Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

Sandstone Cutting Machine for Quarrying & Block Cutting

SSQJ-1400

Compatible Materials & Products

Sandstone ❯ Block Cutting

|

|

|

| Sandstone quarrying requires efficient block extraction and dimensioning for construction industry applications. The DINOSAW sandstone cutting machine excels at primary block cutting in quarry environments, using horizontal and vertical saws that work simultaneously to extract large uniform blocks directly from the quarry face. |

Limestone ❯ Quarrying

|

|

|

| Limestone quarrying operations require efficient extraction methods to maximize production in quarry sites worldwide. The DINOSAW sandstone cutting machine excels in limestone quarrying environments, utilizing adjustable cutting pressure that automatically adapts to the material's natural variations. |

Laterite ❯ Mining

|

|

|

| Laterite mining presents unique challenges due to its iron-rich composition and variable hardness in tropical regions. The DINOSAW sandstone cutting machine is specifically calibrated for laterite mining operations, utilizing moderate cutting speeds and optimized blade pressure that prevents material crumbling while maintaining efficient extraction rates. |

The machine's specialized dust extraction system effectively manages the characteristic red particulate, allowing mine operators to achieve consistent production with minimal material loss and environmental impact, meeting modern mining standards for both efficiency and sustainability.

Travertine ❯ Extraction

|

|

|

| Travertine extraction requires specialized approaches to maintain material integrity while preserving its distinctive natural characteristics throughout the quarrying process. The DINOSAW sandstone cutting machine features calibrated cutting speeds and controlled pressure systems specifically optimized for travertine's moderate hardness and unique void patterns, producing clean separation without disrupting the material's natural formation. |

The machine's stable platform ensures efficient extraction even with travertine's inherent structural variations, enabling quarry operators to maximize yield while minimizing waste, resulting in higher profit margins and sustainable resource utilization in decorative stone operations.

Architectural Fabrication

Achieving Complex Design Elements with Unmatched Precision

A Brazilian quarry implemented DINOSAW's machine with dual-saw system cutting at 25m/min. This eliminated secondary processing, reduced waste by 30%, and enabled consistent block production with clean edges to fulfill large construction orders.

Landscape Products Manufacturing

Scaling Production Without Compromising Craftsmanship

A UK limestone quarry adopted DINOSAW technology to produce blocks at 20m/min speeds. The horizontal and vertical cutting system eliminated multi-step extraction, reduced labor costs by 50%, and delivered consistent dimensions with clean edges that minimized on-site finishing.

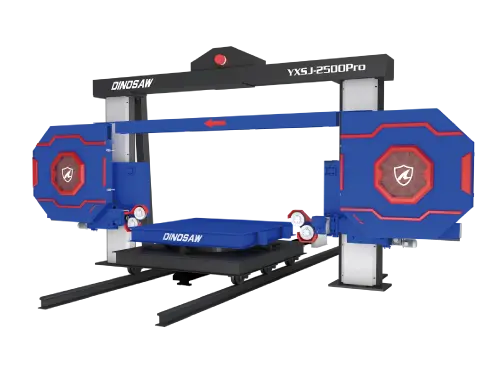

Specs and options

Specifications customizable upon request.

| Model | Unit | SSQJ-1400 |

|---|---|---|

| Vertical | kw | 75 |

| Horizontal | kw | 45 |

| Rail | kw | 5.5 |

| Moving speed (forward &backward) | m/min | 10 - 45 |

| Max distance of cylinder lifting | mm | 700 |

| Max cutting depth | mm | 520 |

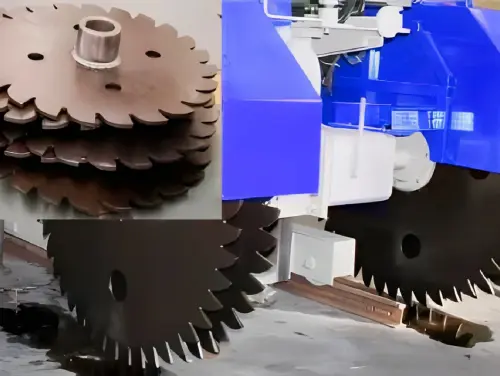

| Diameter of the vertical | m | 1330 |

| Diameter of the horizontal | mm | 600 |

| Thickness | mm | 11.5 |

Engineered for excellence in every cut, maximizing value and quality

Precision Cutting That Transforms Sandstone Into Possibilities

Integrated Cutting and Mining

Combines cutting and mining processes for consistent block sizes while minimizing waste alt 7: DINOSAW Machine Integrating Cutting and Mining Processes for Efficient Stone Production

Track-Based Mobility

Ensures smooth movement across quarry sites, allowing easy repositioning even in challenging terrains

Operator-Friendly Cabin

Ergonomic control station with intuitive joystick system reduces fatigue during extended operations

Simple Structure

Easy operation and maintenance with straightforward controls and accessible components

Environmentally Friendly

Low noise and minimal dust generation during operation

Durable Construction

Built with heavy-duty steel frame and premium electrical components

FAQs

Common Questions About DINOSAW Stone Cutting Machines

What types of stone can a sandstone cutting machine process?

The DINOSAW sandstone cutting machine is primarily designed for sandstone but effectively cuts multiple low-density stones. It's optimized for sandstone, limestone, and laterite with their granular structures and moderate hardness.

The machine features adjustable cutting speeds (10-45 meters/minute) and pressure settings that automatically adapt to different stone densities. This versatility makes it ideal for quarry operations where multiple stone types are processed, maximizing equipment investment while maintaining optimal cutting performance across materials.

What is the cutting capacity and production rate of a sandstone cutting machine?

The DINOSAW sandstone cutting machine handles blocks up to 0.52 meters in height. Its dual-saw system (horizontal and vertical) enables cutting speeds of 10-45 meters per minute in dry conditions, significantly outperforming traditional drilling and splitting methods.

The simultaneous dual-direction cutting reduces processing time by up to 60% compared to single-direction systems, making it ideal for high-volume production environments where efficiency directly impacts profitability.

What maintenance does a sandstone cutting machine require?

Maintaining a DINOSAW sandstone cutting machine is straightforward due to its simple mechanical design. Daily maintenance includes clearing dust from critical components, checking diamond blades for wear, and inspecting drive systems. Weekly tasks involve lubricating moving parts and cleaning any sediment buildup.

Major maintenance is only required every 500-600 operating hours and includes blade replacement, belt tension adjustment, and alignment verification. The machine's simple structure allows most maintenance to be performed by operators with basic training, reducing specialized service costs. Following this maintenance schedule typically extends machine life by 40% and prevents costly production interruptions.

What environmental and safety considerations apply to sandstone cutting machines?

The DINOSAW sandstone cutting machine is designed with environmental sustainability in mind. It generates significantly less dust than conventional drilling methods and operates with lower noise levels. Its efficient cutting mechanism reduces waste material by up to 35%, maximizing resource utilization.

For operator safety, the machine features emergency stop systems, blade guards, and stable operational platforms. Since it's designed for dry cutting conditions, there's no water contamination or slurry disposal concerns.

Operators should still wear appropriate PPE including eye protection, dust masks, and hearing protection during operation, though requirements are reduced compared to traditional stone cutting methods.

Certifications & Standards

Precision Cutting That Transforms Sandstone Into Possibilities

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Revolutionize Your Sandstone Processing?

Contact DINOSAW experts today for a personalized consultation and discover how our cutting technology can transform your production capabilities.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Stone Cutting Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский