Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

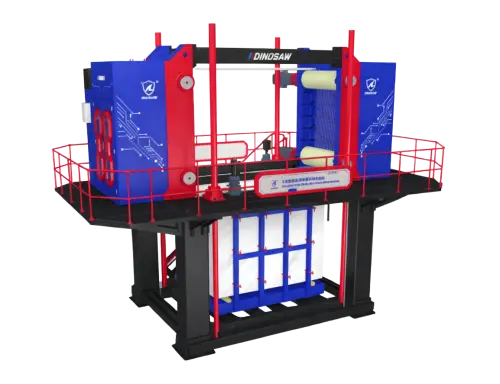

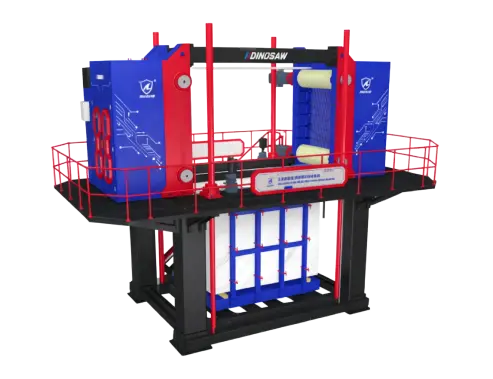

Up‑feed Thin Multi‑Wire Stone Cutting Machine

DS‑3412H

Compatible Materials & Products

Materials to Premium Thin Slabs & Panels

Marble ❯ Countertops

|

|

Up‑feed thin multi‑wire stone cutting machine for marble countertop cutting meets premium market demand in commercial fabrication, focusing on flawless, smooth finish.

DINOSAW diamond multi‑wire saw applies constant tension, fine‑tuned wire speed, and streamlined debris evacuation to slice medium blocks into thin slabs with exact thickness and small kerf.

Precision cutting yields superior flatness and optimized consistency; high‑performance processing reduces polishing workload and breakage.

Results: premium kitchen & bath slabs with professional surface quality and uniform thickness ready for industrial applications and construction projects.

Summary: this precision stone cutting machine maximizes yield while keeping finish impeccable—ideal for marble thin‑slab fabrication.

|

Luxury stone ❯ Facade panels

|

|

Up‑feed thin multi‑wire stone cutting machine targets luxury stone facade panels with minimal waste and premium surface for architectural construction projects.

DINOSAW diamond multi‑wire saw maintains tension stability and optimized feed, delivering exact slicing with precision guidance and efficient coolant management.

Superior finish and accuracy improve panel quality; optimized, high‑performance processing boosts productivity and consistency.

Outcomes: high‑grade facade panels with commercial‑grade flatness and uniform thickness, maximizing yield on expensive blocks.

Summary: precision stone processing elevates ROI for premium projects while keeping kerf loss low.

|

Engineered quartz ❯ Thin slabs

|

|

For engineered quartz thin slabs, the up‑feed thin multi‑wire stone cutting machine ensures robust yet precise fabrication for industrial applications.

DINOSAW diamond multi‑wire saw uses constant tension, gantry rigidity, and optimized wire speed to deliver exact slicing and uniform thickness.

Precision cutting and optimized consistency reduce polishing time; streamlined processing secures high throughput.

Results: professional thin slabs with smooth finish and production stability for commercial fabrication lines.

Summary: a precision stone cutting machine that balances strength and accuracy for dependable mass thin‑slab production. |

Sintered stone ❯ Large panels

|

|

Sintered stone large panels require gentle, precision cutting to protect brittle big formats in construction projects.

DINOSAW up‑feed multi‑wire process with constant tension, precision guidance, and efficient cooling minimizes chipping and keeps exact thickness.

Superior edges and smooth finish prove optimized, high‑performance processing for big panels.

Results: uniform, premium large panels ready for architectural and industrial applications with reliable throughput.

Summary: a precision stone cutting machine that stabilizes large‑format slicing while keeping kerf small. |

Alumina ceramic ❯ Thin slices

|

|

Technical ceramics like alumina demand low‑damage precision cutting for lab and industrial production.

DINOSAW diamond multi‑wire saw applies constant tension, fine‑tuned parameters, and precision guidance to achieve exact slicing.

Precision cutting minimizes micro‑cracks; optimized processing ensures high‑grade integrity and repeatability.

Results: professional thin slices with smooth finish and consistent thickness for technical applications.

Summary: a precision stone cutting machine enabling reliable low‑damage ceramic slicing. |

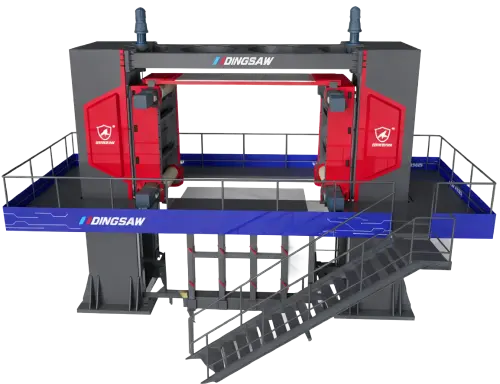

Specs and options

Specifications customizable upon request.

| Item | Unit | DS-3412H |

|---|---|---|

| Feed type | / | Up-feed |

| Cutting feed rate | mm/h | 100-280 |

| Diamond wire diameter | mm | 0.35-0.8 |

| Slab thickness | mm | 2-30 |

| Cutting tension | N | 0-300 |

| Table lift travel | mm | 2400 |

| Wire storage | m | 30000 |

| Roller diameter | mm | 320-450 |

| Main motor power | kW | 64x4 |

| Max workpiece size (LxWxH) | mm | 3400x1100x2300 |

| Machine weight | T | 27-38 |

| Overall dimensions | mm | 8900x6400x5300 |

Option | Function | Recommendation |

|---|---|---|

Rotating table | Rotate block without re-hoisting; adjust cutting angle | Recommended for irregular blocks / non-standard angles |

Transfer cart (aux table) | Parallel loading/unloading beside main table | Must‑have for peak throughput |

Extended rails | Longer cart travel space for multi‑cart / long pieces | Pair with transfer cart or when layout needs longer travel |

Spindle box set (drive/idler) | Spare assembly for quick swap to cut downtime | Buy as spare if production loss is costly |

Roller | Key wire‑net part; different materials/coatings affect wear/inertia | CF+PU for high speed/energy saving; iron/aluminum for budget |

Wire welder | Repair broken wire; fast wire recovery | Essential for most users |

Roller lathe | Pre‑recoat turning & alignment; reduce run‑out/vibration | Own in high‑utilization plants; outsource if low |

Tension wheel | Keep wire tension stable; core force element | Stock as consumable; set preventive replacement & calibration |

Guide wheel rubber ring | Protect wire & guide; improve friction & stability | Track wear & replace early for stable cutting quality |

Wire winder | Fast uniform winding; control pitch & initial tension | Standard for multi‑wire; best with wire welder |

Advanced control meets practical productivity.

Small Kerf. Big Yield. Flawless Thin Slabs.

High Yield, Low Kerf Loss

Constant tension and fine-wire cutting boost material yield. Kerf is ≈0.5–0.8mm for more thin slabs.

Premium Surface Quality

Up-feed design allows smooth debris removal and consistent thickness, reducing polishing and breakage.

Stable Thin-Slab Throughput

Gantry rigidity and wire speed management ensure more stable slicing for high-volume thin slab orders.

Compact Footprint

Our machine occupies less space and requires a lower investment in foundation work.

Energy & Noise Reduction

Lower energy consumption and reduced noise levels make it an eco-friendly choice for modern plants.

Smart Diagnostics

Predictive maintenance alerts and intelligent diagnostics help maximize machine uptime and productivity.

FAQs

Common Questions About Up‑feed Thin Multi‑Wire Stone Cutting Machine

What is a thin multi‑wire stone cutting machine?

- Constant tension + optimized wire speed → uniform thickness

- Lower heat input → smoother finish

- Narrow kerf → higher yield, less polishing, fewer breaks

Up‑feed vs down‑feed: which for my materials?

- Up‑feed: smooth debris, reduced wire bow

- Down‑feed: stable clamping, stronger cutting pressure

- Many plants deploy both for process segmentation

What materials suit an up‑feed thin multi‑wire stone cutting machine?

- Small kerf → higher yield

- Thickness uniformity → better downstream fit

- Flat surface → reduced finishing time

How narrow is the kerf and why it matters?

- Less lateral damage → cleaner edges

- Fewer micro‑cracks → higher quality

- Lower OPEX → better profitability

Can an up‑feed thin multi‑wire handle brittle large panels?

- Minimal chipping

- Uniform thickness

- Clean edges with small kerf → facade‑grade finish

How do rotating table and transition carts lift thin‑slab capacity?

- Angle adjustment without re‑hoisting

- Parallel loading/unloading next to main table

- Smoother takt and safer handling for thin‑slab lines

What is the typical process window?

- Co‑optimize tension/cooling/guidance

- Store per‑material recipes to balance yield, finish, wire life

Where does multi‑wire beat gangsaws most?

- Higher yield per m³

- Better finish

- Smaller footprint + lower foundation cost

- Lower waste/effluent and noise

- Reduced energy/consumables/polishing → consistent thin‑slab quality for green, scalable lines

Certifications & Standards

Small Kerf. Big Yield. Flawless Thin Slabs.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to scale premium thin‑slab output?

Use DINOSAW up‑feed thin multi‑wire to increase yield and finish quality across marble and sintered stone.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский