Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

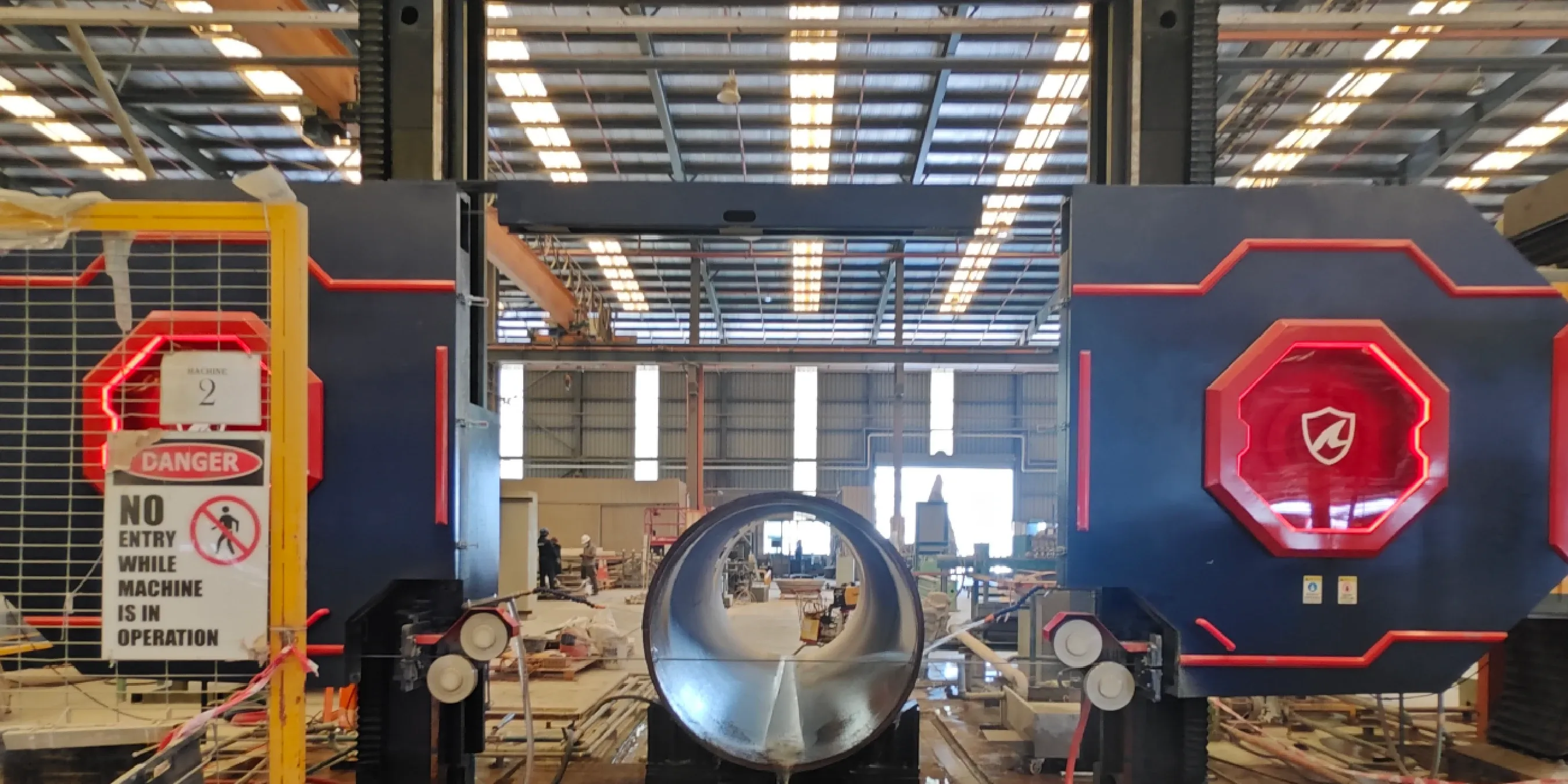

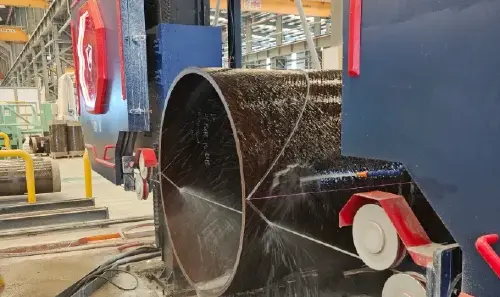

CNC wire saw cutting case for large-diameter FRP pipes, showing controlled curved and angled cuts for industrial piping and custom composite fabrication.

Case Snapshot

Material

FRP pipe (Fiber Reinforced Plastic / GRP)

Processing Method

CNC wire saw cutting

Typical Application

Industrial piping, chemical pipelines, custom composite pipe sections

Applicable Industries

Chemical engineering, water treatment, energy, industrial infrastructure

Processing Focus

Large-diameter pipe cutting with curved and angled profiles

Associated Product

Dinosaw CNC Diamond Wire Saw Machine

Application / Production Context

Large-diameter FRP pipes are widely used in industrial environments due to their corrosion resistance and structural stability.

In many projects, pipes must be cut at specific angles or curved profiles to meet installation requirements, rather than simple straight cross-cuts.

Compared with metal pipes, FRP materials behave differently during cutting.

They require stable cutting force and consistent coolant control to avoid surface tearing, fiber pull-out, or dimensional deviation.

Practical Challenges in FRP Pipe Cutting

Workshops handling FRP pipe cutting commonly face several issues:

Large pipe diameter makes stable positioning difficult

Curved or angled cuts must follow precise layout lines

Excessive vibration can damage the composite structure

Surface integrity must be preserved for later assembly

Traditional abrasive or blade-based cutting methods often struggle to maintain smooth edges on thick FRP sections, especially when the cut path is not straight.

Workshop Insights

Why is wire saw cutting suitable for FRP pipes?

Operators find that wire saw cutting applies continuous, evenly distributed cutting force, which is especially important for composite materials like FRP.

Instead of aggressive contact, the diamond wire gradually removes material, reducing stress concentration on the pipe wall.

What matters most during the cutting process?

The key focus is wire stability and feed consistency.

For large-diameter pipes, maintaining smooth wire travel prevents sudden fiber breakage and helps keep the cut edge clean and uniform.

How is cut quality evaluated on site?

Quality is judged by edge continuity, dimensional accuracy, and surface condition.

If the cut pipe can be directly fitted or moved to secondary finishing without additional rework, it meets production requirements.

How the Cutting Was Performed

The FRP pipe was securely supported to prevent deformation during cutting.

The cutting path was programmed to match the required curved profile along the pipe surface.

The CNC wire saw executed the cut with stable feed speed and continuous cooling, allowing the wire to pass smoothly through the composite structure.

After cutting, the pipe section retained clean edges suitable for installation or further processing.

Observed Results in Production

The cutting process remained stable throughout the operation.

The pipe structure showed no visible delamination or fiber tearing.

Curved and angled profiles were achieved accurately along the full pipe diameter.

The resulting sections met on-site assembly requirements without additional corrective work.

Who This Case Is Relevant For

This case is relevant if you are working with:

Large-diameter FRP or GRP pipes

Industrial piping systems requiring custom cuts

Composite materials sensitive to vibration

Projects where cut accuracy affects on-site installation

If your workshop handles non-metallic industrial pipes and needs controlled, profile-based cutting, this case reflects a practical, real-world solution.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский