Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

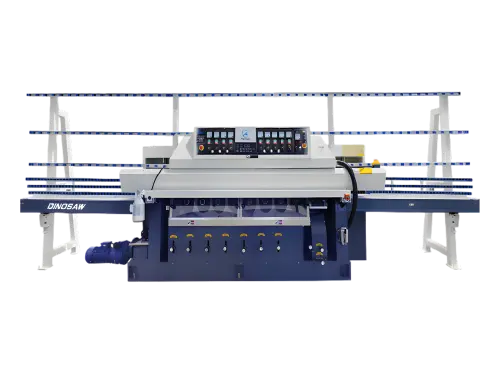

Thin Multi Wire Saw Machines for Natural Stone Block

DSY-XY3411/DSY-JS3411/DSY-XY3623/DSY-JS3623

Compatible Materials & Products

Transforming Premium Stone Materials into High-Value Finished Products

▶ Product Demo

▶

▶

Marble ❯ Ultra-thin Luxury Slabs

|

|

|

Premium marble varieties like Calacatta, Carrara, and Statuario represent the pinnacle of luxury stone applications. Their distinctive veining patterns and translucent properties make them highly sought after for elite interior projects and statement features.

Our multi-wire cutting machine excels with these materials, producing slabs as thin as 3mm with minimal kerf loss. The precision diamond wire technology reduces material waste by up to 35% compared to traditional gang saws, preserving more of these valuable resources while maintaining perfect surface quality.

The ultra-thin cutting capability opens new design possibilities including backlit features, furniture inlays, and book-matched wall panels where the natural veining creates mirror-image patterns across adjacent surfaces. Our 0.35mm diamond wire ensures clean, consistent cuts even through delicate areas.

Fabricators working with premium marble benefit from significantly improved yield rates, transforming standard blocks into more finished product with less waste. The precision surface quality also reduces polishing requirements, saving time and preserving the natural stone character.

Perfect for: Luxury hospitality feature walls, book-matched panels, translucent backlit installations, yacht interiors, designer furniture, and premium architectural details where material efficiency and aesthetic perfection are paramount.

Luxury Stone ❯ Large Background Walls

|

|

|

Luxury stones represent the pinnacle of natural elegance, featuring dramatic veining, unique coloration, and exceptional visual impact. These materials, including rare marbles, onyx, and semi-precious varieties, are increasingly sought after for large-format background walls in prestigious commercial and residential environments.

Our multi-wire cutting machine excels at producing oversized panels up to 3m×1.8m with consistent thickness and perfect edge quality. The diamond wire saw stone cutting technology maintains precise tension control throughout the entire cutting surface, eliminating edge chipping and ensuring uniform thickness across large dimensions essential for seamless installation.

The super thin multi-wire saw machine creates panels as thin as 5mm, reducing weight while maintaining structural integrity. This enables installation in applications where traditional thicker slabs would be impractical due to weight limitations. The reduced material volume also significantly improves cost-efficiency when working with these premium materials.

For luxury interior designers and architectural firms, these large-format background walls create breathtaking visual statements that showcase the stone's natural beauty across expansive surfaces. The book-matching capability enabled by precise cutting ensures continuous veining patterns across adjacent panels for truly spectacular installations.

Perfect for: Hotel lobbies, corporate headquarters, luxury retail environments, private residences, and exclusive hospitality venues where dramatic stone features create unforgettable impressions and elevate the overall design aesthetic to new levels of sophistication.

Premium Jade ❯ High-Value Stone Slabs

|

|

|

Premium jade represents one of the most culturally significant and valuable stone materials in the world. These rare, semi-precious stones feature distinctive colors ranging from vibrant greens to whites, lavenders, and blacks, with exceptional translucency and structural density that have made them prized throughout history.

Processing jade requires extraordinary precision due to its exceptional value and distinctive material properties. Our diamond wire saw stone cutting technology achieves material yield improvements of 40-50% compared to traditional methods, transforming more of these precious resources into finished products while preserving their natural beauty and integrity.

The multi-wire cutting machine delivers consistent 4-8mm slabs with exceptional surface quality, minimizing the need for extensive finishing processes that could compromise the stone's value. Our AI-powered Smart Recipe system automatically adjusts cutting parameters based on the specific characteristics of each jade block, ensuring optimal results even with material variations.

For specialty stone processors working with these high-value materials, our technology provides unprecedented control and efficiency. The precision cutting process preserves more of the natural material while ensuring consistent quality, significantly improving profitability when working with stones that can command thousands of dollars per kilogram.

Perfect for: Museum-quality installations, luxury residential features, high-end commercial spaces, cultural monuments, and exclusive decorative elements where the natural beauty and cultural significance of jade create distinctive focal points of exceptional value and meaning.

Rare Stone ❯ Exclusive Architectural Panels

|

|

|

Rare and exotic stone varieties represent the ultimate expression of natural luxury in architectural applications. These exceptional materials, including Azul Bahia, Sodalite, Blue Louise, and Patagonia, feature dramatic colors and patterns that occur in extremely limited quantities, making them highly coveted for exclusive architectural installations.

Our multi-wire saw technology provides unparalleled precision when processing these irreplaceable materials. The diamond wire cutting process significantly reduces kerf width to as little as 0.5mm, compared to 4-5mm with traditional gang saws. This precision translates directly into material yield improvements of 35-45%, preserving more of these valuable resources.

The super thin multi-wire saw machine's advanced tension control system automatically adjusts to variations in material density and structure, preventing breakage while maintaining optimal cutting efficiency. This adaptive capability ensures consistent results even with the irregular crystalline structures often found in rare stone varieties, delivering panels with perfect dimensional consistency.

For architects and designers working with these exceptional materials, our technology enables the creation of distinctive architectural elements that showcase the stone's natural beauty while maximizing material utilization. The precise cutting capability allows for the creation of complex shapes and perfectly matched panels for truly one-of-a-kind installations.

Perfect for: Signature architectural features, exclusive residential projects, luxury hospitality environments, high-end retail spaces, and prestigious commercial installations where these rare materials create distinctive design statements that cannot be replicated with more common stone varieties.

Premium Marble Processing in Italy

35% Higher Yield with Diamond Multi-Wire Technology

A leading stone processor in Carrara, Italy struggled with material waste when cutting premium Calacatta marble blocks. After implementing DINOSAW multi-wire saw with 0.35mm diamond wires, they increased slab yield by 35%.

Luxury Background Wall Production

Ultra-Thin Cutting Excellence for Middle East Projects

A high-end stone supplier in Dubai faced significant challenges producing large-format thin stone panels for luxury hotel background walls. Traditional cutting methods resulted in breakage and inconsistent thickness. DINOSAW multi-wire saw achieved consistent 5mm cuts at dimensions up to 3m×1.8m.

Rare Stone Processing in the USA

40% Material Yield Improvement for Exclusive Markets

A premium stone processor in Vermont specialized in rare materials like Blue Bahia and Sodalite faced 55% waste using conventional saws. After implementing DINOSAW's Multi-Wire Saw with the AI-powered "Smart Recipe" profile, they achieved consistent 6mm cuts with perfect edge quality.

Specs and options

Specifications customizable upon request.

| Model | Unit | DSY-XY3411 | DSY-JS3411 | DSY-XY3623 | DSY-JS3623 |

|---|---|---|---|---|---|

| Feed Type | / | downward pressing | up lifting | downward pressing | up lifting |

| Cutting Feed Rate | mm/h | 0 - 180 | 0 - 180 | 0 - 200 | 0 - 200 |

| Diamond Wire Diameter | mm | 0.35 - 0.8 | 0.35 - 0.8 | 0.35 - 0.8 | 0.35 - 0.8 |

| Cutting Thickness | mm | 5 ~ 30 | 5 ~ 30 | 5 ~ 30 | 5 ~ 30 |

| Cutting Tension | N | 0 - 250 | 0 - 350 | 0 - 250 | 0 - 350 |

| Worktable Vertical Travel | m | 2400 | 2400 | 2400 | 2400 |

| Wire Storage Capacity | m | 30000 | 30000 | 30000 | 30000 |

| Roller | mm | 320~450 | 320~450 | 320~450 | 320~450 |

| Main Motor Power | KW | 60x4 | 60x4 | 60x4 | 60x4 |

| Processing Dimensions(L×W×H) | mm | 3400x1100x2200 | 3400x1100x2200 | 3400x2000x2200 | 3400x2000x2200 |

| Machine Weight | T | 30~35 | 30~35 | 35~40 | 35~40 |

| Overall dimensions (L x W x H) | m | ≈8.9x6.4x5.3 | ≈8.9x6.4x5.3 | ≈9.2x7.5x5.3 | ≈9.2x7.5x5.3 |

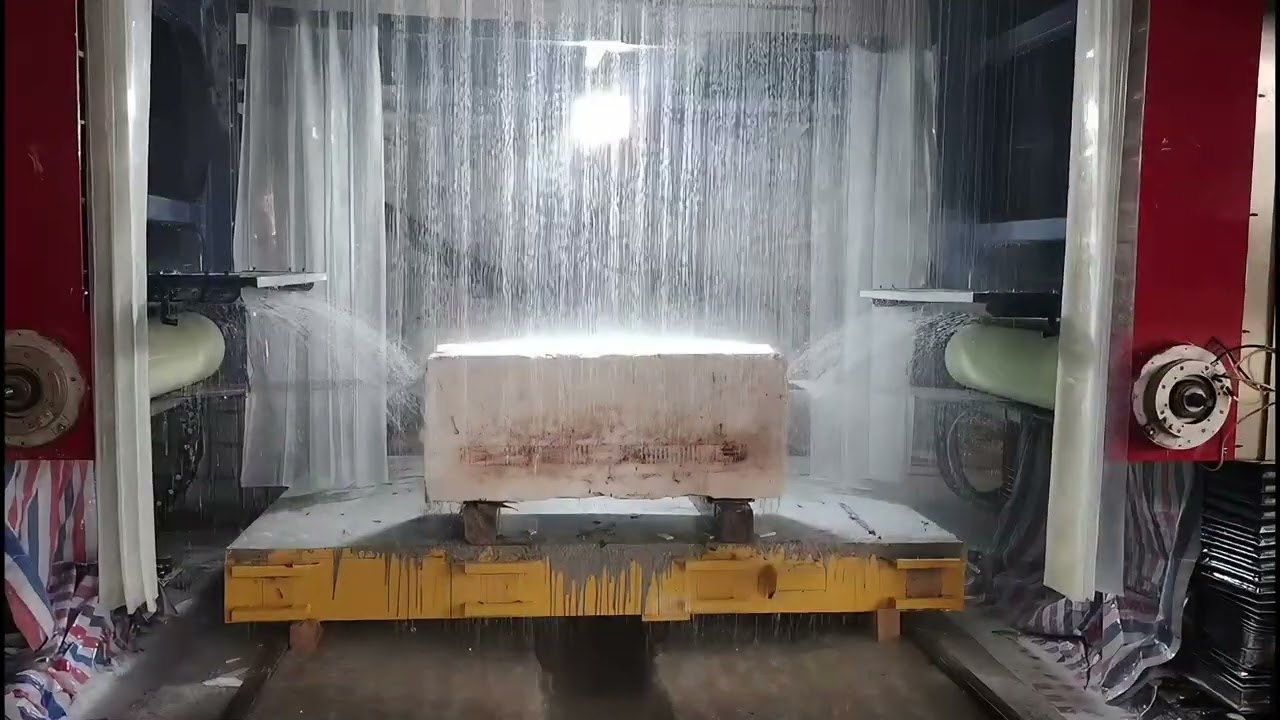

Diamond Wires Transform Stone Blocks into Ultra-Thin Slabs

Transform Premium Stone into Maximum Profit

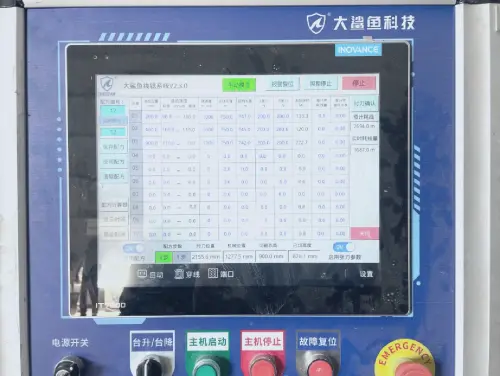

5-Minute AI Operation

CNC system with AI cutting library auto-recommends optimal parameters for one-click operation.

3mm Ultra-Thin Slab Cutting

Low vibration system prevents edge chipping and breakage, enabling thin cuts on delicate stone.

97% Material Yield

Narrow diamond wire reduces kerf width, maximizing slab output from each stone block.

High-Speed Cutting

Advanced 3S quick start-stop system with 42m/s high-speed cutting

Precision Control

Siemens servo motors provide precise tension control with ±1N, ensuring consistent cutting quality.

Tension Feedback Safety System

Adaptive cutting speed based on tension feedback minimizes wire breakage risk during operation.

Quiet Operation

Advanced noise design creates a quieter workshop under 75dB, improving worker comfort and safety.

20% Energy Saving System

Energy recovery system converts braking energy back to electricity, reducing operating costs.

Eco-friendly Production

Filtration system reduces cutting slurry and wastewater by over 80%

FAQs

Common Questions About DINOSAW Thin Multi-Wire Saw Machines

What are the main advantages of a multi-wire saw over traditional gang saws?

Multi-wire saw machines offer six significant advantages over traditional gang saws.

1. Higher material yield (10%-25% increase) - when cutting 1.75cm thick slabs, gang saws produce 47m² per cubic meter while multi-wire saws yield 55m².

2. Environmental performance with 80% reduction in wastewater and residue.

3. Lower energy and material consumption, with 50% noise reduction.

4. Smaller footprint - 30% less floor space and 80% lower foundation costs.

5. Ultra-thin processing capability, directly cutting 3mm slabs without secondary splitting.

6. Excellent operational stability with minimal vibration, eliminating breakage risk and producing highly flat surfaces.

These advantages make multi-wire saws an efficient, eco-friendly, and economical choice for the stone processing industry.

What types of stones can be processed with multi-wire saw machines?

DINOSAW multi-wire saw machines can effectively process five major categories of stone materials:

1. Luxury Marble: Calacatta Gold, Statuario Venato, Carrara White, Emperador Dark, Thassos White

2. Premium Onyx: Blue Onyx, Green Onyx, Honey Onyx, White Onyx, Red Onyx

3. Rare Quartzite: Azul Macaubas, Super White, Sea Pearl, Arctic White, Silver Cloud

4. High-grade Granite: Blue Bahia, Sodalite Blue, Kashmir White, Black Galaxy, Imperial Red

5. Industrial Hard Materials: Single Crystal Silicon, Silicon Carbide Ceramics, Graphite Blocks,Industrial Ceramics, Engineered Quartz

Each stone category requires specific cutting parameters that our machines automatically optimize through the CNC control system. From the softest marble to the hardest industrial materials, DINOSAW multi-wire technology delivers superior cutting precision with minimal waste across all stone types.

How thin can slabs be cut with DINOSAW multi-wire saw machines?

DINOSAW multi-wire saw machines cut ultra-thin 3mm slabs consistently, even with delicate luxury stones like onyx and marble.

Our exclusive dual-stage tension system makes this possible: first applying gentle tension to prevent flexing, then making precise adjustments during cutting. The machine's solid frame and vibration control create stable cutting conditions, while our "Thin-Slab" smart profile automatically adjusts parameters for optimal results. For harder materials like granite, minimum practical thickness is typically 5-8mm depending on the specific stone characteristics.

What is the difference between DINOSAW's Up-Feed and Down-Feed configurations?

Down-Feed Configuration (DSY-XY Series):

- Mechanism: Wire system presses downward through the stone block

- Advantages: Superior stability for large blocks, reduced wire vibration

- Ideal For: Large granite blocks, dense quartzites, maximum stability requirements

Up-Feed Configuration (DSY-JS Series):

- Mechanism: Stone block is lifted upward into the cutting wire system

- Advantages: Better cooling efficiency, easier slab removal, reduced power consumption

- Ideal For: Marble, onyx, and softer materials where precise cooling is critical

How does DINOSAW ensure consistent cutting quality?

Our diamond wire saw stone cutting systems incorporate multiple technologies:

Precision Control Systems:

- Siemens Servo Motors with ±1N accuracy

- Real-time tension feedback and automatic adjustment

- Variable cutting speed based on material resistance

AI-Powered Optimization:

- Smart Recipe System for optimal cutting parameters

- Material-specific profiles with learning capability

- Historical data analysis for continuous improvement

Advanced Cooling and Quality Assurance:

- Precision cooling system with temperature monitoring

- Continuous self-diagnostics and wire wear monitoring

- Production data logging for quality tracking

How can wire breakage issues be minimized during operation?

Common Causes:

- Excessive tension beyond recommended limits

- Improper feed rate through hard materials

- Inadequate cooling causing overheating

- Pulley misalignment and material inclusions

DINOSAW Technical Solutions:

- Real-time tension feedback system

- Adaptive cutting speed based on material resistance

- AI-based Smart Recipe parameter optimization

- 3S Quick Start-Stop system reducing wire stress

Best Practices:

- Material assessment before cutting

- Progressive engagement with gradual parameter increase

- Consistent cooling throughout process

- Regular wire inspection and parameter logging

Diamond Wire Break-In Procedure:

- Install according to manufacturer guidelines

- Begin with 50% of normal operating tension

- Use 60% of standard feed rate for first 0.5m²

- Gradually increase to normal parameters over next 1m²

- Monitor and adjust as needed

Certifications & Standards

Transform Premium Stone into Maximum Profit

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Revolutionize Your Stone Cutting Efficiency?

Contact DINOSAW today for a personalized consultation and discover how our multi-wire saw technology can transform your production.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский