Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

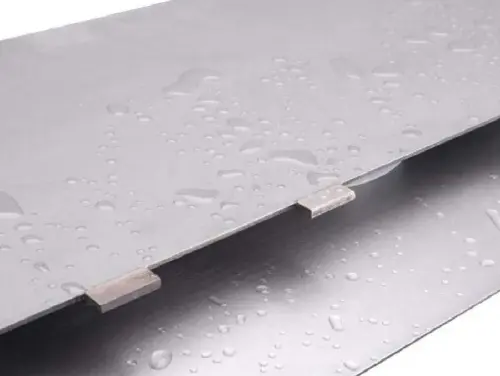

Diamond Gangsaw Segments for Soft Stone

2.5-4.0mm

Compatible Materials & Products

Soft-stone focus: marble, limestone, sandstone slab cutting

Marble > Slab Cutting

Marble slab cutting on frame gangsaws demands fast penetration, a stable kerf, and tight edge control for premium finishes.

Soft‑bond diamond gangsaw segments with mid‑grade diamonds and tuned segment geometry keep multi‑blade kerfs aligned; ensure stroke alignment and abundant coolant to clear fines and reduce heat.

Smooth surfaces and uniform thickness reduce polishing, raise yield per block, and shorten production schedules.

Limestone > Slab Cutting

Limestone cuts easily yet may smear when bonds are too soft, affecting surface quality.

Balanced bond hardness and diamond concentration curb clogging; match feed rate and stroke on the frame gangsaw and maintain coolant to prevent paste buildup and keep the kerf steady.

Clean faces reduce rework and finishing cost, improving line efficiency and consistency.

Sandstone > Panel Cutting

Sandstone is abrasive and accelerates segment wear during panel cutting.

Slightly harder bonds with strong diamond retention extend segment life; steady coolant evacuation removes grit and preserves cutting speed and kerf stability.

Longer tool life with consistent panels lowers downtime and total cutting cost across batches.

Marble > Bookmatching Prep

Bookmatching prep requires straight, smooth kerfs to achieve mirrored seams and clean aesthetics.

Tuned segment geometry minimizes deflection; verify frame alignment and tension on the gangsaw to keep cuts true and maintain kerf stability.

Cleaner seams reduce finishing steps and deliver superior visual results for premium installations.

Specs and options

Specifications customizable upon request.

| Gangsaw Blade Thickness | Segment Dimension | ||

|---|---|---|---|

| mm | Length/mm | Width/mm | Height/mm |

| 2 | 20 | 3.2/3.7 | 8 |

| 2.5 | 20 | 3.7/4.2 | 8 |

| 3 | 20 | 4.2/4.5 | 8 |

| 3.5 | 20 | 4.8/5.3 | 8 |

| 4 | 20 | 5.0/5.5 | 8 |

| Gangsaw Blade Specification | Segment Qty | ||

| Length/mm | Width/mm | pcs | |

| 2000 | 180 | 14-16 | |

| 2500 | 180 | 17-19 | |

| 2700 | 180 | 20-22 | |

| 3000 | 180 | 21-23 | |

| 3100 | 180 | 26-28 | |

| 3500 | 180 | 27-29 | |

| 3800 | 180 | 28-30 | |

| 3950 | 180 | 30-32 | |

| 4300 | 180 | 32-35 | |

| 4500 | 180 | 34-37 | |

Fast Cutting. Smooth Slabs. Longer Life.

Soft-stone gangsaw segments for marble/limestone with optimized bond

High Throughput on Soft Stone

Soft-bond formula boosts cutting speed while maintaining stable kerf and slab thickness.

Clean Surfaces, Low Chipping

Tuned diamond grade reduces micro-chips and polishing time.

Balanced Life, Lower Cost

Robust retention extends segment life, reducing downtime and total cost.

Consistent Multi-Blade Kerf

Geometry stability supports uniform thickness in parallel cuts.

Coolant-Friendly Design

Works reliably with factory cooling to evacuate fines.

FAQs

Common Questions About Diamond Gangsaw Segments for Marble

What is a diamond gangsaw segment?

A sintered diamond segment mounted on a frame gangsaw for cutting soft stones into slabs.

- Composition: diamonds + metal bond (soft bond for marble/limestone, slightly harder for sandstone)

- Motion: reciprocating stroke; multi‑blade parallel cuts demand kerf stability

- Design: tuned segment geometry and diamond grade for fast cutting and low chipping

How should I choose segments for marble, limestone, and sandstone?

Match bond hardness and diamond grade to each material’s abrasiveness.

- Marble: soft bond, mid‑grade diamonds; prioritize sharpness and clean faces

- Limestone: balanced bond to prevent smearing; steady feed + stroke alignment

- Sandstone: slightly harder bond with strong retention; focus on life and kerf stability

What setup and installation practices improve kerf stability on frame gangsaws?

- Alignment: check blade parallelism, tension, and fixture integrity

- Stroke: confirm stroke length/tempo suits the segment design and material

- Coolant: maintain flow/filtration to evacuate fines and control heat

- Advantages:

- Fewer corrective passes and lower polishing time

- Add a weekly checklist for alignment and coolant inspection

How does bond hardness and diamond grade impact cutting speed and life?

Softer bonds increase sharpness; harder bonds extend life; diamond grade controls exposure rate.

- Soft stones (marble/limestone): soft bond + mid‑grade diamonds → fast penetration, low chipping

- Abrasive stones (sandstone): slightly harder bond + robust retention → longer life, consistent panels

- Grade tuning: adjust diamond size/concentration to maintain steady exposure

What coolant and filtration practices help soft‑stone cutting?

Keep high‑flow coolant and effective filtration to evacuate fines.

- Flow: maintain consistent delivery along blade pack, avoid dry spots

- Filtration: media or bag filters to capture fines; periodic replacement

- Heat control: adequate coolant reduces thermal effects and smearing

Certifications & Standards

Soft-stone gangsaw segments for marble/limestone with optimized bond

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Scale Your Soft-Stone Cutting Today

Talk to DINOSAW for verified specs, CE/ISO compliance, and factory-ready segment options.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond Segment Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский