Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

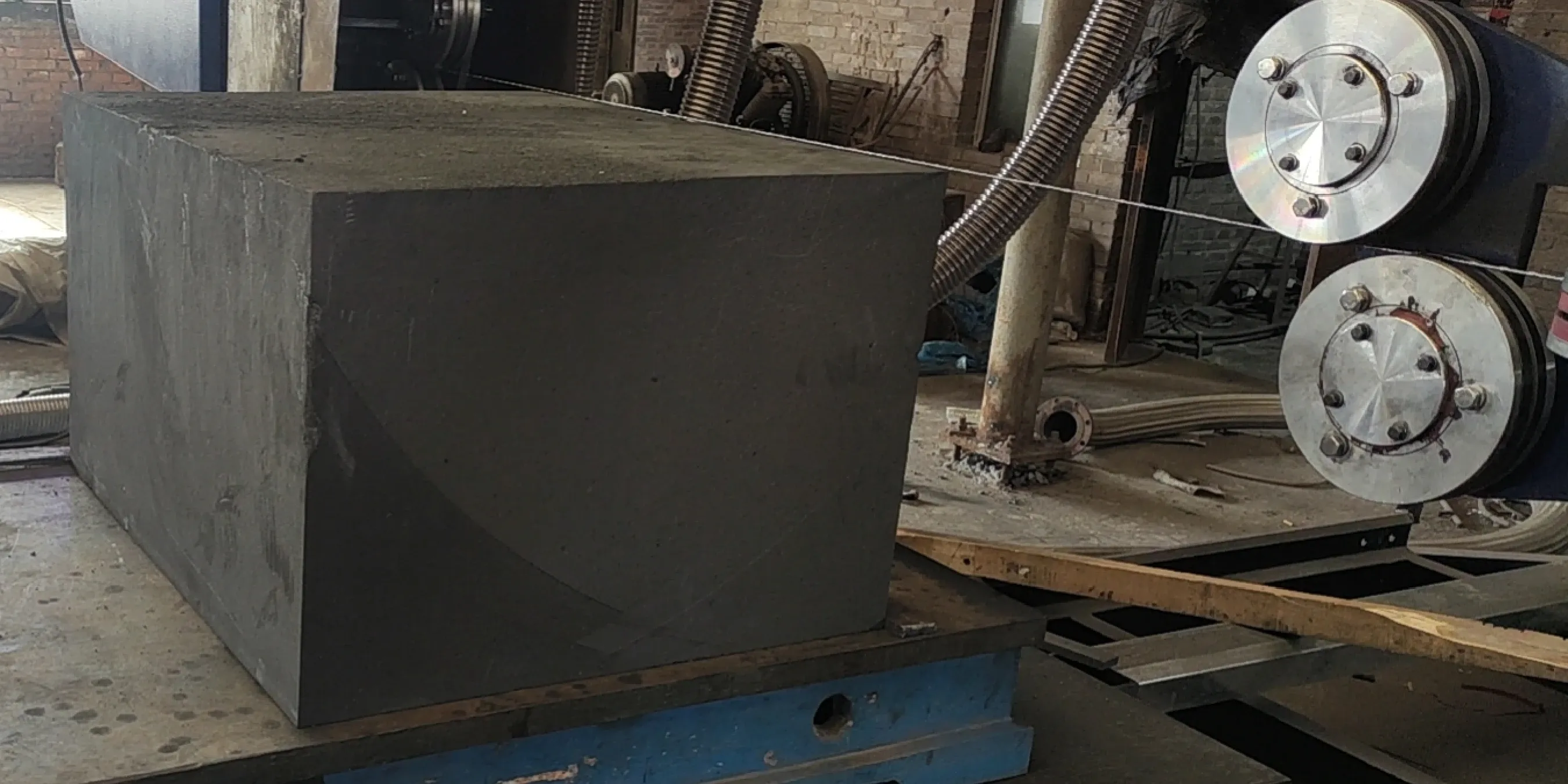

CNC wire saw cutting case for large graphite blocks, showing controlled profile and slot cutting for industrial graphite components and downstream machining preparation.

Case Snapshot

Material

Industrial graphite block

Processing Method

CNC wire saw cutting

Typical Application

Graphite components, electrode blanks, industrial structural parts

Applicable Markets

Metallurgy, energy, semiconductor, industrial manufacturing

Processing Focus

Large-format graphite block cutting with internal slots and shaped profiles

Associated Product

Dinosaw CNC Diamond Wire Saw Machine

Application / Production Context

Large graphite blocks are commonly used as semi-finished materials rather than final products.

They are typically cut into blanks, plates, or profiled sections before moving to downstream machining processes such as milling, drilling, or EDM-related applications.

In this case, the graphite blocks were supplied in oversized formats and needed to be sectioned and shaped to match specific internal structures required by the next production stage.

Practical Challenges in Large Graphite Block Cutting

Workshops processing large graphite blocks often face several practical difficulties:

Graphite is brittle and prone to edge chipping

Large block size makes handling and fixturing difficult

Internal slots and profiles must remain dimensionally consistent

Excess vibration can cause surface tearing or micro-cracks

Traditional blade cutting methods tend to generate excessive stress on graphite, especially when cutting deep slots or non-linear profiles.

Workshop Insights

What makes cutting large graphite blocks challenging in practice?

Operators point out that graphite behaves very differently from stone or metal.

It cuts easily, but it also breaks easily.

The challenge is not hardness, but controlling the cut so the material does not fracture or collapse along thin sections.

Why was wire saw cutting chosen for this material?

Wire saw cutting applies continuous, low-impact cutting force, which suits graphite well.

Instead of forcing material removal, the wire gradually separates the block, reducing sudden stress release inside the material.

What do operators watch most closely during the process?

Attention is focused on wire stability and cutting path continuity.

Any sudden change in feed or vibration can affect edge integrity, especially near internal corners or narrow slots.

How is acceptable quality judged on site?

Cut quality is judged by edge cleanliness, slot straightness, and structural integrity.

If the graphite section can move directly to the next machining stage without repair or reinforcement, it is considered acceptable.

How the Cutting Was Handled

The graphite blocks were securely positioned to minimize movement during cutting.

Cut paths were planned to separate the block into functional sections while preserving internal features.

The CNC wire saw executed the cuts in a controlled sequence, allowing the wire to pass smoothly through the graphite structure.

After cutting, the resulting pieces maintained stable geometry suitable for downstream processing.

Observed Results in Production

The cutting process remained stable throughout large-section cuts.

Edges showed minimal chipping and clean separation lines.

Internal slots and profiles were formed consistently across the block.

The processed graphite sections were ready for subsequent machining without corrective work.

Who This Case Is Relevant For

This case is relevant if you are handling:

Large industrial graphite blocks

Graphite used as electrode or structural material

Applications requiring internal slots or shaped sections

Fragile materials sensitive to vibration and cutting stress

If your workshop needs controlled cutting of large graphite formats before secondary processing, this case reflects a realistic and proven approach.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский