Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

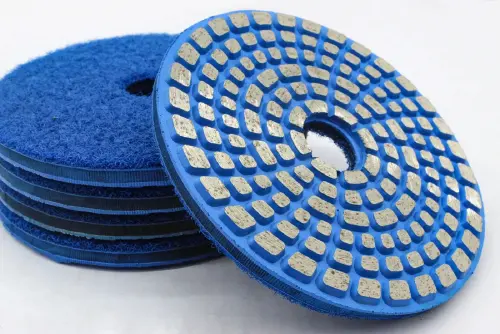

Diamond Polishing Pads for Granite, Marble & Concrete

Wet/Dry Diamond Polishing Pads for sale

Compatible Materials & Products

Granite > Countertops & Memorials

|

|

|

Granite's durability and aesthetic appeal make it the preferred choice for kitchen countertops and memorial monuments, requiring high-quality polishing to reveal its natural beauty.

DINOSAW diamond polishing pads use calibrated diamond concentration and strategic particle arrangement to efficiently work with granite's crystalline structure. Starting with coarser grits (50-100) for initial grinding, then progressing through medium (200-400) and fine grits (800-3000), these pads create a systematic refinement process that removes scratches while developing a high-gloss finish on both flat surfaces and edge details.

Stone fabricators achieve consistent polish across varied granite types, while distributors benefit from reliable product performance and reduced customer support requirements.

Marble > Luxury Floors & Decorative Elements

|

|

|

Marble's soft, calcium-based composition requires specialized polishing approaches to achieve the luxurious sheen expected in high-end floors and decorative applications.

DINOSAW marble polishing pads utilize a calibrated resin bond that prevents overheating and micro-fractures in sensitive stone. The process typically begins with medium grits (200-400) unless repair is needed, followed by progressive refinement through finer grits (800-3000). The flexible backing provides optimal contact with curved or irregular surfaces, while controlled diamond exposure prevents etching or damage to the delicate material.

Professional fabricators achieve consistent results that enhance marble's natural luminosity, providing both reliable performance and maintenance simplicity for end customers.

Concrete > Industrial Floors & Surfaces

|

|

|

Concrete polishing transforms ordinary industrial floors into durable, low-maintenance surfaces with aesthetic appeal and enhanced functionality for commercial and manufacturing environments.

DINOSAW concrete polishing pads feature a structured diamond matrix designed to manage the varied densities in concrete aggregate. The process typically begins with metal-bond pads (30-50 grit) for initial grinding, transitioning to resin-bond pads (100-3000 grit) for refinement and final polishing. This systematic approach opens the concrete surface, increases density through proper chemical treatment, and creates a mechanically polished finish with specified reflectivity levels.

Contractors complete projects efficiently while providing their clients with floors that offer reduced maintenance costs, improved light reflectivity, and extended service life.

Quartz > Precision Edge Details

|

|

|

Quartz's exceptional hardness and crystalline structure require specialized polishing approaches to achieve precision edge details and perfect corner transitions in premium countertop installations.

DINOSAW quartz polishing pads feature higher diamond concentrations specifically designed for dense, hard materials. The optimized diamond particle shape and distribution creates efficient cutting action while preventing chipping on vulnerable edges and corners. The systematic progression from medium grits (200-400) through ultra-fine finishing grits (1500-3000) reveals the full clarity and depth of quartz structures.

Fabricators achieve clean, precise edge transitions and corner details that enhance overall installation quality, while satisfying the expectations of design-conscious clients.

Terrazzo > Commercial Flooring

Terrazzo combines cement or resin with decorative aggregate to create versatile flooring solutions for commercial spaces, requiring specialized polishing to achieve a uniform finish across varied material densities.

DINOSAW terrazzo polishing pads utilize a balanced diamond formulation that addresses both the harder aggregate materials and softer binding matrix. The process typically begins with coarser grits (50-100) for initial leveling, progressing through medium and fine grits to develop an even, consistent finish. The specialized resin bond prevents preferential cutting of softer areas, maintaining the intended pattern and design integrity throughout the polishing sequence.

Commercial flooring contractors deliver durable, attractive surfaces with optimal light reflectivity and simplified maintenance requirements for high-traffic public spaces.

3 Steps Diamond Polishing Pads Demo

▶

▶

Kitchen Countertop Fabrication

Achieving Perfect Edge Details and Surface Polish in Half the Time

Chicago countertop fabricator using DINOSAW diamond polishing pads reduced polishing time by 40% while improving edge consistency. Extended pad life and lower labor costs increased profit margins despite market pricing pressures.

Concrete Floor Restoration

Transforming Worn Industrial Spaces into Premium Environments

Renovation specialist transformed 15,000 sq ft warehouse concrete into modern office flooring using DINOSAW concrete-specific diamond pads. Project completed 3 days early with high-gloss, low-maintenance surface that reduced ongoing costs.

Memorial Stone Finishing

Honoring Memories with Flawless, Enduring Craftsmanship

Monument company achieved deeper blacks, vibrant colors and perfect surface reflection on diverse granites with DINOSAW diamond pads. Improved finish quality enabled premium pricing while extended pad life reduced production costs by 22%.

Specs and options

Specifications customizable upon request.

For our complete range of diamond polishing pads with various specifications, contact our technical team for parameter sheets and custom options.

DINOSAW diamond tool experts will recommend the optimal pad type, grit sequence, and specifications for your project.

Engineered for consistent performance across different materials

Complete Polishing Solutions for All Stone Applications

Comprehensive Product Range

Complete selection of wet, dry and hybrid pads covering all stone polishing applications from 30 to 3000 grit

Material-Specific Formulations

Optimized diamond concentration and bonding technology for specific materials from granite to engineered stone

Extended Service Life

Resin bond technology increases pad durability and delivers consistent performance throughout the pad's service life

Multiple Backing Options

Hook and loop, PSA, and snail lock backing systems compatible with all standard polishing equipment

Systematic Color Coding

Clear identification system prevents confusion during progressive polishing sequences, improving workflow efficiency

Distributor Support Program

Comprehensive inventory solutions, merchandising displays, and technical training for trade partners

FAQs

Common Questions About DINOSAW Diamond Polishing Pads

What is the difference between wet and dry diamond polishing pads?

Wet diamond polishing pads are designed to be used with water as a coolant and lubricant. The water helps prevent overheating, extends pad life, reduces dust, and improves polishing quality. These pads typically have channels or patterns that help distribute water and remove slurry from the polishing surface.

Dry polishing pads feature specialized heat-resistant bonds that allow them to perform without water cooling. They are engineered with cooling agents in the resin matrix and designed to dissipate heat effectively. Dry pads are ideal for job site work, repairs, and situations where water access is limited.

DINOSAW also offers hybrid pads that can be used in both wet and dry conditions, though wet polishing generally provides better results and longer pad life for most applications. The choice between wet, dry, or hybrid pads depends on your specific work environment, material type, and application requirements.

How do I choose the right diamond polishing pad for my specific material?

Selecting the right diamond polishing pad depends on several factors:

1. Material Type: Different materials require different pad formulations. DINOSAW offers specific pads optimized for granite, marble, concrete, engineered stone, and other materials. Harder materials generally require more aggressive diamond concentrations.

2. Working Environment: Consider whether you'll be polishing in a controlled shop environment with water access (wet pads), on-site with limited water (dry pads), or in varying conditions (hybrid pads).

3. Finish Requirements: For mirror finishes, you'll need a complete grit progression from coarse to extra-fine. For honed finishes, you may only need to progress to medium grits.

4. Equipment Compatibility: Ensure the pad backing system (hook and loop, PSA, or snail lock) matches your polishing equipment.

Our color-coded system makes it easy to identify the appropriate grit level, and our packaging clearly indicates material compatibility. For specific recommendations tailored to your unique application, contact our technical team who can provide detailed guidance.

Are DINOSAW diamond pads compatible with all polishing machines?

DINOSAW diamond polishing pads are designed for maximum equipment compatibility through multiple backing options: hook and loop (Velcro-style) for most modern polishers, PSA (Pressure Sensitive Adhesive) for smooth backing plates, and snail lock for specific professional equipment.

Available in standard sizes (3", 4", 5", 6", 7") with industry-standard center hole configurations, these pads fit handheld polishers, pneumatic machines, and floor polishers from major manufacturers like DINOSAW, Makita, DeWalt, Flex, Alpha and MK Diamond.

For specialized mounting requirements, our technical team can recommend appropriate adapter systems or create custom pads to meet your specific needs.

What makes DINOSAW diamond polishing pads better than competitors?

DINOSAW diamond polishing pads offer several key advantages: Our proprietary multi-angled diamond particle technology provides superior cutting efficiency with diamonds that work from every direction rather than relying on random orientation.

Our advanced resin bonding system holds diamonds more securely while releasing them at the optimal rate as they wear. Material-specific formulations optimize diamond concentration and bond strength for particular stone types rather than using one-size-fits-all solutions.

Our complete product range covers wet, dry and hybrid applications for every material type. Strict quality control includes batch testing for diamond retention and performance consistency, with rejection rates below 0.5%. For distributors, we offer complete inventory solutions and comprehensive technical support.

Certifications & Standards

Complete Polishing Solutions for All Stone Applications

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Professional Diamond Polishing Solutions for Every Application

Contact DINOSAW experts for technical specifications, distributor programs, or customized solutions for specific project requirements.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond Polishing Pads Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский