Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

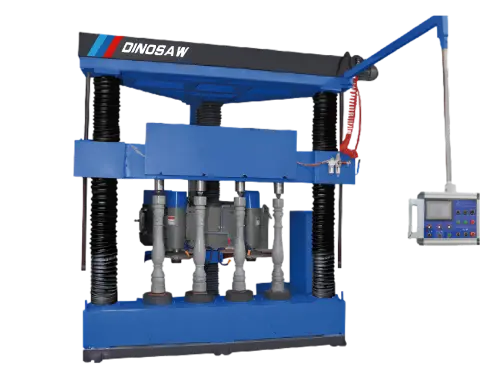

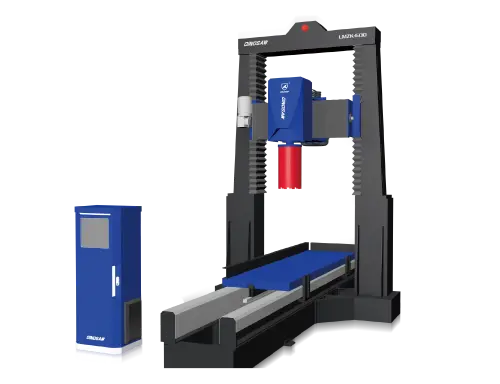

Vertical 4-Workpiece Baluster Profiling Machine

LGFX-LS4

Compatible Materials & Products

▶ Product Demo

▶

▶

Granite > Balusters & Railings

|

|

|

The global balustrade market is rapidly expanding, projected to reach USD 7.24 Billion by 2032, with granite balusters maintaining premium status in luxury construction. This growth creates tremendous demand for efficient, precise fabrication methods that can deliver consistent quality while minimizing labor costs and material waste.

The DINOSAW Vertical 4-Workpiece Stone Cutting Machine revolutionizes baluster production with its isosceles trapezoid structure and control system. Unlike conventional machines, it employs four synchronized cutting heads that simultaneously process multiple workpieces while maintaining perfect symmetry. The precise template tracking system ensures accurate replication, achieving dimensional tolerances within ±0.5mm even across complex profiles.

Fabricators using this technology report productivity increases of up to 300% compared to manual methods. A single operator can simultaneously manage multiple production lines after initial setup, drastically reducing labor costs. Material utilization improves by 15-20% through optimized cutting patterns, while rejection rates typically fall below 2% due to the consistent precision across all produced pieces.

The machine's intuitive interface allows even less experienced operators to achieve professional results after minimal training. Tool change operations are simplified through quick-release mechanisms, and the PLC control system stores multiple cutting profiles for rapid switching between production runs. Safety features include emergency stop buttons, optical safety barriers, and overload protection to ensure operator security.

Beyond technical specifications, this machine transforms businesses by enabling the consistent production of high-value architectural elements that command premium pricing. Fabricators can expand their product lines to include custom decorative balusters that were previously only available through labor-intensive handcrafting, opening new market opportunities in luxury residential and heritage restoration projects.

Marble > Columns & Capitals

|

|

|

Marble columns and capitals remain essential architectural elements in high-end construction, hospitality venues, and historical restoration projects. Traditional production methods involve extensive manual labor, resulting in inconsistent quality, high costs, and limited production capacity – challenges that significantly restrict market growth and profitability for stone fabricators.

The DINOSAW Vertical 4-Pillars Stone Cutting Machine employs advanced control technology specifically calibrated for producing complex column designs. The machine's trapezoid structure provides exceptional stability during the cutting process, virtually eliminating vibration-related flaws. Dual-axis movement enables the creation of intricate fluting, tapers, and entasis curves characteristic of classical orders, while achieving surface finishes that require minimal additional polishing.

Manufacturers report that column production time decreases by up to 75% compared to conventional methods. The machine can simultaneously process multiple column sections of varying diameters up to 220mm when working with four workpieces, or 300mm when operating in two-workpiece mode. This parallel processing dramatically increases throughput while maintaining dimensional accuracy within 0.3mm across repeated production runs.

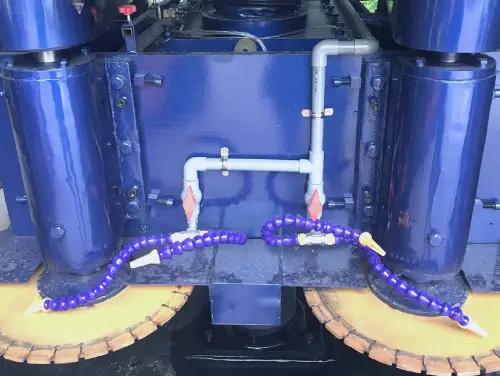

The system's efficient water cooling feature helps maintain optimal cutting conditions, making it environmentally responsible while ensuring quality results. The cooling system optimizes blade temperature for extended tool life, while the maintenance-friendly design ensures all mechanical components maintain peak performance with minimal service requirements.

The economic impact extends beyond production efficiencies. By enabling precise replication of historical column designs, the machine allows fabricators to compete for heritage restoration contracts previously limited to specialized artisans. The consistent quality and reduced lead times open new business opportunities in commercial construction, where scheduling precision is critical to project timelines and profitability.

Concrete > Decorative Roadblocks

|

|

|

Urban infrastructure and security barriers increasingly demand aesthetically pleasing solutions that blend functionality with architectural harmony. Decorative concrete roadblocks represent a growing market segment that requires both structural integrity and visual appeal. Traditional manufacturing methods struggle with the precision and consistency needed for mass production while maintaining decorative quality.

The DINOSAW Vertical 4-Pillars Stone Cutting Machine addresses these challenges with its specialized concrete processing capabilities. The machine's robust frame withstands the demanding requirements of dense concrete cutting, while its precision control systems enable the creation of complex security barriers with decorative profiles. The integrated dust extraction system maintains air quality during operation, extending component life while ensuring workplace safety.

Production advantages include 4-workpiece batch processing capability, ensuring dimensional consistency critical for interlocking security installations. The machine achieves production rates of up to 32 standard-sized decorative roadblocks per 8-hour shift, representing a 200% efficiency improvement over conventional methods while maintaining superior detail reproduction.

The system's versatility extends to handling various concrete formulations, including reinforced concrete and specialized architectural mixtures. Programmable cutting paths allow for consistent replication of municipal-specific designs, ensuring brand identity across city installations. The machine's quick-change tooling accommodates different profile requirements without extensive downtime, maximizing production flexibility.

Beyond manufacturing efficiency, the DINOSAW system opens new market opportunities by enabling municipalities and contractors to offer customized security solutions that complement urban design schemes. The ability to create cohesive architectural elements from functional barriers transforms utilitarian objects into design features, adding value through aesthetic integration while maintaining security performance.

Natural Stone > Garden Ornaments

|

|

|

The luxury landscaping and high-end garden ornament market continues to expand globally, with natural stone elements commanding premium prices. Traditional production of complex garden features such as vases and decorative planters has been largely artisanal, limiting production capacity and creating challenges in maintaining consistency across matched sets.

The DINOSAW Vertical 4-Pillars Stone Cutting Machine transforms garden ornament production through its specialized template-following capabilities. The precise template tracking system enables exact reproduction of complex ornamental designs. The machine's isosceles trapezoid structure provides exceptional stability during intricate cutting operations, delivering consistency impossible to achieve with manual methods.

Manufacturing efficiencies include simultaneous production of matched sets, with 4-workpiece capacity for small ornaments or two-workpiece capability for larger pieces processed in parallel. The synchronous lifting and left-right walking mechanisms ensure perfect alignment during complex cutting paths, essential for creating symmetrical ornamental features. Producers report production time reductions of 65-80% compared to traditional methods, with substantial improvements in surface finish quality.

The machine's adaptability extends to various natural stone types, from dense granite to more delicate limestone, with automatically adjusted cutting parameters optimizing results for each material. The water cooling system maintains clean cutting conditions for quality results. Tool wear is minimized through optimized speed and feed rate adjustment based on material characteristics.

The business impact for stone fabricators extends beyond production efficiency. The ability to consistently create high-quality matched ornamental sets allows companies to target the lucrative estate landscaping and luxury hotel markets. The precision and detail quality achievable with the DINOSAW system enable the reproduction of classical and contemporary designs that attract premium pricing, opening new revenue streams in the high-end landscape architecture sector.

Baluster Manufacturing

Enhancing Stone Balustrade Production Efficiency

A stone supplier using the DINOSAW 4-Workpiece Machine with PLC control increased output by 240% while reducing labor costs 60%. The automated template system ensures consistent symmetry across all balusters, eliminating matching issues and installation delays. This improved workflow quality and accelerated project timelines.

Decorative Vase Production

Precision Crafting for Slender Stone Vessels

A stone fabricator expanded into decorative products using the DINOSAW 4-Workpiece system with CNC control. They now produce elegant slender vases up to 1.2m tall with intricate profiles. The machine processes matching sets simultaneously, cutting production time by 65% while maintaining perfect dimensional consistency across all pieces.

Fountain Center Column Production

Creating Sophisticated Water Features with Precision

A landscape supplier implemented the DINOSAW 4-Workpiece system with PLC control to meet growing demand for fountain elements. They now efficiently produce decorative fountain columns up to 1.2m long with consistent water flow channels and precise details. Material waste decreased 22% while production capacity tripled.

Specs and options

Specifications customizable upon request.

| Model | Unit | LGFX - LS4 |

|---|---|---|

| Cutting length | mm | 200 - 1200 (Export type 1000) |

| Max.cutting diameter | mm | 300/2pcs、220/4pcs |

| Max.diameter of blade | mm | 440/470 |

| Main motor power | kw | 11/2 pcs |

| Total power | kw | 29.37 |

| Water consumption | m³/h | 3 |

| Approximate weight | t | 4.2 |

| Overall dimensions(LxWxH) | m | 2.4x2.2x2.75 (Export type) |

8-workpiece stone processing with one-click automation

Precision Stone Profiling with Maximum Efficiency

PLC/CNC Control System

Choose PLC or CNC systems for one-click setting and automatic cutting

Multi-Workpiece Processing

Process up to 8 workpieces simultaneously for small elements, boosting production output

Multi-Material Cutting

11kw×2 high-power spindles cut marble, granite, travertine, concrete and lightweight materials

Remote System Upgrade

OTA technology for remote updates, IoT connectivity, and online pattern library access

Versatile Shape Profiling

Create balusters, vases, columns, guide bars, handrails and decorative elements with one machine

Cast Iron Trapezoid Structure

Durable cast iron body with isosceles trapezoid design for stability and vibration reduction

Single-Operator Multi-Machine Control

Simple operation allows one operator to manage multiple machines, reducing labor needs

Safety Features

Emergency stop buttons and overload protection mechanisms for operator safety

FAQs

Common Questions About DINOSAW Baluster Profiling Machines

What is the maximum cutting capacity of the Vertical 4-Pillars Stone Cutting Machine?

Our Vertical 4-Workpiece Stone Cutting Machine offers flexible cutting capacities to meet various project needs. The standard configuration processes four workpieces simultaneously with diameters up to 220mm, or two workpieces with diameters up to 300mm.

For high-volume production, we offer a separate 8-Workpiece Baluster Profiling Machine designed specifically for mass production. The 4-Workpiece machine handles materials from 50mm to 1200mm in length, making it suitable for both small decorative elements and slender architectural components.

This flexibility lets fabricators optimize production based on batch requirements - choosing either higher volume with smaller pieces or larger dimensions with fewer pieces.

What products can be manufactured with this baluster profiling machine?

The DINOSAW Vertical 4-Workpiece Stone Cutting Machine creates revolving stone elements up to 1.2m long. It excels at producing balusters, handrail spindles, newel posts, slender vases, and fountain center columns.

The machine performs best with symmetrical profiles requiring consistent dimensions across multiple identical pieces. Its multi-workpiece capability makes it ideal for balustrade systems, stair components, fence posts, and thin ornamental elements that need precise contours.

Unlike larger column profiling machines, this equipment specializes in smaller diameter revolving elements with greater precision. For full-height columns, column bases/caps, or spherical elements, we recommend our specialized column profiling machines designed specifically for those applications.

How does the machine ensure precision and consistency across multiple pieces?

Our Vertical 4-Pillars Stone Cutting Machine achieves precision through several integrated systems. The patented isosceles trapezoid structure creates a stable foundation that reduces vibration, while synchronous lifting and walking mechanisms ensure alignment during complex cutting.

For template operations, the optical fiber probe system tracks templates with ±0.5mm accuracy. This system continuously monitors the cutting path and automatically adjusts blade position to maintain exact replication across all workpieces simultaneously.

With CNC control, pre-programmed cutting paths ensure consistent replication across production runs. The PLC system constantly monitors machine parameters, making adjustments to maintain dimensional consistency regardless of material variations. This approach ensures all pieces in a batch maintain uniform dimensions, essential for components like balusters that must match exactly when installed.

What is the warranty period and what kind of after-sales support is provided?

Our machine comes with a one-year warranty covering all mechanical and electrical components (excluding consumables like diamond blades). This warranty provides investment protection with quick response to any manufacturing defects or unexpected issues.

Our after-sales support extends throughout the entire lifecycle of your machine - not just during warranty. We offer lifetime technical support with a 24/7 technical team available for operational questions and troubleshooting. For internet-connected machines, we provide remote diagnostics, allowing our engineers to access your control system (with permission) to identify issues, adjust parameters, or update software without on-site visits.

For installation and training, we provide comprehensive video guides making setup straightforward. When needed, our engineers can travel to assist with installation, calibration, and operator training. With DINOSAW, you receive complete peace of mind with full lifecycle support that keeps your equipment operating at peak performance year after year.

How does the PLC or CNC control system work?

Our Vertical 4-Pillars Stone Cutting Machine offers a choice between PLC (Programmable Logic Controller) or CNC (Computer Numerical Control) systems, letting customers select the option that best fits their production needs.

The PLC system excels at template-following operations, tracking physical templates to reproduce designs. It's ideal for existing designs, custom one-off pieces, or working from physical models. The intuitive operation allows operators with limited technical background to quickly become proficient.

The CNC system uses programmed cutting paths designed in CAD/CAM software, perfect for consistent reproduction of standardized designs. It stores cutting profiles in memory for quick switching between product lines. G-code programming enables complex cutting operations difficult to achieve with templates alone.

Customers choose based on their production requirements - PLC for custom work with its simplicity and adaptability, or CNC for production runs with its precision and repeatability. This approach ensures the machine matches your specific manufacturing needs.

What's the difference between this Vertical 4-Workpiece Stone Cutting Machine and other profiling machines?

Our stone profiling equipment includes specialized machines for different applications. The Vertical 4-Workpiece Stone Cutting Machine excels at processing smaller revolving elements up to 1.2m long, including balusters, spindles, decorative vases, and fountain columns.

The Column Cup & Base Profiling Machine specializes in larger spherical elements, decorative caps, column bases, and large vases. Our Column Profiling Machine is designed for tall columns exceeding 1.2m, with specialized fixtures for safely handling extended workpieces.

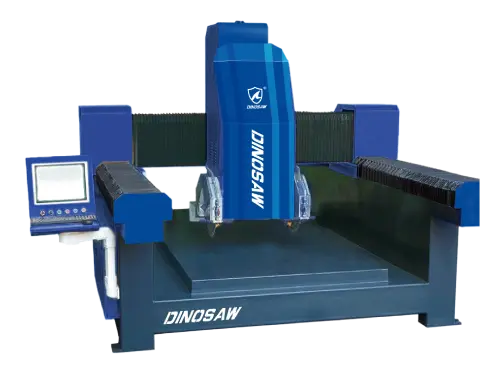

For high-volume production, we offer an 8-Workpiece Baluster Profiling Machine for mass production of small decorative elements (typically under 150mm diameter). Additionally, our Integrated CNC Bridge Profiling Machine creates square balusters, window frames, door casings, and decorative moldings in a single setup, combining cutting and grinding operations for finished products that require no manual refinishing.

What materials can be processed with the Vertical 4-Workpiece Stone Cutting Machine?

Our machine efficiently processes a wide range of materials including granite, marble, limestone, sandstone, travertine, engineered stone, terrazzo, and concrete. The powerful dual 11kW motors provide consistent cutting performance across these varied materials.

The cutting parameters can be easily adjusted based on material hardness and density, ensuring optimal results for each specific type. For harder materials like granite, the machine maintains precision while extending tool life through optimized cutting speeds. For softer materials like limestone or sandstone, the system prevents chipping and ensures clean edge finishes.

Additionally, the machine handles lightweight building materials effectively, making it versatile for various architectural and decorative applications. Water cooling systems are automatically adjusted based on material type to maintain ideal cutting conditions and maximize surface finish quality.

Certifications & Standards

Precision Stone Profiling with Maximum Efficiency

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Revolutionize Your Stone Baluster Production?

Boost your output 4X with the DINOSAW Vertical 4-Workpiece Stone Cutting Machine - precision meets efficiency

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Stone Profiling Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский