Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

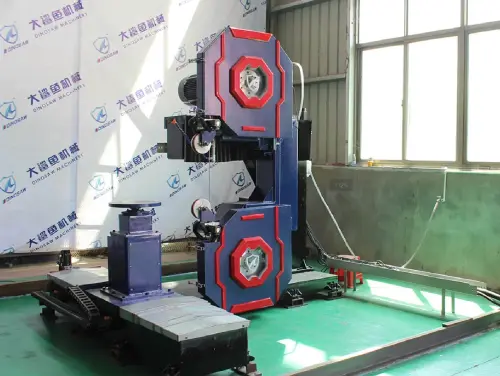

CNC Vertical Wire Saw Machine for High-Precision Cutting

LSSJ-800

Compatible Materials & Products

Precision Cutting Across Multiple Stone Materials for Premium Memorial Products

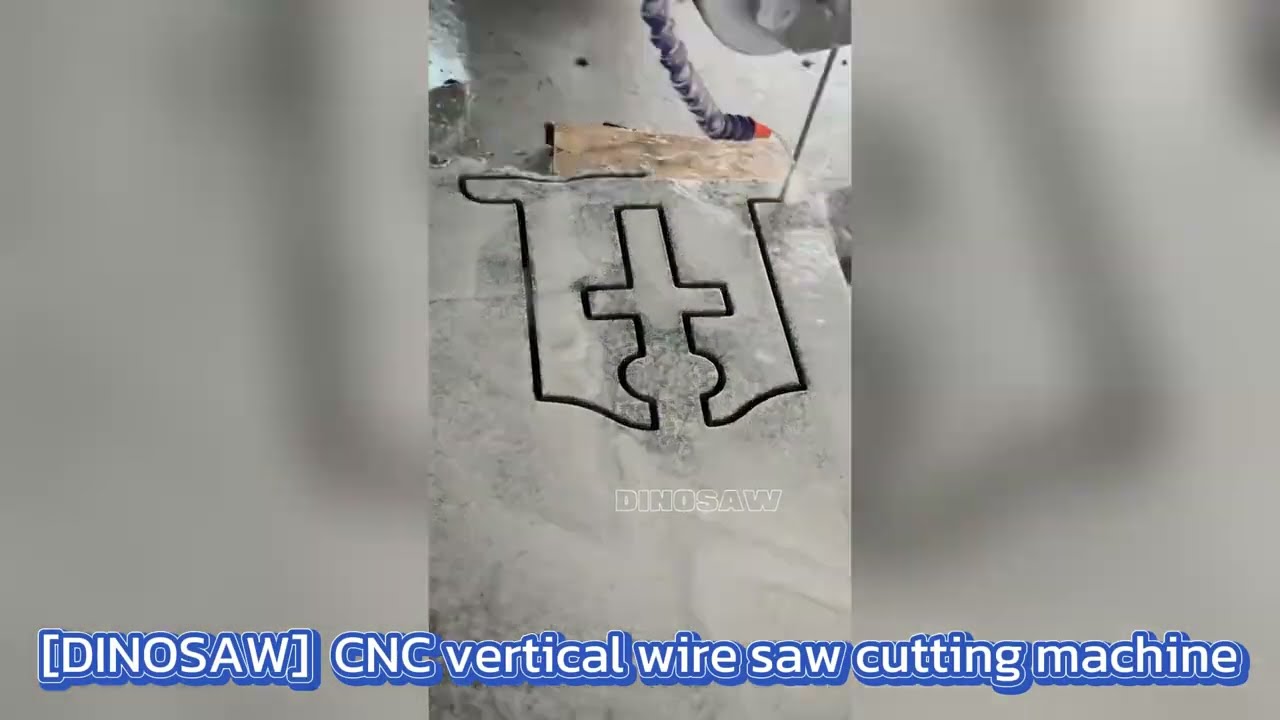

▶ Product Demo

▶

▶

|

|---|

| DINOSAW CNC Vertical Wire Saw Machine Video |

Granite ❯ Tombstones

|

|

|

| Granite Tombstone cutting with DINOSAW Vertical Wire Saw Machine |

This significantly reduces labor costs and production time while maintaining the highest quality standards essential for memorial stones. Monument makers achieve perfect straight cuts and custom shapes in a single efficient process, elevating craftsmanship while maintaining productivity.

Marble ❯ Crosses

|

|

|

| Marble's delicate beauty demands precision cutting to preserve its natural elegance. Our diamond wire saw provides the gentle yet accurate cutting action needed for religious memorial symbols like crosses. |

The machine's advanced speed control system adapts to marble's unique crystalline structure, preventing micro fractures while maintaining cutting efficiency. This ensures perfect edges and clean intersections essential for cross designs, where any imperfection would be immediately visible.

Craftsmen can confidently process valuable marble pieces with minimal material waste, preserving more of this precious stone while creating refined religious memorial products.

Granite ❯ Monuments

|

|

|

| Large-scale granite monuments require both precision and power for impressive results. Our diamond wire saw efficiently processes massive granite blocks into majestic memorial structures. |

The machine's robust cutting capability handles monumental-sized granite pieces while maintaining exact dimensional accuracy. Its specialized tension management system provides consistent cutting quality throughout the entire process, crucial when working with expensive, large-format stone that cannot be replaced if errors occur.

Monument manufacturers deliver imposing yet intricately detailed granite memorials that stand as lasting tributes for generations to come.

Basalt ❯ Decorative Elements

|

|

|

| Basalt's dark, distinctive appearance creates striking decorative elements for memorial installations. Our diamond wire saw precisely shapes this volcanic stone despite its exceptional hardness and density. |

The machine's powerful cutting system maintains consistent performance through basalt's homogeneous structure, producing exceptionally clean edges ideal for accent pieces and decorative inlays. Its precision control enables intricate cutting patterns that highlight basalt's unique visual character without compromising structural integrity.

Memorial designers incorporate these dramatic basalt elements to create visual contrast and architectural interest in sophisticated monument designs.

Italian Marble Tombstone Workshop

Doubling Production Capacity While Reducing Material Waste

A family-owned memorial workshop in Carrara, Italy upgraded to our vertical diamond wire saw, achieving 15% savings in expensive marble material costs and 45% reduction in cutting time. The precision system creates complex shapes with minimal kerf width.

The space-efficient design allowed installation without facility expansion, while eliminating the need for multiple specialized tools. Production capacity doubled within three months, with higher quality finishes requiring less secondary processing.

American Memorial Design Studio

Expanding Design Capabilities for Premium Client Demands

A monument manufacturer in Vermont, USA implemented our vertical diamond wire saw to handle complex custom designs that traditional methods couldn't fulfill. This unlocked the ability to create intricate curved shapes previously requiring outsourcing.

The precision control system executes sophisticated designs directly from CAD files, reducing production delays by 60%. Client satisfaction increased as the company delivered custom monuments with previously impossible design elements.

Brazilian Granite Monument Specialist

Achieving Intricate Natural Designs with Modern Efficiency

A premium memorial producer in Espírito Santo, Brazil transformed their workflow with our vertical diamond wire saw. It enables precision cutting of complex organic patterns and regional motifs while maintaining their renowned artistic quality.

The technology reduced labor costs by 35% and cut material waste in half. Production time for specialized curved elements decreased from 3 days to 7 hours, allowing more specialized orders and expansion of their premium product line.

Specs and options

Specifications customizable upon request.

| Model | Unit | LSSJ-1900-9H |

|---|---|---|

| flywheel | mm | 2x900 |

| Max.cutting height | mm | 800mm |

| Trimming diameter range | mm | 1600~1900mm |

| Wire diameter | mm | 4~8.8 |

| Main motor power | kw | 11 |

| Overall dimensions | m | 3.69x1.9x3.6 |

Discover why DINOSAW diamond wire saw is the ideal solution for stone memorial profiling.

Big Cutting Power, Small Footprint

5-Minute Quick Operation

Self-developed CNC control system, no programming required.

Double Cutting Efficiency

Industrial permanent magnet motor achieves 1.5㎡/h cutting speed for granite.

20% Energy Savings

High-efficiency permanent magnet synchronous motor.

Integrated Frame Design

Easy installation - simply secure the machine body to begin operation.

Remote Operation

OTA technology for remote updates and maintenance support.

Reduced Labor Costs

Smooth cutting surface eliminates the need for secondary polishing processes.

FAQs

Common Questions About Vertical Diamond Wire Saw Machines

What types of stone can this diamond wire saw machine cut?

Our vertical diamond wire saw efficiently cuts through granite, marble, limestone, basalt, quartz, and engineered stone. The machine's adjustable tension and speed controls allow optimal cutting parameters for each material type, ensuring clean cuts regardless of hardness or density.

For particularly abrasive materials like granite, we recommend our specialized wire saw options which maintain cutting efficiency while maximizing wire life.

How does a vertical wire saw differ from horizontal models?

Vertical diamond wire saw machines offer significant space advantages, requiring up to 40% less floor space than horizontal alternatives while maintaining the same cutting capacity. The vertical orientation also provides better visibility of the cutting process, allowing operators to monitor precision cuts more effectively.

What is the maximum cutting capacity of this machine?

Our standard vertical diamond wire saw models accommodate workpieces up to 1900mm × 1900mm × 800mm, though custom configurations can be engineered for larger requirements. For significantly larger workpieces, consider our horizontal diamond wire saw machines that offer expanded cutting capacity.

How long do diamond wires typically last?

Diamond wire lifespan varies based on material being cut, cutting parameters, and wire quality. To maximize wire life, our machine features an intelligent tension control system that automatically adjusts wire tension during operation, preventing excessive wear while maintaining cutting efficiency. Proper cooling and lubrication further extend wire life, with our built-in cooling system providing optimal wire protection during extended operations.

What maintenance does the machine require?

Our vertical diamond wire saw machines are designed for minimal maintenance requirements. Daily maintenance includes checking cooling fluid levels, cleaning the cutting area, and visual inspection of wire condition. Weekly maintenance involves lubricating guide components and checking belt tension.

Major servicing is only required every 2000 operating hours, including roller bearing inspection, control system diagnostics, and thorough cleaning of all components. The machine's modular design makes maintenance straightforward, with easily accessible service points and clear maintenance indicators in the control system.

Can this machine cut curved or irregular shapes?

Yes, creating curved and irregular shapes is one of the primary advantages of our diamond wire saw technology. The machine's programmable control system allows for precise execution of complex cutting paths, enabling both simple curved cuts and intricate profile shapes for decorative elements.

For complex designs, the CNC control system imports cutting paths directly from CAD files, ensuring perfect reproduction of even the most detailed designs. The system's precision allows maintaining tight tolerances throughout curved cuts, something traditional cutting methods cannot achieve with comparable accuracy or efficiency.

What power and installation requirements does the machine have?

We offer customizable voltage options for our machines with standard three-phase power (380V/50Hz or 220V/60Hz available). Power consumption is typically around 11kW for standard configurations. The machine's compact vertical design requires minimal floor space of 3.69m × 1.9m for the basic unit, with additional clearance recommended for material handling.

Our engineering team provides comprehensive installation guidance and on-site support to ensure optimal setup for your specific production environment, with particular attention to proper foundation preparation and electrical connection.

Certifications & Standards

Big Cutting Power, Small Footprint

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Transform Your Memorial Stone Production Today

Experience precision cutting with minimal waste and maximum efficiency. Our experts will customize the perfect solution for your specific needs.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский