Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

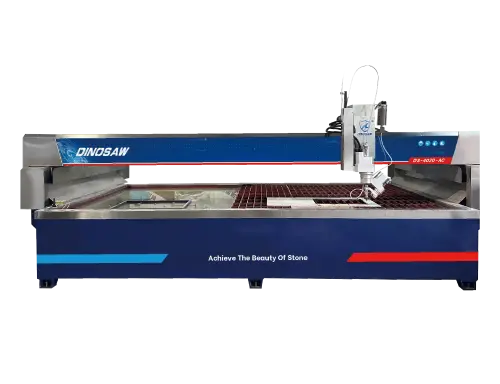

5 Axis CNC Waterjet Cutting Machine for Sale

WZSD-4020-AC

Compatible Materials & Products

Sintered Stone > Countertops & Sinks

|

|

|

Sintered stone requires precision cutting for modern countertops and integrated sinks. DINOSAW 5-axis CNC waterjet excels with dynamic cutting angles that create seamless transitions between surfaces. The system delivers ±0.1mm accuracy while cutting and drilling holes for fixtures with complex geometries. Cold cutting technology eliminates micro-fractures, preserving the material's structural integrity and appearance. The A-axis (±106°) and C-axis (±540°) motion enables undermount sink cutouts and curved transitions with perfect precision.

Natural Stone > Stairs & Inlays

|

|

|

Stone staircase components and inlaid patterns demand exceptional cutting accuracy and edge quality. Our 5-axis CNC waterjet delivers precise cuts in marble, granite, and limestone, creating perfectly matched inlays and complex geometric patterns. The high-pressure waterjet (450MPa) produces clean edges that require minimal finishing, reducing production time by up to 35%. Five-axis technology enables beveled edges and angled cuts essential for stair treads and risers. The cold cutting process ensures no thermal damage, preserving the stone's natural beauty while achieving intricate details impossible with conventional methods.

Glass > Bathroom Doors

|

|

|

Bathroom glass doors require precision cuts and clean edges for hardware installation. Our 5-axis CNC waterjet system delivers exceptional results with accurate hinge cutouts and perfect drill holes. We offer complete glass production lines with automated loading, cutting, drilling, washing, and unloading—eliminating manual handling to reduce scratches and breakage. The cold cutting process eliminates micro-fractures common with traditional glass cutting, reducing breakage risk during tempering by 40%. Five-axis capabilities enable beveled edges and rounded corners without secondary processing. The waterjet cuts glass with ±0.1mm precision, ensuring perfect hardware alignment and smooth operation.

Stainless Steel > Seamless Basins

|

|

|

Stainless steel seamless basins require precision cutting and drilling with perfect edge quality. Our 5-axis CNC waterjet combines high-pressure abrasive technology with multi-axis motion to create complex curved surfaces and precise drain openings. The cold cutting process prevents thermal distortion, maintaining material flatness essential for seamless integration. The system achieves ±0.1mm accuracy while cutting 304/316 stainless steel up to 10mm thick. Five-axis capability enables perfect transitions between vertical and horizontal surfaces, creating ergonomic designs with smooth edges that require no deburring, reducing manufacturing time by 28%.Alt 4: 5-axis CNC waterjet cutting seamless stainless steel basin with precision curved edges

Carbon Fiber > Precision Cutting

|

|

|

Carbon fiber composites present unique challenges due to delamination risks during cutting. Our 5-axis CNC waterjet system includes an optional drill attachment for pre-drilling before waterjet cutting, preventing delamination issues. The specialized process first creates pilot holes with carbide drill bits, then uses precise waterjet cutting to complete complex shapes. This hybrid approach maintains composite integrity while achieving ±0.1mm accuracy. The 5-axis configuration enables angled cuts and tapered edges with consistent quality throughout the material thickness. This specialized technique is ideal for aerospace components, automotive parts, and high-performance sporting equipment.

Luxury Stone Sink & Vanity Manufacturing

Combining Precision Cutting & Drilling for Luxury Stone

European stone fabricator cuts and drills bathroom fixtures with our 5-axis waterjet. Production time reduced by 35%. Five-axis motion creates smooth curves without micro-fractures. Cold cutting produces edges needing no finishing, increasing profits.

Precision Metal Components Manufacturing

Cutting & Drilling Complex Metal Components

Manufacturers cut and drill metal components with our waterjet. 5-axis system creates precise mounting holes at compound angles. ±0.1mm accuracy with no heat effects maintains material integrity. Automatic sand feeding reduces waste and labor by 28%.

Bathroom Glass Door & Enclosure Fabrication

Precision Cutting & Drilling for Glass Enclosures

Glass fabricators make shower doors with our 5-axis waterjet. Cuts edges and drills holes without secondary polishing. Creates precise hinge slots ensuring alignment. Cold cutting prevents stress points, reducing breakage during tempering.

Specs and options

Specifications customizable upon request.

| Model | WZSD - 4020 - AC |

| Control Cabinet | AC shaft CNC system |

| Automatic sand supply system | 100L |

| Processing range | 4000mm×2000mm |

| Cutting accuracy | ±0.1mm |

| Cooling tower capacity | 3 m³ |

| X axis running speed(Drive parts) | 0 - 6000mm/min |

| Y axis running speed(Drive parts) | 0 - 6000mm/min |

| Z axis running speed(Drive parts) | 0 - 200mm/min |

| A axis(Drive parts) | ±106° |

| C axis(Drive parts) | ±540° |

Customized Waterjet Solutions for Every Industry

DINOSAW offers tailored 5-axis CNC waterjet solutions for stone, glass, metal, and composite materials processing, with specific systems designed for each industry's unique requirements.

We customize solutions based on your production volume and provide technical consultation

Cut faster, more precisely, with one-click operation

Speed. Precision. Simplicity. The Ultimate Waterjet Solution

30% Faster Cutting

Ultra-high pressure intensifier pump delivers 460MPa working pressure

0.05mm High-Precision Control

Advanced servo control system, oil-immersed rails and screws for perfect results

One-Click Operation with CNC System

Built-in process library and intuitive CNC interface enable effortless production

Durable Construction

Cast iron beam and stainless steel tank provide stability and resistance to deformation and wear

Safety Features

Limit protection and automatic alarm systems provide real-time feedback on abnormal conditions

18% Energy Saving

Energy-efficient main motor reduces power consumption while maintaining optimal cutting performance

FAQs

Common Questions About DINOSAW 5-axis CNC Waterjet Cutting Machines

What are the key advantages of a 5-axis abrasive waterjet cutting machine over traditional methods?

The 5-axis CNC waterjet machine offers 4 significant advantages over traditional cutting methods.

1. Complex three-dimensional cutting with angles and bevels is achieved through A-axis rotation and C-axis rotation that would be impossible with conventional systems.

2. The cold cutting process eliminates heat-affected zones, preventing thermal distortion and maintaining material properties—critical when working with heat-sensitive materials.

3. Versatility allows processing diverse materials from stone to metal to glass with a single system, eliminating the need for multiple specialized machines.

4. High precision (±0.05mm positioning accuracy) with our advanced servo control system and oil-immersed rails delivers smooth, burr-free edges that require no secondary finishing.

What materials can be cut with a 5-axis CNC waterjet machine?

The 5-axis CNC waterjet machine is remarkably versatile in terms of material compatibility.

Our 5-axis CNC waterjet effectively processes five key material categories:

1) Sintered stone for countertops and integrated sinks, with perfect transitions between surfaces

2) Natural stone (marble, granite) for stairs and complex inlaid patterns with exceptional edge quality

3) Glass for bathroom doors and enclosures, with precise hardware cutouts and no micro-fractures

4) Stainless steel (304/316) for seamless basins with complex curved surfaces and precise drain openings

5) Carbon fiber composites using our specialized hybrid process with pre-drilling to prevent delamination

Beyond these primary materials, our system also effectively cuts ceramics, rubber, plastics, non-ferrous metals (aluminum, copper, titanium), textiles, foam materials, wood, and virtually any material requiring precision cutting without heat-affected zones.

The cold cutting technology handles material thicknesses from thin sheets to blocks up to 200mm thick depending on material composition, making our system a versatile solution for diverse manufacturing requirements.

What are the key features of the DINOSAW 5-axis CNC waterjet machine?

The DINOSAW 5-axis CNC waterjet machine features industry-leading technology designed for maximum productivity and precision:

Our system delivers 30% faster cutting with a powerful 600MPa high-pressure intensifier pump and 460MPa cutting pressure, dramatically reducing processing time while maintaining superior edge quality. The advanced servo control system with oil-immersed rails and screws achieves exceptional ±0.05mm positioning accuracy for perfect results every time.

Operators benefit from one-click operation through our intuitive CNC interface with built-in process library, enabling efficient production with minimal training. The durable cast iron beam construction and stainless steel tank provide excellent stability and resistance to deformation and wear, ensuring long-term reliability.

Comprehensive safety features include independent cooling air conditioning to prevent overheating, limit protection and automatic alarm systems for real-time feedback on abnormal conditions. Our energy-efficient 30KW main motor reduces power consumption by 18% while maintaining optimal cutting performance.

What is the precision capability of the 5-axis CNC waterjet machine?

The 5-axis CNC waterjet machine delivers exceptional precision with positioning accuracy of ±0.05mm and repeat positioning accuracy of ±0.02mm-±0.03mm. This high-level accuracy is achieved through DINOSAW's precision-engineered motion control systems incorporating advanced servo motors and oil-immersed rails that continuously monitor and adjust cutting parameters. The five-axis capability enables complex cutting angles with A-axis rotation (±106°) and C-axis rotation (±540° unlimited) for achieving perpendicular edges even on thick materials.

How does the 5-axis CNC waterjet machine reduce production costs?

The 5-axis CNC waterjet machine offers multiple pathways to production cost reduction. Material utilization is maximized through efficient nesting software that optimizes part layout and minimizes waste—particularly valuable when working with expensive materials like marble or titanium. The elimination of secondary finishing operations (deburring, grinding, polishing) significantly reduces labor costs and production time.

The cold cutting process preserves material integrity, reducing rejection rates and rework. Automated features like the sand delivery system minimize operator intervention, allowing a single operator to manage multiple tasks. The water recycling capability reduces water consumption by up to 80%, lowering utility costs and environmental impact. Additionally, the versatility to process multiple materials with a single machine reduces capital investment compared to requiring separate specialized equipment for different materials.

How does the waterjet cutting process compare to laser or plasma cutting?

Waterjet cutting offers distinct advantages compared to laser and plasma cutting technologies. Unlike laser and plasma, waterjet is a cold cutting process that eliminates heat-affected zones, preventing material distortion, hardening, or stress—ideal for heat-sensitive materials and preserving material properties. With our 460MPa high-pressure system, waterjet can cut much thicker materials (up to 200mm depending on material) than typical laser or plasma systems.

Waterjet offers superior material versatility, processing virtually any material from soft rubber to hardened steel. The waterjet process produces no harmful fumes or gases, providing environmental and workplace safety advantages. While laser cutting may achieve faster speeds on thin metal sheets, waterjet excels with thicker materials and provides superior edge quality without dross or slag. The 5-axis capability further extends waterjet versatility by enabling complex bevels and 3D geometries.

Certifications & Standards

Speed. Precision. Simplicity. The Ultimate Waterjet Solution

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Transform Your Material Processing with 5-Axis Waterjet Technology?

Our high-pressure abrasive waterjet cutting system delivers precision and versatility for your demanding applications.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy CNC Waterjet Cutting Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский