Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

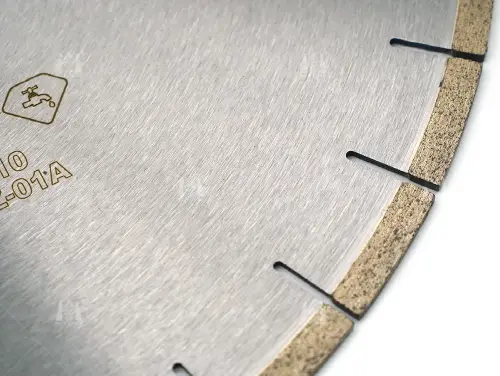

Diamond Saw Blade for Dekton & Sintered Stone

300-500mm

Compatible Materials & Products

Engineered for Clean Finishes on Ultra-Compact Surfaces

Dekton > Countertop Cutting

Cutting Dekton for countertops requires high precision to help prevent chipping and internal stress fractures, as the material's high density and brittleness pose a challenge.

This blade features a continuous rim with fine diamond grit, formulated for ultra-compact materials. The thin-kerf design minimizes cutting resistance. For best results, use on a bridge saw or CNC with ample water cooling, following the recommended RPM range and a steady feed rate for a stable, cool cut.

The outcome is a smooth edge with minimal chipping, which reduces finishing time, helps lower material waste, and supports the structural integrity of the final product.

Sintered Stone > Panel Trimming

Trimming large sintered stone panels for architectural applications requires consistent cuts without compromising edge quality, as defects can be highly visible.

The blade's specialized bond system is engineered to maintain sharpness when cutting these abrasive materials. Its reinforced steel core provides stability for long, straight cuts at optimal linear speeds. Effective water cooling is necessary to prevent thermal shock and maintain blade performance.

This supports enhanced productivity with fewer blade changes, helps achieve dimensional accuracy for panel installation, and provides a clean edge finish suitable for architectural standards.

Porcelain Slab > Straight Panel Cutting

Cutting large‑format porcelain panels requires stable, straight cuts with low chipping. This blade’s continuous rim and thin‑kerf design reduce cutting resistance. Use on a bridge saw or CNC with ample water cooling and a steady feed to maintain cut quality.

Benefits: Clean edges with reduced chipping, shorter finishing time, and consistent dimensional accuracy for panel installation.

Quartz > Miter Edge Cutting

Achieving 45-degree miter cuts on quartz is important for creating waterfall edges and aprons, but chipping along the edge can be a common issue.

Achieving 45-degree miter cuts on quartz is important for creating waterfall edges and aprons, but chipping along the edge can be a common issue.

This blade's ultra-thin profile and specific diamond concentration are optimized for quartz, allowing it to cut through the material cleanly and reduce blowouts on the edge. The rigid core helps prevent blade deflection during angled cuts on a bridge saw, ensuring a straight line. Ample coolant directed at the cut is key.

The result is clean, mitered edges that require minimal touch-ups, enabling faster fabrication of high-quality joints and delivering a clean, high-end appearance.

Dekton Kitchen Island Fabrication

Reducing Material Waste in Countertop Production

A kitchen fabricator reported a significant reduction in material waste on Dekton island projects after using our blade. The low-chipping performance meant cuts were consistently clean, which helped lower their scrap rate and save costs on slabs.

Large-Format Porcelain Facade Panels

Improving Timelines on Commercial Projects

A contractor reported a 30% reduction in facade installation time on a commercial project. The blade's fast, clean cutting of large porcelain panels allowed for direct on-site fitting, which streamlined their workflow and helped meet deadlines.

Sintered Stone Bathroom Vanities

Delivering Consistent Finishes for Project Designs

A hotel supplier achieved smooth edges on hundreds of sintered stone vanities. The consistent cut quality reduced the need for secondary polishing, which lowered labor costs and delivered a finish that met client specifications.

Specs and options

Specifications customizable upon request.

| Diameter | Segment Dimension | Teeth Qty. | Arbor | |||

|---|---|---|---|---|---|---|

| Inches | mm | Length / mm | Width / mm | Height / mm | pcs | mm |

| 12" | 300 | 41 / 43 | 3.2 | 10 | 22 | 50 / 60 |

| 14" | 350 | 41 / 43 | 3.4 | 10 | 25 | 50 / 60 |

| 16" | 400 | 41 / 43 | 3.6 | 10 | 29 | 50 / 60 |

| 18" | 450 | 41 / 43 | 4.0 | 10 | 32 | 50 / 60 |

| 20" | 500 | 41 / 43 | 4.2 | 10 | 36 | 50 / 60 |

Precision Cutting for Ultra-Compact Surfaces.

Dekton saw blade with thin kerf for wet cutting.

Reduced Edge Chipping

The continuous rim design with fine diamond grit delivers clean edges, which helps to reduce rework.中文:减少边缘崩边

Lower Material Waste

The thin-kerf design minimizes cutting stress, helping to prevent cracks and save material.

Long Blade Lifespan

A specialized bond formula is designed for high durability, reducing tool changes and operational costs.

High Cutting Efficiency

Engineered for fast, smooth operation on cutting saws, which supports workshop productivity.

Supports Stability and Precision

A reinforced steel core helps prevent wobble, supporting straight and accurate cuts.

Optimized for Wet Cutting

Designed for effective performance with water cooling, helping to prevent heat damage to the material.

FAQs

Common Questions About Our Diamond Saw Blade for Dekton

What makes this blade different from a standard tile saw blade?

Standard tile blades are not typically designed for the hardness and density of Dekton or sintered stone. Using one can result in rapid wear, slow cutting, and edge chipping.

This blade is engineered with a specific diamond grit and bond matrix tailored for these ultra-compact materials. Its continuous rim and thin-kerf design help to minimize stress and heat, which is important for preventing micro-cracks and achieving a clean cut.

For better results, it is recommended to use this specialized blade with sufficient water cooling on a stable bridge saw or CNC machine. This supports both the quality of the work and the longevity of the blade.

Can I use this blade for dry cutting Dekton?

Dry cutting Dekton and similar materials is not recommended. The friction generates significant heat, which can cause thermal shock, leading to cracks in the slab and blade damage. It also creates hazardous silica dust.

This blade is optimized for wet cutting. Water serves three important functions:

- Cooling: Helps prevent the blade and material from overheating.

- Lubrication: Reduces friction for a smoother cut.

- Dust Suppression: Controls airborne dust particles.

Always ensure a consistent and ample flow of clean water directly onto the cutting area. This practice is important for safety, cut quality, and maximizing the tool's service life.

Is this blade certified for safety standards?

Workplace safety is a priority, especially when working with high-speed cutting tools. Using non-compliant tools can pose a risk to operators.

DINOSAW diamond tools are manufactured in facilities that adhere to the ISO quality management system and meet CE conformity requirements for the European market. Where applicable, our products are also designed in accordance with safety standards like EN 13236. We recommend you check the product markings and contact our team to verify the specific certifications for your chosen blade model and region before purchasing.

How do I know when the blade needs to be replaced?

Continuing to use a worn-out blade can damage the material and machine. Key indicators can signal it is time for a replacement. Look for these signs:

- Decreased Cutting Speed: The blade struggles to cut at the normal feed rate.

- Increased Chipping: The edge quality deteriorates.

- Visible Wear: The diamond segment height is significantly reduced or the steel core is exposed.

- Increased Machine Load: The saw's motor works harder, indicated by sound or amperage draw.

Regularly inspecting your blade and replacing it when needed will help prevent damage and maintain consistent production quality.

Certifications & Standards

Dekton saw blade with thin kerf for wet cutting.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Request Information on Precision Dekton Cutting

Contact our experts to get a quote and learn how to reduce chipping in your workflow.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond Saw Blade Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский