Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

Automatic Stone Drilling Machines for Stone Core Drill

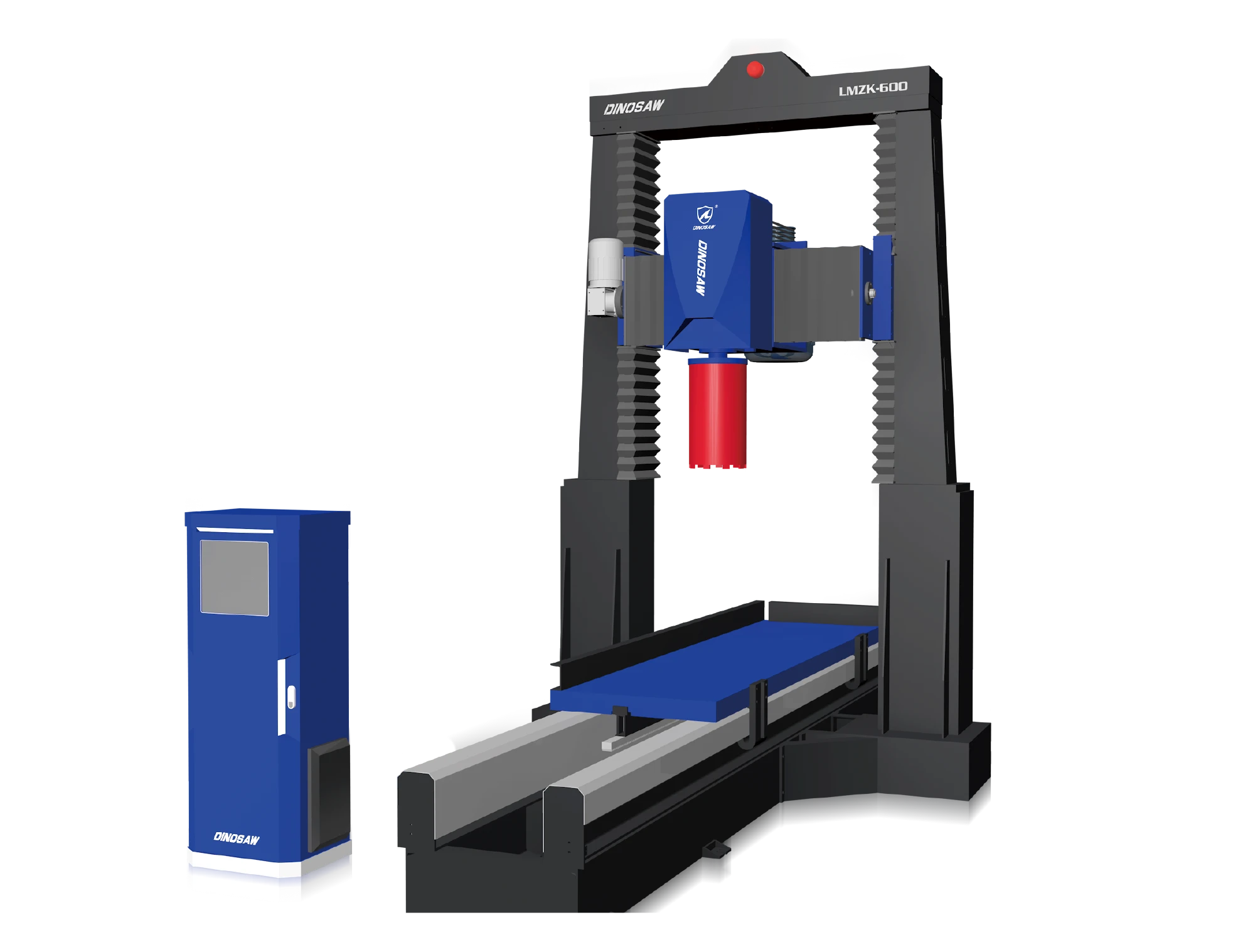

LMZK-600 / ZDZK-300

Compatible Materials & Products

Factory Stone Processing Solutions with 600mm Drilling Capacity

Granite > Columns, Balusters & Bollards

|

|---|

|

Granite, renowned for its durability and natural beauty, serves as the ideal material for columns, balusters, and security bollards in high-end architectural projects. Our stone drilling machines excel at creating precise cylindrical cores up to 600mm in diameter, essential for crafting elegant columns, decorative balusters, and sturdy bollards with perfect symmetry and structural integrity.

The diamond core drilling technology in our LMZK-600 machine penetrates granite with exceptional precision, creating clean, perfect cylindrical forms even in the densest varieties. For architectural columns, this means flawlessly shaped components with consistent dimensions throughout the entire length, ensuring proper load distribution and aesthetic consistency. The precise depth control up to 900mm ensures columns can be fabricated to exact specifications for various architectural applications.

With adjustable drilling speeds and advanced cooling systems, our granite dillers prevent overheating and maintain tool longevity while working with granite, reducing production costs and increasing output quality simultaneously. Architectural fabricators report 40% faster production time and significantly improved dimensional accuracy when creating cylindrical elements for luxury buildings, monuments, and high-end residential projects.

Marble > Vases & Bathtubs

Marble's elegant veining and luxurious appearance make it ideal for decorative vases and premium bathtubs. However, creating precise cylindrical voids and functional hollows in this delicate material presents unique drilling challenges that our machines are specifically designed to overcome.

Our marble drilling machines approach marble with the perfect balance of power and finesse. The PLC-controlled drilling process applies precisely calibrated pressure to prevent micro-fractures while creating perfectly cylindrical voids from 15mm to 300mm in diameter. This careful approach maintains the material's integrity around decorative vase interiors and bathtub cavities – critical areas where subpar drilling can lead to costly cracks and material failure. The ZDZK-300's precision allows artisans to create intricate vessel interiors while our LMZK-600 excels at the larger dimensions required for luxury bathtubs and soaking tubs.

Fabrication studios using our technology report significantly fewer material failures and enhanced production capabilities, translating to higher profit margins and expanded product offerings. The ability to precisely core marble for decorative vases and luxury bathtubs has opened new design possibilities previously unachievable with traditional methods, allowing manufacturers to create more intricate vases and ergonomically designed bathtubs with consistent wall thickness and exceptional structural integrity.

Blue Limestone > Urns & Memorial Products

Blue limestone has been valued for centuries for its unique color and texture, making it ideal for ceremonial and memorial products such as urns and ash containers. Creating these meaningful pieces requires drilling technology that respects both the material's properties and the cultural significance of the final products.

Our stone drilling machines excel at creating precisely formed urns and memorial products from blue limestone in factory settings. With capability to drill holes from 15mm to 600mm in diameter and depths up to 900mm, our equipment allows fabricators to efficiently produce rough-shaped ceremonial vessels that will later receive detailed carving and finishing. The precision positioning system ensures perfect symmetry and balanced wall thickness, critical for both aesthetic quality and structural integrity of these important pieces.

Memorial product manufacturers using our drilling technology report 45% faster production times when creating blue limestone urns and ash containers. The precision core drilling creates consistent interior cavities with uniform wall thickness, significantly reducing manual hollowing work while ensuring these ceremonial pieces maintain their structural integrity during the finishing process. This level of consistency is particularly valuable for memorial products where quality and durability are paramount considerations for honoring loved ones.

Engineered Stone > Planters & Fish Tanks

Engineered stone, with its consistent composition and exceptional durability, has become the material of choice for creating modern planters and fish tanks that combine aesthetics with functionality. Unlike natural stone, these quartz-based composites offer uniform density and predictable behavior during drilling operations, allowing for precise waterproof containers that maintain structural integrity even with constant water exposure. The non-porous nature of engineered stone makes it particularly suitable for aquatic applications where water retention is essential.

Our stone drilling machines excel at processing engineered stone with remarkable efficiency and precision. The PLC-controlled system adjusts drilling parameters specifically for the unique properties of resin-bound stone composites, preventing the micro-fractures and edge chipping that often occur with improper processing techniques. With capability to create cylindrical cores from 15mm to 300mm in diameter, our equipment produces perfectly formed planters and fish tanks with exceptional wall consistency. The variable speed control prevents overheating of the binding resins during drilling, maintaining the material's structural integrity and aesthetic appearance.

Manufacturers using our drilling technology for engineered stone products report 35% faster production cycles and significantly reduced material waste compared to conventional methods. The vibration-resistant design of our machines ensures clean, precise drilling even on large engineered stone panels, allowing fabricators to create custom garden features and aquarium components with intricate designs that command premium prices in the luxury outdoor and indoor decor markets. This precision drilling capability has opened new creative possibilities for designers working with engineered stone in landscape and aquatic applications.翻译:

Travertine > Stone Benches & Lanterns

Travertine, a natural limestone formed through mineral deposit in hot springs, offers a distinctive rustic appearance with its characteristic porous texture, making it ideal for creating elegant stone benches and decorative lanterns. The unique thermal resistance and weathering properties of travertine make it exceptionally well-suited for outdoor furniture elements that must withstand temperature fluctuations while maintaining their aesthetic appeal. When properly processed, travertine elements add a timeless, organic character to garden spaces and landscape architecture.

Our stone drilling machines address the unique challenges of travertine processing with specialized techniques. The natural voids and varying density of this limestone variety require precise control during drilling operations. The variable frequency drive in our equipment automatically adjusts cutting parameters in real-time, responding to density changes within the material to prevent structural weaknesses. For stone benches, our LMZK-600 creates precisely positioned mounting holes up to 600mm in diameter with clean edges, while for decorative lanterns, the ZDZK-300 excels at creating delicate interior cavities with the controlled precision needed for light diffusion effects.

Stone artisans specializing in travertine report that our drilling technology has revolutionized their craftsmanship capabilities, allowing them to create more complex and durable outdoor furniture pieces. Production efficiency for travertine lanterns has increased by 50%, with material breakage during processing reduced from 25% to just 4%. The precision hole formation enables the creation of elegant illumination features with sophisticated light patterns that showcase travertine's natural beauty. Additionally, stone benches produced with our drilling systems feature perfectly aligned structural connections that enhance longevity in outdoor installations while maintaining the authentic character that makes travertine a favorite among landscape designers.

▶ Product Demo

▶

▶

Granite Bollard Production

High-Volume Security Bollard Manufacturing

A commercial security provider used our ZDZK-300 for granite bollard production. Their manufacturing speed increased 60% when making security bollards for shopping centers and public spaces. This eliminated bottlenecks and met high-volume orders while maintaining structural integrity.

Decorative Stone Vase Production

Precision Interior Hollowing for Luxury Decor

A marble manufacturer added our ZDZK-300 to their vase production line. Hollowing precision improved to ±0.3mm - vital for expensive materials. Breakage dropped from 18% to 2%, boosting profits significantly. Each marble block represents a major investment, making precision essential.

Memorial Urn Production

Precision Crafting for Ceremonial Products

A memorial maker used our drilling technology for limestone urns. The machine created uniform wall thickness with minimal variance between products. This consistency was crucial for ceremonial items where quality matters, ensuring reliable quality for these culturally significant products.

Specs and options

Specifications customizable upon request.

| Model | Unit | LMZK - 600 | ZDZK - 300 |

|---|---|---|---|

| Max. Drilling Diameter | mm | 600 | 300 |

| Max. Drilling Depth | mm | 900 | 450 |

| Main Motor Power | kw | 22 | 7.5 |

| Overall Dimensions | mm | 2300×5500×3500 | 1300×800×2500 |

| Weight | t | 4.9 | 1.2 |

| LMZK - 600 | ZDZK - 300 |

|---|---|

|  |

Fast factory drilling for stone columns, vases, urns and decorative products

Precision Stone Drilling: 15-600mm Capacity for Factory Production

Simple One-Touch Operation

PLC system allows easy parameter setting and one-button automatic processing

High-Speed Drilling Performance

Equipped with 22kW high-power main motor for rapid drilling even in hard stone

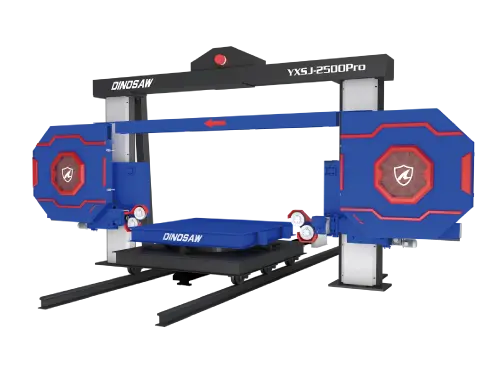

Stable Gantry Structure

Gantry design provides superior stability for large-diameter drilling and heavy stone

Multi-Material Adaptability

Frequency converter allows drilling speed adjustment according to material hardness

Easy Installation & Transport

Integrated compact structure for convenient transportation and simple setup

Quick Drill Bit Replacement

Optional quick-change adapter allows fast tightening and loosening, saving valuable time

FAQs

Common Questions About DINOSAW Stone Drilling Machines

What stones can a DINOSAW core drilling machine drill?

Our stone drilling machines effectively process both natural and engineered stone materials including:

• Natural stones: granite, marble, limestone, travertine, quartzite, soapstone, slate, and sandstone

• Engineered materials: quartz composites and porcelain slabs

Diamond core technology ensures clean, chip-free drilling even in hard stones like granite. The variable speed control and PLC system let operators optimize drilling parameters for each material type, preventing damage and ensuring perfect results regardless of stone hardness or composition.

Gantry vs vertical stone drilling machine - which is better?

The choice depends on your specific needs:

Gantry drilling machines:

• Best for: Large stone slabs and high-volume production

• Drilling capacity: LMZK-600 up to 600mm diameter, 900mm depth

• Advantages: Stable platform, precise positioning, multiple sequential holes

• Typical users: Large fabrication facilities with heavy workload

Vertical drilling machines:

• Best for: Smaller workshops and detail work

• Drilling capacity: ZDZK-300 up to 300mm diameter, 450mm depth

• Advantages: Compact footprint, easy setup, cost-effective

• Typical users: Small to medium workshops with space limitations

Both provide high precision, but production volume, available space, and application requirements should determine your choice.

What products can I make with a stone drilling machine?

Our stone drilling machines create rough-shaped products for various applications:

• From granite: Columns, balusters, and security bollards

• From marble: Decorative vases and luxury bathtubs

• From blue limestone: Ceremonial urns and memorial products

• From engineered stone: Planters and fish tanks

• From travertine: Stone benches and decorative lanterns

These machines create initial cylindrical forms with consistent wall thickness that serve as the foundation for finished products after additional processing. The precision drilling significantly reduces material waste and manual labor while ensuring high-quality results.

Does a stone drilling machine need water cooling?

Yes, water cooling is essential for four key reasons:

1. Prevents diamond bit overheating and extends tool life by up to 300%

2. Reduces dust for safer working conditions and better air quality

3. Flushes away debris to create cleaner, more precise holes

4. Improves overall cutting quality and efficiency

Our machines include integrated water cooling systems with adjustable flow based on material and drilling parameters. For environmentally conscious operations, we offer closed-loop water recycling systems that filter and reuse water, reducing consumption by up to 85%.

What to do when the drill bit gets stuck in stone?

When a drill bit gets stuck during operation, follow these steps:

1. Immediately stop the machine and cut power

2. Don't force rotation or apply excessive pressure as this may damage the machine

3. Apply small amounts of cooling water around the bit to reduce friction

4. Gently attempt reverse rotation at very low speed (if your machine has this function)

5. For persistent jams, use the emergency release system built into our machines

Most drilling jams occur due to improper speed settings, insufficient cooling, or material density variations. Our PLC-controlled machines feature automatic torque monitoring that detects resistance changes and adjusts drilling parameters to prevent most jamming situations before they occur.

How to reduce noise from stone drilling operations?

Controlling noise in stone drilling operations requires a multi-faceted approach:

• Equipment selection: Our machines feature noise-dampening technology that reduces operational noise by 15-20dB compared to standard models

• Proper installation: Mount machines on vibration-isolating pads to minimize structural noise transfer

• Enclosure options: Semi or fully enclosed drilling stations can reduce ambient noise by 25-30%

• Maintenance: Regular lubrication and part inspection prevents excess noise from worn components

• Operational techniques: Optimal drilling speeds and water flow reduce friction noise

For workshop environments requiring additional noise reduction, we can customize acoustic barrier solutions based on your specific needs. These custom solutions can help reduce noise levels to meet international workplace safety standards while maintaining production efficiency in your particular setting.

How to maintain a stone drilling machine?

Proper maintenance ensures maximum uptime and performance:

Daily tasks:

• Check and clean water filters and spray nozzles

• Inspect drill bits for wear and replace as needed

• Clear debris from work area and drilling surfaces

Weekly tasks:

• Lubricate all moving parts according to manual

• Check belt tensions and adjust if necessary

• Inspect all electrical connections

Monthly tasks:

• Perform thorough inspection of mechanical components • Verify calibration of positioning systems • Clean the entire coolant system Most components are easily accessible, and our machines include diagnostic systems that alert operators to potential issues before they cause downtime.

Certifications & Standards

Precision Stone Drilling: 15-600mm Capacity for Factory Production

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Revolutionize Your Stone Drilling Process?

Contact us today for a demonstration and discover how our drilling technology can transform your stone fabrication productivity.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Stone Drilling Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский