Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Can this stone turning machine handle your parts? Our guide covers baluster profiling, material compatibility, vertical vs horizontal stone lathes, and marble baluster cutting.

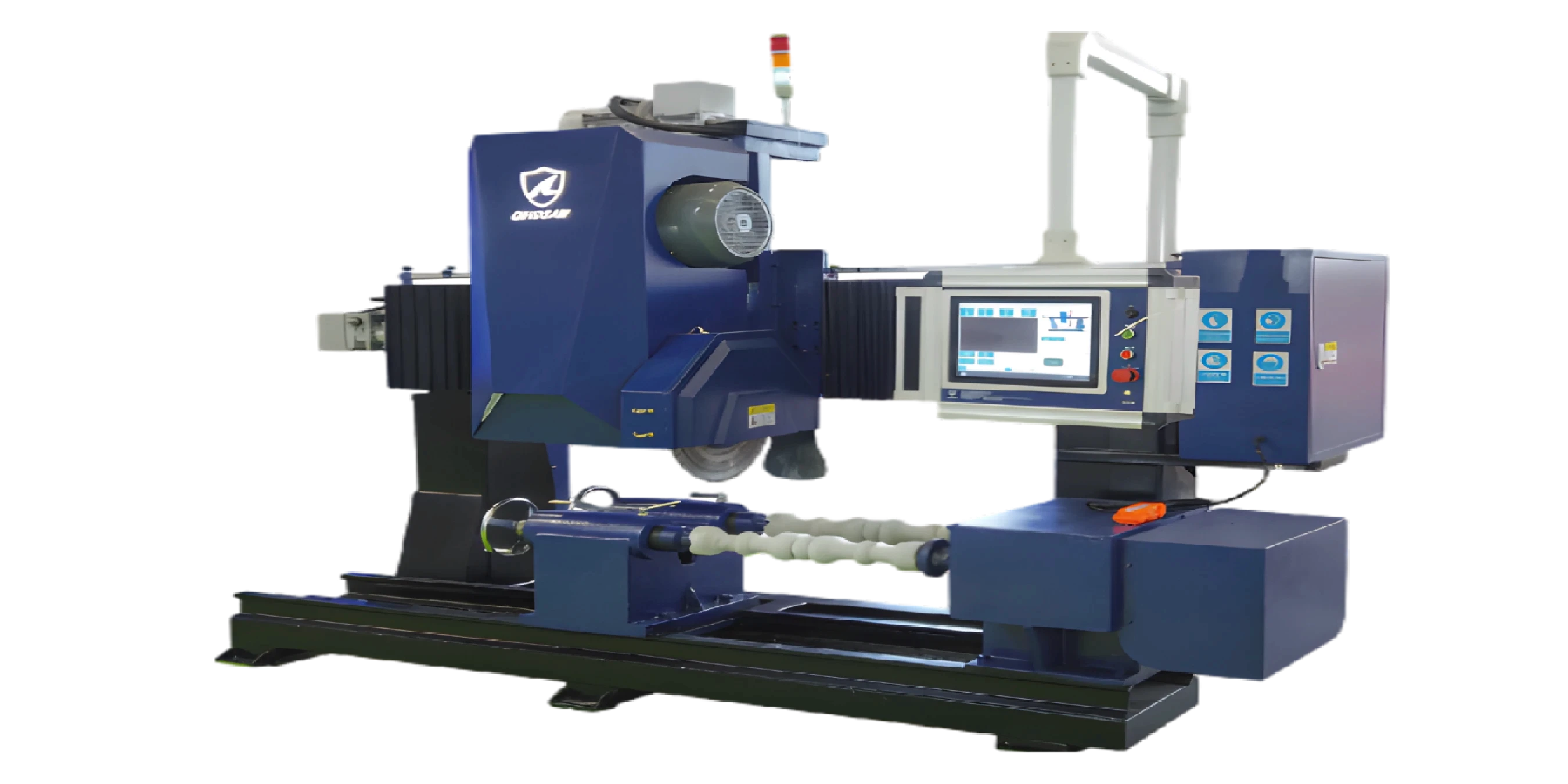

If you shape granite columns, balusters, or other circular stone components, a CNC stone lathe is the key to eliminating rework and unlocking repeatable precision for profitable custom work. Unlike manual methods that depend heavily on operator skill, a CNC-driven process ensures every piece meets exact specifications, reducing waste and boosting your bottom line.

This guide is designed for procurement managers and distributors who need to answer a critical question: "Can this CNC stone lathe process my parts efficiently and reliably?" We'll walk through its applications, capabilities, and the practical considerations for integrating it into your workflow.

Talk to a DINOSAW engineer about your cutting size and tooling selection to confirm compatibility.

What This Stone Lathe Machine Can Do

A stone lathe machine is engineered for turning and profiling cylindrical stone workpieces. Its primary function is to shape raw blocks of stone into finished architectural and decorative elements with high precision. Common applications include:

- Architectural Columns: Crafting everything from monolithic granite columns to smaller decorative pillars.

- Balusters & Railings: Producing uniform sets of monument balusters and railing sections from marble, limestone, and sandstone.

- Decorative Items: Creating custom stone vases, garden ornaments, and other high-value pieces that are impossible to mass-produce manually.

The machine's capabilities are directly tied to its dimensional capacity. For example, a stone column machine configuration will support larger diameters and lengths (e.g., Ø ~1500mm, L ~3000mm (model-dependent)), while smaller models are optimized for balusters (e.g., Ø ~300mm, L ~1200mm (model-dependent)).

Can A CNC Stone Lathe Process My Part?

To determine if a CNC stone lathe fits your needs, follow this decision logic:

- Material Hardness: Is your material hard like granite or softer like marble or limestone? This choice influences tooling and parameter selection. For instance, limestone baluster machining requires different settings than harder stones to prevent fractures.

- Part Geometry: Is the design primarily cylindrical with profiles, tapers, or grooves? The lathe excels at these shapes. Complex, non-symmetrical features may require a different type of stone CNC machine.

- Support Needs: Long, slender parts like those for sandstone railing turning may require a tailstock or steady rests to prevent vibration and deflection during processing.

- Surface Finish: Are you aiming for a rough-cut profile or a near-polished finish? The final quality depends on the final pass parameters and tooling choice.

- Batch Size: The CNC system is ideal for both one-off custom jobs and repeatable batch production, offering significant efficiency gains over manual setups for series of identical parts.

Vertical vs Horizontal Stone Lathe for Baluster Profiling

The orientation of the lathe-vertical or horizontal-impacts workholding, footprint, and precision. A vertical stone lathe is excellent for heavy, large-diameter parts, as gravity assists with secure clamping and alignment. However, a horizontal stone lathe is often preferred for long, slender parts like balusters, as it provides easier access and support along the length of the workpiece. The choice also affects the factory footprint.

As for controls, our machines are CNC by default for maximum flexibility, though a PLC can be fitted for simpler, repetitive tasks. For a detailed breakdown, see our guide on How to Choose the Right Stone Lathe: CNC vs. PLC.

Tooling for Granite Column Turning & Custom Vases

Tool selection is critical for success. For aggressive material removal in granite column turning, diamond segments are often used. When creating a custom vase stone lathe project, a combination of tools may be required to rough out the shape and then refine the final profile.

Start with conservative feed, moderate RPM, and continuous wet-cutting; refine via test cuts.

Processing Boundaries (What It Can and Cannot Do)

While versatile, the stone lathe has its limits. It is not recommended for processing unsupported, thin, or brittle materials like some sintered stones, which may fracture under clamping or turning forces. A thorough review of the material properties and part geometry is a prerequisite to avoid costly failures.

Brief Workflow for Column Base Profiling

A typical workflow for column base profiling involves four main steps:

- Clamping: Securely mount the stone block in the chuck and tailstock (if needed).

- Centering: Ensure the workpiece is perfectly centered to prevent eccentric rotation.

- Test Cut: Perform a shallow test cut to verify parameters and alignment.

- Fine-tuning: Adjust feed rate, speed, and depth of cut based on the test cut results before running the full program.

Advantages vs Legacy Stone CNC Machinery

Compared to older stone CNC machinery, a modern CNC stone lathe offers tangible benefits. Versus manual lathes, it delivers unparalleled repeatability and reduces labor dependency. Against PLC-only lathes, it provides far greater programming flexibility for custom jobs. When compared to trying to adapt a bridge saw for turning, the lathe offers superior roundness, surface finish, and overall efficiency for cylindrical parts.

Three Mini Cases of CNC Stone Lathe

Case 1: Monument Baluster Batch

- Input: 100 raw marble blocks (300x300x1200mm).

- Process: A CNC program was created for the baluster profile. The machine ran continuously with minimal operator supervision.

- Output: 100 identical marble balusters.

- Result: Production time was reduced by 60% compared to the previous manual process, with zero rejects for dimensional errors.

Case 2: Column Base Restoration

- Input: A damaged historical limestone column base.

- Process: The original profile was digitized, and a CNC program was generated. The lathe precisely replicated the intricate details.

- Output: A historically accurate replacement column base.

- Result: The restoration project was completed with a level of accuracy that would have been prohibitively expensive with manual carving. It showcases how a CNC stone lathe can unlock CNC Stone Lathe: Unlock High-Profit Architectural Elements.

Case 3: Custom Vase Production

- Input: A single block of onyx.

- Process: A designer's 3D model was converted to a toolpath. The lathe performed roughing and finishing passes.

- Output: A one-of-a-kind, high-value decorative vase.

- Result: The fabricator was able to enter a new, profitable market for bespoke stone art pieces.

Next Steps: Get a Quote

Ready to see if a CNC stone lathe is right for your application? Contact our engineering team to discuss your specific part dimensions, materials, and production goals. We can provide a detailed quote and confirm if our CNC Stone Lathe is the right fit for your factory.

Frequently Asked Questions

Can a CNC stone lathe handle Ø200×L1200 balusters?

Yes, this is a standard size for balusters. The machine's suitability depends on the following:

- Capacity: Most models handle dimensions like Ø ~300mm and L ~1200mm (model-dependent).

- Workholding: A chuck and tailstock are required. A steady rest is recommended for long, slender parts to prevent vibration.

- Materials: Ideal for marble, limestone, and sandstone. Granite requires more conservative feed rates.

- Next Step: Share your part drawings with us to confirm programming and fixture requirements.

Vertical vs horizontal stone lathe - which gives better roundness for baluster profiling?

A horizontal lathe generally yields better roundness for long parts like balusters.

- Horizontal Advantage: Provides better support with a tailstock and/or steady rests, which reduces workpiece deflection and vibration.

- Vertical Use Case: Better for heavy, large-diameter, but shorter parts (like column bases) where gravity aids in stable clamping.

- Key Finish Drivers: Overall rigidity, tool condition, feed/RPM rates, and consistent coolant flow are critical for a good finish on either machine type.

How to avoid chipping on a stone turning machine (baluster profiling)?

Control stress at the tool's entry/exit points and maintain system rigidity.

- Machine Settings: Use sharp tools, moderate RPMs, and adequate coolant.

- Cutting Strategy: Our bidirectional cutting capability reduces stress and chip risk at the edges of the workpiece.

- Setup Checklist: Verify secure clamping, minimize workpiece overhang, and always perform a test cut to fine-tune parameters before a full run.

Power & dust control requirements for a stone lathe for sale?

You need an industrial three-phase power supply plus a system for wet cutting and slurry management.

- Power: A 380V/50Hz or 480V/60Hz supply is typical (local-dependent).

- Dust Control: Wet cutting is the primary method to suppress dust and ensure compliance with silica dust regulations.

- Facility Requirements: Plan for floor drainage, a water filtration/recycling system, and designated areas for Personal Protective Equipment (PPE).

Typical starting parameters for granite vs marble ?

Parameters are set during commissioning and fine-tuned with test cuts, as they are tool- and machine-specific.

- For Granite: Use lower feed rates and higher tool pressure due to its hardness.

- For Marble: Use higher feed rates but avoid aggressive passes to prevent fractures.

- Coolant: Ensure ample flow directed at the cutting zone for both materials.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский