Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

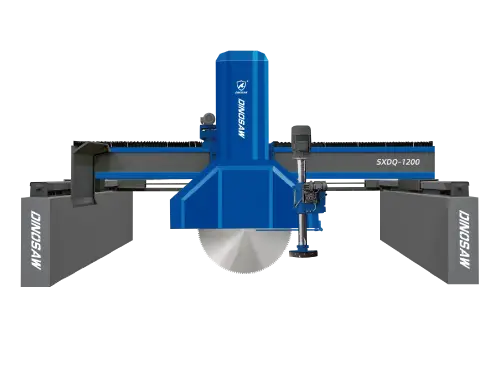

Stone Block Cutter with Horizontal Blade

SXDQ-1200/1400/1600

Compatible Materials & Products

Professional Stone Block Cutting and Trimming

▶ Product Demo

▶

▶

Granite > Tombstone Cutting

|

|---|

|

|

Granite blocks require precise cutting to create tombstones that honor memories while meeting strict dimensional requirements. Traditional tombstone production often struggles with inconsistent thickness and rough edges that require extensive finishing work. DINOSAW's dual-blade system addresses these challenges by delivering clean, precise cuts that maintain granite's natural beauty while achieving the exact specifications demanded by memorial stone fabricators.

The horizontal blade coordination with vertical cutting creates complete tombstone blanks with professional edges, eliminating the labor-intensive manual splitting process. This automation is particularly valuable in tombstone production where dimensional accuracy directly affects engraving quality and installation fit. Furthermore, the consistent cutting process ensures uniform thickness across all tombstones, making inventory management and pricing more predictable for monument dealers.

What makes this technology especially effective for granite tombstone cutting is its ability to handle granite's varying hardness zones without compromising surface quality. The PLC control system automatically adjusts cutting parameters to accommodate granite's natural characteristics, ensuring that each tombstone blank meets the high standards expected in memorial stone work. This reliability translates to reduced waste, faster production times, and enhanced customer satisfaction.

Marble > Dimensional Slab Cutting

Marble dimensional slab cutting requires exceptional precision to preserve the stone's natural veining while achieving consistent thickness for commercial applications. Traditional cutting methods often introduce stress fractures or surface imperfections that compromise marble's inherent beauty. DINOSAW's vibration-free cutting technology addresses these concerns by maintaining marble's delicate veining patterns while producing dimensional slabs with mirror-like surfaces that meet architectural specifications.

The automated dual-blade system transforms marble blocks into standardized dimensional slabs with remarkable consistency. Unlike conventional methods that rely on manual splitting, this coordinated cutting approach eliminates human error and material waste. The horizontal cutting capability ensures complete separation from blocks, delivering slabs that are ready for immediate processing or installation without secondary finishing operations.

Consider the economic advantages: marble's value depends heavily on consistent quality and minimal waste. DINOSAW's precision cutting maximizes yield from each block while maintaining the dimensional accuracy that architects and contractors demand. The system's ability to handle marble's natural variations in density ensures consistent results regardless of the stone's geological characteristics, making it an ideal solution for large-scale dimensional slab production.

Limestone > Kerb Stone Cutting

Limestone kerb stone cutting demands precision to meet municipal infrastructure standards while handling the material's unique processing challenges. Limestone's softer composition and varying density zones require careful parameter control to achieve uniform dimensions without material degradation. DINOSAW's adaptive cutting technology manages these variables effectively, producing kerb stones with clean edges and consistent dimensions that meet strict municipal specifications.

The horizontal cutting system revolutionizes kerb stone production by eliminating manual splitting operations that often resulted in dimensional inconsistencies. Traditional methods required workers to manually separate vertically cut limestone sections, a process prone to human error and material waste. DINOSAW's automated approach ensures complete separation from blocks, creating ready-to-install kerb units with uniform 150mm×300mm dimensions and ±2mm tolerance.

Municipal contractors particularly value the system's ability to maintain cutting quality across limestone's natural variations in hardness and porosity. The PLC control automatically adjusts cutting parameters to accommodate these differences, ensuring consistent performance throughout the entire block. This capability is essential for infrastructure projects where dimensional accuracy directly impacts installation efficiency and long-term roadway performance.

Sandstone > Block Trimming

Sandstone block trimming requires delicate handling to prevent delamination while achieving precise dimensional tolerances for architectural applications. Sandstone's layered geological structure presents unique challenges that traditional trimming methods often struggle to address effectively. DINOSAW's controlled cutting approach manages sandstone's characteristics through precise pressure regulation and optimized cutting speeds, ensuring clean trimming operations without compromising structural integrity.

The dual-blade trimming system excels at removing irregular surfaces and achieving precise block dimensions for architectural projects. Unlike manual trimming methods that can introduce stress concentrations, the automated cutting process maintains uniform pressure distribution across the cutting surface. This consistency is particularly important for sandstone, where uneven pressure can cause unwanted fracturing along natural bedding planes.

What distinguishes this technology in sandstone block trimming is its ability to accommodate the material's natural variations while maintaining cutting precision. The integrated dust management system is especially crucial when trimming sandstone, as this material generates significant fine particles during cutting. The water cooling system not only controls dust but also prevents heat buildup that could affect sandstone's natural coloration and texture, preserving the material's aesthetic qualities for architectural use.

Quartzite > Block Cutting

Quartzite block cutting presents the ultimate test for stone processing equipment due to the material's exceptional hardness and crystalline structure. Traditional cutting methods often struggle with quartzite's resistance, leading to excessive blade wear and inconsistent results. DINOSAW's high-torque cutting system is specifically engineered to handle quartzite's demanding characteristics, delivering precise block cutting capabilities that maintain efficiency despite the material's extreme hardness.

The coordinated dual-blade approach is particularly advantageous for quartzite block cutting, as it distributes cutting forces more effectively than single-blade systems. This force distribution prevents the stress concentrations that can cause micro-fractures in quartzite's crystalline matrix. The automated cutting process maintains the stone's natural strength characteristics while achieving the precise dimensions required for high-end applications where quartzite's durability is paramount.

Furthermore, the system's robust construction ensures consistent performance even when processing the most challenging quartzite varieties. The precision control systems monitor cutting parameters continuously, adjusting for variations in material hardness to maintain optimal cutting efficiency. This reliability is crucial for commercial operations where quartzite's premium value demands zero tolerance for processing errors that could compromise material integrity or dimensional accuracy.

Infrastructure Kerb Stone Manufacturing

50% Efficiency Boost, ±2mm Precision

Municipal contractor used DINOSAW for limestone kerb stones. Horizontal blade eliminated manual splitting. Results: uniform 150mm×300mm stones, ±2mm tolerance. Efficiency increased 50%. Waste reduced 25%. Completed 10km roadway ahead of schedule.

Architectural Panel Processing

800+ Panels, Zero Rework Required

Stone supplier upgraded to DINOSAW SXDQ-1200 for sandstone panels. Dual-blade system produced 800+ panels, consistent 40mm thickness. Eliminated handling damage. Zero rework needed. Delivery time reduced 3 weeks. New quality standards established.

Specs and options

Specifications customizable upon request.

| Model | Unit | SXDQ - 1200 | SXDQ - 1600 |

|---|---|---|---|

| Crossbeam length | mm | 7260 | 7500 |

| Diameter of blade | mm | 1200 | 1600 |

| Max. cutting size (L×W) | mm | 3800×2100 | 3400×2100 |

| Max. vertical travel | mm | 1350 | 1350 |

| Main motor power | kw | 55/75 | 55/75 |

| Diameter of horizontal blade | mm | 400 - 600 | 400 - 600 |

| Vertical stroke of horizontal cutting column | mm | 850 | 850 |

| Main motor power for horizontal blade | kw | 11 | 11 |

| Overall dimensions (L×W×H) | mm | 7500×4350×6500 | 7500×4350×6500 |

| Water consumption | m³/h | 20 | 20 |

| Approximate weight | t | 9 | 9.5 |

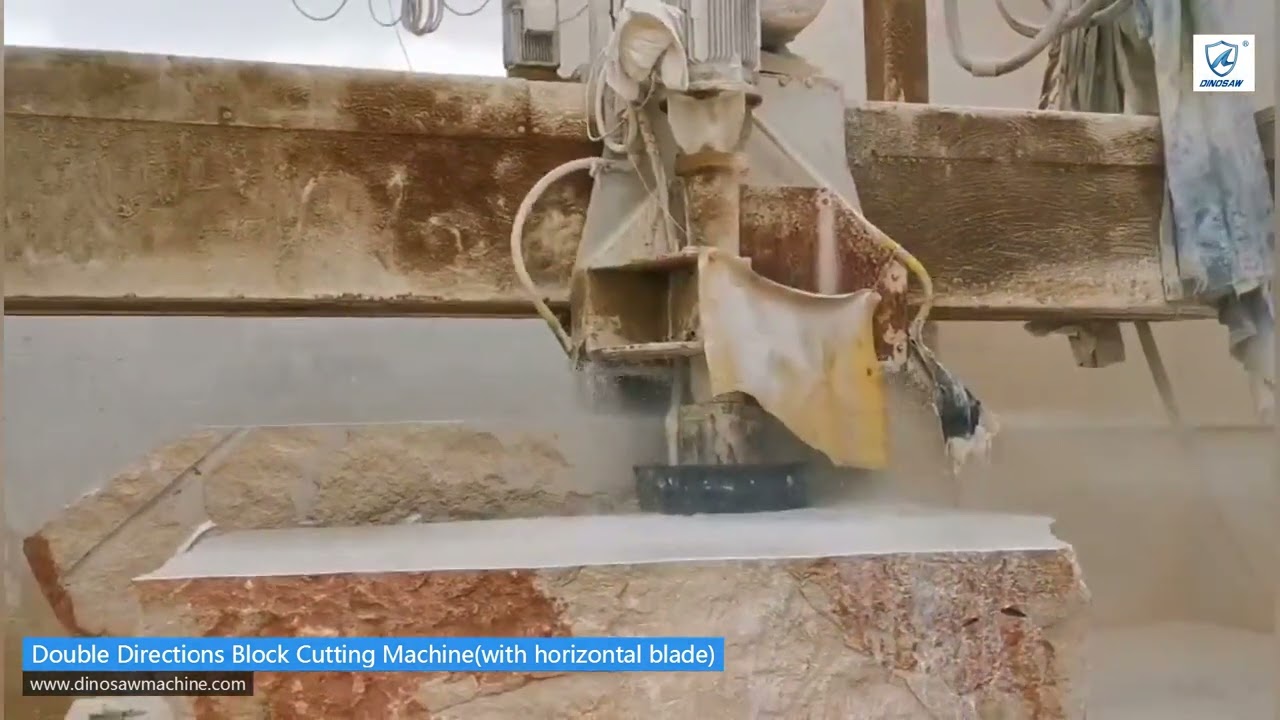

Horizontal cutting revolutionizes stone cutting

Dual-Blade. Automated. Efficient.

Automated Dual-Blade Cutting

Horizontal blade coordinates with vertical cutting to complete slab separation automatically

Eliminates Manual Splitting Operations

Maintains clean block foundations while cutting complete slabs, no secondary processing needed

PLC Control System

Programmable control enables precise parameter adjustment and automated cutting sequences for consistent results

Enhanced Operational Safety

Hydraulic feed and enclosed cutting area protect operators from injury

Minimal Maintenance Requirements

Robust bridge structure and quality components reduce downtime significantly

Versatile Material Compatibility

Cuts granite, marble, limestone, and other stones with equal efficiency

FAQs

Common Questions About Stone Block Cutter with Horizontal Blade

What is a stone block cutter with horizontal blade?

A stone block cutter with horizontal blade is a specialized machine that combines vertical and horizontal cutting capabilities to process stone blocks into slabs. The dual-blade design allows simultaneous cutting operations, significantly improving efficiency compared to single-blade systems. DINOSAW's SXDQ series features PLC control, hydraulic feed, and precision encoders for consistent results. This technology is particularly effective for granite and marble processing in commercial stone fabrication operations.

What materials can this stone block cutting machine process?

The DINOSAW stone block cutter processes granite, marble, limestone, sandstone, quartzite, and other natural stones effectively. It handles hardness variations from soft limestone to extremely hard granite with equal precision. The adjustable cutting parameters and robust bridge structure accommodate different stone densities and characteristics. Material thickness can range from 10mm for thin tiles up to 80mm for thick slabs, making it versatile for various applications including countertops, flooring, and architectural cladding.

How does dual-blade cutting improve efficiency?

Dual-blade cutting improves efficiency by performing vertical and horizontal cuts simultaneously, reducing processing time by up to 40%. Traditional single-blade machines require multiple passes or repositioning, while DINOSAW's system completes both operations in one cycle. The integrated design eliminates material handling between cutting stages, reducing labor requirements and potential damage. This efficiency gain directly translates to higher throughput and lower production costs per slab.

How much space does the machine require?

The SXDQ-1200 requires 7500×4350×6500mm installation space, while SXDQ-1600 needs similar footprint. Additional clearance for material handling and maintenance access should be planned. The machine can be installed on ground level without special foundations in most cases. Water supply connections and electrical requirements should be considered during facility planning. Our installation team provides detailed site preparation guidelines to ensure optimal setup.

What maintenance does the stone cutting machine require?

Regular maintenance includes daily blade inspection, weekly lubrication of moving parts, and monthly hydraulic system checks. The robust design minimizes maintenance requirements compared to conventional machines. Critical components use high-quality bearings and seals for extended service life. Preventive maintenance schedules are provided with detailed procedures. Technical support and genuine parts are available globally through DINOSAW's service network.

Can the machine cut different slab thicknesses?

Yes, the machine adjusts cutting thickness from 10mm to 80mm automatically through PLC programming. Multiple thickness settings can be programmed for batch production of various slab sizes. The hydraulic cutting head adjusts position precisely for each thickness requirement. This flexibility allows processors to respond quickly to market demands without manual adjustments or tooling changes.

What safety features are included?

Safety features include emergency stop buttons, protective enclosures around cutting areas, automatic blade guards, and hydraulic safety locks. Operators remain safely distanced from cutting operations through automated material handling. Water spray systems suppress dust and control temperatures. The PLC system monitors all safety parameters continuously and stops operation immediately if unsafe conditions are detected. All safety systems comply with international industrial safety standards.

Certifications & Standards

Dual-Blade. Automated. Efficient.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Transform Your Stone Cutting Operation?

Discover how DINOSAW dual-blade technology can boost your productivity and profits.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Stone Cutting Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский