Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

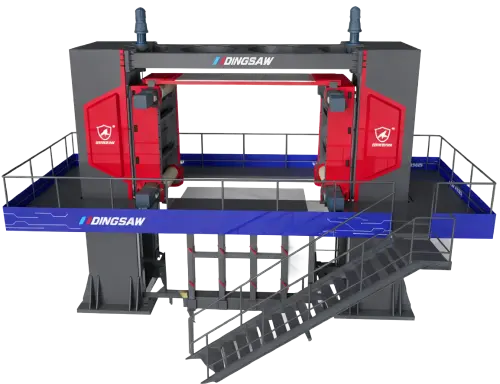

Thin Multi‑Wire Saw for Granite & Quartz Slabs

DS‑3623A

Compatible Materials & Products

hard stones thin/medium‑thin slabs

Granite ❯ Façade thin slabs

|

|

Introduction: Granite façade thin slabs demand precision and efficiency. Processing Technology: DINOSAW down‑feed thin multi‑wire provides stable clamping for large granite blocks; optimized wire speed and constant tension deliver smooth, chip‑free slicing for façade panels (typical granite wire speed 25–35 m/s). Technical Advantages: Small kerf (≈0.5–0.8mm), robust gantry, and ±0.5 N constant tension ensure uniform thickness and premium flatness across the slab. Application Results: Compared to gangsaw/multi‑blade cutters, finish quality improves and polishing workload drops; yield is higher due to minimal kerf loss in large‑format façade projects. Value Summary: Ideal for premium granite thin slabs in architectural façades; the down‑feed thin multi‑wire setup maximizes material utilization and line stability. |

Engineered Quartz ❯ Countertop slabs

|

|

Introduction: Engineered quartz countertop slabs require high-throughput processing with consistent color and flawless surfaces, a key market for stone fabricators. Processing Technology: The DINOSAW down-feed thin multi-wire saw utilizes its robust gantry and stable down-feed pressure to efficiently slice large quartz blocks. Optimized wire speed and tension control manage the material's hardness, ensuring a smooth, chip-free cutting process for countertop slab production. Technical Advantages: The machine's constant tension system (±0.5 N precision) prevents wire marks and ensures uniform thickness across the entire slab, a critical factor for high-value quartz countertops. Application Results: Fabricators achieve higher yield due to the minimal kerf loss (≈0.5–0.8mm) and a premium finish that significantly reduces subsequent polishing time and costs, boosting overall productivity for commercial projects. Value Summary: This down-feed multi-wire cutting solution transforms engineered quartz processing by delivering superior finish quality and higher material utilization, making it the ideal choice for competitive countertop slab manufacturing. |

Sintered Stone ❯ Large‑format panels

|

|

Introduction: Large-format sintered stone panels are in high demand for modern architecture, requiring cutting solutions that can handle large dimensions while maintaining material integrity and aesthetic consistency. Processing Technology: The DINOSAW down-feed multi-wire saw is engineered for large block slabbing. Its stable down-feed mechanism provides secure clamping for large sintered stone blocks, while the high-speed diamond wire slicing process ensures efficient and precise cutting into large-format panels. Technical Advantages: The machine's capability to handle blocks up to 3600x2100x2300 mm, combined with its small kerf (≈0.5–0.8mm), maximizes the number of high-value panels from a single block and ensures exceptional flatness. Application Results: Producers of sintered stone panels benefit from reduced material waste, faster production cycles, and a superior surface finish that meets the exacting standards of high-end architectural and interior design projects. Value Summary: By enabling high-yield, high-quality production of large-format panels, this multi-wire cutting machine provides a critical competitive edge for sintered stone manufacturers aiming to dominate the premium building materials market. |

Luxury Stone/Quartzite ❯ slabs

|

|

Introduction:Luxury stones like quartzite are prized for their unique beauty and durability, commanding high prices. Maximizing yield from every block is paramount, making thin slab cutting a high-stakes, high-reward application. Processing Technology:The down-feed thin multi-wire saw’s design provides the extreme stability required for cutting hard, high-value quartzite. Its patented constant tension control and optimized wire speed deliver a flawless cut, preserving the integrity and aesthetic of the luxury stone. Technical Advantages:The ability to use thin diamond wires (0.35-0.8mm) results in an ultra-small kerf, drastically increasing the number of premium thin slabs harvested from each expensive block. Application Results:Stone suppliers see a direct increase in revenue per block. The superior surface quality minimizes polishing needs, reducing labor costs and the risk of damaging the high-value slabs, ensuring maximum profitability. Value Summary:For luxury stone processing, this thin multi-wire saw is not just a machine but a profit multiplier. It unlocks the full value of premium materials through unmatched yield and exceptional finish quality. |

Specs and options

Specifications customizable upon request.

| Item | Unit | DS-3623A |

|---|---|---|

| Feed type | / | Down-feed |

| Cutting feed rate | mm/h | 100-280 |

| Diamond wire diameter | mm | 0.35-0.8 |

| Slab thickness | mm | 2-30 |

| Cutting tension | N | 0-300 |

| Table lift travel | mm | 2400 |

| Wire storage | m | 30000 |

| Roller diameter | mm | 320-450 |

| Main motor power | kW | 64x4 |

| Max workpiece size (LxWxH) | mm | 3600x2100x2300 |

| Machine weight | T | 34-42 |

| Overall dimensions | mm | 9200x7500x5300 |

Option | Function | Recommendation |

|---|---|---|

Rotating table | Rotate block without re-hoisting; adjust cutting angle | Recommended for irregular blocks / non-standard angles |

Transfer cart (aux table) | Parallel loading/unloading beside main table | Must‑have for peak throughput |

Extended rails | Longer cart travel space for multi‑cart / long pieces | Pair with transfer cart or when layout needs longer travel |

Spindle box set (drive/idler) | Spare assembly for quick swap to cut downtime | Buy as spare if production loss is costly |

Roller | Key wire‑net part; different materials/coatings affect wear/inertia | CF+PU for high speed/energy saving; iron/aluminum for budget |

Wire welder | Repair broken wire; fast wire recovery | Essential for most users |

Roller lathe | Pre‑recoat turning & alignment; reduce run‑out/vibration | Own in high‑utilization plants; outsource if low |

Tension wheel | Keep wire tension stable; core force element | Stock as consumable; set preventive replacement & calibration |

Guide wheel rubber ring | Protect wire & guide; improve friction & stability | Track wear & replace early for stable cutting quality |

Wire winder | Fast uniform winding; control pitch & initial tension | Standard for multi‑wire; best with wire welder |

Robust gantry + constant tension enable stable thin‑slab production.

Precision Down‑feed. Thin Slabs, High Yield.

Continuous Line Ready

Supports large blocks and parallel loading.

Energy & Noise Reduced

Lower OPEX with cleaner, quieter operation.

Predictive Diagnostics

Intelligent monitoring supports proactive maintenance and higher uptime.

FAQs

Common Questions About Thin Multi-Wire Stone Cutting

What is a down-feed thin multi-wire saw and how does it work?

A down-feed thin multi-wire saw is an industrial machine designed for high-precision slicing of hard materials like granite and quartz into thin slabs. It works by pressing a high-speed array of diamond wires downward through a stationary block, using gravity and mechanical pressure to ensure a stable, powerful cut. This method is ideal for achieving uniform thickness and a superior finish on high-value stone slabs.

The process starts with securely clamping the stone block onto the worktable. The wire-web, consisting of multiple diamond wires, then descends at a controlled feed rate (e.g., 100-280 mm/h) while moving at high speeds (up to 40 m/s). This downward force, combined with the block's own weight, minimizes vibration and enhances cutting stability, which is crucial when processing dense materials. A continuous flow of coolant lubricates the cutting zone, dissipates heat, and flushes away debris to prevent wire marks.

This down-feed technique is particularly effective for hard stone slab production, as the consistent pressure results in excellent flatness and reduces the risk of wire bowing. Fabricators benefit from higher material yield due to the small kerf (≈0.5–0.8mm) and reduced post-processing work, making it a highly efficient solution for producing granite countertops, engineered quartz panels, and other premium architectural materials.

Why use a down-feed vs. an up-feed multi-wire saw?

- Down-feed (A-Series): Maximizes cutting force and stability. Ideal for high-hardness granite and quartz. The block's weight assists in secure clamping, enhancing efficiency.

- Up-feed (H-Series): Excels at debris removal due to gravity. This results in a better surface finish, making it perfect for marble thin slabs and high-value brittle materials like ceramics or crystals where surface integrity is paramount.

What materials are best for this thin multi-wire saw?

- Hard Natural Stones: Especially effective for granite and quartzite, where its cutting force and stability are essential.

- Engineered Stones: Ideal for engineered quartz slabs used in countertops and panels.

- Sintered Stones & Ceramics: Capable of slicing large sintered stone blocks and other dense ceramic materials into large-format panels.

How do options like rotary tables improve productivity?

- Rotary Worktables: Allow block angle correction or 90-degree rotation for secondary cuts without re-hoisting. This saves hours of crane time and manual labor.

- Transition Carts: Enable a parallel workflow. While one block is being cut, another can be loaded onto a spare cart, and a finished set of slabs can be unloaded from a third. This ensures the thin multi-wire saw is almost always slicing.

What kerf and thickness consistency can I expect?

- Kerf (Sawing Gap): Typically between 0.5mm and 0.8mm, depending on the diamond wire diameter (e.g., 0.35-0.6mm wire) and process parameters. This is a dramatic improvement over gang saws, whose kerf can be 7mm or more.

- Thickness Consistency: The combination of a robust gantry, carbon-fiber rollers, and a patented constant tension system (controlling tension to ±0.5 N) minimizes wire bow, ensuring uniform thickness across the entire slab.

How does a thin multi-wire saw compare to a gangsaw?

- Higher Yield: A thin multi-wire saw produces around 10%-25% more finished slabs from the same block due to its ultra-small kerf.

- Lower OPEX: It consumes less energy, uses less water, and creates over 80% less slurry waste. It also has a smaller footprint (~30% less space) and requires much simpler foundations (~80% lower cost).

- Better Quality: The slabs produced are flatter and have a smoother surface, significantly reducing polishing time and costs.

How to choose the right wire diameter and tension settings?

Selecting the correct wire diameter and tension is a critical process window adjustment that depends on the material's hardness, the desired slab thickness, and your production goals (speed vs. finish). A general rule is that harder materials require higher tension and line speeds for efficient cutting. Here are some starting guidelines: Our machines feature advanced control systems with pre-saved recipes for various materials, simplifying the setup process. Our technicians also provide on-site training to help your team master the process window for your specific stone blocks, ensuring you achieve the optimal balance of productivity and quality.

- Wire Diameter: For thin slab production, a diameter between 0.35mm and 0.6mm is common. Thinner wires create a smaller kerf and increase yield, but they require more precise tension control to prevent breakage.

- Tension & Speed for Granite/Quartz: These hard materials typically require higher tension and a wire speed in the range of 25–35 m/s to ensure effective abrasion.

- Tension for Sintered Stone: This material benefits from a very stable feed rate and consistent tension to prevent chipping and micro-cracks.

What is the maintenance schedule for stable performance?

A proactive maintenance schedule is key to ensuring long-term stable performance, consistent finish quality, and high uptime from your thin multi-wire saw. Maintenance focuses on monitoring wear parts in the wire path and ensuring the precision of the tensioning system. A typical preventive maintenance plan includes: In addition, our machines are equipped with intelligent diagnostic systems that provide predictive maintenance alerts, warning of potential issues before they cause downtime. This allows you to schedule maintenance proactively and maximize productivity.

- Roller Maintenance: The polyurethane on the rollers wears over time. They can be re-grooved with a lathe about 6 times before requiring a complete re-coating. A new coating typically lasts for approximately 160,000 m² of cutting.

- Wear Part Inspection: Regularly inspect and replace consumable parts like tension wheels and guide rings based on production hours or visible wear to prevent wire breaks.

- System Calibration: Periodically calibrate tension sensors to maintain cutting accuracy and ensure uniform slab thickness.

Is this machine good for small-scale workshops?

This large-format down-feed thin multi-wire saw is primarily designed for medium- to large-scale industrial fabricators who process multiple blocks per day and require high throughput. Its size, capacity, and investment level are best suited for production-focused operations. For smaller workshops, research labs, or companies focused on pilot production or custom one-off jobs, a smaller machine would be a more appropriate fit. A smaller model offers several advantages for such environments: If your business focuses on high-volume slab production from large blocks (e.g., up to 3600 x 2100 x 2300 mm), this machine is the right choice. If your needs are smaller-scale, we recommend exploring our compact models designed for R&D and small-batch processing.

- Smaller Footprint: Easier to install in facilities with limited space.

- Lower Investment: More accessible capital cost for smaller businesses.

- Process Flexibility: Ideal for testing cutting parameters on new materials without committing a large production machine.

Certifications & Standards

Precision Down‑feed. Thin Slabs, High Yield.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to scale thin slab production?

Adopt DINOSAW down‑feed thin multi‑wire to boost yield and finish quality across granite, engineered quartz, and sintered stone.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский