Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

CNC wire saw cutting case for granite blocks used in precision instrument table bases, focusing on stable sectioning for machine foundations and metrology platforms.

Case Snapshot

Material

Granite

Processing Method

CNC wire saw cutting

Typical Application

Precision instrument tables, machine bases, measurement platforms

Applicable Markets

Metrology, semiconductor equipment, industrial machinery, laboratory systems

Processing Focus

Large granite block cutting with flatness control and internal relief sections

Associated Product

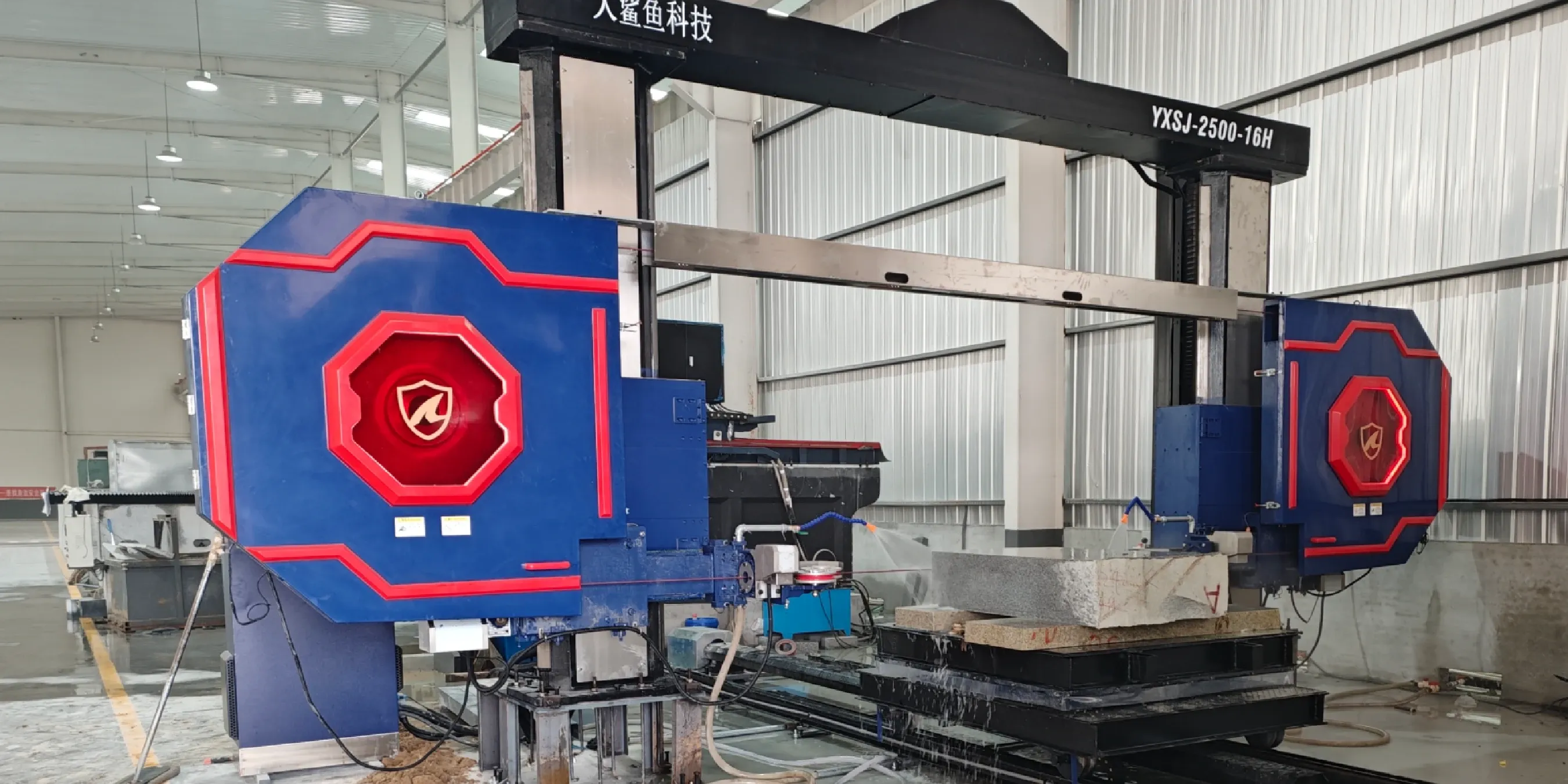

Dinosaw CNC Wire Saw Cutting Machine

Application / Production Context

Granite is widely used as a base material for precision instruments and heavy equipment, even though this application is unfamiliar to many outside the industry.

Its natural stability, vibration damping behavior, and long-term dimensional consistency make it suitable for machine foundations, inspection tables, and high-precision platforms.

In this case, large granite blocks were processed as semi-finished bases, which would later be ground, lapped, and assembled into precision instrument tables.

Practical Challenges in Granite Cutting for Instrument Bases

Cutting granite for precision equipment differs from decorative or architectural stone processing.

Workshops typically face several challenges:

Large block size requires controlled sectioning

Internal stress must be released gradually

Flat reference surfaces must be preserved

Excessive vibration can affect downstream accuracy

Unlike decorative stone, these granite blocks are judged not by appearance, but by how well they perform as structural and reference components.

Workshop Insights

Why is granite used for precision instrument tables?

Operators explain that granite offers natural vibration damping and thermal stability.

Once processed and stabilized, it maintains geometry well over time, which is critical for measurement accuracy and machine alignment.

What makes cutting granite for this application different?

The goal is not speed or visual finish.

The focus is on controlled separation, ensuring the block remains structurally stable for later surface finishing and calibration.

What do operators pay closest attention to during cutting?

Attention is given to cut sequence and stability.

Releasing internal stress gradually helps prevent distortion that could affect later precision grinding.

How is acceptable quality judged on site?

Quality is judged by structural integrity and consistency.

If the granite section remains stable and suitable for precision surface processing, it meets requirements.

How the Cutting Was Handled

The granite block was positioned to maintain even support throughout the cut.

Cut paths were planned to divide the block into instrument base sections while minimizing stress concentration.

The CNC wire saw executed the cuts with continuous, uniform force, allowing the granite to separate cleanly without inducing sudden movement.

After cutting, the blocks were ready for precision grinding and surface calibration.

Observed Results in Production

The cutting process remained stable throughout large-format sectioning.

Granite surfaces showed clean separation lines without structural damage.

Block geometry remained consistent for downstream lapping and finishing.

The processed granite sections were suitable for precision instrument assembly.

Who This Case Is Relevant For

This case is relevant if you are handling:

Granite used as machine bases or instrument tables

Precision equipment foundations

Applications sensitive to vibration and long-term stability

Large granite blocks requiring controlled sectioning

If your production involves granite for functional, high-precision use rather than decoration, this case reflects a real and practical cutting approach.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский