Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

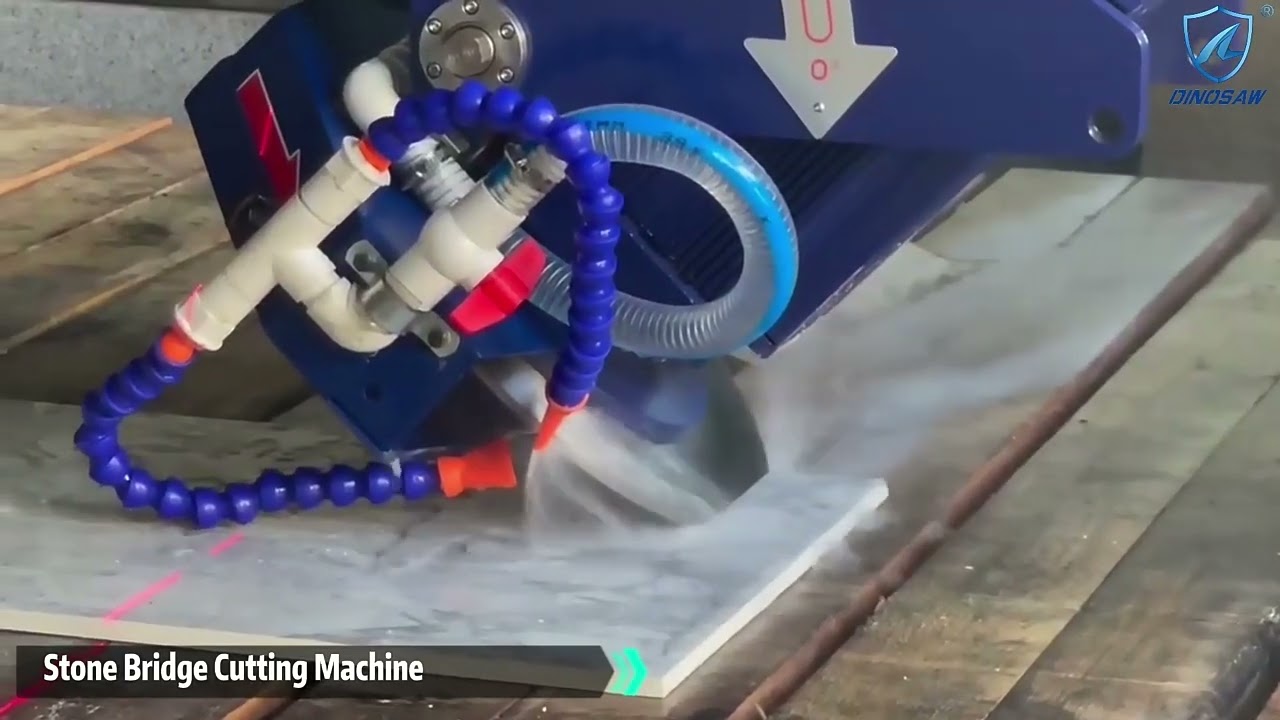

Monoblock Bridge Saw CNC Stone Cutter

YTQJ-600

Compatible Materials & Products

Precision Cutting Solutions for Natural Stone & Engineered Materials

▶ Product Demo

▶

▶

Granite > Kitchen Countertops

|

|---|

|

|

|

Granite kitchen countertops represent the pinnacle of residential luxury, demanding precise fabrication to meet modern design standards. The YTQJ-600 excels in cutting and manufacturing granite slabs into custom countertops, utilizing its CNC-controlled cutting head and variable speed control to achieve perfect edge profiles and sink cutouts.

The bridge saw's tilting capability and rotational head enable complex angle cuts and seamless joint preparation. This precision fabrication reduces installation time, minimizes waste, and delivers the flawless finishes that homeowners expect from premium granite installations.

Marble > Bathroom Vanities

|

|---|

|

Marble bathroom vanities epitomize elegance and sophistication in luxury bathroom design. The YTQJ-600's advanced CNC control enables precise marble slab processing for vanity tops, ensuring perfect dimensional accuracy and smooth edge finishing.

The monoblock bridge cutting machine's infrared positioning system and servo motor control provide exceptional stability during delicate marble cutting operations. Professional fabricators achieve superior results with reduced material loss and enhanced surface quality, meeting the exacting standards required for high-end residential and commercial bathroom installations.

Quartz > Commercial Surfaces

|

|---|

|

Commercial quartz surfaces demand durability and consistency for high-traffic environments. The stone cutting machine excels in processing engineered quartz slabs for restaurant counters, office reception desks, and retail displays.

Advanced CNC control enables precise cutting of dense quartz material while maintaining edge integrity. The machine's robust construction and powerful motor handle the hardness of engineered quartz efficiently.

Professional installations benefit from perfect dimensional accuracy and seamless joints. This precision reduces on-site adjustments and delivers the flawless commercial-grade finishes that businesses require for their public spaces.

Engineered Stone > Flooring

Engineered stone flooring combines natural beauty with enhanced performance characteristics. The bridge saw processes composite stone materials into precise flooring tiles and large format slabs for luxury installations.

Multi-axis capability enables complex edge profiles and interlocking designs essential for modern flooring systems. Variable speed control optimizes cutting performance across different engineered stone compositions.

Fabricators achieve consistent thickness and perfect edge matching critical for seamless floor installations. The precision cutting reduces waste and ensures tiles fit perfectly together, creating stunning continuous surface appearances in high-end residential and commercial projects.

Ceramic > Wall Cladding

|

|---|

|

Ceramic wall cladding transforms architectural facades with sophisticated design possibilities. The bridge stone cutting machine handles large ceramic panels and intricate cutting patterns required for modern building exteriors and interior feature walls.

Precision CNC control prevents chipping and ensures clean edges essential for professional cladding installations. The machine's capability for decorative interior products offers precision cutting that meets architectural specifications.

Architects achieve complex geometric patterns and seamless panel alignments that enhance building aesthetics. The accurate cutting enables tight joints and perfect panel registration, creating striking visual effects that define contemporary architectural design.

Residential Kitchen Fabrication

Transforming Production Efficiency for Custom Countertops

A leading countertop fabricator upgraded to the YTQJ-600 to meet growing demand for custom granite installations. The machine's 18.5kW motor and precision capabilities reduced production time by 40% while maintaining edge quality.

Specs and options

Specifications customizable upon request.

| Model | Unit | YTQJ - 600 |

|---|---|---|

| Blade diameter | mm | 350 - 600 |

| Max. Working size (L×W×H) | mm | 3200×2000×180 |

| Worktable size | mm | 3200×2000 |

| Max.lifting travel | mm | 230 |

| Max. Horizontal running travel | mm | 3200 |

| Water consumption | m³/h | 3 |

| Main motor | kw | 18.5 |

| Overall dimension (L×W×H) | mm | 5800×2700×2250 |

| Weight | t | 5.5 |

| Worktable tilting degree (optional) | n° | 0 - 85° |

| Blade rotated angle (optional) | n° | 90/180/270/360° |

| Blade tilted angle (optional) | n° | 0 - 45° |

Monoblock design meets CNC precision for ultimate stone cutting

Monoblock Bridge Saw: Precision Stone Cutting

Easy Operation with CNC System

User-friendly CNC interface with touchscreen control simplifies programming and operation

Ultra-Precision Cutting Technology

Servo motor system with encoder positioning ensures ±0.5mm cutting accuracy

Monoblock Design Advantages

Single-piece construction enables easy transportation and installation without foundation

Maximum Production Efficiency

18.5kW motor with variable speed control maximizes cutting speed

Versatile Multi-Axis Capability

3-5 axis operation with rotation and tilting enables complex shapes

Cost-Effective Operation

Reduced waste and faster processing lower production costs significantly

FAQs

Common Questions About Monoblock Bridge Saw Stone Cutting Machines

What is a monoblock bridge saw machine?

Definition and Core Features:

A monoblock bridge saw is a single-piece stone cutting machine specifically engineered for precision fabrication of natural and engineered stone materials. Key characteristics include:

- Single-piece construction: Eliminates assembly requirements and foundation needs

- Enhanced stability: The monoblock design of this stone machinery allows for greater stability during the cutting process

- CNC automation: Up to 5-axis operation for complex cutting geometries

- Versatile applications: Countertops, monuments, architectural elements

The YTQJ-600 represents advanced monoblock technology with CNC control system, delivering exceptional precision for demanding stone fabrication projects.

What can the bridge saw cut?

Comprehensive Material Compatibility:The YTQJ-600 handles diverse stone materials with its 18.5kW motor power and 350-600mm blade diameter range:

Natural Stones:

- Granite (all hardness levels)

- Marble and limestone

- Sandstone and travertine

- Slate and quartzite

Engineered Materials:

- Quartz composites and engineered stone

- Ceramic and porcelain slabs

- Ultra-compact surfaces (Dekton, Neolith)

- Sintered stone materials

The machine's variable speed control optimizes cutting performance across different material densities, ensuring clean cuts and minimal chipping regardless of material type.

How accurate is the monoblock bridge saw cutting precision?

Precision Specifications and Technology:

The YTQJ-600 achieves industry-leading cutting accuracy through advanced control systems:

Precision Specifications:

- Cutting accuracy: ±0.5mm (demonstrated in laboratory conditions)

- Maximum blade diameter: 600mm for optimal cutting depth

- Working dimensions: 3200×2000×180mm capacity

Precision Technology:

- Ultra-high precision rotary encoder positioning

- Servo motor control with closed-loop feedback

- Linear slide guidance system

- Robust monoblock construction eliminating vibration

This precision level makes the YTQJ-600 ideal for demanding applications including luxury countertops, architectural elements, and precision monument work.

What are the main advantages of 5-axis bridge saw?

Multi-Axis Capabilities and Benefits:

5-axis operation transforms stone fabrication possibilities through advanced movement control:

Axis Capabilities:

- X-Y axes: Horizontal movement across work surface

- Z-axis: Vertical blade positioning and depth control

- A-axis: Blade can rotate 90 degrees and tilt 45 degree while worktable can rotate 360 degrees and tilt 85 degrees

- C-axis: Continuous 360° head rotation capability

Operational Advantages:

- Complex geometries: Cut curves, bevels, and intricate shapes without repositioning

- Time efficiency: Reduces setup time by 60% compared to manual repositionin

- Quality consistency: Eliminates human error in angle adjustments

- Advanced fabrication: Enables previously impossible geometric cuts

- Reduced waste: Optimal material utilization through precise positioning

This multi-axis capability significantly enhances productivity while enabling complex stone fabrication projects that define modern architectural design.

How does the CNC control system improve bridge saw operation?

Advanced CNC Control System Features:

The YTQJ-600's CNC control system revolutionizes stone cutting through intelligent automation:

Control Interface:

- 12" touchscreen display: Cnc axes control unit with 12'' touchscreen colour display for cuts programming

- Human-machine interface: Intuitive programming and operation

- Multi-language support: Operator-friendly interface design

- Real-time monitoring: Live cutting parameters and status display

Automated Functions:

- Automatic execution: Allow the automatic execution of cutting, drilling and milling cycles without manual intervention

- Parametric programming: Parametric geometric shape generation function to facilitate the creation of the most common cutting programs

- Error prevention: Built-in safety checks and collision avoidance

- Precision control: Exact parameter control reduces operator error

- Consistent results: Repeatable quality across production runs

This advanced control system transforms complex stone fabrication into simplified, automated processes while maintaining exceptional precision and quality.

What maintenance does the monoblock bridge cutter require?

Comprehensive Maintenance Schedule:The YTQJ-600's robust construction minimizes maintenance requirements while ensuring optimal performance:

Daily Maintenance (5-10 minutes):

- Water flow system verification and pressure check

- Work surface cleaning and debris removal

- Visual blade inspection for wear or damage

- Coolant level and quality assessment

Weekly Maintenance (30 minutes):

- Linear guide lubrication and cleaning

- Servo motor alignment verification

- Water filtration system cleaning

- Safety system function testing

Monthly Maintenance (2 hours):

- Encoder calibration and positioning accuracy check

- Spindle bearing inspection and lubrication

- Electrical connection tightening and inspection

- Complete system diagnostic and performance review

Durability Features: The galvanized frame construction and quality components significantly extend service intervals and reduce overall maintenance costs.

Can the bridge cutting machine handle large stone slabs?

Large Slab Processing Capabilities:The YTQJ-600 is specifically designed for efficient processing of large-format stone materials:

Physical Specifications:

- Working dimensions: 3200×2000×180mm (L×W×H)

- Maximum slab size: Accommodates industry-standard 3200×2000mm slabs

- Load capacity: 2000 lbs (approximately 900kg) table capacity

- Material thickness: Up to 180mm cutting capability

Handling Features:

- Hydraulic tilting: Optional system for easier material loading and positioning

- Extended travel: 3200mm horizontal running travel eliminates repositioning needs

- Vacuum system: Secure slab holding during cutting operations

- Support structure: Reinforced frame handles maximum loads safely

Productivity Benefits: Full-size slab processing capability improves material yield, reduces handling time, and maintains consistent cut quality across large workpieces, making it ideal for commercial countertop and architectural applications.

Certifications & Standards

Monoblock Bridge Saw: Precision Stone Cutting

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Transform Your Stone Slab Cutting Operations?

Discover how Monoblock Bridge Saw delivers precision, efficiency and profitability.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Monoblock Bridge Saw Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский