Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

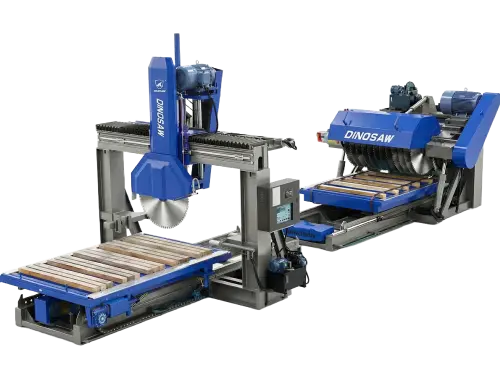

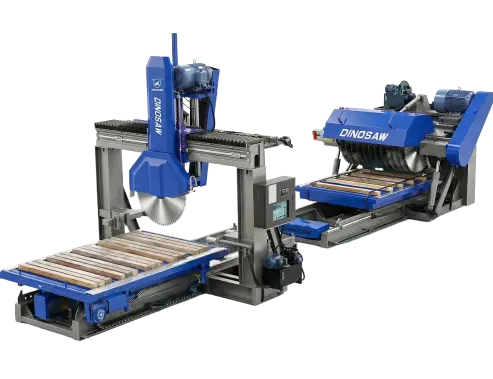

Automatic Curbstone Cutting Machine | Kerbs Production Line

LYFP-1200 & LYQB-1200

Compatible Materials & Products

Advanced Curbstone and Kerbstone Cutting Solutions for Urban Infrastructure

Granite > Urban Road Curbstones

|

|

|

Granite curbstones represent the gold standard for urban road infrastructure, offering unmatched durability for high-traffic municipal applications. Their dense crystalline structure withstands decades of weathering, heavy loads, and vehicle impacts, making them ideal for busy city streets and highways where replacement costs are prohibitive. This exceptional longevity delivers lifetime infrastructure cost savings of 35-45% compared to alternative materials.

Municipal engineers specifically choose granite for its proven 50+ year service life in harsh urban environments. Its resistance to freeze-thaw cycles, deicing chemicals, and constant vehicle impacts provides critical performance advantages where road safety and longevity intersect. The minimal edge degradation even after decades of snow plow contact preserves crosswalk alignments and water drainage profiles, key factors in urban planning regulations.

Our production system's precision cutting ensures the dimensional consistency required by municipal specifications, typically ±0.5mm tolerances across thousands of linear feet. This precision eliminates the costly on-site adjustments that plague less accurately manufactured curbstones. The smooth, flat surfaces and perfect 90° edges create tight-fitting joints that prevent water infiltration, extending pavement life and reducing maintenance costs.

Contractors appreciate the reduced installation time resulting from our granite curbstones' consistent dimensions and square edges. The reduced need for field adjustments accelerates project timelines while decreasing labor costs. For city planners, the combination of premium appearance, exceptional durability, and reduced lifecycle costs makes our precision-cut granite curbstones the financially responsible choice for urban infrastructure designed to last generations.

Concrete > Simple Straight Curbs

|

|

|

|

Concrete straight curbs deliver exceptional cost-effectiveness for large-scale infrastructure projects, offering the ideal balance of performance, durability, and budget efficiency. These versatile elements form the backbone of municipal projects, parking areas, and residential developments where maximizing taxpayer or investor value is paramount. At 40-50% lower material cost than natural stone alternatives, concrete curbs provide the responsible economic choice for volume-intensive applications.

Project managers select concrete curbs specifically for their favorable cost-to-performance ratio and production scalability. The homogeneous composition ensures consistent quality across massive production runs, critical for developments requiring thousands of linear feet of identical curbing. For parking facilities, retail developments, and planned communities, this material provides predictable performance at controlled costs, simplifying both budgeting and installation planning. Our production process enhances concrete's natural advantages through precision manufacturing. The computer-controlled cutting system ensures dimensional consistency within ±1mm across entire production batches, creating perfectly uniform units that accelerate installation.

Our equipment's vibration dampening technology prevents microcracking during fabrication, a common issue with conventional concrete cutting that can compromise longevity, especially in freeze-thaw environments. Contractors report installation efficiency improvements of 30-40% with our precision-cut concrete curbs compared to site-cast or traditionally manufactured alternatives. The consistent dimensions eliminate time-consuming field adjustments, while the perfectly square corners create professional-looking joints that enhance project appearance.

For municipal projects operating under strict budgets and timelines, these efficiencies translate directly to taxpayer savings while maintaining excellent quality standards. The combination of initial affordability and long-term performance makes our concrete curbs the economically sound choice for infrastructure development.

Cast Stone Brick > Pavers

|

|

|

Cast stone bricks create attractive, consistent walkways that enhance residential community aesthetics while offering homeowners practical, low-maintenance pedestrian pathways. These engineered materials combine the visual appeal of natural stone with manufactured precision, providing developers with cost-effective alternatives that don't compromise on appearance or durability.

Their uniform texture and consistent coloration create visually harmonious residential environments that maintain their appearance through seasonal weather changes. Residential developers choose cast stone for its balance of aesthetics, walkability, and installation efficiency. The precise dimensional consistency simplifies installation while reducing labor costs – critical advantages in competitive housing markets where both construction efficiency and final appearance affect profitability. These materials enhance neighborhood character and create defined pedestrian zones that improve community functionality while increasing property marketability.

Our production technology provides residential contractors with cast stone pavers of exceptional dimensional precision. The ±0.5mm tolerances across all dimensions create tight-fitting installations that minimize weed growth between units – a significant maintenance advantage appreciated by homeowners and property managers. The precisely squared corners and smooth cut surfaces allow for faster installation with reduced skill requirements, helping builders complete projects on schedule even with labor shortages.

Homeowners benefit from the resulting walkways through enhanced property value and reduced maintenance requirements. The stable, even surfaces provide safe pedestrian paths for all age groups, while the dimensional consistency prevents trip hazards from developing over time. With proper installation, these precision-cut cast stone walkways maintain their appearance and functionality for decades, providing excellent return on investment through reduced lifecycle costs and continued aesthetic appeal. For residential developers focused on delivering both immediate value and long-term homeowner satisfaction, our cast stone products offer the ideal combination of beauty, practicality, and affordability.

Basalt > Borders

|

|

|

Basalt borders deliver exceptional durability in industrial environments where extreme conditions would quickly deteriorate conventional materials. This igneous stone's dense molecular structure provides remarkable resistance to chemical corrosion, heavy vehicle traffic, and temperature fluctuations, making it ideal for manufacturing facilities, industrial parks, and heavy logistics areas. Its naturally dark appearance maintains a professional aesthetic even under constant exposure to industrial contaminants, while its extraordinary compressive strength exceeds 300 MPa – supporting the heaviest operational loads.

Industrial engineers specify basalt specifically for high-stress boundaries between operational zones and traffic corridors where safety and longevity are paramount. Its superior abrasion resistance withstands constant heavy equipment movement, while its chemical stability prevents deterioration even when exposed to industrial solvents, oils, and mild acids common in manufacturing environments. The non-porous nature prevents absorption of contaminants, simplifying cleaning protocols in regulated industrial settings.

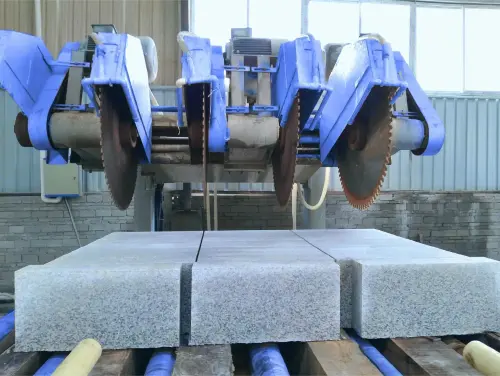

Our curbstone production line processes basalt with exceptional precision despite its extreme hardness. The LYFP-1200 slicing machine with 12 diamond blades operating simultaneously cuts through basalt's dense structure with calibrated feed rates that prevent blade overheating. The hydraulic material transport system smoothly transfers cut sections to the LYQB-1200 edge cutting machine, where the 55kw motor powers through final dimensioning with the precision required for industrial applications. Industrial contractors achieve significant installation and maintenance advantages through our precision-manufactured basalt borders.

The dimensional consistency (±0.5mm tolerances) eliminates time-consuming field adjustments during installation in large industrial facilities. The perfect 90° edges create clean, professional demarcations between different operational zones while withstanding impacts from heavy equipment. With 50+ year performance expectancy even in harsh industrial environments, these borders deliver exceptional lifetime value while maintaining clear safety boundaries that meet industrial compliance requirements.

Limestone > Landscape Curbing

|

|

|

Limestone landscape curbing brings natural harmony to designed outdoor spaces, offering warm, earthy tones that integrate seamlessly with surrounding plantings and architectural elements. Its subtle texture and inviting appearance make it particularly suitable for parks, gardens, and residential landscaping where environmental cohesion takes precedence over industrial durability. This natural material develops a distinctive patina over time, creating landscape borders that appear increasingly integrated with their surroundings – a living quality synthetic alternatives cannot replicate.

Landscape architects specify limestone specifically for its balanced hardness and workability. Softer than granite yet more durable than sandstone, limestone strikes the ideal middle ground for applications where natural aesthetics must be balanced with practical longevity. Its neutral color palette complements both traditional and contemporary landscape designs, providing definition without visual disruption. This versatility makes limestone the preferred material for creating garden borders that enhance rather than dominate carefully composed outdoor spaces.

Our production process preserves limestone's natural characteristics while ensuring dimensional precision. Unlike conventional cutting methods that can damage stone edges, our technology produces clean, consistent cuts that highlight limestone's natural beauty. The system's calibrated cutting speeds prevent the edge chipping common with this material, delivering landscape elements with the refined appearance sophisticated projects demand.

Landscape contractors benefit from our limestone curbing through simplified installation and enhanced project aesthetics. The precision-cut dimensions allow for tight-fitting joints that prevent soil erosion between sections – a particular advantage in sloped garden applications. The consistency of each piece accelerates installation while ensuring the fluid, continuous lines essential to successful landscape design. For premium residential and commercial landscapes where material authenticity and installation quality directly affect client satisfaction, our limestone curbing provides the perfect combination of natural beauty, dimensional accuracy, and practical performance.

Residential Community Project

Stone Processing for Residential Pathways and Borders

Green Valley Homes achieved 32m³ daily production using our cutting line, fabricating three residential stone products: driveway entrance curbstones, walkway pavers, and garden borders. These products were installed throughout their 500-unit residential community, creating pathways and property boundaries.

Industrial Zone Construction

Heavy-Duty Basalt Cutting for Continuous Stone Fabrication

Industrial Stone Corp operates our cutting line with one operator managing the entire process. This reduced workforce by 70% while increasing output. The system processes basalt borders continuously with hydraulic pushers ensuring precise dimensions in 24/7 operation.

Specs and options

Specifications customizable upon request.

| Machine | Curbstone Slicing Machine | Curbstone Edge Cutting Machine |

|---|---|---|

| Model | LYFP - 1200 | LYQB - 1200 |

| Dimension | 5500×4000×4500mm | 5500×2300×2500mm |

| Diameter of blade | 1200mm | 1200mm |

| Number of blades | 12pcs | 1pcs |

| Max.cutting size | 2500×1800×450mm | 2500×1800×450mm |

| Worktable size | 2500×1800mm | 2500×1800mm |

| Weight | 9t | 10t |

| Main motor power | 22kw | 55-75kw |

Chamfering Machine Integration: For customers requiring chamfered curbstones, our optional chamfering machine can be integrated into this production line. The chamfering unit connects seamlessly with the existing workflow, adding precision edge beveling capabilities while maintaining the automated material handling throughout the production process.

Engineered for batch processing and fully automated roadside stone production

High-Volume Automated Curbstone Production with Maximum Efficiency

Boost Daily Output

30-35m³ daily output with dual-machine system. Continuous operation maximizes production capacity

Cut Labor Costs

One operator manages entire line vs 3-4 workers. Automated transport eliminates manual handling

Consistent Quality Without Skilled Labor

Precise dimensions through hydraulic positioning and automated measurement regardless of operator skill

Operate From Anywhere

Control operations remotely with integrated PLC system for improved workplace safety and flexibility

Reduce Blade Costs by 40%

3-5mm precision cutting depth extends diamond blade life, reducing consumable costs by 40%

Maximize Your Workshop Space

High production capacity in compact 12×5m footprint. Saves valuable workshop space for other operations

Minimize Downtime & Maintenance

Premium components from trusted brands ensure reliable performance with minimal maintenance requirements

FAQs

Frequently Asked Questions About Curbs/Kerbs Cutting Machines

What makes this curbstone cutting production line different from competitors?

Our curbstone cutting production line stands out with two key advantages: high-volume batch processing and full automation. The integrated dual-machine system features:

• Slicing Machine (LYFP-1200): Uses 12 diamond blades simultaneously with laser positioning for precision width cutting

• Edge Cutting Machine (LYQB-1200): Uses 1 precision blade with automated measuring for accurate length determination

• Automated Transport: Hydraulic roller system connects both machines

• Advanced Controls: Touchscreen PLC control system with real-time cutting data feedback

This continuous workflow achieves 30-35m³ daily production with just one operator, eliminating multiple manual handling steps required by competitors' single-machine solutions. The simplified operation, foundation-free installation and compact 12×5m footprint make this the most efficient straight curbstone production system available.

How long does the curbstone cutting machine installation and setup typically take?

Installation is rapid due to our all-in-one design requiring no foundation work. Complete setup typically takes just 1 day, compared to traditional systems requiring concrete foundations that need 3-5 days. The installation process includes:

• Equipment Positioning: Precise placement of slicing (LYFP-1200) and edge cutting machines (LYQB-1200)

• Electrical Connections: Connecting power systems for slicing (22kw) and edge cutting (55-75kw) machines

• Water Supply Setup: Installation of cooling and lubrication systems

• Operator Training: Complete equipment operation and maintenance guidance

Our technical team provides on-site support to ensure optimal configuration for your specific production needs. The foundation-free design also means you can easily reposition the equipment if your facility layout changes.

What stone types can your roadside stone cutting equipment process?

Our kerbstone cutting line handles all common stone types including granite, marble, sandstone, basalt, limestone, and quartzite, as well as concrete, cement, and lightweight building materials like Cast Stone Brick.

The dual-plate trolley with precision positioning can process two blocks simultaneously, with each plate supporting up to 800kg. The heavy-duty spindle design ensures consistent results across all materials from soft sandstone to extremely hard quartzite and various concrete products.

What are the daily production capacity and efficiency rates of your curbstone cutting line?

Our curbstone cutting production line achieves 30-35m³ daily output in 24-hour operation. This high productivity comes from:

• Multi-blade Configuration: 12 blades on slicing machine (LYFP-1200)

• Precision Edge Cutting: Single 1200mm blade on edge cutting machine (LYQB-1200)

• Powerful Motors: 22kw (slicing) and 55-75kw (edge cutting)

• Automated Material Handling: Eliminates downtime between operations

The automated feed system and precision positioning controls minimize downtime between cuts, maintaining consistent production rates throughout extended operations.

What maintenance requirements and operating costs should I expect?

Maintenance requirements are minimal due to robust construction and quality components:

• Daily Maintenance: Blade inspections, lubrication checks, cooling system monitoring

• Weekly Maintenance: Hydraulic system checks and component cleaning

• Extended Component Life: Heat-treated spindle and cast iron structure significantly increase durability

• Reduced Operating Costs: Lower energy consumption, single-operator design, optimized cutting parameters

• Cost Savings: Most customers report 40-60% lower operating costs compared to traditional cutting methods

What makes your curbstone cutting machine suitable for different applications?

Our curbstone cutting production line is designed for high-volume straight cutting applications across various materials:

• Specialized Application: Precisely dimensioned straight curbstones, pavers, and borders

• Target Markets: Urban infrastructure, commercial plazas, residential developments

• Adaptability: Adjustable cutting parameters for different stone hardness and dimensional requirements

• Limitations: Does not perform angle cuts or complex profiles

• Expansion Options: Optional chamfering machine can be integrated for complete workflow solution while maintaining automated material handling advantages

Certifications & Standards

High-Volume Automated Curbstone Production with Maximum Efficiency

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Transform Your Roadside Stone Cutting Operations?

Get expert consultation on curbstone cutting machines, kerbstone production systems, and stone fabrication solutions

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Curbstone Cutting Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский