Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

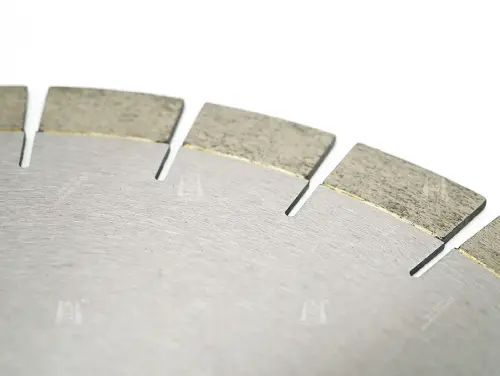

Quartz Diamond Saw Blade — Thin‑Kerf, Chip Control

300-500mm

Compatible Materials & Products

Optimized for Quartz & Ultra‑Compact Surfaces

Quartz Slab > Countertop Cutting

Quartz countertops demand flawless edges due to their high density and brittleness, where micro-chipping is a primary fabrication challenge.

This blade features a thin-kerf design and a specialized soft-bond matrix with high diamond concentration. This combination reduces cutting stress and material waste. Ample wet cutting is essential to cool the blade and flush out slurry, while a stable feed rate prevents vibration, ensuring a chip-free finish.

Delivers factory-quality edges that require minimal post-processing, significantly reducing polishing time, labor costs, and material defects.

Porcelain > Edge Profiling

Large-format porcelain tiles and slabs require exceptionally clean profiles for high-end aesthetic applications, where edge integrity is non-negotiable.

The blade’s narrow slot design and optimized soft bond ensure precise, low-vibration cuts. It is engineered for wet cutting to prevent thermal shock and micro-fractures in the delicate porcelain body. A consistent, moderate feed rate is key to achieving a flawless miter or bullnose edge.

Produces clean, sharp profiles with minimal chipping, drastically reducing rework and ensuring a consistent, high-quality finish for luxury installations.

Sintered Stone > Panel Sawing

Sintered stone is extremely hard and compact, demanding blades that can maintain straightness and resist deflection during large panel sawing.

Built on a high-tension steel core, this thin-kerf blade ensures maximum rigidity. The diamond segments are formulated to stay sharp when cutting ultra-hard materials. Continuous coolant flow is critical for performance, preventing blade overheating and ensuring a smooth cutting path with minimal drag.

Achieves perfectly straight kerfs with minimal chipping, leading to higher material yield, faster panel processing, and lower overall production costs.

Engineered Stone > Full‑depth Slab Cutting

Engineered stone slab cutting requires long, straight kerfs without stress cracks.

Large‑diameter thin‑kerf blade on bridge/gantry saws; soft‑bond, high diamond concentration; continuous wet cutting and steady feed maintain straightness and edge quality.

Clean, straight kerfs across full thickness, less rework and faster throughput.

Specs and options

Specifications customizable upon request.

| Diameter | Segment Width | Segment Height | Teeth Qty. | Arbor | |

|---|---|---|---|---|---|

| Inches | mm | mm | mm | pcs | mm |

| 12" | 300 | 3.2 | 10 / 20 / 25 | 21 | 50 / 60 |

| 14" | 350 | 3.4 | 10 / 20 / 25 | 24 | 50 / 60 |

| 16" | 400 | 3.6 | 10 / 20 / 25 | 28 | 50 / 60 |

| 18" | 450 | 4 | 10 / 20 / 25 | 32 | 50 / 60 |

| 20" | 500 | 4.2 | 10 / 20 / 25 | 36 | 50 / 60 |

Chip‑Control Cuts. Thin‑Kerf Power. Built for Quartz.

Thin‑kerf quartz blade with chip control for multi‑machine setups.

Stable Wet Cutting

Coolant reduces heat and dust, protecting edge quality.

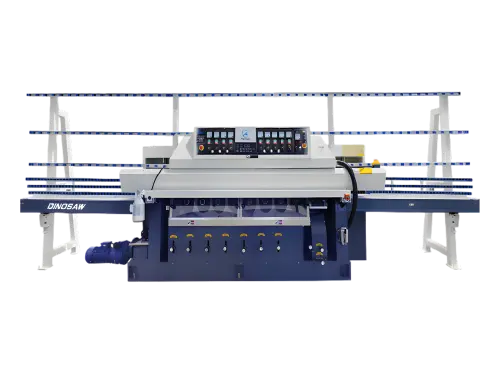

Multi‑Machine Compatibility

Works across bridge saws, gantry saws, and CNC cutting machine.

Global Use Cases

Suitable for quartz, porcelain, sintered stone across regions.

FAQs

Common Questions About Quartz Diamond Saw Blades

Can a diamond blade cut quartz countertops?

Yes, a specialized diamond blade is required. Quartz is dense and brittle, making its edges prone to chipping during cutting.

Use a thin-kerf blade on a bridge saw with continuous wet cutting, a proper RPM range, and a steady feed rate to ensure clean cuts.

Always verify the blade is rated for quartz. Before purchasing, request technical specifications and confirm it meets CE & ISO standards.

How to choose a blade for quartz vs porcelain?

Both materials are very hard, but porcelain often requires exceptionally clean profiles for aesthetic applications.

For both, a thin-slot blade with a relatively soft bond is ideal. For porcelain, ensure the blade design minimizes vibration and is paired with ample coolant to prevent thermal shock and micro-chipping.

Match the blade's bond and diamond concentration specifically to the material. Always confirm the recommended operating parameters with the supplier.

Does thin-kerf reduce chipping on quartz?

Chipping is caused by excessive stress at the cutting edge.

Yes, a thin-kerf (narrow cutting path) blade removes less material, which reduces cutting forces and lowers stress on the edges. This effect is maximized when combined with a stable feed rate and effective wet cutting.

We recommend running trial cuts on scrap material to optimize parameters. Evaluate the final finish and calculate the total cost of ownership (TCO), including rework costs.

What specs matter for bridge saw quartz cutting?

Ensuring compatibility between the saw and the blade is critical for performance and safety.

Key specifications include:

- Diameter & Arbor Hole: Must match your bridge saw.

- Slot Design: Thin-kerf or narrow slots are preferred for quartz.

- Bond Hardness: A softer bond is generally better for hard, dense materials.

- RPM Range: Must align with your machine's capabilities.

How to maintain edge quality during long runs?

Heat buildup and blade wear can degrade the cut finish over time.

Maintain a consistent coolant flow to manage heat. Use a dressing stick as needed to expose fresh diamonds if cutting speed drops. Most importantly, keep the feed rate steady and avoid pushing the blade too hard.

Schedule regular checks of the blade for signs of excessive wear. Replace the blade when the kerf widens or chipping increases noticeably.

Can this quartz blade handle sintered stone panels?

Sintered stone is extremely hard and requires straight, chip-free cuts for paneling applications.

Yes, the principles are similar to cutting quartz. A thin-kerf path, ample wet cutting, and a proper RPM are essential for achieving clean cuts on sintered stone.

Confirm the blade specifications are suitable for the specific thickness and density of your sintered stone panels before use.

Are CE & ISO supported for global markets?

International compliance signals quality and safety, building trust with global buyers.

Yes, our products are manufactured to meet global standards, supporting CE marking for market access and adherence to the ISO 9001 quality management system.

Please contact a DINOSAW representative to request the latest valid certificates for the product you are interested in.

Certifications & Standards

Thin‑kerf quartz blade with chip control for multi‑machine setups.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Cut Quartz Faster with Chip‑Controlled Thin‑Kerf

Get CE & ISO‑compliant quartz blades for your setup. Ask our experts for specs and trial cuts.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond saw blade Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский