Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

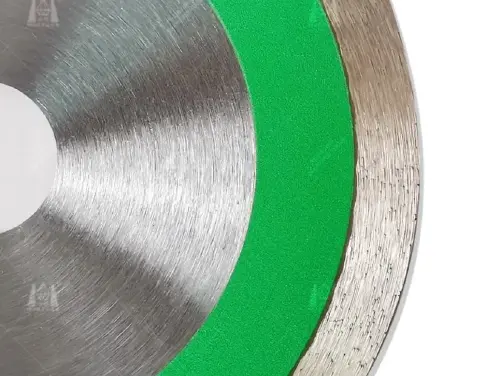

Sintered Continuous Rim Diamond Cutting Disc for Tile

105-300mm/4.13"-12"

Compatible Materials & Products

Precision cutting for premium finishes on brittle materials.

Porcelain Tile > Chip-free miter cuts

Porcelain’s dense, brittle nature makes 45° miter cuts prone to chipping. Achieving a flawless edge for seamless corners requires a cutting disc that operates smoothly without causing micro-fractures, especially when using an angle grinder or tile saw.

Our continuous rim disc uses a specialized fine-grit diamond bond in a solid, uninterrupted edge. This design eliminates the impact of segmented slots, ensuring consistent contact and smooth material removal. Wet cutting is essential to cool the disc and reduce thermal stress on the tile.

The result is a perfectly sharp, chip-free miter edge ready for fabrication. This enhances aesthetic quality, reduces material waste, and minimizes post-cut polishing, boosting productivity for high-end tiling projects.

Ceramic Tile > Clean wet saw cutting

Cutting standard ceramic tile demands a clean edge for tight grout lines. Aggressive discs can easily chip the glazed surface, leading to rework and wasted material, especially during repetitive cuts on a tile saw or circular saw.

The sintered continuous rim provides a gentle yet effective cutting action. Its uniform diamond distribution ensures a consistent abrasion process. When used with water, it continuously clears debris and prevents overheating, preserving both the disc and the tile glaze.

This disc delivers consistently clean cuts, improving installation speed and finish quality. It reduces tile breakage, lowers project costs, and produces a smooth edge that simplifies grouting and ensures a superior final look.

Marble > Fine edge trimming

Marble is a relatively soft stone susceptible to fracturing and edge chipping during final trimming. Precision is paramount, as any imperfections on expensive slabs can detract from the luxury finish.

Our cutting disc's continuous rim and high-concentration diamond formula are engineered for delicate materials. The sintered bond ensures diamonds are securely held, providing a stable and smooth cutting pass that minimizes vibration and impact.

Achieve razor-sharp, clean edges on marble countertops and tiles. This disc reduces the risk of costly material damage and significantly lessens the time required for subsequent edge polishing, improving fabrication efficiency.

Sintered Stone > Low-chipping finish

Sintered stone is ultra-compact and hard, making it challenging to cut without chipping. The material’s internal stresses require a highly stable cutting disc that can withstand intense abrasion while maintaining a clean cutting path on a masonry saw.

Our continuous rim disc features a rigid steel core and a durable sintered bond designed for hard materials. The uniform diamond exposure along the rim provides consistent cutting power, preventing deflection and edge damage. Wet cutting is mandatory to manage heat.

Produce clean, low-chipping cuts on demanding sintered stone surfaces. This improves fabrication quality, reduces waste of expensive materials, and ensures finished panels meet the highest visual and structural standards.

Specs and options

Specifications customizable upon request.

| Diameter | Diameter | Segment Width | Segment Height | Arbor |

|---|---|---|---|---|

| Inches | mm | mm | mm | mm |

| 4.13" | 105 | 2 | 10 | 20 |

| 4.5" | 115 | 2 | 10 | 20 |

| 5" | 125 | 2.2 | 10 | 20 |

| 6" | 150 | 2.4 | 10 | 20 |

| 7" | 180 | 2.6 | 10 | 22.23 |

| 8" | 200 | 2.6 | 10 | 25.4 |

| 9" | 230 | 2.8 | 10 | 25.4 |

| 10" | 250 | 2.8 | 10 | 25.4 |

| 12" | 300 | 3 | 10 | 25.4 |

Flawless Cuts, Zero Compromise.

Our diamond disc for chip-free wet cutting of porcelain tile.

Superior Chip-Free Edge

Delivers flawless cuts on brittle materials, reducing the need for secondary finishing processes.

Extended Disc Lifespan

Advanced sintered bond matrix ensures consistent wear and long-lasting performance in wet applications.

High Cutting Precision

The rigid steel core and continuous rim design minimize vibration for perfectly straight cuts on any saw.

Optimized for Wet Cutting

Designed for wet use to prevent heat buildup, protecting both the disc and the material integrity.

Versatile Machine Compatibility

Fits angle grinders, tile saws, and masonry saws with various arbor sizes (22.23/20/5/8").

Consistent Performance

The sintered manufacturing process ensures reliable, uniform cutting quality from start to finish.

FAQs

Common Questions About Sintered Continuous Rim Discs

Can I use this diamond cutting disc on an angle grinder for porcelain?

Yes, this disc is ideal for cutting porcelain tile with an angle grinder, especially when a high-quality, chip-free finish is required.

Porcelain is extremely dense, and its brittleness makes it prone to chipping. Our continuous rim disc provides a smooth, abrasive action that minimizes stress on the material. For optimal results, use it with a wet cutting attachment to prevent thermal shock and clear debris.

By pairing this disc with a proper wet-cutting setup on your grinder or tile saw, you will achieve clean, precise cuts ready for installation.

Continuous rim vs. turbo cutting disc for porcelain: which is better?

The choice depends on prioritizing cut quality versus cutting speed.

- Continuous Rim Disc:Offers the highest quality finish with virtually no chipping. It is the best choice for visible edges and miter cuts where perfection is key. Its cutting speed is generally slower.

- Turbo Rim Disc:Cuts faster and offers good cooling. However, it may produce minor micro-chipping. It is excellent for rapid straight cuts where edge quality is less critical.

For high-end porcelain projects, always choose a continuous rim disc. For high-volume cutting, a turbo disc can be more efficient.

What RPM is recommended for a 7" diamond disc on a tile saw?

The optimal RPM depends on the specific design and material, but a general range can be provided.

For a7-inch (180 mm) diameter disc, a typical operating speed is between3,000 to 4,500 RPM. Running the disc too fast can cause overheating, while running it too slow reduces efficiency. Always check the maximum safe RPM marked on the disc.

We recommend consulting your tile saw's specifications and our disc's technical data to match the optimal speed for the best performance and safety.

How do I reduce chipping with a continuous rim cutting disc?

If you experience chipping, it is usually due to operational factors.

To minimize chipping, ensure the following:

- Sufficient Water Flow:A consistent supply of water is critical for cooling.

- Steady Feed Rate:Do not force the disc. Apply light, consistent pressure and let the diamonds do the work.

- Stable Support:Ensure the tile is fully supported on a flat surface to prevent vibration.

- Disc Condition:A dull disc needs re-dressing. Cut into an abrasive material (like a dressing stone) for a few seconds to expose new diamonds.

What arbor sizes are available for these cutting discs?

Our discs are designed to fit a wide range of tile saws, circular saws, and angle grinders.

We offer several industry-standard arbor sizes:22.23 mm (7/8")、20 mm、5/8".

Custom arbor sizes may be available upon request. Please contact our technical team with your machine's specifications to confirm the correct fitment.

Do you offer tiered pricing for bulk B2B orders?

Yes, we provide a competitive tiered pricing structure for B2B clients, including distributors and large-scale contractors.

Pricing is based on order volume, with significant discounts available for higher quantities. Our sales team works directly with you to understand your inventory needs and provide a customized quote that reflects your purchasing power.

Contact us with your required quantity and specifications to receive a detailed quotation and explore our partnership programs.

What is the lead time for custom arbor sizes or OEM orders?

Lead times vary based on the complexity and volume of the custom order.

For standard products, lead times are typically between 7-15 days. For custom arbor sizes, specific bond formulations, or full OEM/ODM orders with custom branding and packaging, the lead time generally ranges from 15-30 days after technical drawing confirmation and deposit.

We recommend discussing your specific requirements with our technical sales team for an accurate timeline and production schedule.

Certifications & Standards

Our diamond disc for chip-free wet cutting of porcelain tile.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Get the Perfect Edge for Your Professional Projects

Contact our experts to find the ideal cutting disc for your angle grinder, tile saw, or other equipment.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond Cutting Disc Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский