Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

A CNC stone lathe is a transformative investment, with the value it creates far exceeding its cost for businesses in architectural and decorative stone fabrication.

Here's the thing about the stone fabrication business - you're either growing or you're dying. I learned this the hard way when my biggest competitor landed a $200K architectural project that I couldn't even bid on. Why? Because they had a CNC stone lathe, and I was still doing everything by hand.

That wake-up call led me to spend the next six months researching every CNC stone lathe on the market. What I discovered changed everything about how I viewed my business. A CNC stone lathe isn't just another piece of equipment - it's basically a time machine that lets you skip five years of manual skill development and start competing with the big players immediately.

What Actually Makes a CNC Stone Lathe Special?

Let me paint you a picture. Last month, a client wanted eight identical balusters for a grand staircase restoration. Using traditional methods, this would have taken my best craftsman nearly three weeks, assuming he didn't mess up (and trust me, marble doesn't forgive mistakes). With our CNC lathe? We knocked them out in two days, and each one was so identical you'd need calipers to tell the difference.

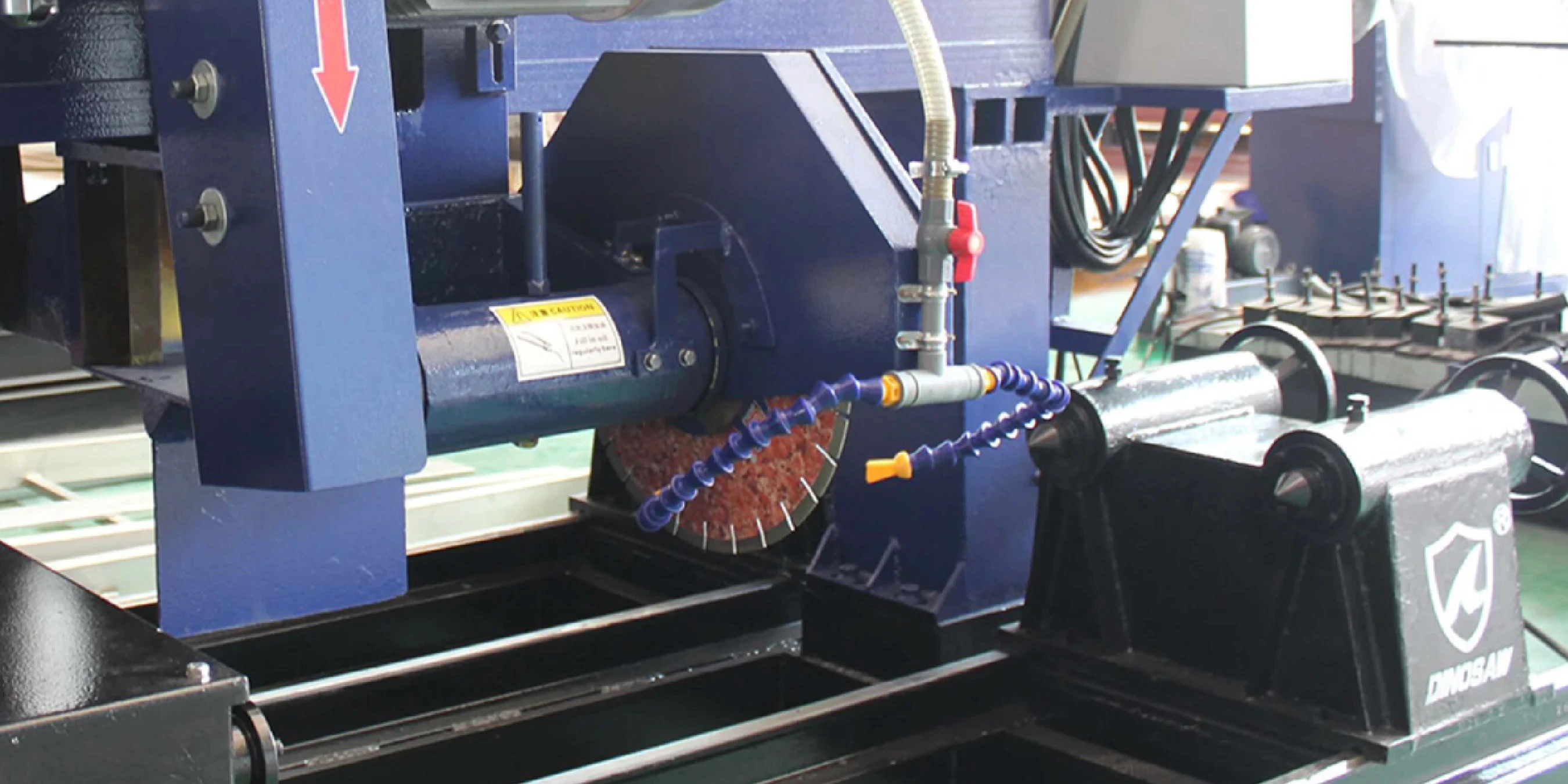

Think of a CNC stone lathe as the love child of a pottery wheel and a supercomputer. Instead of your hands shaping clay, you've got diamond-tipped tools guided by precise digital instructions, slowly sculpting marble or granite into those elaborate columns you see on fancy buildings. It's honestly mesmerizing to watch - like seeing Michelangelo work, except the artist never gets tired and never makes a mistake.

The Technical Reality Behind the Magic

Now, here's where it gets interesting from an engineering perspective. Unlike wood or metal lathes that actually cut material, stone lathes work through abrasive grinding. We're talking diamond-tipped tools that essentially wear away the stone bit by bit. This creates an incredible amount of dust and slurry - basically a soup of stone particles and cooling water.

I've seen people try to adapt regular CNC machines for stone work. Big mistake. A proper stone lathe needs to be built like a tank. The guide rails, bearings, everything needs to be sealed tighter than a submarine because that stone slurry will kill regular machinery faster than you can say "warranty void."

How the Digital Workflow Actually Works

The process is surprisingly straightforward once you get the hang of it:

- Design: Everything starts with a 3D model. Sometimes clients bring us old architectural drawings, sometimes we scan existing pieces. Our CAD software turns these into precise digital blueprints.

- Programming: This is where the magic happens. CAM software translates that 3D model into thousands of precise movements. Speed, depth, tool changes - it's all calculated automatically.

- Setup: Mount the raw stone block (this part still requires some muscle), load the program, and set your reference points.

- Let it run: Hit start and walk away. The machine can run for hours, even overnight. I've programmed jobs on Friday evening and come back Monday to perfect pieces.

The Real Benefits (Beyond the Marketing Hype)

Precision That Actually Matters

Here's what really sold me on the technology - it's not just about speed. It's about consistency. When you're hand-carving, your third piece might be slightly different from your first because, well, you're human. CNC doesn't have bad days, doesn't get tired, and doesn't have off-days. It's like having a master craftsman who never needs coffee breaks.

But here's the kicker - this precision translates directly to your bottom line. I used to waste about 15% of my expensive marble stock due to human error. With CNC, that waste dropped to less than 3%. When you're dealing with $200-per-square-foot Carrara marble, those numbers add up fast.

The Production Speed Revolution

Let me give you some real numbers from our shop. A complex Corinthian column capital that used to take our master carver two weeks now takes 18 hours of machine time. And I can run it overnight while nobody's even in the shop. That's not just efficiency - that's like having a second shift that works for free.

What really changed our business model was the ability to quote jobs accurately. Before CNC, estimating a complex carving job was basically educated guesswork. Now, the CAM software tells me exactly how long something will take. No more "it'll probably take about..." conversations with clients.

Opening New Revenue Streams

This is where it gets exciting. A CNC stone lathe doesn't just make you faster at what you already do - it lets you bid on projects you never could before. Restoration work, custom architectural elements, art installations. We've gone from being a countertop shop to a specialty architectural stone fabricator.

Last year, we landed a $150K job creating replica columns for a historic courthouse renovation. Without CNC, I would have had to subcontract that work or pass entirely. Now? It was our most profitable project of the year.

The Investment Reality Check

Okay, let's talk money. Because despite all the benefits, a CNC stone lathe is a serious investment. I'm not going to sugarcoat this - when I first saw the price tags, my accountant nearly fainted.

What You'll Actually Pay

The market breaks down pretty clearly into tiers. Entry-level machines from solid manufacturers like Dinosaw typically run $13,000 to $25,000. Mid-range European machines might hit $42,000 to $52,000. And if you want the Rolls Royce - those Italian and German machines - you're looking at $150,000 and up.

But here's my take after three years of ownership: unless you're running a massive operation, the mid-range machines are the sweet spot. We went with a Dinosaw machine at $19,000, and it's been absolutely bulletproof. Sure, the fancy European machines have more bells and whistles, but for most shops, you're paying for prestige more than performance.

The Hidden Costs Nobody Mentions

Here's what the sales brochures don't tell you. The machine price is just the beginning:

- Diamond tooling: Budget $2,000-5,000 annually. Those diamond bits wear out, and they're not cheap to replace.

- Infrastructure: You'll need proper electrical (three-phase power isn't standard in most shops), a reinforced concrete pad, and industrial-grade dust collection. We spent $8,000 getting our shop ready.

- Training: Here's where DINOSAW really shines compared to other manufacturers. Their operating system is refreshingly simple and intuitive, with full multi-language support. I was honestly skeptical when they said 30 minutes of training would get me started, but they weren't kidding. Within half an hour, I was running my first test piece. It took just 1-3 days to master the basic operations completely - a far cry from the months I'd heard other operators talking about with different brands.

- Water treatment: That stone slurry can't just go down the drain. A proper water reclamation system adds another $3,000-7,000 to your setup costs.

New vs. Used: Why I Learned This Lesson the Hard Way

I almost bought a used machine to save money. Thank God I didn't. Here's why: CNC stone lathes work in one of the harshest environments imaginable. That stone slurry gets into everything, and you have no idea how well the previous owner maintained the machine.

I've seen too many people buy "bargain" used equipment only to spend more on repairs than a new machine would have cost. Plus, with a new machine, you get warranty, training, and technical support. When you're down and losing money every hour, having a manufacturer's support line to call is worth its weight in gold.

Real-World ROI: The Numbers That Matter

Let me share some actual numbers from our shop, because spreadsheet projections are one thing - real performance is another.

Our Dinosaw machine paid for itself in 14 months. Here's how: Before CNC, we could complete maybe 2-3 major carving projects per month with our hand carvers. Now we're doing 8-10 projects monthly, with higher precision and less waste. Our average project value increased from $3,500 to $6,200 because we can take on more complex work.

But the real game-changer was labor efficiency. We went from needing a master carver for every project (at $35/hour) to having one skilled operator who can manage multiple machines. Our labor costs per piece dropped by 60%, while our output tripled.

Who Should Actually Buy One?

Not everyone needs a CNC stone lathe. If you're happy doing simple countertops and basic stonework, stick with what you know. But if any of these sound familiar, it might be time to seriously consider the investment:

- You're turning down projects because they're too complex or time-consuming

- Your skilled craftsmen are becoming your bottleneck

- You want to compete for architectural restoration and custom work

- You're tired of explaining to clients why their eight balusters aren't perfectly identical

- You're ready to work smarter, not harder

My Final Take

After three years of ownership, I can honestly say our CNC stone lathe was the best business decision I've made. It didn't just make us more efficient - it fundamentally changed what kind of company we could be.

Yes, the upfront investment is significant. Yes, there's a learning curve. And yes, you'll have moments where you question your sanity (usually when something goes wrong at 2 AM during an overnight run). But if you're serious about growing your stone fabrication business, CNC technology isn't optional anymore - it's the price of admission to the next level.

The stone industry is evolving faster than ever. The shops that embrace automation are pulling ahead, while the ones stuck in manual methods are being left behind. Don't be the one explaining to your grandkids why you didn't invest in the future when you had the chance.

Frequently Asked Questions

What can you actually make with a CNC stone lathe?

Anything round or rotationally symmetric. Columns, balusters, vases, bowls, architectural details, newel posts, finials - if it spins on an axis, we can carve it. The limitation isn't the machine; it's your imagination and CAD skills.

How long does it really take to learn?

This is where DINOSAW has completely changed the game. With their intuitive interface and built-in shape library, you can be productive almost immediately. Need to make standard columns, spheres, balusters, or vases? Just select from their pre-loaded templates and modify a few parameters - we're talking minutes, not hours. Got existing CAD files? One-click import and you're ready to start cutting. You only need to manually draw from scratch when you're doing truly custom pieces. And if you ever get stuck, their technical support team is incredibly responsive. Most operators are fully comfortable within 1-3 days, not the months other systems require.

What's the biggest mistake new owners make?

Skipping proper training and trying to figure it out themselves. The second biggest? Not investing in proper tooling from the start. Cheap diamond bits will cost you more in the long run through poor surface finish and constant replacements.

Is financing worth it?

For most shops, absolutely. The cash flow improvement from increased productivity usually covers the monthly payments easily. Plus, you get the tax benefits of equipment financing. Just make sure you have enough working capital for the learning curve period.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский