Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

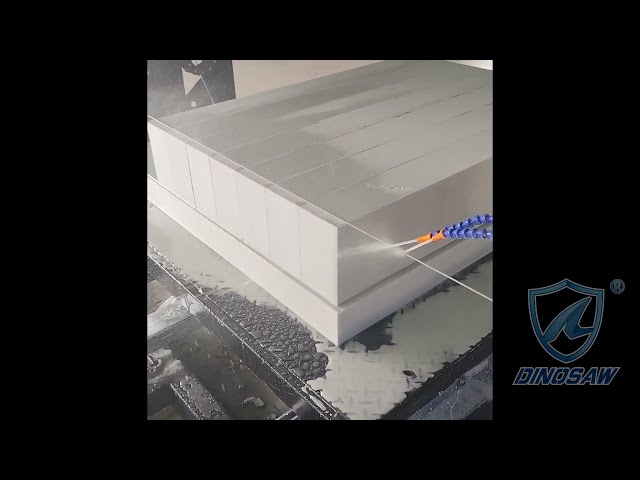

Foamed ceramic corbel cutting case study using a CNC wire saw by Dinosaw Machinery, focusing on complex profiles, edge integrity, and stable processing for architectural decoration.

▶

▶Case Snapshot

Material: Foamed Ceramic

Processing Method: Cutting

Typical Application: Architectural decorative corbels and façade components

Applicable Markets: Architectural decoration and prefabricated building materials

Processing Focus: Profile accuracy and edge integrity on lightweight ceramic elements

Associated Product: Dinosaw CNC Wire Saw Machine for foamed ceramic

Application Context for Foamed Ceramic Corbel Production

Foamed ceramic corbels are widely used in architectural decoration projects where lightweight materials and intricate profiles are required.

These components are typically installed as decorative or semi-structural elements on façades, columns, and interior architectural features.

In production environments, manufacturers are often required to process multiple corbel designs with varying shapes while maintaining consistent dimensions to meet installation and visual alignment requirements.

Practical Challenges in Cutting Foamed Ceramic Corbels

Compared to dense stone or concrete materials, foamed ceramic presents a different set of processing challenges.

Workshops handling similar corbel applications typically encounter issues such as:

Material fragility during cutting operations

Risk of edge chipping along decorative contours

Difficulty maintaining profile accuracy on complex shapes

Sensitivity to sudden force changes during cutting

Maintaining consistency across different corbel designs

These challenges make cutting stability and process control more important than cutting speed.

Workshop Insights from Corbel Cutting Operations

What makes foamed ceramic corbel cutting different from standard stone processing?

Foamed ceramic has a lightweight and porous internal structure, which behaves differently from dense stone materials.

While it is easier to shape, it is also more sensitive to cutting stability, particularly around edges and decorative features.

Small variations in cutting conditions can affect surface integrity, making controlled cutting paths essential for preserving design details.

Why is wire saw cutting suitable for complex corbel profiles?

Wire saw cutting is often selected for decorative corbel production because it allows smooth transitions along curved and stepped profiles.

This approach reduces localized stress on the material compared to rigid cutting methods, helping to maintain clean edges and consistent shapes.

In this application, the CNC wire saw solution provided by Dinosaw Machinery supported the controlled movement needed for shaping intricate corbel designs.

What do operators pay most attention to during the cutting process?

During cutting, operators focus primarily on profile accuracy and edge condition.

Maintaining a smooth and continuous cutting motion is critical, especially when transitioning between different profile sections.

Operators also ensure that the material is properly positioned and secured before cutting begins, as foamed ceramic components can be affected by even minor instability.

How is acceptable cutting quality judged for finished corbels?

From a production standpoint, corbels are considered acceptable when their profiles match design specifications and edge conditions remain clean and intact.

Finished components should require minimal corrective work before downstream finishing or installation.

These criteria are commonly used in architectural decoration manufacturing to ensure both functional fit and visual consistency.

How the Foamed Ceramic Corbel Cutting Process Was Handled

In this case, foamed ceramic blocks were positioned and cut according to predefined corbel profiles.

The cutting process emphasized controlled movement along the cutting path to avoid sudden load changes that could compromise material integrity.

This handling approach supports repeatable production of decorative corbels while minimizing material damage during processing.

The CNC wire saw system from Dinosaw allowed consistent execution of complex profile cuts across different corbel designs.

Observed Results in Foamed Ceramic Corbel Processing

Based on the observed cutting process:

Corbel profiles were formed accurately according to design requirements

Edge conditions remained clean with minimal chipping

Finished components were suitable for downstream finishing or direct installation

Cutting stability was maintained across multiple corbel designs

These outcomes meet common production expectations for foamed ceramic architectural elements.

Who This Case Is Relevant For

This case is particularly relevant for:

Manufacturers producing foamed ceramic architectural decorations

Workshops processing decorative corbels, brackets, or façade elements

Fabricators working with lightweight ceramic materials and complex profiles

Facilities evaluating CNC wire saw solutions from Dinosaw Machinery for decorative applications

If you are processing foamed ceramic components that require precise profiles and consistent quality, this case provides a practical reference scenario.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский