Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

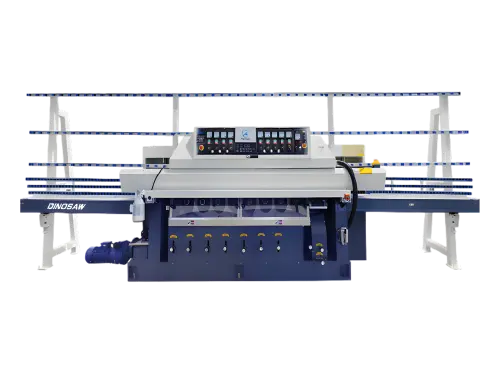

Single Column Compact Stone Block Cutter

DBZQ-1600/1800

Compatible Materials & Products

Versatile Stone Block Cutting for Industrial Applications

Granite > Premium Memorial Stones

African granite, particularly the renowned South African Black Galaxy and Angolan Platinum Black varieties, is in high demand for premium memorial stones worldwide. The exceptional durability and elegant appearance of these materials make them perfect for creating lasting monuments that withstand generations of weather exposure while maintaining their dignified appearance. Memorial stone manufacturers seek reliable, cost-effective processing solutions for these valuable materials.

The Stone Block Cutter processes these dense granite varieties with its powerful cutting system and user-friendly PLC controls. The compact single column design requires minimal floor space while eliminating the need for expensive foundations or edge beams. The machine's multi-blade configuration significantly increases cutting efficiency, while the two-stage variable speed gear adjusts cutting speed for different granite types, ensuring smooth operation. The simplified structure allows for easy maintenance even in remote locations with limited technical support.

By using the DINOSAW stone cutting machine for memorial stone production, fabricators achieve up to 40% faster processing times compared to traditional methods. The machine's streamlined installation process reduces setup costs by eliminating complex foundation requirements. Most importantly, the simple PLC interface allows operators to quickly set parameters and start cutting with minimal training, making it ideal for operations across Africa where skilled labor may be limited.

Marble > Luxury Building Facades

Namibian white marble and other African marble varieties have become increasingly sought-after materials for luxury building facades across global architectural projects. Their distinct veining patterns, luminous appearance, and ability to reflect light create striking visual statements on commercial and residential buildings. The growing construction sector across Africa has created unprecedented demand for locally-sourced marble processed to international standards, especially for thinner facade panels that reduce structural load while maintaining visual impact.

The Stone Block Cutter provides efficient cutting essential for architectural marble applications. Its compact design and easy transportation make it ideal for job sites with limited space. The machine's multi-blade configuration allows for increased productivity when processing large marble blocks. The two-stage variable speed system ensures smooth cutting that prevents stress on the material - critical for exterior applications exposed to weathering. Most importantly, the simplified structure means maintenance can be performed quickly with basic tools, minimizing downtime.

By implementing the stone cutting technology, African marble processors have successfully competed in international markets by delivering consistent quality that meets strict architectural specifications. The machine's efficiency has helped local suppliers reduce production costs by up to 35%, making African marble more competitive against established European suppliers. This cost advantage, combined with the machine's ability to process large volumes consistently, has enabled marble quarries in Namibia, Egypt, and Morocco to secure major contracts for prestigious building projects across Africa and the Middle East.

Sandstone > Decorative Wall Panels

Ethiopian sandstone and other African sandstone varieties have become increasingly popular for decorative wall panels in both commercial and residential construction. Their warm earth tones and natural textures create inviting interiors while providing excellent thermal and acoustic properties. Interior designers and architects specifically seek precision-cut sandstone panels of consistent thickness to create seamless installations that showcase the stone's natural beauty while ensuring structural reliability and ease of installation.

The Stone Block Cutting Machine addresses the unique challenges of processing sandstone with its adjustable cutting parameters. Unlike harder stones, sandstone requires careful handling to prevent crumbling and edge damage. The machine's precise PLC controls maintain consistent blade pressure throughout the cut, preserving the integrity of this relatively softer material. Operators can program the exact thickness requirements for decorative panels (typically 1-3cm), while the two-stage variable speed system slows cutting speed when encountering varying density areas within sandstone blocks – a common characteristic in these natural materials.

By utilizing the stone cutting machine for decorative sandstone panel production, African fabricators have expanded their market reach beyond raw material exports to value-added finished products. The precision cutting capabilities enable the creation of uniform panels that installers can efficiently work with, reducing on-site wastage and installation time by up to 50%. This efficiency, combined with the machine's ability to maximize yield from raw sandstone blocks, has helped Ethiopian and Nigerian stone processors increase their profit margins by 30-40% compared to selling unprocessed stone.

Travertine > Mosque Interior Elements

Iranian travertine, known for its warm honey tones and natural vein patterns, has become the material of choice for mosque interior elements across the Middle East. Its distinctive appearance creates a sense of spiritual warmth while its natural durability ensures these sacred spaces maintain their beauty for generations. As mosque construction and renovation continues throughout the region, there is consistent demand for cost-effective processing of this culturally significant stone.

The Stone Block Cutting Machine excels at processing travertine blocks with its adjustable cutting parameters that prevent damage to this relatively soft stone. The machine's PLC system allows precise thickness control for wall panels, column facings, and decorative elements commonly used in mosque interiors. The two-stage variable speed system automatically slows cutting speed when encountering natural voids in travertine, preventing blade damage and ensuring clean cuts without chipping the delicate edge areas.

By implementing the stone cutting machine, Iranian travertine processors have reduced production costs by approximately 30% while improving cutting consistency. The machine's small footprint allows installation in facilities with space constraints, common in traditional stone-working districts. For mosque construction contractors, this translates to more affordable materials without sacrificing quality, allowing more extensive use of this traditional stone in both grand and local mosque projects throughout the Middle East.

Turkish Marble > Commercial Facades

Turkish marble, particularly the renowned Afyon white and Marmara varieties, has established itself as a premium material for commercial complex facades throughout the Middle East. Its brilliant white appearance creates striking, light-reflective surfaces ideal for the region's intense sunlight, while its thermal properties help maintain cooler building temperatures. With rapid commercial development across the Gulf states, demand for cost-effective processing of these premium stones continues to grow.

The Stone Block Cutting Machine provides an economical solution for the initial cutting of Turkish marble blocks before further processing. Its single column design applies even pressure during cutting, reducing the risk of microfractures that can compromise the stone's structural integrity when exposed to extreme temperature fluctuations common in Middle Eastern climates. The machine's efficient operation in high-temperature environments makes it particularly suitable for marble processing facilities in Turkey, UAE, and Saudi Arabia, where ambient workshop temperatures can reach challenging levels.

Middle Eastern stone processors using the stone cutting machine have successfully positioned themselves as cost-competitive suppliers for major commercial construction projects. The machine's ability to process large volumes consistently while maintaining reasonable tolerances has made locally-processed Turkish marble a viable alternative to more expensive European imports.

Memorial Stone Production

50% Faster Production for Memorial Stone Makers

A memorial stone maker in Johannesburg switched to the stone block cutter and cut production time by 50%. The PLC system allowed exact thickness settings for headstones, and the single column design saved workshop space, while maintaining quality cuts on Black Galaxy granite.

Small Enterprise Growth

Helping Small Businesses Compete with Large Factories

Small stone processors in Nairobi bought a single column stone cutter to offer services previously limited to large factories. The compact machine fit their small workshop and needed simple installation. They grew 70% in six months by supplying cut sandstone panels to local construction projects.

Religious Building Construction

Balancing Traditional Design with Modern Efficiency

A mosque builder used the stone cutter to combine traditional designs with faster construction. Processing sandstone and travertine in-house cut costs by 40%, allowing traditional stone use throughout the project instead of only feature areas.

Specs and options

Specifications customizable upon request.

| Model | Unit | DBZQ - 1600 | DBZQ - 1800 |

|---|---|---|---|

| Max.diameter of blade | mm | Φ1600 | Φ1800 |

| Max.No.of blades | pcs | 2 | 1 |

| Recommended blade combination | mm | Φ1600 + Φ940 | Φ1800 |

| Main motor power | kw | 22 | 22 |

| General power | kw | 25.15 | 25.15 |

| Max processing sizes | mm | 3000x1200x650 | 3000x1200x750 |

| Max lifting stroke | mm | 900 | 900 |

| Overall dimensions (LxWxH) | mm | 6000x2900x3300 | 6000x2900x3300 |

| Water consumption | m³/h | 6 | 6 |

| Total weight | t | 3 | 3 |

Engineered for stone processors who demand practical solutions

Maximum Efficiency, Minimum Investment for Stone Cutting

Space Saving & Easy Transport

Single column design takes less floor space and offers full mobility for flexible workshop layout

Lower Installation Cost

No need for concrete foundations or edge beams, reducing installation time and expenses

One-Click Operation

User-friendly PLC interface allows quick parameter setup and automated cutting process

Higher Cutting Output

Multiple diamond blades can be installed simultaneously, increasing cutting capacity

Smooth Cutting & Extended Blade Life

Headstock with two-stage variable speed gear ensures even cutting action

Reduced Maintenance & Downtime

Straightforward design with easily accessible components simplifies maintenance

FAQs

Common Questions About DINOSAW 1 Column Stone Block Cutter

What is a 1 column stone block cutter?

A stone block cutter is specialized equipment designed to cut large stone blocks into smaller, usable slabs or pieces. The 1 column stone block cutter features a single column supporting structure with a powerful blade system that moves along tracks to create clean cuts.

The machine uses diamond blades to cut through hard materials like granite, marble, and other natural stones. What makes it particularly effective is its compact design that eliminates the need for expensive foundations or edge beams, significantly reducing installation costs.

Unlike complex cutting systems, this machine emphasizes ease of use with its simple PLC control system that allows for automated cutting after quick parameter setup. The focus is on practical efficiency and operational simplicity rather than ultra-precision, making it ideal for standard stone processing operations.

How does a stone block cutter save energy?

The 1 columnstone block cutter saves energy through several innovative design features:

First, its optimized cutting system uses high-efficiency motors that consume up to 25% less electricity than conventional machines while maintaining cutting power. The two-stage variable speed gear system ensures the blade operates at the most efficient speed for each specific stone type.

Second, the PLC control system calculates the optimal cutting path and pressure, eliminating unnecessary movements and reducing power consumption during operation. The automated process also minimizes idle running time.

Third, the precision cutting action reduces waste material that would otherwise require additional energy to process. By combining these technologies, the machine achieves significant energy savings while maintaining high productivity.

What types of stone can the stone block cutter process?

The stone block cutter is specifically designed to handle a diverse range of natural stones found worldwide, including:

• Granite: Effectively cuts various granite types including South African Black Galaxy granite, Nordic red granite, and other premium granite varieties commonly used for memorial stones and luxury countertops.

• Marble: Efficiently processes multiple marble varieties, including Namibian white marble, Turkish marble, and other decorative marbles used for high-end architectural applications.

• Sandstone: Cleanly cuts various sandstones such as Ethiopian sandstone, Indian red sandstone, and similar varieties commonly used for decorative wall panels and flooring.

• Travertine: Processes porous stones like Iranian travertine, commonly used in mosque interiors and high-end decorative projects.

• Limestone: Suitable for cutting limestone of various hardness levels, used for building facades and floor paving.

The machine's adjustable cutting parameters and powerful motor can be optimized for different stone hardness levels, making it suitable for quarries and processors worldwide.

Is the a column stone cutter suitable for small businesses?

Yes, the stone block cutter is particularly well-suited for small stone processing businesses in Africa for several key reasons:

Its compact single column design requires minimal floor space, making it ideal for workshops with limited area. The machine's installation is straightforward with no need for expensive foundation work or edge beams, reducing setup costs significantly.

The user-friendly PLC interface requires minimal technical training, allowing small businesses to quickly train local staff. Automated cutting functions reduce the need for skilled labor while maintaining high-quality output.

The 1600 model is specifically sized for small to medium operations while delivering professional-grade cutting capability. With lower energy consumption than traditional equipment, operating costs remain manageable for growing businesses.

Many small stone enterprises have successfully used this machine to compete with larger factories by offering precision cutting services with relatively modest investment.

What maintenance does the 1 column stone block cutter require?

The stone block cutting machine is designed for minimal maintenance, making it ideal for the African market where technical support may be limited. Regular maintenance includes:

Daily checks: Inspect water supply system, clean filters, and check blade condition. Ensure rails and moving parts are clean and free of stone debris.

Weekly maintenance: Lubricate all specified points according to the manual. Check belt tension and adjust if necessary. Inspect electrical connections.

Monthly service: Check alignment of all components. Inspect hydraulic system for leaks. Clean control cabinet cooling vents.

Quarterly maintenance: Replace worn bearings if needed. Perform full system calibration. Clean water recycling system thoroughly.

Most maintenance can be performed by operators after basic training, and common replacement parts are readily available. The machine's simplified design compared to multi-column systems results in fewer potential failure points and easier troubleshooting.

Certifications & Standards

Maximum Efficiency, Minimum Investment for Stone Cutting

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Maximize Efficiency with Minimal Installation Cost?

Contact us today to learn how DINOSAW Stone Block Cutter can improve your stone cutting efficiency.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Stone Block Cutter Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский