Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

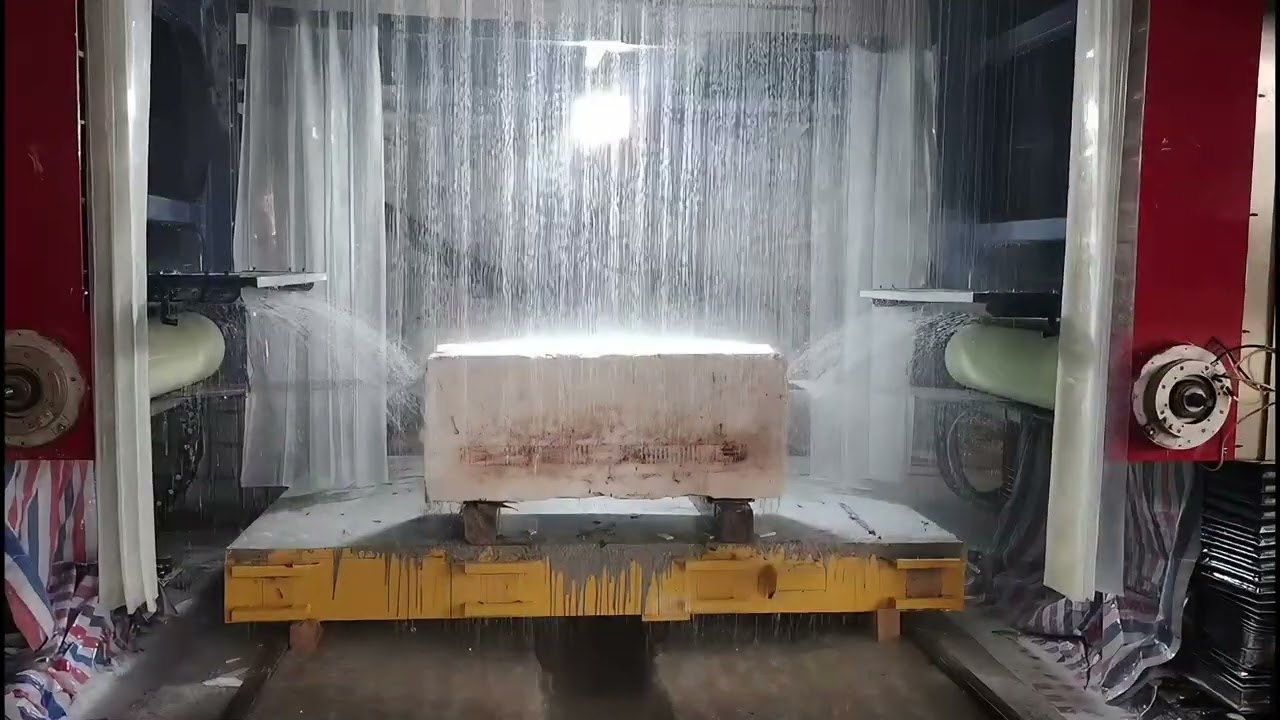

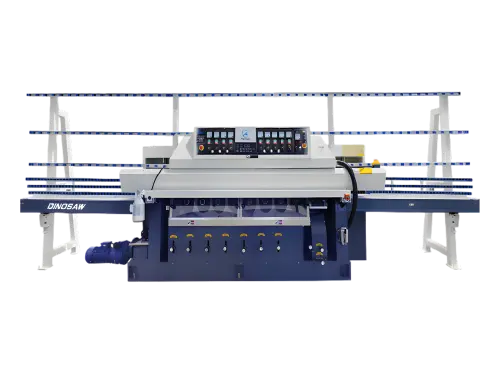

CNC Diamond Thin Multi-Wire Saw Machine

DS-3412A/DS-3623A

Compatible Materials & Products

Stone Block Cutting for High-End Interior Applications

Marble ❯ Feature Walls & Floors

Italian marble has become essential in luxury hotels, high-end homes, and exclusive retail spaces. As demand grows for thinner materials in architecture, quality marble processing needs advanced cutting solutions.

DINOSAW's Multi-Wire Saw represents a major advancement in stone fabrication. The system cuts premium Calacatta White and Carrara marble into slabs as thin as 3mm with consistent thickness. The 0.35mm diamond wire creates just 0.5mm cutting width. This maximizes material yield while ensuring perfect book-matching across large installations.

These lightweight marble panels reduce installation costs and structural requirements. The excellent surface quality from multi-wire cutting eliminates extensive secondary processing. This reduces production time by up to 40%. The system can process multiple slabs simultaneously, further enhancing efficiency.

Applications range from hotel entrances with dramatic veining to boutique fitting rooms and private residences. The superior edge finish and consistent thickness make these panels ideal for large architectural applications where both visual appeal and structural integrity matter.

Travertine ❯ Counters & Displays

Premium travertine creates stunning focal points in upscale hospitality venues. Its natural porosity and warm tones make it ideal for illuminated applications. Traditional cutting methods struggle to maintain the uniform thickness needed for even light transmission.

DINOSAW's Multi-Wire Saw transforms travertine processing with precision cutting. The machine produces 5-8mm Italian Silver Travertine panels that balance translucency with strength. These are perfect for dramatic lighting in hotel bars, executive lounges, and restaurants. The system's vibration control prevents micro-fractures that would damage the stone's delicate structure.

Multi-wire cutting significantly reduces processing time compared to traditional gang saws. Surface quality remains exceptional throughout cutting. The CNC system automatically adjusts cutting parameters based on material density variations. This intelligent adaptation ensures uniform thickness for even light transmission.

These elegant travertine elements transform commercial spaces with their warm, textured presence. Stone fabricators can offer hospitality clients signature design features that elevate guest experiences. The material yield improvement of up to 40% makes these applications more economical for large commercial projects.

Onyx ❯ Dividers & Claddings

Exotic onyx serves as functional art in museums, luxury retail spaces, and upscale homes. In the stone industry, these semi-precious materials present unique cutting challenges. Their crystalline structure and variable density make them difficult to process. Traditional equipment often wastes material and produces inconsistent quality.

DINOSAW's Multi-Wire Saw technology is a breakthrough for cutting delicate materials. The advanced machinery cuts rare materials like Blue Bahia, Sodalite, and premium onyx into thin, uniform panels with minimal waste. The tension control system maintains consistent wire pressure throughout cutting. This is essential for preserving the stone's natural patterns and integrity. The efficiency is most evident when producing free-standing dividers and seamless wall installations.

The precision control system maintains consistent 5-8mm slices with perfect parallelism. This creates stable architectural elements that meet exact design specifications. The minimal kerf technology reduces waste by up to 40% compared to conventional methods.

Designers use these translucent panels to create stunning visual statements in high-end spaces. The stone's natural patterns and gentle translucency transform ambient light into an immersive experience. This effect works in boutiques, museum spaces, or private residences. The surface quality achieved enhances the stone's natural luminosity, creating dramatic lighting impossible with conventional cutting.

Luxury Stone ❯ Museum Elements

Luxury stone elements represent the pinnacle of architectural stone applications. These installations demand exceptional precision, consistency, and surface quality. This is particularly important when showcasing rare materials with distinctive patterns and optical properties.

DINOSAW's Multi-Wire Saw enables fabricators to produce thin slabs of Prada Green, Bolivia Blue, and other exclusive materials. These are used for museum pedestals, display cases, retail fixtures, and statement walls. The vibration control system ensures consistent cuts with perfect edge quality. This eliminates fracture risks in valuable materials that cost thousands per square meter.

The precision cutting capabilities transform yield calculations for luxury stone processors. Fabricators can create dramatic book-matched patterns across vertical surfaces. The system's exact cutting maintains pattern continuity - critical for high-value applications. The CNC-controlled process automatically adjusts to material variations, ensuring consistent results even with challenging stone types.

These premium stone elements allow designers to incorporate rare materials into cultural and commercial environments. The efficiency achieved through multi-wire cutting makes previously expensive applications economically viable. The result is distinctive brand expressions for luxury fashion houses, immersive backdrops for artifacts, and memorable spaces that engage visitors through authentic materials.

▶ Product Demo

▶

▶

Jade Processing

35% Material Yield Improvement

A Japanese fabricator cut premium jade with 35% less waste using DINOSAW's multi-wire saw. The 0.5mm kerf technology maximized slab yield while tension control maintained ±0.2mm thickness tolerance. This eliminated secondary processing and delivered superior surface quality for high-end furniture tabletops.

Italian Travertine Floor Panel Production

Ultra-Thin Cutting Excellence for Museum Flooring

A Milan supplier needed thin panels for museum floors. DINOSAW's multi-wire saw cut 3m×1.8m Italian Silver Travertine panels with consistent 5mm thickness. The low-vibration system prevented edge chipping while precision cutting created perfectly matched patterns for premium exhibition spaces.

Luxury Onyx Divider Fabrication

40% Material Yield Improvement for Translucent Applications

A Vermont fabricator wasted 55% material cutting premium onyx. DINOSAW's multi-wire saw delivered consistent 6mm cuts with perfect edges across varying material densities. The system auto-adjusted to stone variations, reducing wire breakage by 80% while enabling thin panel production for boutique hotel room dividers.

Specs and options

Specifications customizable upon request.

| Model | Unit | DSY-XY3411 | DSY-JS3411 | DSY-XY3623 | DSY-JS3623 |

|---|---|---|---|---|---|

| Feed Type | / | downward pressing | up lifting | downward pressing | up lifting |

| Cutting Feed Rate | mm/h | 0 - 180 | 0 - 180 | 0 - 200 | 0 - 200 |

| Diamond Wire Diameter | mm | 0.35 - 0.8 | 0.35 - 0.8 | 0.35 - 0.8 | 0.35 - 0.8 |

| Cutting Thickness | mm | 5 ~ 30 | 5 ~ 30 | 5 ~ 30 | 5 ~ 30 |

| Cutting Tension | N | 0 - 250 | 0 - 350 | 0 - 250 | 0 - 350 |

| Worktable Vertical Travel | m | 2400 | 2400 | 2400 | 2400 |

| Wire Storage Capacity | m | 30000 | 30000 | 30000 | 30000 |

| Roller | mm | 320~450 | 320~450 | 320~450 | 320~450 |

| Main Motor Power | KW | 60x4 | 60x4 | 60x4 | 60x4 |

| Processing Dimensions(L×W×H) | mm | 3400x1100x2200 | 3400x1100x2200 | 3400x2000x2200 | 3400x2000x2200 |

| Machine Weight | T | 30~35 | 30~35 | 35~40 | 35~40 |

| Overall dimensions (L x W x H) | m | ≈8.9x6.4x5.3 | ≈8.9x6.4x5.3 | ≈9.2x7.5x5.3 | ≈9.2x7.5x5.3 |

Diamond Wire Technology for Precision Block Cutting

Transform Stone Blocks into Maximum Value

High-Speed Stone Cutting

Fast start-stop system with high-speed cutting enhances production efficiency and throughput

Precision Tension Control

Servo motors deliver accurate tension for consistent surface quality across varied materials

Adaptive Cutting System

Real-time feedback adjusts cutting parameters for optimal performance

Low-Noise Operation

Reduced noise design creates a quieter workshop, improving working conditions

Energy Efficient

Energy recovery system converts braking energy back to electricity, reducing operating costs

Minimal Waste Generation

Minimal cutting width produces less stone powder and wastewater

FAQs

Common Questions About DINOSAW Multi-Wire Saw Machines

What are the main advantages of a multi-wire saw over traditional stone cutting methods?

Multi-wire saws deliver significant advantages over traditional cutting methods:

1. Higher Material YieldThe minimal-kerf technology reduces cut width to just 0.5mm compared to 2-5mm with gang saws. This results in 10-30% more slabs per block, significantly improving economics for high-value stone materials.

2. Enhanced SafetyThe low-vibration cutting system significantly reduces the risk of stone shifting or falling during processing operations. This creates a safer working environment and protects valuable materials from damage during handling.

3. Reduced Noise LevelsTraditional gang saws operate at 110-130dB noise levels, while diamond multi-wire technology runs at just 60-80dB. This dramatic noise reduction improves the working environment and reduces operator fatigue during extended production runs.

4. Environmental BenefitsThe smaller kerf width generates significantly less stone powder and wastewater, reducing environmental impact and lowering water treatment costs. This makes the technology more sustainable and economical for stone processors working with premium materials.

5. Advanced Control SystemsThe CNC system with material detection reduces labor requirements and improves consistency across variable stone density - critical for high-end architectural applications.

What types of stones can be cuttib with multi-wire saw machine?

DINOSAW Multi-Wire Saw technology excels at processing a comprehensive range of stone materials with varying hardness levels and structural characteristics. The system delivers exceptional cutting results across:

- Premium marbles: The technology is particularly valuable for processing high-value varieties like Calacatta White, Statuario, and Carrara marble, where maximum material yield and surface quality are critical economic factors. The multi-wire system preserves delicate veining patterns while achieving thin cuts.

- Luxury decorative stones: Materials like onyx, alabaster, and travertine benefit from the low-vibration cutting process that preserves their delicate crystalline structures. The precise tension control prevents micro-fractures that traditional cutting methods often create in these sensitive materials.

- Semi-precious materials: Rare stones including jade, agate, sodalite and Blue Bahia can be processed with minimal waste - a crucial advantage when working with materials that can cost thousands per square meter. The multi-wire technology's minimal kerf width maximizes yield from these valuable blocks.

- Specialty stones: The adaptive cutting system automatically optimizes parameters for materials with varying density like Italian Silver Travertine, Prada Green, and Bolivia Blue. This versatility across different stone types while maintaining consistent surface quality makes the technology invaluable for fabricators working with diverse premium materials for high-end architectural projects.

How thin can stone slabs be cut using multi-wire cutting machine?

DINOSAW Multi-Wire Saw technology can reliably cut marble slabs as thin as 3mm, while harder luxury stones typically achieve minimum thicknesses of around 5mm. There is no upper thickness limit with our technology.

Different market segments require specific thickness ranges for optimal applications. Residential and commercial projects often use 5-10mm slabs for wall cladding and feature walls, balancing weight reduction with durability. Ultra-thin 3mm panels are increasingly specified for luxury furniture, backlit features, and renovation projects where weight constraints are critical. Museum and hospitality applications typically require 8-12mm thickness for high-traffic areas.

This precision cutting performance is achieved through our advanced tension control system that maintains exact wire tension throughout the cutting process. Our low-vibration technology prevents edge chipping and breakage even at minimal thicknesses, delivering excellent structural integrity that traditional methods cannot achieve. The resulting slabs feature perfect edge quality and superior surface finish, reducing or eliminating secondary processing requirements.

These capabilities have transformed the architectural stone industry by enabling lightweight applications that were previously impossible or economically unfeasible.

What is the difference between Up Lifting and Downward Pressing configurations?

DINOSAW offers two primary cutting configurations in our Multi-Wire Saw machines: Up Lifting (JS series) and Downward Pressing (XY series), each with distinct mechanical principles:

Up Lifting (JS Series):

- Cutting components remain fixed while stone block moves upward on lifting platform

- Higher efficiency and lower wire breakage rate due to structural stability

- Superior cutting flatness (±0.2mm) and longer machine lifespan

- Separates operation area (top) from cutting zone (bottom) for better operator safety

- Ideal for precision applications requiring consistent surface quality

- Higher initial investment but better long-term economics

Downward Pressing (XY Series):

- Stone block remains stationary while cutting assembly moves downward

- Lower initial cost and can utilize existing traditional gangsaw foundations

- Less stable as upper components must both bear wire tension and move downward

- Suitable for standard applications where ultimate precision is less critical

- Shorter service life compared to up-feed configuration

Both utilize our precision tension control technology, with selection depending on material requirements and budget considerations.

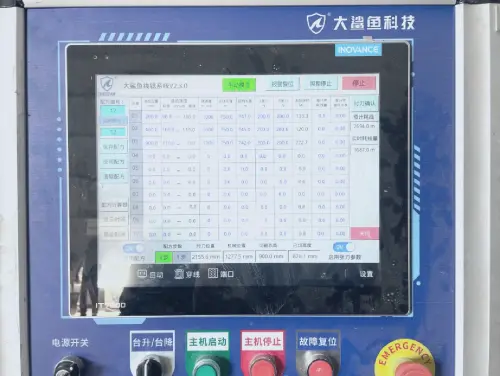

How does DINOSAW multi-wire saw ensure consistent cutting quality?

DINOSAW ensures exceptional cutting consistency through a comprehensive quality control system throughout the cutting process:

1. Precision Tension Control: Our wire management system maintains diamond wire tension throughout the cut, automatically compensating for density variations within the stone block.

2. Material Analysis: The CNC system analyzes stone hardness variations and automatically selects optimal cutting parameters including wire speed, feed rate, and tension profiles based on material characteristics.

3. Real-Time Feedback Control: Continuous monitoring from multiple sensors tracks cutting forces, wire wear, and material response, with the system making adjustments during operation to maintain consistent surface quality.

4. Vibration-Dampening Frame: The machine's rigid frame design and precision-balanced wire guide system minimize vibration, preventing surface imperfections or thickness variations.

5. Intelligent Wire Management: The system tracks diamond wire performance, automatically adjusting parameters to compensate for wear while alerting operators when replacement is needed.

This integrated approach ensures that even when processing blocks with varying density zones or natural fissures, the system maintains consistent slab thickness tolerance, excellent surface finish, and minimal variation across production runs.

Can the multi-wire saw produce slabs of different thicknesses in one cutting cycle?

Yes, the DINOSAW Multi-Wire Saw can produce slabs of varying thicknesses in a single cutting cycle, which is a significant advantage for fabricators requiring different slab specifications from the same stone block. This capability is enabled by our Variable Spacing Technology:

The system allows operators to precisely position each diamond wire at custom intervals through the computerized control system. This means you can program specific distances between adjacent wires - for example, setting up the machine to simultaneously cut 5mm, 10mm, and 20mm slabs from the same block.

This versatility offers several benefits:

- Maximize block value by cutting optimal thicknesses for different applications

- Create custom material packages for projects requiring coordinated thicknesses

- Reduce handling time by processing multiple specifications in one operation

- Optimize yield based on stone quality zones within the same block

However, there are potential risks such as wire jumping when cutting varying thicknesses. We recommend maintaining smaller thickness intervals between adjacent slabs and consulting DINOSAW technicians for proper cutting setup assistance to ensure optimal results and minimize operational risks.

How does the surface smoothness of multi-wire saw cutting compare to gangsaw cutting?

Multi-wire saw technology delivers superior surface smoothness with a measured Ra2.0 rating, compared to Ra2.2 for traditional gang saws - a significant quality difference in stone fabrication.

The superior smoothness comes from fundamental cutting mechanics: traditional gang saws use thick blades that exert considerable pressure against stone during cutting, causing micro-vibrations and potential stress fractures. This pressure-based cutting inevitably creates small surface irregularities.

In contrast, diamond multi-wire technology employs a fundamentally different cutting action. The thin diamond wire (0.35mm) doesn't compress the stone during cutting, instead performing a clean, precise separation of material. This no-compression cutting methodology produces significantly smoother surfaces requiring minimal secondary processing.

This surface quality advantage translates to measurable benefits:

- Reduced polishing time and abrasive consumption

- Better light reflection properties for highly polished finishes

- Superior edge quality with fewer micro-chips

- Improved material integrity preservation

For applications where surface quality is critical - luxury countertops, decorative panels, and precision architectural elements - this Ra2.0 surface quality represents a significant competitive advantage that directly impacts production economics and final product value.

Certifications & Standards

Transform Stone Blocks into Maximum Value

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Transform Your High-value Stone Block Cutting

Contact DINOSAW today for a customized analysis and discover how our multi-wire saw technology maximizes material yield

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Multi-Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский