Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

CNC Diamond Wire Saw Cutting Machine for Tombstone

YXSJ-1500/2400

Compatible Materials & Products

CNC Wire Saw Cutting for Stone Monuments Profiling

Granite ❯ Tombstones & Monuments

|

|

|

|

|

Granite's exceptional durability and timeless beauty make it the premier choice for lasting memorial stones and monuments. The dense crystalline structure and natural weathering resistance ensure tombstones maintain dignity through decades of exposure.

DINOSAW's CNC diamond wire saw employs multiple tension-controlled wires to cut dense granite with precision. The advanced CNC system enables vertical cutting, 45° beveling, curved profiles, and custom shapes while multi-wire design allows simultaneous slab cutting. Diamond wire creates smooth surfaces with minimal kerf loss, eliminating secondary finishing needs.

This precision cutting reduces production time by 40% while maintaining consistent dimensions. The automated process minimizes material waste by 25% and delivers superior edge quality. Memorial fabricators achieve higher throughput with reduced labor costs and offer complex custom designs to meet families' unique requirements.

Marble ❯ Memorial Sculptures

|

Marble's natural elegance and workability have made it the sculptor's choice for centuries, perfect for intricate memorial sculptures that capture departed loved ones' essence. Its fine grain structure allows detailed carving while maintaining structural integrity for outdoor applications.

DINOSAW's CNC diamond wire saw adapts to marble's characteristics using controlled wire tension and optimized speeds to prevent chipping. The precision CNC system enables complex three-dimensional profiling, allowing sculptors to rough-cut intricate forms before hand finishing. Diamond wire's minimal heat preserves marble's properties while smooth cutting maintains integrity.

Memorial artists achieve unprecedented design freedom with 60% faster rough cutting versus traditional methods. Precision cuts reduce hand-finishing time by 35% while eliminating material stress causing future cracking. This technology enables cost-effective custom memorial sculpture production, making personalized artistic memorials accessible.

Basalt ❯ Modern Memorial Stones

|

Basalt's contemporary appeal and exceptional strength make it ideal for modern memorial designs reflecting today's architectural aesthetics. This volcanic stone's uniform texture and deep color create striking contemporary monuments as powerful remembrance symbols in modern cemetery landscapes.

DINOSAW's CNC diamond wire saw overcomes basalt's notorious hardness through advanced diamond bead technology and precise tension control. The multi-axis CNC system enables clean geometric cuts and angular profiles defining modern memorial design. Wire saw's continuous cutting prevents thermal stress that traditional methods create in heat-sensitive volcanic stone.

Modern memorial designers achieve crisp architectural lines with 50% less processing time than conventional methods. Precision technology enables thin-section cutting for contemporary layered designs while maintaining structural strength. Memorial fabricators offer innovative geometric forms and clean minimalist aesthetics appealing to contemporary families.

Limestone ❯ Carved Memorial Tablets

Limestone's soft workability and natural warmth create ideal conditions for carved memorial tablets featuring detailed inscriptions and decorative elements. This sedimentary stone's consistent texture allows both machine precision and hand-carved details, perfect for traditional memorial tablets.

DINOSAW's CNC diamond wire saw handles limestone's variable density through adaptive cutting parameters adjusting automatically to stone characteristics. Gentle cutting preserves the stone's natural layered structure while creating flat surfaces for inscription work. Wire saw precision enables consistent thickness across large tablets and clean edges requiring minimal finishing.

Memorial craftsmen achieve uniform tablet blanks with 45% improved surface quality versus traditional sawing. Precision cutting eliminates edge chipping common with limestone, reducing preparation time by 30% before inscription work. This efficiency allows memorial workshops to offer competitive pricing on custom carved tablets while maintaining traditional craftsmanship.

▶ Product Demo

▶

▶

Granite Memorial Production

Transforming Production Efficiency for Memorial Fabricators

A memorial stone fabricator in the USA installed two DINOSAW CNC Diamond Wire Saw machines to replace their aging bridge saws.

Their precision cutting operations now deliver consistent thickness across all stones with perfect edge quality, eliminating the need for extensive edge work and finishing. The automated CNC operations also reduced their labor needs by 35%.

Custom Memorial Design

Expanding Creative Possibilities in Memorial Stonework

A boutique memorial studio in Europe specialized in custom-designed monuments faced challenges creating complex curves and unique shapes. After implementing DINOSAW Diamond Wire Saw , they achieved unprecedented design flexibility with the ability to cut intricate profiles and curved sections with perfect precision.

The CNC control system allowed them to import designs directly from CAD, translating artistic concepts into precise cutting paths without manual interpretation errors.

Memorial Stone Recycling

Sustainability and Cost Efficiency in Stone Processing

A memorial services company specializing in stone recycling and repurposing implemented DINOSAW CNC Diamond Wire Saw to precisely cut and reshape existing memorial stones. The minimal kerf width of the diamond wire technology allowed them to maximize material recovery from older monuments, cutting thin slabs with minimal waste.

Their sustainable approach reduced raw material costs by 45% while providing an environmentally responsible service to their community.

Specs and options

Specifications customizable upon request.

| Model | YXSJ-1500-9H | YXSJ-2400-13H |

|---|---|---|

| Max working dimensions | 1.5x1.5x0.8m | 2.5x2.4x1.2m |

| Wire diameter | 7.6-11.5mm | 7.6-11.5mm |

| Main motor power | 11kw | 15-30kw |

| Worktable size | 2.5x1.4m | 2.5x1.4m |

| Overall dimensions | 5.7x3.5x2.5m | 7.0x6.5x2.5m |

| Approximate weight | 3.8t | 5t |

Engineering excellence meets masterful stone craftsmanship in a machine designed for perfect memorial stonework

Precision Cutting that Transforms Stone into Art

Batch Processing Capability

Multiple materials arranged in parallel, capable of cutting up to 9 tombstones at once.

Double Cutting Efficiency

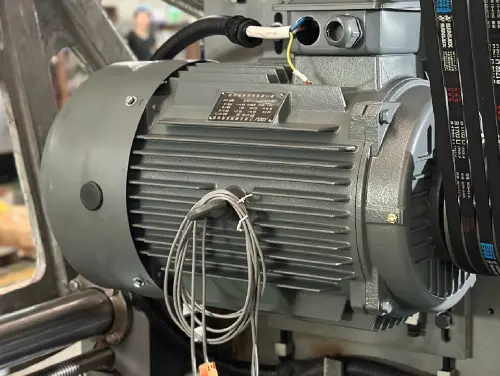

Industrial permanent magnet motor achieves 1.5㎡/h cutting speed for granite.

Reduced Labor Costs

Smooth cutting surface eliminates the need for secondary polishing processes.

5-Minute Quick Operation

Self-developed CNC control system, no programming required.

±1mm Precision Cutting

Servo motor with hydraulic tensioning maintains constant wire saw pressure.

20% Energy Savings

High-efficiency permanent magnet synchronous moto.

Remote Operation

OTA technology for remote updates and maintenance support.

Versatile Cutting

Multi-axis control enables linear, curved & custom cuts for tombstones, monuments & crosses.

Robust Construction

Cast iron columns with Siemens and NSK components ensure durability.

FAQs

Key Questions About CNC Diamond Wire Saw for Tombstone Cutting

How does a diamond wire saw compare to traditional bridge saws for tombstone profiling?

Diamond wire saws offer significant advantages over traditional bridge saws for tombstone cutting. The key benefit is exceptional flexibility for cutting curved profiles and custom shapes that bridge saws simply cannot achieve. While bridge saws are limited to straight-line cuts, diamond wire technology can create smooth arcs, complex contours, and customized designs directly in the stone, opening new creative possibilities for memorial designs.

Another major advantage is the ability to cut multiple tombstones simultaneously. This multi-block cutting capability transforms production efficiency, allowing memorial fabricators to complete in hours what would take days with traditional methods. Wire saws also generate less waste due to thinner kerf width, saving approximately 25% more material while operating with lower noise and vibration.

What tombstone materials can this machine process?

DINOSAW's CNC diamond wire saw processes all major tombstone materials including granite, marble, basalt, limestone, sandstone, and quartzite. The machine's adaptive cutting parameters automatically adjust to different stone densities and hardness levels.

For granite (hardness 6-7), it achieves cutting speeds of 1.5㎡/h with excellent finish.Marble (hardness 3-4) cuts faster at 2.0㎡/h while maintaining smooth surfaces ideal for detailed carving. Basalt benefits from continuous cutting that prevents thermal stress. The machine also handles composite materials and engineered stones used in modern memorial applications.

How many tombstones can be cut simultaneously?

The number of tombstones that can be cut simultaneously with the DINOSAW CNC diamond wire saw is not fixed, but primarily depends on the machine's processing width and the thickness of the tombstones. Wider equipment models can accommodate more tombstones in a single cutting operation. The YXSJ-1500 model handles smaller tombstones (max 1.5x1.5x0.8m), while the YXSJ-2400 accommodates larger monuments (up to 2.5x2.4x1.2m).

This simultaneous cutting capability increases production output compared to single-piece methods, significantly reducing per-unit costs and labor requirements. The CNC system ensures consistent dimensions across all pieces, maintaining quality while maximizing efficiency. Setup time is minimal as operators can arrange multiple slabs and program the entire cutting sequence in advance.

How easy is it to operate this CNC diamond wire saw machine?

The DINOSAW CNC diamond wire saw features an intuitive self-developed control system requiring no programming knowledge. Operators can master basic operations within 5 minutes using the user-friendly interface. The machine includes pre-programmed cutting patterns for common tombstone shapes, allowing operators to simply select the desired profile and start cutting. Additionally, the system supports CAD drawing imports, enabling custom designs to be directly transferred from digital files to cutting patterns.

The CNC system automatically controls cutting speed, wire tension, and feed rates based on material type. Safety features include emergency stops, wire break detection, and protective guards. Remote operation through OTA technology enables technical support and software updates.

What technical support and training are provided?

DINOSAW provides comprehensive technical support including on-site installation, operator training, and ongoing maintenance support. Initial training covers machine operation, safety procedures, maintenance schedules, and troubleshooting common issues. Training typically requires 1-3 days for complete operator certification.

Technical support includes 24/7 remote assistance through OTA technology, allowing real-time diagnostics and software updates. Video technical support helps resolve issues quickly without on-site visits. DINOSAW maintains a global network of service technicians and readily available spare parts inventory. Warranty coverage includes one year for machine components.

How does the machine handle different stone hardness levels?

The CNC control system automatically adjusts cutting parameters based on stone hardness and density through adaptive cutting technology. For soft stones like limestone (hardness 3-4), the system reduces cutting speed and wire tension to prevent chipping. For hard materials like granite (hardness 6-7), it increases wire tension and optimizes cutting speed for efficient material removal.

The machine's servo motor with hydraulic tensioning maintains constant wire pressure regardless of material variations. Diamond bead selection can be customized for specific stone types - softer bonds for hard materials and harder bonds for soft stones.

Certifications & Standards

Precision Cutting that Transforms Stone into Art

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Transform Your Memorial Stone Production Today

Elevate quality, increase efficiency, and expand design possibilities with DINOSAW's precision CNC wire saw technology.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский