Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Optimize your stone factory's profitability with our expert guide to industrial stone lathes. Compare CNC and PLC systems, analyze machine capabilities, and find the perfect equipment for your business needs.

Cut through the marketing noise and find the perfect machine for your business. This guide breaks down everything you need to know about stone lathes-from PLC vs CNC systems to real ROI calculations.

Looking for a stone lathe that actually pays for itself? You're not alone. Most factory owners struggle with the same question: "Which machine will boost my productivity without breaking the bank?"

Here's what I've learned after helping dozens of stone factories upgrade their equipment: the right choice depends on three factors-your typical order size, customization level, and budget constraints. Let's dive into what really matters.

Stone Lathe Comparison: Quick Find Your Perfect Match

Everything you need to compare our stone lathes in one place. This comprehensive table cuts through the technical jargon and shows you exactly what each machine does best, along with the specs that actually matter for your daily operations.

| Machine Type | Best For | Working Area | Spindle Power | Machine Weight |

|---|---|---|---|---|

| CNC Bridge Type Stone Lathe | Custom Roman columns, de corative pieces,vases, balls | 230/4pcs, 460/2pcs | 11*2kw | 5t |

| CNC Integrated Profiling Machine | Mixed production, versatile projects | 2500×3300mm | 22kw | 8t |

| PLC Vertical Multi-Head Stone Lathe | High-volume balusters, railings | 300/2pcs, 220/4pcs | 11*2kw | 4.2t |

| PLC Column Cap & Base Profiling Machine | Extra-large monuments, massive fountains | φ 2000mm | 15kw | 6.5t |

📏 Working Area Reality:

Think about your typical piece size. The "customizable" options usually add 4-6 weeks to delivery but are worth it if you need specific dimensions.

⚡ Control System Basics:

- CNC = Flexible programming for custom work

- PLC = Reliable automation for repetitive tasks

- Wecon systems provide solid support worldwide

Still not sure which machine fits your needs? Get personalized recommendations based on your specific production requirements and budget. Our experts can help you choose the right stone lathe machine and calculate your expected ROI.

Deep Dive: Which Machine Actually Fits Your Business?

Numbers and specs are nice, but what do they mean for your bottom line? Let me break down each machine based on real-world performance and actual customer feedback.

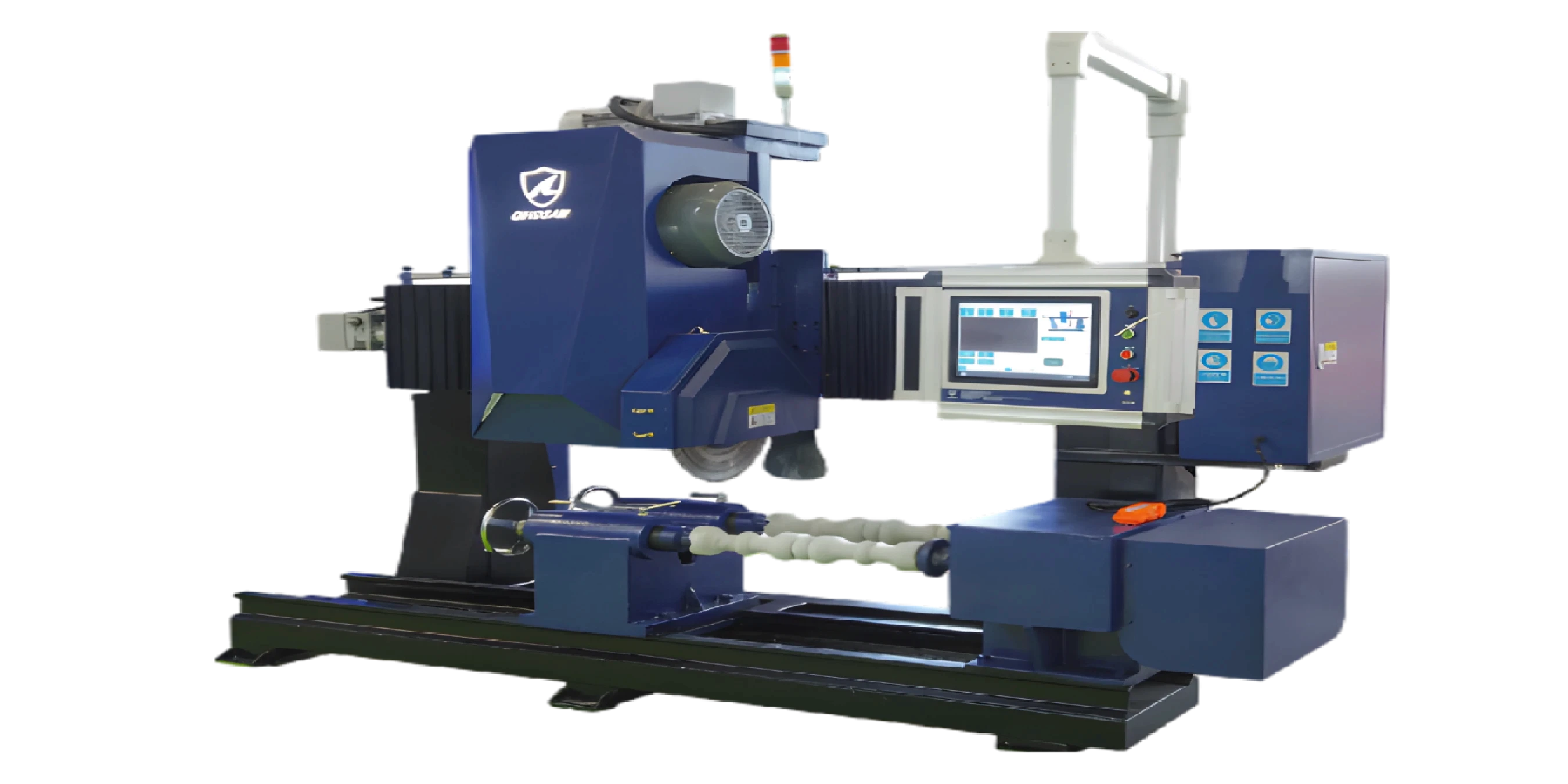

CNC Bridge Type Stone Lathe Machine: The Custom Work Champion

What makes this machine special? It's all about flexibility without the complexity. Think of it as your Swiss Army knife for stone work-versatile enough for custom projects but simple enough that you won't need a PhD to operate it.

Why customers love it:

- CNC system that actually makes sense (no engineering degree required)

- Built-in shape library gets you started fast

- Bidirectional cutting cuts production time nearly in half

- Perfect for those "unique" customer requests that pay premium rates

Real-world performance:

- Handles columns from 200-600mm diameter

- Typical setup time: 15-30 minutes per new design

- Material waste reduced by 20-30% vs manual methods

- Average operator training: 2-3 weeks

💰 ROI Reality Check:

Most factories see payback in 12-18 months. The key? It lets you say "yes" to custom projects that typically command 40-60% higher margins than standard work.

PLC Vertical Multi-Head Stone Lathe: The Volume Monster

Need to crank out hundreds of identical pieces? This is your machine. While others are making one baluster, you're making eight. It's that simple.

The numbers that matter:

- 8 identical pieces processed simultaneously

- Up to 800% faster than single-head machines

- PLC system = rock-solid reliability

- Perfect for landing those big construction contracts

Best use cases:

- Balusters for large residential projects

- Standard columns for commercial buildings

- Repetitive architectural elements

- Any high-volume, standardized production

🎯 Who should buy this:

If your typical order is 100+ identical pieces, this machine will transform your business. One customer told me it let them bid on projects they previously couldn't handle due to timeline constraints.

CNC Stone Profiling Machine: The All-in-One Solution

Ever wished you could cut, profile, and finish in one setup? That's exactly what this machine does. It's like having three machines rolled into one-which explains the higher price tag.

Why it's worth the investment:

- No more moving heavy pieces between machines

- Switch between projects with a few clicks

- Handles both flat and complex 3D profiles

- Expands your service offerings significantly

Perfect for:

- Architectural facade work

- Custom fireplace surrounds

- Intricate railing designs

- Mixed production environments

⚠️ Honest assessment:

This is the most expensive option, but also the most versatile. If you're doing diverse, high-value projects, it pays for itself. If you're mainly doing one type of work, you might be better with a specialized machine.

Column Cap & Base Stone Lathe Machine: The Heavy-Duty Specialist

When standard machines can't handle the size, this is what you need. It's built for those massive pieces that make neighbors stop and stare.

🎯 Niche but profitable:

This machine opens doors to high-margin landscape and monument projects. One fountain job can pay for months of regular work. Just make sure you have the market for large-scale pieces before investing.

Roman Column Profiling Machine: The Length Master

Need to handle columns that are several meters long? Most machines struggle with maintaining precision over such lengths. This one doesn't.

🏗️ Specialized market:

Perfect for architectural restoration, luxury homes, and commercial buildings that need authentic long columns. The market is smaller, but the margins are typically excellent.

Your Questions Answered

What's the real ROI timeline for a CNC stone lathe?

Here's the honest answer: it depends on your current setup and order mix. Most customers see breakeven in 12-24 months, but I've seen it happen in 8 months for high-volume shops.

The real value comes from three areas: reduced labor costs (typically 30-40% savings), less material waste (20-25% improvement), and the ability to take on higher-margin custom work. One customer told me the machine paid for itself in 10 months just from being able to bid on projects they couldn't handle before.

PLC vs CNC-which system makes more sense for my business?

Think of it this way: PLC is like cruise control for highway driving (perfect for repetitive work), while CNC is like having a GPS that can take you anywhere (ideal for custom projects).

Choose PLC if:

- 80%+ of your work is standardized pieces

- You value reliability over flexibility

- Your operators prefer simple, consistent interfaces

- High-volume production is your main goal

Choose CNC if:

- Custom projects make up 40%+ of your revenue

- You want to expand into new product lines

- Your customers frequently request modifications

- You're comfortable with slightly more complex operation

How critical is after-sales support really?

Extremely critical. I've seen businesses lose weeks of production waiting for parts or technical support. Here's what to look for:

- Local spare parts availability: Can you get common parts within 48 hours?

- Remote diagnostics capability: Can they troubleshoot issues without sending a technician?

- Training quality: Do they provide comprehensive operator training, not just a quick demo?

- Response time guarantees: What's their commitment for urgent issues?

With Dinosaw, we provide comprehensive support including operator training, remote diagnostics, and maintain parts inventory in major markets to minimize downtime.

What maintenance should I budget for?

Most people underestimate this. Budget around 3-5% of the machine cost annually for maintenance and parts. That breaks down roughly like this:

Daily (5-10 minutes):

- Clean work area and coolant system

- Check fluid levels

- Visual inspection of moving parts

Monthly (2-3 hours):

- Lubricate all grease points

- Check electrical connections

- Calibrate axes if needed

The key is consistency. Machines that get regular maintenance typically last 15-20 years. Those that don't? Usually need major repairs within 5-7 years.

How do I choose the right working size?

This is where many people go wrong. Don't just think about your current largest piece- consider where your business is heading. Here's my recommendation process:

- Analyze your last 100 orders: What size covers 80% of your work?

- Look at lost opportunities: How many projects did you decline due to size limitations?

- Consider future growth: Where do you want your business in 3-5 years?

- Factor in costs: Larger working areas cost more upfront and ongoing (bigger workspace, higher power consumption)

Generally, I recommend sizing for your "stretch" projects-about 20% larger than your current typical maximum. This gives you room to grow without overbuying.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский