Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

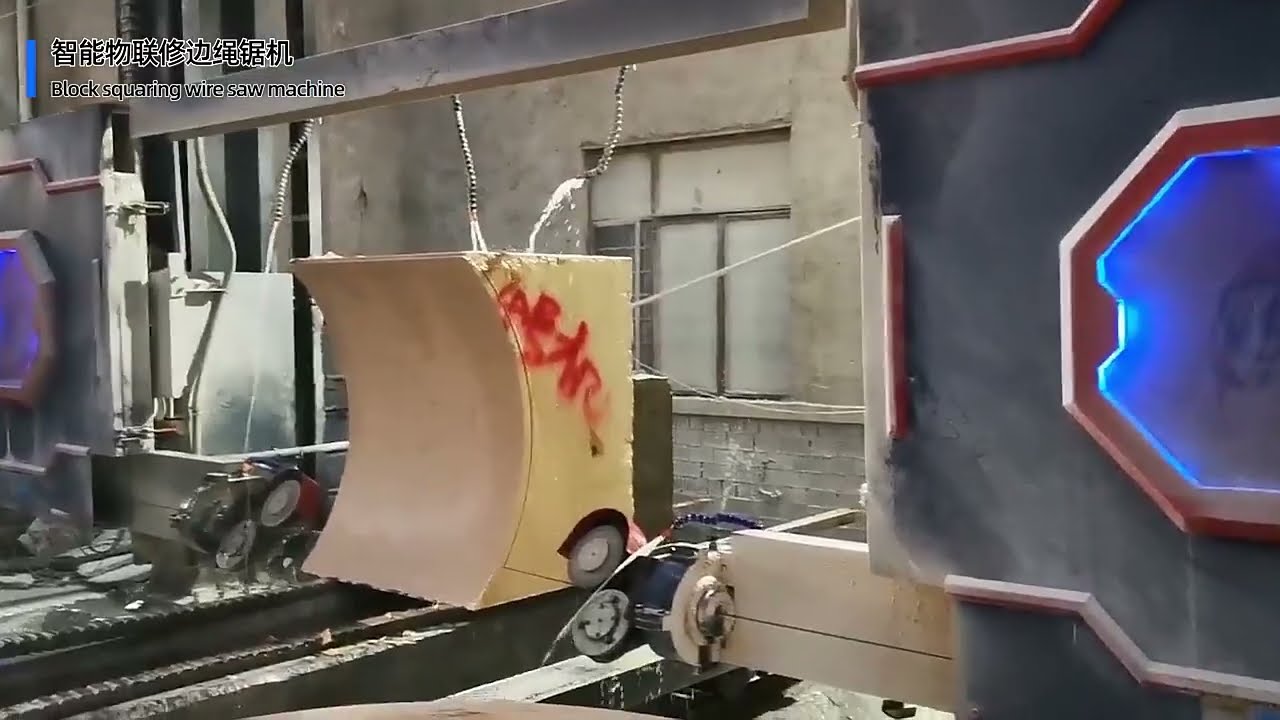

Stone Block Cutting Wire Saw Machine

XBSJ-3000/3500/4000

Versatile Stone Cutting: Materials & Products

DINOSAW block squaring diamond wire saw machine precisely and efficiently processes various materials, producing perfectly squared blocks ready for further processing.

Granite ❯ Precision Block Squaring

|

|

| Granite Block cutting with DINOSAW squaring wire saw machine |

|

| Granite splitting with DINOSAW stone block wire saw cutting machine |

|

| DINOSAW diamond wire saw machine cutting granite block |

|

Granite quarries and fabricators demand perfect squared blocks to maximize material value and downstream processing efficiency. Natural granite's exceptional hardness and variable crystalline structure make precision squaring challenging for conventional equipment, requiring specialized solutions for dimensional accuracy.

DINOSAW's block squaring wire saw system employs high-tensile diamond wire specifically engineered for granite's abrasive properties. Our hydraulic tensioning system automatically adjusts to maintain optimal cutting pressure throughout the process, compensating for natural veining and density variations. The precision-guided wire assembly delivers cuts with ±1mm tolerance across blocks up to 5×2.4m - significantly larger than traditional blade systems can accommodate. The PLC control system maintains consistent cutting parameters while allowing operators to optimize settings for specific granite varieties.

Precisely squared granite blocks command up to 40% higher market values while reducing downstream processing waste. Our customers report significant advantages in production workflows as perfectly squared blocks require less secondary cutting, translating to reduced processing time, lower tool wear, and increased yield. The system's ability to process multiple pieces without intervention achieves 1.5-2.0㎡/hour cutting speeds while maintaining consistent quality, significantly improving overall quarry-to-fabrication productivity.

Marble ❯ Clean-Edge Slabs

|

|

|

| Stone block cutting with diamond wire saw machine on marble slab for clean edges |

|

Premium marble processing requires exceptionally clean, precise edge cuts to preserve the stone's natural beauty and maximize usable material. Marble's varied density and delicate veining patterns present unique challenges for slab production, as thermal stress and vibration from conventional equipment can cause micro-fractures that compromise structural integrity.

DINOSAW's diamond wire technology provides the ideal solution through its vibration-free cutting action and advanced cooling system. Our precision-engineered diamond wire rotates at optimized speeds specifically calibrated for marble's crystalline structure, while continuous water cooling prevents thermal shock. The wire saw's smooth cutting action eliminates the vibration common with blade systems, protecting delicate material structures. Variable speed controls allow operators to adjust cutting parameters based on marble type, density, and veining patterns using our intuitive PLC interface.

Fabricators achieve remarkably consistent slab dimensions with our system, reducing material loss during polishing and finishing. The clean-edge quality allows for book-matched installations where adjacent slabs perfectly align, enhancing the visual flow of veining patterns across joined pieces. This precision significantly increases the perceived value of finished projects while reducing waste by up to 30%. The reduced need for edge refinishing also accelerates production schedules, allowing fabricators to increase throughput while maintaining premium quality standards.

Concrete ❯ Large Pipe Batch Cutting

|

| Reinforced concrete pipe cutting with DINOSAW wire saw machine |

|

| Reinforced concrete pipe cutting with DINOSAW wire saw machine |

|

|

| Industrial concrete pipe batch cutting using DINOSAW block squaring wire s |

Infrastructure and utility projects require precise cutting of large concrete pipes and structures, presenting significant challenges due to material thickness, reinforcement elements, and the need for clean, structurally sound cuts. Traditional cutting methods often struggle with reinforced concrete's composite nature, resulting in jagged edges, structural weakening, or excessive material waste.

DINOSAW's diamond wire saw system excels at concrete pipe batch cutting through specialized wire configurations designed specifically for reinforced materials. Our machines utilize high-concentration diamond beads optimized for concrete's abrasive properties, capable of cleanly cutting through both concrete matrix and embedded steel reinforcement without differential wear. The system's batch processing capabilities allow multiple pipes to be positioned and cut sequentially without operator intervention, while the PLC control system maintains consistent cutting parameters throughout the production run.

Contractors and precast concrete manufacturers achieve significant efficiency improvements, with production rates up to 35% higher than conventional cutting methods. The precision cutting ensures dimensional accuracy within ±2mm even on large-diameter pipes, facilitating perfect alignment during installation and reducing on-site fitting adjustments. The clean-cut edges eliminate the need for secondary finishing, preserving structural integrity while reducing labor costs. Additionally, the system's dust containment capabilities satisfy environmental regulations without compromising cutting performance.

Graphite ❯ Large Block Division

|

|

|

Graphite processing for industrial applications demands exceptional precision and material integrity. The material's unique properties - high thermal conductivity, electrical conductivity, and brittleness - create significant challenges for conventional cutting methods, which often result in material waste, contamination, or structural damage that compromises performance in critical applications.

DINOSAW's diamond wire technology provides the ideal solution for large graphite block division through specialized configurations designed specifically for this technical material. Our enclosed cutting system features precision-engineered diamond wire with optimized bead spacing and grit characteristics suited to graphite's unique properties. The cutting area's environmental containment prevents dust contamination, while the vibration-free cutting action eliminates micro-fractures common with alternative methods. The system's controlled cooling process prevents thermal shock while minimizing moisture exposure.

Manufacturers in aerospace, energy, and electronics sectors achieve superior dimensional accuracy (±0.5mm) with our graphite cutting system, essential for high-precision components. Material waste is reduced by up to 40% compared to traditional methods thanks to the wire's minimal kerf width. The clean-cut surfaces require minimal post-processing, accelerating production workflows while maintaining material integrity. For specialized applications, our PLC-controlled cutting parameters can be precisely calibrated to specific graphite grades and density characteristics, ensuring consistent results for mission-critical components.

Quartz Glass ❯ Precision Optical Components

|

|

| Industrial quartz glass precision cutting with DINOSAW diamond wire saw machine |

|

| Industrial quartz glass precision cutting with DINOSAW diamond wire saw machine |

|

Quartz glass optical components require extraordinary precision and surface quality for scientific instruments, semiconductor manufacturing, and advanced photonics applications. The material's extreme hardness combined with its brittle nature presents unique cutting challenges, as any imperfection can compromise optical performance and functionality in high-precision environments.

DINOSAW's diamond wire technology delivers unmatched precision for quartz glass through specialized ultra-thin wire configurations with fine diamond grit distribution. Our system's vibration-free cutting action prevents micro-fractures that would create optical distortions, while the programmable speed control allows for extremely slow, controlled cutting rates when needed for perfect surface finish. The custom-designed cooling system uses filtered, deionized water to prevent contamination during cutting, critical for maintaining optical clarity.

Surface quality directly from cutting requires minimal post-processing, reducing production costs while accelerating delivery times. The system's ability to produce complex geometries with consistent quality allows for advanced optical designs previously difficult to manufacture cost-effectively. For ultra-precise applications, our PLC control system maintains consistent parameters throughout extended cutting operations, ensuring uniform results across production batches.

▶ Product Demo

▶

▶

|

| DINOSAW Stone Block Squaring Wire Saw Machine Video |

Stone Fabrication Facilities

Maximizing Quarried Block Value Through Precise Squaring

DINOSAW wire saw processes quarried stone blocks up to 5×2.4m - significantly larger than traditional blade systems.

This outstanding capacity combined with ±1mm precision increases block value by up to 40% as properly squared blocks command higher market prices.

The hydraulic tensioning system maintains consistent cutting even with varying stone properties, reducing processing time by 30%.

Specialty Materials Processing

Streamlining Production with Automated Block Splitting

Stone fabricators need efficiency to stay competitive. DINOSAW's wire saw features PLC-controlled automatic slab cutting system that eliminates manual positioning and alignment.

Continuous batch processing capabilities allow operators to set parameters once and process multiple pieces without intervention, achieving 1.5-2.0㎡/hour cutting speed while maintaining consistent quality.

Built-in 4G connectivity enables remote diagnostics, resolving most issues without waiting for on-site service and minimizing production downtime.

Industrial Metal Recycling

Precision Cutting for High-Value Technical Materials

Industries processing specialty materials such as graphite blocks, natural stone varieties, and quartz glass need high precision cutting.

DINOSAW offers customized configurations including dust collection systems and dry-cutting options specifically designed for each material type and application requirements.

Adjustable parameters optimize settings for each material, while the enclosed cutting area prevents contamination. These specialized configurations ensure material integrity and exceptional dimensional accuracy required for aerospace, electronics, and nuclear applications.

Specs and options

Specifications customizable upon request.

| Model | Unit | XBSJ-3000-25H | XBSJ-3500-25H | XBSJ-4000-25H | XBSJ-5000-25H |

|---|---|---|---|---|---|

| Max working dimensions | m | 3.0x3.0x2.0 | 3.5x3.5x2.0 | 4.0x4.x2.3 | 5x3.3x2.3 |

| Wire diameter | mm | 7.6 - 11.5 | 7.6 - 11.5 | 7.6 - 11.5 | 7.6 - 11.5 |

| Worktable size | mm | 2.0x2.0 | 2.0x2.0 | 2.0x2.0 | / |

| Table rotating degree(Option) | n° | 360° | 360° | 360° | / |

| Main motor power | kw | 15 | 15 | 15 | 15 |

| Water consumption | m³/h | 5 | 6 | 6 | 6 |

| Overall dimensions | m | 7.7x8.2x5.1 | 7.7x8.7x5.1 | 7.7x9.2x5.4 | 7.7x9.2x5.4 |

| Approximate weight | t | 10.8 | 11.5 | 12 | 16.5 |

*Can be customized as per requirement

Diamond innovation meets engineering excellence.

Cut Large. Cut Precise. Cut Any Material.

Extra-Large Size Cutting

Four-pulley structure enables cutting up to 5×2.4m dimensions.

Double Cutting Efficiency

Industrial permanent magnet motor achieves 2㎡/h cutting speed for marble.

Automatic Continuous Processing

PLC-controlled automatic slab segmentation enables continuous batch cutting of materials.

±1mm Precision Cutting

Servo motor with hydraulic tensioning maintains constant wire saw pressure.

Remote Operation

OTA technology for remote updates and maintenance support.

Robust Construction

Cast iron columns with Siemens and NSK components ensure durability.

20% Energy Savings

High-efficiency permanent magnet synchronous motor.

Comprehensive Safety Protection

Software alerts + hardware safeguards with protective covers and limit switches.

Reduced Maintenance

Dust/water-resistant design with automatic lubrication system.

FAQs

Answered: DINOSAW Block Squaring Diamond Wire Saw Machine

What materials can be cut with the DINOSAW diamond wire saw machine?

DINOSAW block squaring diamond wire saw machines are exceptionally versatile, capable of cutting a wide range of natural stones and engineered materials. For natural stones, our machines efficiently process granite, marble, limestone, sandstone, quartzite, travertine, onyx, and soapstone with precision and consistency. Each material type can be programmed with specific cutting parameters optimized for its unique properties.

Beyond traditional stone materials, our systems excel at cutting engineered and technical materials including engineered quartz, sintered stone products, porcelain slabs, ceramic panels, concrete blocks, and reinforced cement composites. For industrial applications, our specialized configurations can process graphite blocks, quartz glass, insulating materials, and select metal composites.

The machine's adaptability comes from its programmable cutting parameters, interchangeable wire specifications, and customizable cooling systems. Our technical team can recommend the optimal configuration based on your specific material processing needs, ensuring maximum efficiency and quality for your unique application requirements.

Can this wire saw machine cut curved or custom shapes?

No, this block squaring diamond wire saw machine is specifically designed for straight-line cutting only.

It excels at vertical squaring, horizontal splitting, and precise slab cutting with straight lines.

For curved or custom shape cutting requirements, we recommend our CNC wire saw machines for profiling that are specifically engineered for contoured and shaped cutting applications. Please contact our sales team for information about our specialized profile wire saw solutions.

What are the advantages of using a diamond wire saw over traditional blade cutting methods?

Diamond wire saw machines offer significant advantages over traditional methods like blade cutting. First, they can process larger blocks (up to 5×2.4m with our DINOSAW system) than traditional blade systems allow. Second, they deliver superior precision with consistently achievable ±1mm tolerance, increasing the value of finished blocks by up to 40%.

Diamond wire cutting produces less waste material due to its thinner cutting kerf compared to blades. The continuous cutting action eliminates vibration and stress that can cause micro-fractures in sensitive materials, preserving the structural integrity of the stone. Additionally, our systems achieve 1.5-2.0㎡/hour cutting speeds while maintaining consistent quality, significantly improving production efficiency.

The technology also offers greater flexibility for cutting various materials with the same machine by simply adjusting parameters and wire specifications, making it a versatile investment for fabrication shops working with multiple stone types.

What are the common issues with diamond wire saw machines and how to troubleshoot them?

Wire breakage is one of the most common issues and typically results from improper tension, excessive cutting speed, or worn components. If experiencing frequent breaks, first check and adjust the wire tension according to material specifications. Reduce cutting speed for particularly hard or inconsistent materials. Inspect pulleys and guides for damage or misalignment that could cause premature wire failure.

Inconsistent or wavy cutting can result from inadequate wire tension, misaligned guide systems, or variable water flow. Ensure the hydraulic tensioning system is properly calibrated and functioning correctly. Verify that all guide pulleys are aligned and rotating freely. Check that the cooling water flow is consistent and sufficient for the material being cut.

If the machine experiences reduced cutting speed, inspect the diamond wire for glazing (smooth, polished appearance of beads) which indicates the wire needs reconditioning or replacement. Check the motor and drive systems for proper operation, including belt tension if applicable. Verify that the material feed rate matches the cutting capacity for the specific stone type. For electrical or PLC-related issues, our machines feature 4G connectivity for remote diagnostics, allowing our technical team to troubleshoot complex problems without site visits in many cases.

What is the load capacity of the trolley system?

We offer various trolley configurations to meet different load requirements: from 20T to 50T.

All trolleys utilize heavy-duty rail systems (the same technology used in train rails) for extended operational life.

Our rotary support design provides superior stability and load-bearing capability compared to conventional gear structures.

How do I maintain optimal performance of my diamond wire saw machine?

Regular maintenance is essential for maximizing the performance and lifespan of your DINOSAW block squaring diamond wire saw machine. After each use, thoroughly clean the machine to remove stone debris, slurry, and dust from all components. Use appropriate cleaning solutions that won't damage electronic or mechanical parts.

Check the diamond wire regularly for signs of wear, fraying, or damage. Replace worn wires promptly to maintain cutting efficiency and prevent breakage during operation. Inspect tension systems daily and ensure proper calibration according to the material being cut. The hydraulic system requires regular checks for leaks or pressure inconsistencies. When the machine will not be used for extended periods, it's crucial to remove the diamond wire completely from the system to prevent metal fatigue and breakage caused by prolonged tension.

Lubricate all moving parts according to the maintenance schedule in your operator manual. The cooling system needs regular inspection to ensure proper flow and temperature regulation. Verify that water filters are clean and functioning correctly to prevent clogging. For electrical components, ensure connections are tight and protected from water and dust. Following these maintenance procedures will significantly extend your machine's operational life and maintain optimal cutting performance.

What warranty is provided with the machine?

We offer a one-year warranty on the machine and all core components (excluding consumable parts such as diamond wire, guide wheels, rubber rings, and rubber strips).

After the warranty period expires, we continue to provide ongoing service support and technical assistance to ensure optimal machine performance throughout its operational lifetime.

What factors should I consider when choosing the right diamond wire saw machine?

When selecting a diamond wire saw machine, first consider your material requirements: types of stone or materials to be cut, maximum block dimensions, and desired finished product specifications. Our DINOSAW machines are available in various configurations to accommodate blocks up to 5×2.4m, but choosing the right size for your typical workpieces optimizes both performance and investment.

Production capacity needs should drive your decision regarding cutting speed capabilities and automation features. Our PLC-controlled systems offer programmable batch processing for high-volume operations, while simpler controls may be sufficient for lower production demands. Consider future growth when making this assessment to avoid premature replacement.

Facility considerations include available space, power supply specifications, water availability for cooling systems, and environmental controls (especially for dust and noise management). Additionally, evaluate total ownership costs beyond the initial investment, including wire consumption rates, maintenance requirements, spare parts availability, and operator training needs. DINOSAW offers comprehensive service packages with remote diagnostics capabilities that significantly reduce downtime costs over the machine's lifecycle, which should factor into your comparative analysis between different equipment options.

What safety features are included in DINOSAW diamond wire saw machines?

Safety is a core design priority in all DINOSAW block squaring diamond wire saw machines. Our comprehensive safety system includes a single emergency stop button located on the operation control panel, allowing operators to immediately halt operations when needed. The wire cutting area is equipped with a diamond wire saw guard that provides protection during operation without interlocked access panels.

Advanced electronic safety features include wire breakage detection systems that instantly shut down the machine and trigger automatic alarms if a wire failure or other malfunction is detected, preventing potential hazards from whipping wires. Tension monitoring systems continuously verify proper wire tension and automatically adjust or stop operations if parameters exceed safe limits. For operator protection, our machines incorporate non-transparent diamond wire saw guards that provide essential safety while maintaining durability in demanding cutting environments.

All control systems include redundant safety circuits with fail-safe design principles ensuring the machine defaults to a safe state during any malfunction. The PLC control system provides comprehensive error diagnostics with clear instructions for safe resolution. Additionally, our machines meet or exceed all applicable international safety standards including CE certification for European markets, demonstrating our commitment to operator safety across global operations.

What training and support does DINOSAW provide for new machine operators?

DINOSAW provides comprehensive training and support programs designed to ensure operators achieve maximum productivity and equipment longevity from day one. Our initial training package includes comprehensive on-site installation and operator training conducted by experienced DINOSAW technicians. This hands-on training covers all aspects of machine operation, from basic controls to advanced program creation, material-specific parameter optimization, and preventative maintenance procedures.

Our support continues well beyond installation with multilingual technical support available through multiple channels. Operators can access our technical team via phone, email, or through the machine's integrated 4G remote assistance system, which allows our technicians to directly observe machine operation and provide real-time guidance. The machine includes comprehensive digital documentation, including detailed operating manuals, maintenance schedules, troubleshooting guides, and instructional videos accessible directly through the control interface.

For ongoing skill development, DINOSAW offers advanced training programs covering specialized cutting techniques, production optimization, and preventative maintenance. These sessions can be conducted either at our training facilities or at customer locations. Additionally, our maintenance contracts include regular preventative maintenance visits, during which our technicians not only service the equipment but also provide refresher training and introduce operators to new techniques or software features. This continuous learning approach ensures operators continuously improve their skills and stay updated on the latest best practices in stone cutting technology.

Certifications & Standards

Cut Large. Cut Precise. Cut Any Material.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Transform Your Stone Processing Capabilities Today

Join industry leaders worldwide who rely on DINOSAW block squaring technology to maximize precision, efficiency, and profitability. Our diamond wire saw solutions are engineered to deliver exceptional results across all materials with unmatched reliability.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский