Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

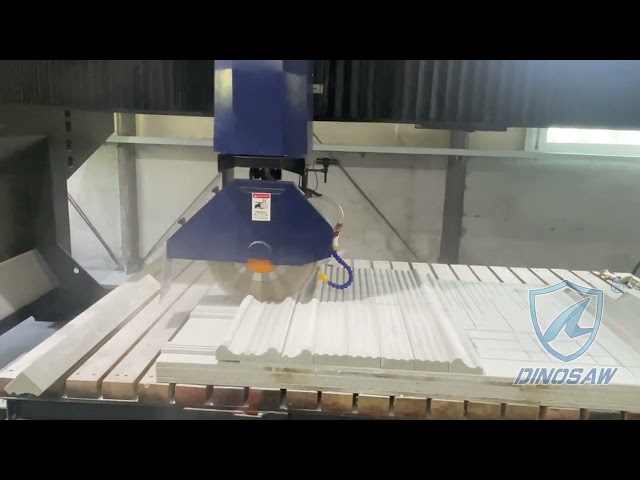

Foam ceramic decorative moulding cutting case study using CNC bridge saw, showing clean profile shaping for architectural trims and linear decorative elements.

▶

▶Case Snapshot

Material

Foam ceramic

Processing Method

CNC bridge saw profile and linear cutting

Typical Application

Foam ceramic decorative mouldings, trims, and architectural linear elements

Applicable Markets

Architectural decoration, façade systems, prefabricated decorative components

Processing Focus

Accurate linear cutting and profile definition for foam ceramic decorative elements

Associated Product

DINOSAW CNC mono-block bridge cutting machine

Foam Ceramic Decorative Mouldings in Architectural Applications

Foam ceramic decorative mouldings are widely used in architectural projects as cornices, window trims, façade lines, and other linear decorative elements.

These components are often installed in continuous sequences, where alignment, profile consistency, and edge quality directly affect the final visual result.

Unlike flat panels, decorative mouldings rely on defined cross-section profiles.

Any deviation during cutting becomes visible once multiple pieces are installed together, making precision cutting a critical step in foam ceramic moulding production.

Practical Challenges in Cutting Foam Ceramic Decorative Lines

Cutting foam ceramic decorative mouldings presents specific workshop challenges.

The material is lightweight but brittle along sharp profile edges.

Decorative lines often include repeating curves, grooves, or stepped profiles.

Maintaining straightness over long lengths is essential for installation alignment.

Surface chipping or profile distortion can compromise the decorative effect.

Workshop Insights from Foam Ceramic Decorative Moulding Cutting

What makes decorative moulding cutting different from flat panel cutting?

From the workshop perspective, mouldings are judged by their profile, not their size.

With flat panels, minor edge defects can sometimes be hidden.

With decorative lines, every edge and curve is exposed once installed, so profile accuracy becomes the main concern.

Why is a CNC bridge saw suitable for cutting foam ceramic mouldings?

A CNC bridge saw provides stable linear movement and controlled cutting depth.

This is important for maintaining consistent cross-section profiles along the full length of each moulding.

For foam ceramic, a stable cutting path helps preserve clean edges without tearing the material.

What do operators focus on most during the cutting process?

Operators focus on material support and alignment before cutting begins.

They pay close attention to how the blade enters and exits the profile, since those points are most prone to chipping.

Consistency from one piece to the next is always a priority.

How is acceptable quality judged on site?

Quality is judged by profile clarity, straightness, and edge condition.

If multiple mouldings can be placed end to end with continuous lines and no visible mismatch, the cut is considered acceptable for architectural use.

How the Foam Ceramic Moulding Cutting Process Was Handled

Foam ceramic blocks were positioned and secured to ensure straight cutting alignment.

Predefined cutting paths guided the bridge saw along the required moulding profiles.

The cutting process emphasized smooth blade movement and controlled feed along linear paths.

Finished mouldings were visually checked for profile consistency before packaging or installation.

Observed Results in Foam Ceramic Decorative Moulding Processing

Decorative mouldings showed clean and well-defined profiles.

Edges remained intact along the full length of each piece.

Multiple mouldings aligned consistently when arranged in sequence.

The cutting process fit smoothly into routine decorative component production.

Who This Case Is Relevant For

If you are producing foam ceramic decorative mouldings or architectural trims,

if your projects require long, continuous decorative lines with consistent profiles,

if installation quality depends on accurate cutting and clean edges,

this case reflects a practical cutting scenario commonly seen in architectural decoration workshops.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский