Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

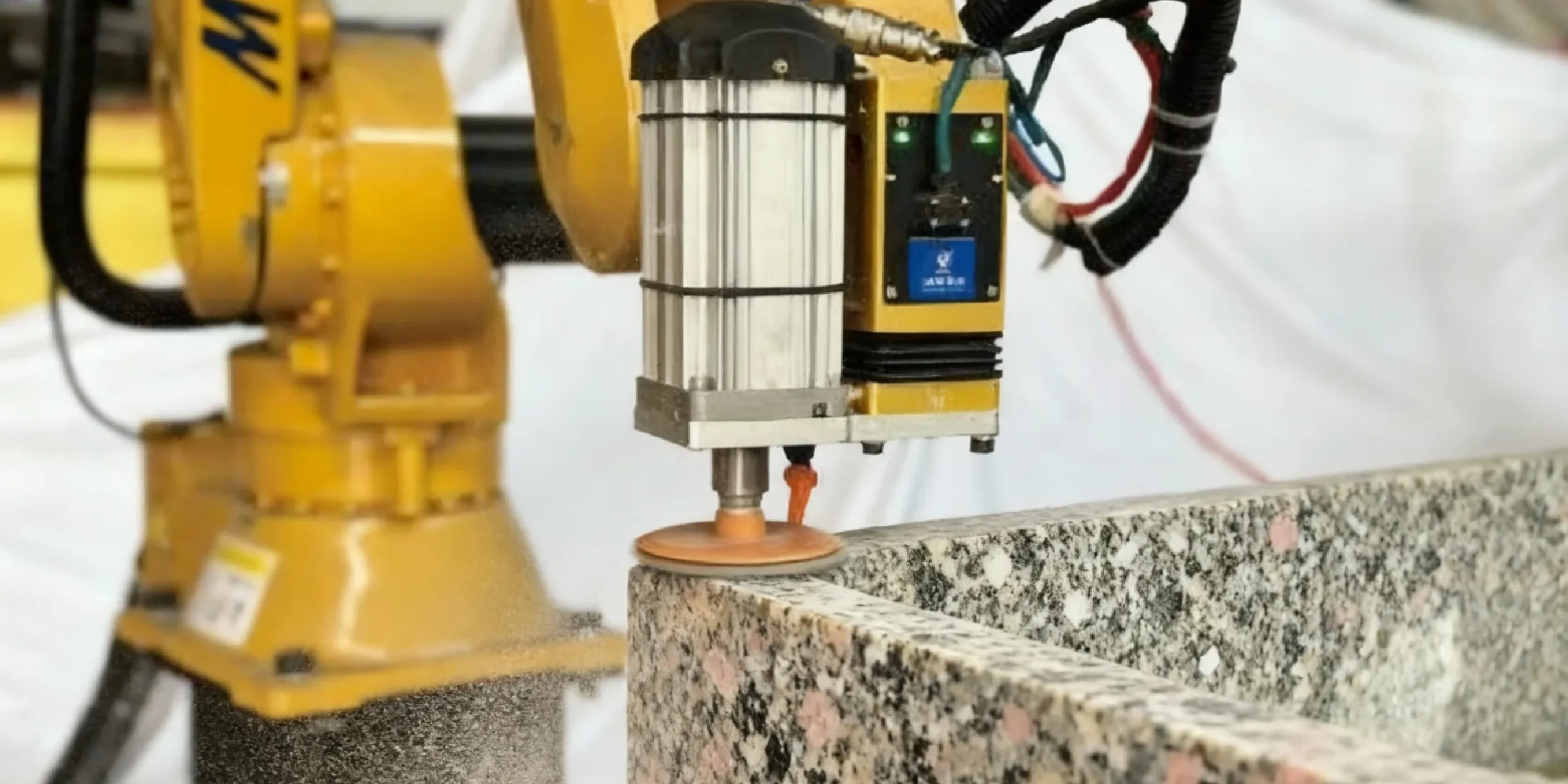

Is automated stone polishing right for you? Learn how a stone polishing robot excels at 3D surface polishing for granite, marble, and quartz countertops.

TL;DR: Should You Get a Robotic Polishing Arm?

- For complex shapes, it’s a game-changer. A robot arm for stone polishing excels at finishing 3D surfaces like sinks, bathtubs, statues, and curved countertop edges where manual labor is slow and inconsistent.

- It’s not for flat slabs. For polishing large, flat surfaces, a dedicated automatic polishing machine for slabs is faster and more cost-effective.

- It solves labor and quality problems. Automation provides consistent quality, reduces the need for highly skilled polishers, and can run 24/7, boosting your output.

- It’s a serious investment. This is a large, stationary machine for a dedicated factory space, requiring three-phase power and a significant capital outlay.

Ready to see if a robotic arm fits your workshop? Contact our engineers for a free workflow assessment.

What Can a Stone Polishing Robot *Actually* Do?

What Materials Can Robotic Polishing Handle?

What Materials Can Robotic Polishing Handle?

Granite & Hard Stones

Marble & Softer Stones

Engineered Stone (Quartz)

3 Mini-Cases: Where Stone Fabrication Robots Deliver ROI

3 Mini-Cases: Where Stone Fabrication Robots Deliver ROI

Case 1: The High-Volume Countertop Fabricator

- Problem: Inconsistent polishing on sink cutouts and curved edges led to a 15% rework rate and delayed shipments.

- Solution: Implemented a robotic arm dedicated to robotic countertop fabrication, specifically for finishing edges and bowl cutouts after the CNC saw.

- Result: Rework rate dropped to under 1%. The robot runs overnight, increasing polishing capacity by 50% without adding staff. The robotic polishing ROI was achieved in 22 months.

Case 2: The Monument & Memorial Manufacturer (Robotic Statue Polishing)

- Problem: Polishing complex 3D carvings on granite tombstones was a major bottleneck, requiring highly skilled artisans and taking days per piece.

- Solution: A 6-axis granite polishing robot was programmed using 3D scan data to automate the polishing of sculpted surfaces.

- Result: Polishing time for a complex headstone was reduced from 2-3 days to just 6 hours. Quality became perfectly uniform, and artisans could focus on new designs instead of repetitive finishing.

Case 3: The Luxury Bath & Spa Designer

- Problem: Creating one-piece marble bathtubs and integrated sinks resulted in extremely high labor costs and occasional cracking during manual finishing due to uneven pressure.

- Solution: A large-reach robotic arm was installed to handle the entire interior and exterior polishing of the bathtubs.

- Result: Material wastage from finishing errors was eliminated. The automated stone polishing process enabled the company to offer more complex designs and reduce the lead time for a custom bathtub by 70%.

Risks & Key Installation Requirements

Risks & Key Installation Requirements

- Permanent Installation: These robots are heavy and powerful. They must be securely bolted to a reinforced concrete floor to maintain stability and accuracy. They are not designed to be moved around a workshop or taken to job sites.

- Industrial Power: The system requires a dedicated three-phase industrial power supply. It cannot run on standard residential or light commercial electricity.

- Factory Environment: This is a solution for a dedicated stone fabrication factory. The workspace must accommodate the robot's full range of motion and include proper safety guarding, water management, and slurry disposal.

- Safety and Compliance: The work cell must be designed to meet safety standards for robotic equipment. Furthermore, wet polishing stone generates slurry and silica dust. Effective engineering controls are mandatory. According to NIOSH, "engineering controls such as water sprays are the most effective way to control silica dust." Your setup must comply with local regulations, such as the OSHA standard for respirable crystalline silica.

Frequently Asked Questions (FAQ)

What are the main benefits of a stone polishing robot?

- Context: It excels when polishing complex 3D surfaces where manual work is inconsistent. It is designed for a factory setting with stable work-holding.

- Benefits: It guarantees a uniform finish, reduces reliance on scarce skilled artisans, and enables 24/7 operation to increase factory throughput.

- Next Step: To see if these benefits apply to your specific products, request a free workflow assessment.

How much does a robotic polishing machine price?

- Context: The total price includes the robot arm, polishing head, control software, safety cell (fencing, sensors), and installation.

- Parameters: A typical system ranges from $150,000 to $300,000, depending on the robot's size, payload, and software features.

- Boundaries: This does not include facility upgrades like a reinforced concrete foundation or three-phase power installation, which are prerequisites.

Can a stone edge polishing robot handle curved countertops?

- Context: Its 6-axis arm allows it to perfectly follow any edge profile, from a simple bullnose to complex ogee or waterfall edges on granite, marble, or quartz.

- Parameters: The system uses force control (e.g., 20-50N) and programmed paths to ensure a consistent sheen and shape that is very difficult to achieve manually.

- Boundaries: The workpiece must be securely fixtured to resist polishing forces without shifting.

What is the typical robotic polishing ROI?

- Context: ROI is driven by tangible cost savings and increased revenue opportunities.

- Key Drivers:

- Reduced labor costs (re-assigning skilled polishers).

- Elimination of rework and material waste from manual errors.

- Increased production capacity (24/7 operation) to take on more high-margin jobs.

How difficult is it to program a polishing robot?

- For Repetitive Parts: Programming is done once. An operator can then load the program and run production. No programmer is needed for daily operation.

- For High-Mix/Custom Parts: A skilled programmer is essential for creating new paths for each unique workpiece. This is a significant consideration.

- Boundary: If you lack programming staff and handle diverse jobs, an intelligent CNC polisher with a simpler operating system might be a better fit.

- Next Step: Discuss your product mix and team skills with our experts to determine the right machine for you.

Robotic polishing machine vs manual: which is better?

- Robot Wins On: Quality, speed, and consistency. It perfectly reproduces the same result 24/7 without fatigue.

- Manual Wins On: Flexibility for one-off artistic pieces or very low-volume jobs where programming time isn't justified.

- Boundary: A robot won't replace a true artisan creating a single masterpiece, but it will outperform and replace a production-line polisher for repetitive tasks.

- Next Step: Evaluate your product mix. If more than 50% is repetitive complex shapes, automation is your path to growth.

What kind of stone workshop automation is best to start with?

- Typical Path:

- Start with a CNC saw or waterjet for precise cutting.

- Add a robotic polisher when 3D finishing (sinks, curved edges) slows down your entire operation.

- Boundary: Don't invest in a polishing robot if you don't already have automated cutting, as you won't be able to supply it with parts fast enough.

How do you ensure stone polishing quality control with a robot?

- Repeatability: The robot's path, speed, and pressure are perfectly repeatable, ensuring every piece is identical to the approved sample.

- Data Logging: The system logs all critical process parameters (force, RPM, cycle time) for each job, creating a digital quality record for traceability and process improvement.

Parameters:

- Granite: Higher force (40-80N ), lower RPM (800-1200 ).

- Marble: Lower force (15-35N), variable RPM (1000-1500) to prevent bruising.

- Quartz: Medium force (30-60N ), strict RPM control to avoid burning resin.

Next Step: Learn how to achieve the best results by reading our guide to achieving mirror-perfect stone finishes.

Conclusion: Is It Time for Your Shop to Automate Polishing?

If you're ready to explore how automated stone polishing can transform your factory, request a free, personalized consultation with our automation experts today.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский