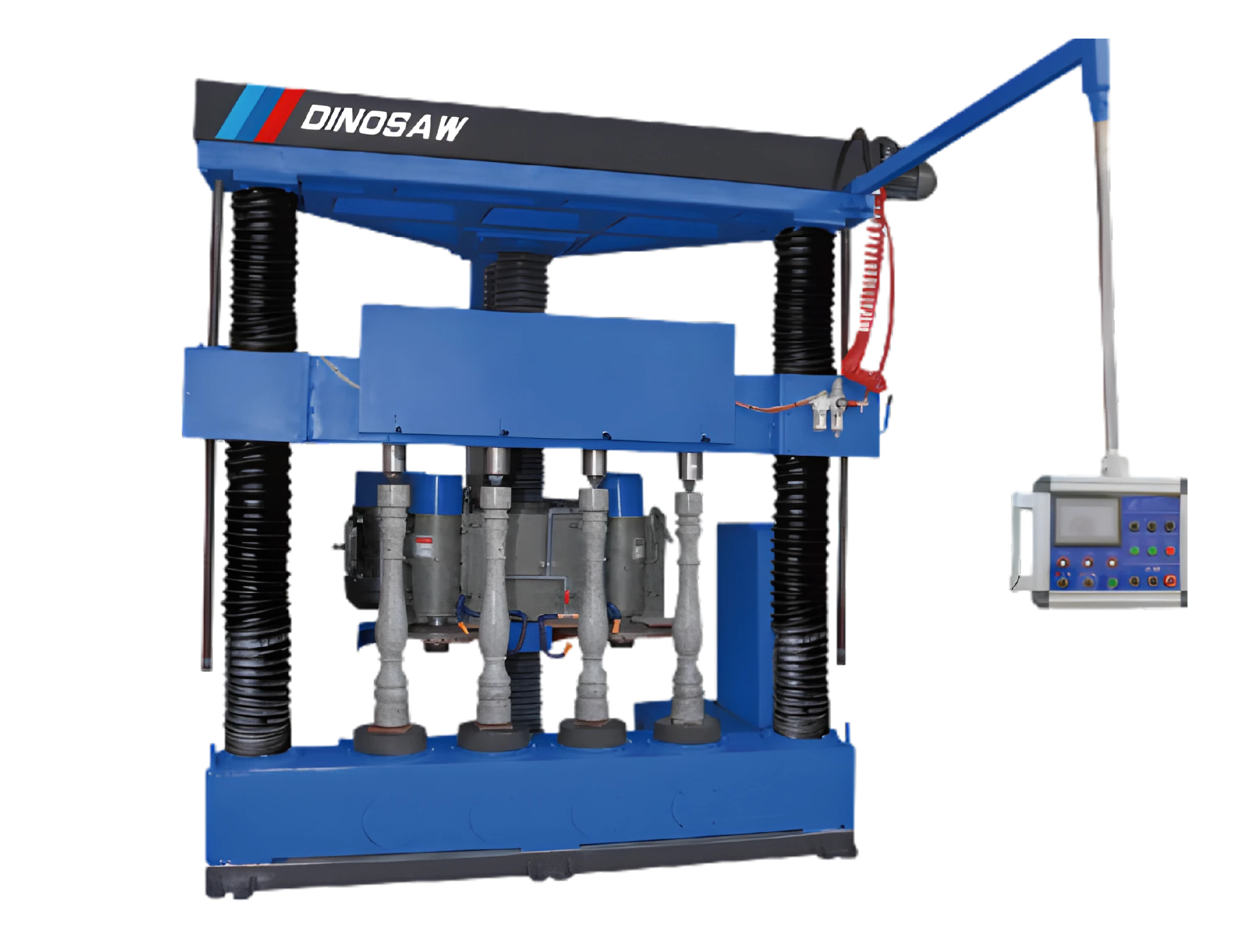

Profiling Machine

Discover Dinosaw’s versatile profiling machines, including bridge profiling machines, vertical models, and horizontal models. Designed for crafting Roman columns, balusters, decorative moldings, and more, these machines offer precision, efficiency, and advanced automation.

What is A Stone Profiling Machine?

A stone profiling machine is used to shape architectural stone components by cutting or turning along a predefined profile.

It is commonly applied to marble, granite, and engineered stone where consistent cross-section geometry or decorative contours are required.

Typical finished products include balusters, columns, column caps and bases, spheres, and decorative edge profiles, widely used in architectural and landscaping stonework.

In English-speaking markets, this category is often broadly referred to as a stone shaping machine.

When the workpiece is rotational, buyers frequently search for CNC stone lathe solutions.

Profiling machines are generally classified by how the shape is formed:

Lathe-type (turning profiling)

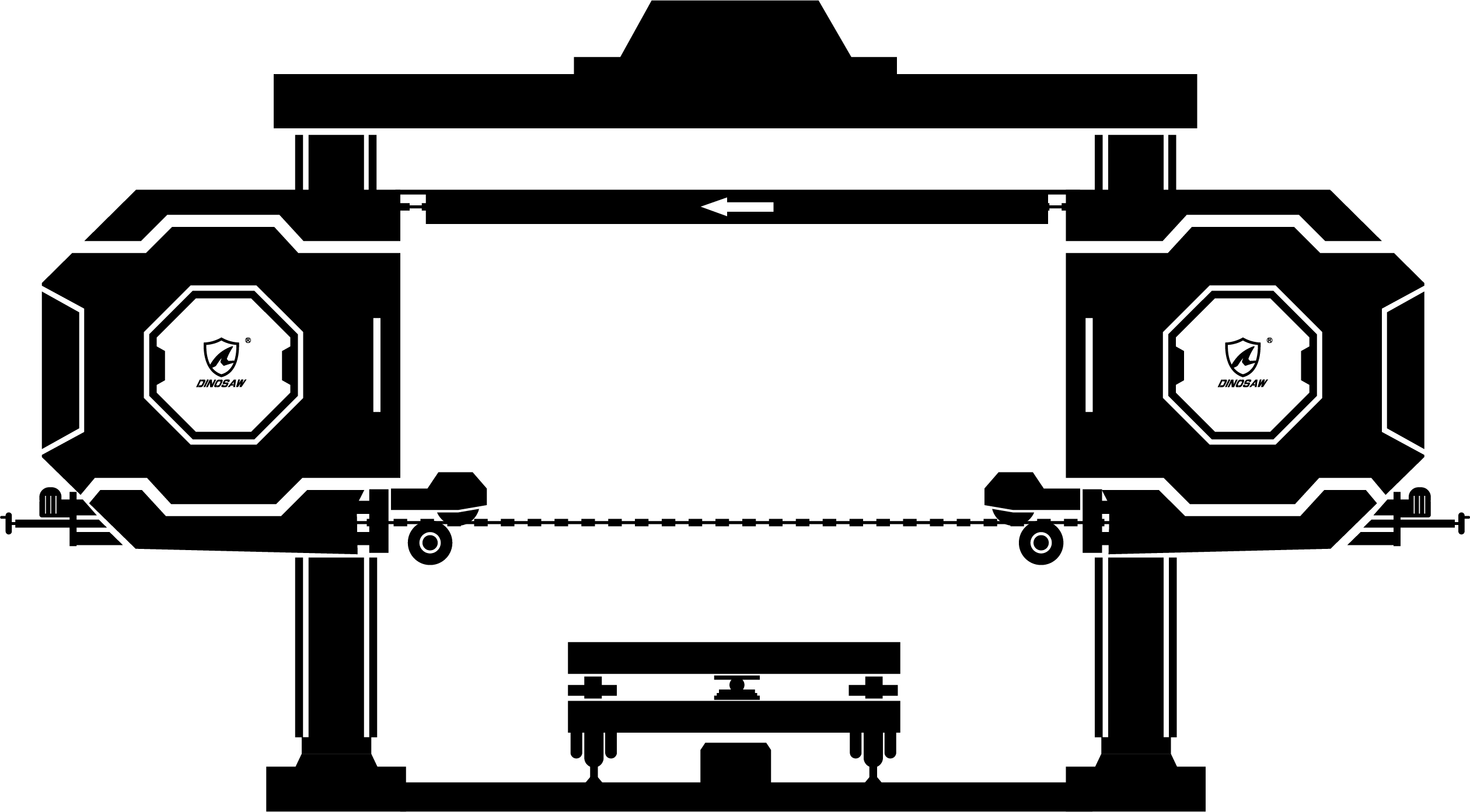

The stone rotates during machining, making this method suitable for round and symmetrical components such as balusters, columns, vases, and spheres.Saw-based / linear profiling

The stone remains stationary while tools move along programmed paths, allowing accurate shaping of square, linear, or structured profiles such as caps, bases, and decorative lines.

Selection principle:

Choose the machine type based on your primary product geometry — rotating round shapes versus non-rotating linear or structured forms.

Profiling Machine Project Cases

Custom Stone Shaping Results

Profiling Machine Operation Guide

How To Create Custom Shapes

Profiling Technology News

Stone Shaping Updates

How to Make Stone Balls Using CNC Stone Lathe ?

What Is a Stone Profiling Machine? A Fabricator's Guide

Best Stone CNC Machine 2025: A Buyer's Guide

Top 10 Stone CNC Machine Manufacturers (2026 Guide)

Which Stone Lathe to Choose: Vertical or Horizontal?

Is a CNC Stone Lathe Worth It? A Complete Cost-Benefit Analysis

How to Choose the Right Stone Profiling Machine for Your Project

Choosing a stone profiling machine is not about brand or machine size first, but about how your stone product is formed during machining.

The core decision starts from geometry, not parameters.

Start With Your Product Shape

The most direct dividing line is whether the workpiece needs to rotate during processing.

If your products are round or axis-symmetrical, such as balusters, columns, vases, or stone spheres, the shape itself requires continuous rotation to maintain profile consistency.

In this case, a lathe-type profiling machine aligns naturally with the product logic, because the rotation ensures uniform cross-sections and stable repetition from piece to piece.

If your products are non-rotating, such as square column caps, bases, cornices, or decorative line profiles with flat faces and corners, rotating the stone adds no value and can even limit accuracy.

Here, saw-based or linear profiling machines provide better control over straight lines, edges, and structured geometry.

Match the Machine to the Forming Logic, Not the Name

In many markets, buyers search broadly for “stone profiling machine” or “stone shaping machine,” but these terms cover very different forming methods.

Lathe-type machines form shapes through controlled turning.

Saw-based profiling machines form shapes through programmed cutting paths.

The machines may look similar in size or automation level, but the forming logic determines suitability, not the label used in listings or brochures.

Consider Production Consistency and Throughput

For projects that require high repeatability across many identical round components, rotation-based profiling reduces manual finishing and keeps dimensions consistent across batches.

For architectural stonework involving multiple profile types, flat surfaces, or changing designs, linear profiling machines offer greater flexibility without reconfiguring rotational setups.

In both cases, CNC control plays a role, but CNC alone does not change the fundamental forming method.

A CNC stone lathe is still optimized for rotation; a CNC linear profiling machine is still optimized for non-rotating profiles.

Typical Application Scenarios

Lathe-type profiling machines are commonly selected for balustrade production lines, column workshops, and projects focused on cylindrical or spherical stone elements.

Saw-based and linear profiling machines are often preferred in architectural stone factories producing caps, bases, frames, borders, and decorative linework where edges and planes must remain well defined.

Practical Selection Guideline

If your primary products are round and symmetrical, start from turning-based profiling.

If your primary products are linear, square, or structured, start from saw-based profiling.

Once this distinction is clear, machine configuration, automation level, and capacity become optimization questions rather than risk factors.

This approach avoids over-buying complexity and ensures the profiling process matches the actual geometry of your stone products.

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский