Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

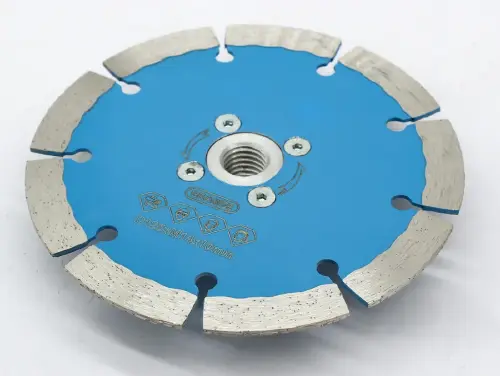

Segmented Diamond Cutting Disc for Concrete & Masonry

105-350mm

Compatible Materials & Products

Precision Cutting Across Concrete, Masonry, and Natural Stone

Granite > Slab Cutting

Granite's hardness and abrasive nature present a significant challenge, demanding cutting discs that can maintain sharpness and resist rapid wear. Achieving clean, chip-free edges on countertops and slabs is critical for high-quality finishes in fabrication workshops.

Our sintered segmented cutting disc is engineered with a specialized hard bond matrix that securely holds high-grade diamonds, ensuring sustained cutting performance in granite. The segmented design facilitates efficient debris removal, while key slots provide essential cooling during dry cutting. For optimal results, match the disc diameter and recommended RPM range to your specific circular saw or bridge saw setup.

This cutting disc delivers faster cutting speeds and superior longevity, reducing disc change downtime and operational costs. The result is a smooth, precise cut with minimal chipping, enhancing the value of the final product and ensuring workshop efficiency.

Reinforced Concrete > Opening Cuts

Cutting through reinforced concrete involves tackling a composite material of hard aggregates and ductile steel rebar. This dual challenge requires a cutting disc that can handle both abrasion and impact without segment loss or premature failure, which is crucial for safety and progress in demolition and renovation projects.

This cutting disc features a robust sintered bond formulated for aggressive cutting in reinforced concrete. The segmented design provides the necessary clearance to eject slurry and cut through rebar efficiently. Laser-welded segments offer a stronger bond to the core, enhancing safety under high stress. The key slots aid cooling, which is vital when cutting deep sections or working in dry conditions.

The result is a reliable and fast-cutting tool that minimizes downtime on the job site. It offers a longer service life compared to standard abrasive wheels, improving cost-effectiveness and ensuring that structural openings and demolition cuts are completed on schedule.

Masonry & Brick > Wall Cutting

Masonry materials like brick and aerated concrete are highly abrasive and can quickly wear down conventional cutting discs. For tasks such as creating window openings, cutting channels for utilities, or performing structural repairs, a durable and fast-cutting disc is essential for maintaining project timelines.

Our sintered segmented cutting disc is designed with a medium-hard bond that is optimized for the high abrasiveness of masonry and brick. This allows for controlled wear, constantly exposing new diamond particles for consistent cutting speed. The gullets between segments efficiently clear dust and debris, preventing disc binding and ensuring smooth operation with masonry saws or handheld power cutters.

This tool offers superior cutting speed and a significantly longer lifespan in abrasive materials. It enables contractors to complete wall sawing and repair jobs faster, with cleaner cuts and less effort, directly contributing to increased productivity and profitability on site.

Concrete Block > General Cutting

Concrete blocks are a staple in construction, but their abrasive composition requires a cutting disc that balances cutting speed with longevity for cost-effective use. On busy construction sites, operators need a reliable, all-purpose disc that performs consistently without frequent changes.

This segmented cutting disc is an ideal choice for general-purpose block cutting. Its sintered segments are formulated to withstand the abrasive nature of concrete blocks, providing a favorable balance between cutting speed and disc life. The design is compatible with standard masonry saws and angle grinders, offering versatility for various cutting tasks on site, from resizing blocks to creating custom shapes.

By choosing this cutting disc, construction professionals gain a durable and efficient cutting solution that reduces the total cost per cut. Its reliable performance minimizes downtime, ensuring that blockwork proceeds smoothly and efficiently, keeping projects on track and within budget.

Natural Stone > Paving Cuts

Cutting natural stone pavers, flagstone, or fieldstone for landscaping projects demands precision for tight fits and clean aesthetics. These materials vary in hardness and density, requiring a versatile cutting disc that can adapt without compromising on cut quality or speed.

Our sintered segmented cutting disc offers excellent performance across a variety of natural stones. The segments are designed for clean, aggressive cutting, allowing landscapers and masons to quickly shape materials on site. Whether used dry on an angle grinder for quick adjustments or wet on a masonry saw for pristine cuts, the disc provides consistent results. The segment height and diamond concentration are optimized for a long cutting life.

This disc empowers professionals to achieve beautiful, precise results in stone landscaping and paving. Its durability and versatility reduce the need to carry multiple specialty blades, streamlining workflow and ensuring projects are completed with a high level of craftsmanship and efficiency.

Specs and options

Specifications customizable upon request.

| Diameter | Segment Width | Segment Height | Arbor | |

|---|---|---|---|---|

| Inches | mm | mm | mm | mm |

| 4.13" | 105 | 1.6 | 8 | 20 / 22.23 |

| 4.3" | 110 | 1.4 | 5/8 | 20 / 22.23 |

| 4.5" | 115 | 1.6 | 8 | 22.23 |

| 5" | 125 | 1.4 | 8 | 22.23 |

| 6" | 150 | 1.6 | 8 | 22.23 |

| 7" | 180 | 1.6 | 8 | 22.23 |

| 8" | 200 | 1.6 | 10 | 22.23 |

| 9" | 230 | 2 | 10 | 22.23 |

| 12" | 300 | 2.2 | 10 | 50 / 25.4 |

| 14" | 350 | 2.6 | 10 | 50 / 25.4 |

Cut Faster, Last Longer.

Our cutting disc for concrete features heat-dissipation slots.

Accelerated Cutting Speed

The segmented design with aggressive diamond concentration ensures rapid material removal and reduces friction.

Extended Disc Lifespan

A durable sintered bond securely holds diamonds, providing superior wear resistance and a lower cost per cut.

Superior Dry Cutting

Key slots in the core provide enhanced air cooling, preventing disc overheating and warping during intense use.

Versatile Material Application

Optimized bond formulation provides excellent results across concrete, granite, brick, and other masonry materials.

Enhanced Debris Removal

The deep gullets between segments efficiently clear cutting dust and slurry, ensuring a smoother, faster cut.

High Operational Safety

Our manufacturing process ensures core integrity and segment bonding strength, compliant with EN 13236 and oSa standards.

FAQs

Common Questions About Sintered Segmented Diamond Cutting Discs

What is a sintered segmented diamond cutting disc used for?

A sintered segmented disc is designed for fast, aggressive cutting of hard construction materials. The "segmented" aspect refers to the gaps (gullets) between the cutting sections, which help cool the disc and clear debris, making it ideal for dry cutting.

The term "sintered" describes the manufacturing process where diamond grit and metal powders are fused under high heat and pressure. This creates a strong, wear-resistant bond that holds the diamonds securely.

This cutting disc is primarily used for:

- Cutting concrete, including reinforced concrete

- Sawing through granite, natural stone, and pavers

- Applications involving brick, block, and other masonry materials

How to choose a segmented disc for concrete vs granite?

Choosing the right cutting disc depends on the material's hardness and abrasiveness. The key difference lies in the "bond," the metal matrix holding the diamonds.

For hard, less abrasive materials like granite, you need a softer bond. The softer metal wears away faster, exposing new, sharp diamonds to maintain cutting speed. For softer, more abrasive materials like concrete or asphalt, you need a harder bond to resist the abrasive wear and extend the disc's life.

As a general rule:

- Hard Materials (Granite, Reinforced Concrete): Softer bond disc.

- Abrasive Materials (Green Concrete, Asphalt, Block): Harder bond disc.

Always consult our technical team to select the perfect bond formulation for your specific application to maximize both cutting speed and lifespan.

Can this segmented disc cut reinforced concrete with rebar?

Yes, this cutting disc is engineered to cut reinforced concrete containing steel rebar. This is a demanding application that tests the limits of a diamond tool.

The disc's success depends on two factors: a tough, durable bond that prevents premature segment loss when hitting rebar, and an aggressive segment design that can cut through both hard aggregate and soft steel. Our discs are designed to handle these alternating stresses effectively.

For best results:

- Maintain a steady cutting pressure; do not force the disc.

- Ensure adequate cooling, especially during deep cuts (wet cutting is often preferred).

- Use a saw with sufficient power (e.g., a high-power floor saw or wall saw).

Proper use ensures efficient cutting through rebar with minimal disc wear, enhancing safety and productivity. (Note: Performance may vary based on rebar diameter and density).

What are the benefits of key slots for dry cutting?

The key slots (also known as gullets) between the segments are critical for high-performance dry cutting. They provide multiple significant advantages over a continuous rim disc in this application.

Their primary functions are:

- Heat Dissipation: The slots allow air to flow through the disc, actively cooling the steel core. This prevents the disc from overheating, warping, or losing tension, which is a common failure point in dry cutting.

- Debris Removal: They provide a clear path for cutting dust and debris to be ejected, preventing the disc from binding in the cut and allowing for smoother, faster operation.

- Stress Relief: The slots also allow the disc core to flex slightly under cutting pressure, reducing stress and the risk of cracking.

What diameters and arbor sizes are available for the cutting disc?

We offer a comprehensive range of sizes to fit most professional machinery, including angle grinders, circular saws, and masonry saws.

Our standard stock typically includes:

- Diameters: Ranging from 4.13 inches (105mm) up to 14 inches (350mm) and larger upon request.

- Arbor Sizes: Common sizes like 20mm, 22.23mm (7/8"), and 25.4mm (1") are available. Knockout bushings or custom arbor holes can also be supplied.

Since specifications can be customized, we recommend contacting our sales team with your machine's model and requirements. We will ensure you receive a cutting disc with the perfect diameter, arbor hole, and segment height (e.g., 8mm, 10mm) for optimal performance and a secure fit.

How do I know when to replace my segmented diamond disc?

Knowing when to replace a cutting disc is crucial for safety and efficiency. There are several clear indicators that a disc has reached the end of its service life.

Look for these signs:

- Segment Wear: The most obvious sign is when the diamond segment is worn down close to the steel core. There should always be a visible portion of the segment remaining. Cutting with a worn-out segment can damage the core and the material.

- Cracks or Damage: Inspect the steel core for any cracks, especially around the arbor hole or gullets. A cracked disc is extremely dangerous and must be discarded immediately.

- Wobbling or Vibration: If the disc starts to wobble or vibrate excessively during use, it may be warped or have lost tension due to overheating. This indicates it is no longer safe to use.

- Reduced Cutting Speed: A significant drop in cutting performance that cannot be fixed by "dressing" the disc (cutting a soft, abrasive material to expose new diamonds) means it is likely worn out.

Certifications & Standards

Our cutting disc for concrete features heat-dissipation slots.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Get a Quote for Your High-Performance Cutting Needs

Contact our experts for custom specifications, global supply, and dedicated technical support.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond Cutting Disc Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский