Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Comparing CNC wire saws, band saws, and waterjets for foamed ceramics? Our guide covers decision drivers, TCO, and an If-Then selection tree to help you choose.

TL;DR: Decision Framework

- Choose a CNC Wire Saw if: Your priority is cutting complex 3D shapes, preserving material integrity (no micro-cracks), and minimizing waste (low kerf) on high-value fragile materials.

- Choose a Band Saw if: You need low-cost, simple, linear cuts on softer ceramics or non-abrasive foams where precision and surface finish are not critical.

- Choose a Waterjet if: You cut a wide variety of materials (including metals), and water absorption into your porous ceramic is not a concern for your application.

30-Second Decision Guide: Choose CNC Diamond Wire Saw vs Waterjet (procurement guide)

- IF you need complex 3D shapes or curved cuts, THEN a multi-axis CNC Diamond Wire Saw is your primary option.

- IF finish quality and avoiding micro-cracks is critical for structural integrity, THEN the abrasive, low-stress wire saw is superior.

- IF material waste (kerf loss) is a major cost driver for your expensive ceramics, THEN the ultra-thin diamond wire offers the best yield.

- IF you need low-cost, simple linear cuts on soft, non-abrasive materials, THEN a band saw might suffice.

- IF you need to cut a wide variety of materials (including metal) and water absorption is not a concern, THEN a waterjet could be considered.

- IF high-volume, automated production is the goal, THEN a CNC-integrated wire saw is essential for efficiency and repeatability.

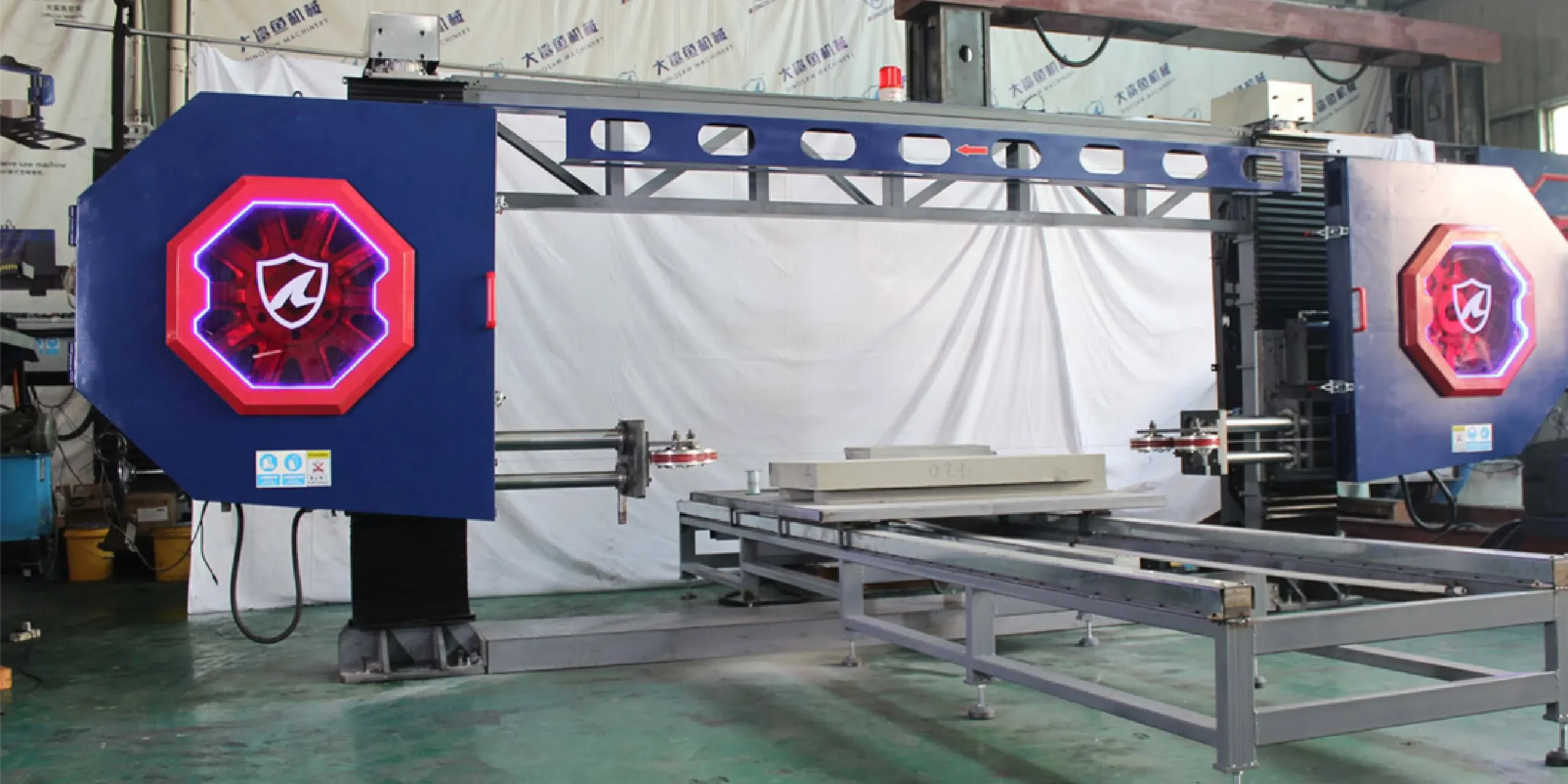

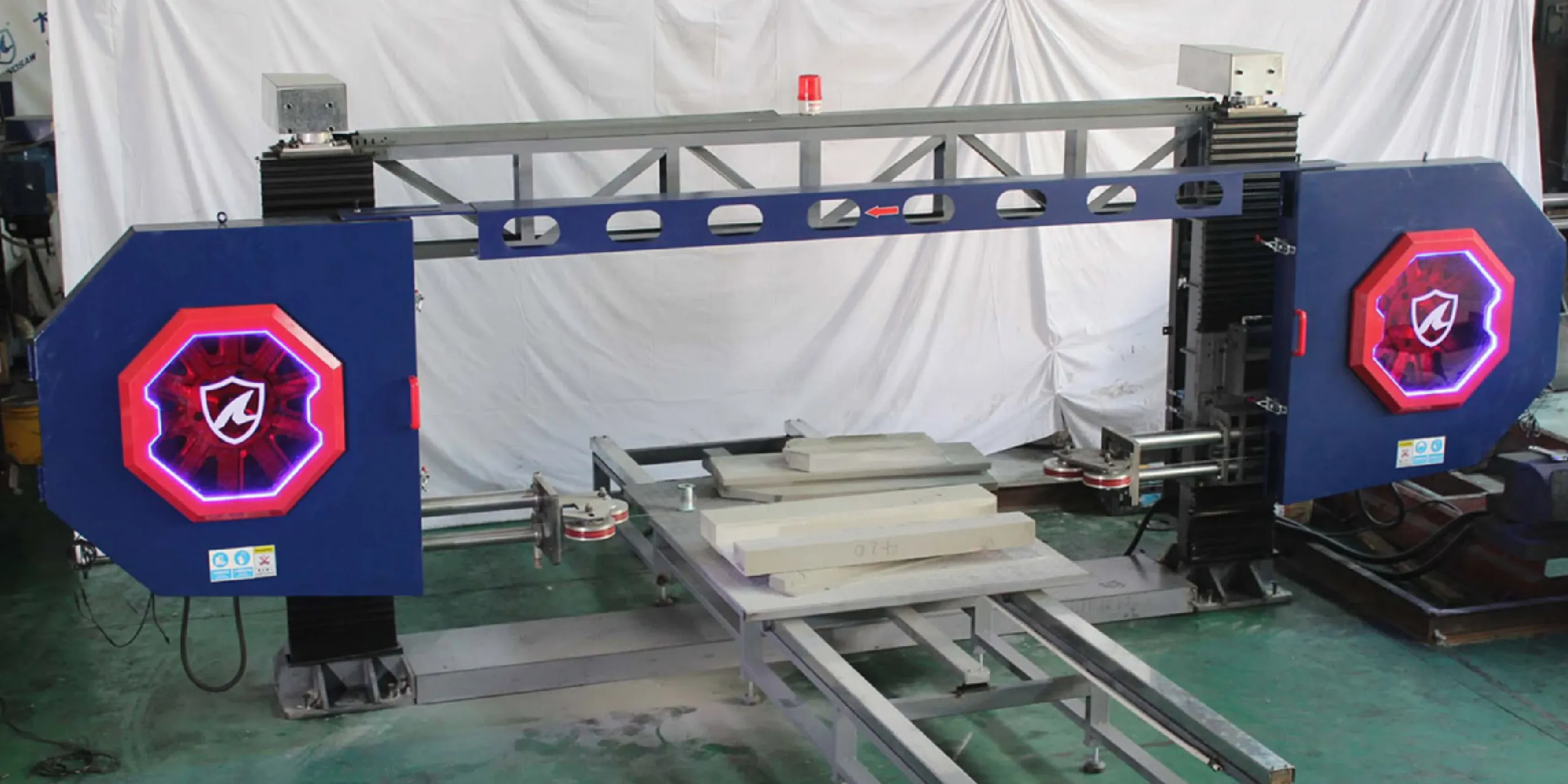

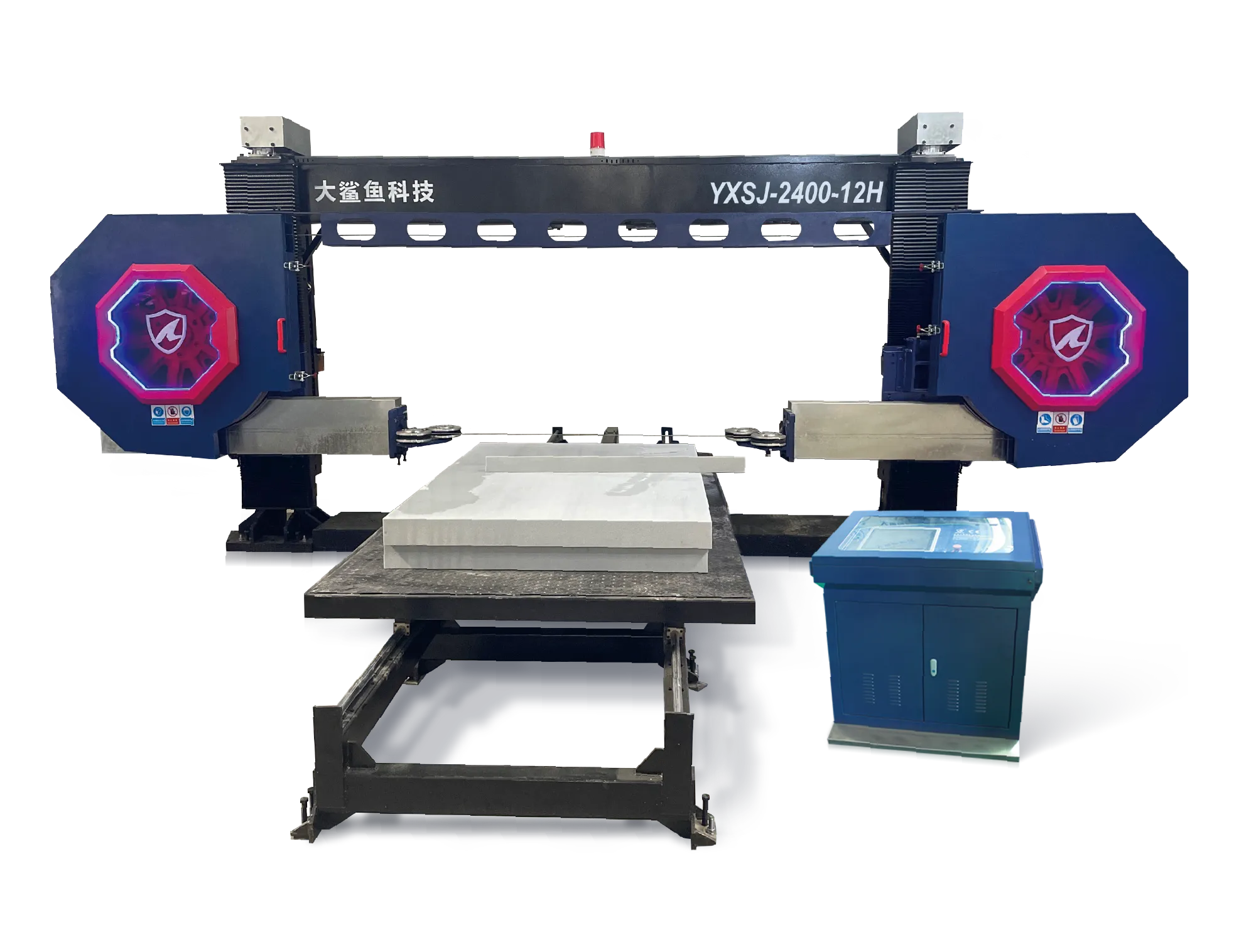

Wire Saw vs. Wire Saw: Ceramic-Focused vs. Stone Wire Saw Machine

Attribute | CNC Diamond Wire Saw (For Foamed Ceramics) | Traditional Stone Wire Saw Machine (For Blocks/Slabs) |

|---|---|---|

Target Materials | Fragile, lightweight, abrasive materials (Foamed Ceramics, Cellular Glass, GRC). | Hard, dense, large-format materials (Granite, Marble, Quartzite blocks). |

Wire Diameter & Grit | Fine (e.g., typically 3–4 mm) with finer diamond grit for smooth finishes. | Thick (e.g., 6.3mm - 11mm) with coarse diamond beads/rings for aggressive cutting. |

Kerf Characteristics | Very low (typically <3mm), maximizing material yield. | High (typically >8mm), focused on cutting speed over material savings. |

Stress/Micro-crack Risk | Very low; process is optimized to prevent subsurface damage in fragile materials. | Moderate; designed for brute-force cutting, not preserving delicate structures. |

Cooling/Dust Control | Typically uses controlled water cooling. Requires integrated systems for slurry management and HEPA dust extraction. | Primarily uses heavy water cooling to manage heat and slurry. |

Automation & Axes | High automation with multi-axis (3 to 5+ axes) CNC for complex geometries. | Lower automation, often focused on simple linear cuts with fewer axes. |

Wire Saw vs Waterjet vs Band Saw vs Blade Saw

Wire Saw vs Waterjet vs Band Saw vs Blade Saw

Feature | CNC Diamond Wire Saw | Band Saw | Blade Saw | Waterjet |

|---|---|---|---|---|

Precision | Excellent | Low | Moderate | Very Good |

Kerf Loss | Very Low | Moderate | High | Low |

Material Integrity | Excellent (no micro-cracks) | Poor (high risk of chipping) | Moderate (risk of micro-cracks) | Good, but high-pressure water stream creates significant water absorption and delamination risk. |

Speed | Moderate | Fast (for soft materials) | Fast (for linear cuts) | Slow to Moderate |

Material Versatility | Good (excels at hard, brittle materials) | Limited (soft, non-abrasive) | Limited (hard materials, simple cuts) | Excellent (cuts almost anything) |

Operational Cost | Low to Moderate | Low | Moderate | High |

Manual vs Automatic: Neutral Comparison for Current/Traditional Processes

Criterion | Manual Process (Band Saw / Blade Saw / Handheld) | Automatic Process (CNC Diamond Wire Saw) |

|---|---|---|

Precision & Repeatability | Low; highly dependent on operator skill. Difficult to maintain consistency. | Excellent; Sub-millimeter precision with high batch-to-batch repeatability. |

Material Waste (Kerf) | High; thicker blades lead to more material loss per cut. | Very Low; ultra-thin wire minimizes kerf, maximizing material yield. |

Geometric Complexity | Limited to simple linear cuts. | High; capable of complex 2D and 3D contours, curves, and angles. |

Setup Time | Short for simple cuts, but long for any complex jigging. | Longer for initial program loading, but very fast for repeat jobs. |

Typical Throughput (line profiles) | Varies widely; lower effective throughput due to thicker kerf and more rework for fragile materials. | Approximately 500–800 meters per 8‑hour day under balanced settings (optimize by wire speed, feed rate, geometry). (Observed on Big Shark foamed ceramic wire saw with stable tension control). |

Labor Requirement | High; requires constant skilled operator attention. | Low; allows for unattended operation after setup. |

Procurement Topics: TCO, Spares, Training for CNC Stone Cutting Machine

- Total Cost of Ownership (TCO): Look beyond the initial purchase price. A comprehensive TCO analysis should include initial cost, consumables (e.g., diamond wire, blades, garnet), energy consumption, maintenance, and potential revenue from reduced material waste. A wire saw often has a lower TCO than a waterjet due to savings on high-pressure pumps and abrasives.

- Spare Parts & Consumables Availability: How quickly can you get replacement wires, pulleys, or other critical parts? Downtime waiting for parts can be more costly than the parts themselves. Inquire about the supplier’s stock and lead times.

- Maintenance Window & Serviceability: Ask about the required daily, weekly, and monthly maintenance tasks. A well-designed machine allows for quick wire changes and easy access to lubrication points, minimizing service downtime.

- Operator Training & Learning Curve: What level of training is required? A machine with an intuitive user interface and robust CNC control system can reduce the learning curve and minimize operator error.

- Warranty & Service Level Agreements (SLA): Understand the warranty coverage and what SLAs are available for technical support and on-site service. This is your insurance against unexpected, prolonged downtime.

- Certifications: Ensure the machine complies with safety and electrical standards relevant to your region (e.g., CE for Europe, UL for North America). Compliance with standards from bodies like OSHA on silica dust is also a critical consideration for facility safety.

Scenario Recommendations: Best Stone CNC Machine Types for Foamed Ceramics

Scenario Recommendations: Best Stone CNC Machine Types for Foamed Ceramics

Prototyping Complex Parts

High-Volume Slab Slicing

Budget-Constrained Job Shop

Frequently Asked Questions (FAQ)

What is the typical throughput for foamed ceramic line profiles?

- Context: Throughput depends on wire speed, feed rate, profile complexity, and material;

- Procedure: Start with conservative settings, validate with short trial runs, then ramp;

- Next Step: Record parameters per material/profile to maintain consistent output.

Wire saw vs waterjet, which is better for foamed ceramics?

- Context: The primary drawback of waterjets for this material is that the porous structure absorbs water, which can compromise structural integrity and require lengthy, costly drying times. A wire saw's dry process eliminates this risk.

- Procedure: A wire saw uses a low-stress abrasive action, which is purpose-built for fragile, brittle materials. A waterjet, while versatile, can cause delamination or surface erosion on certain hard ceramics.

- Next Step: If your application cannot tolerate any moisture intrusion, the choice is clear: a wire saw is the technically correct solution.

How much does a CNC diamond wire saw cost?

- Context: Price varies widely based on size, number of axes, and features. However, a wire saw’s lower consumable and energy costs often make it more economical long-term compared to a waterjet with a similar cutting envelope.

- Procedure: To make an informed decision, a procurement guide should focus on TCO, which includes the initial price plus ongoing costs for consumables, energy, and maintenance.

- Next Step: Contact our team for a custom quote and a TCO analysis based on your specific production needs.

Can I use the same machine for cutting granite and foamed ceramics?

- Context: The machine is one of the best stone cnc machine types for profiling granite, but it is also gentle enough for fragile ceramics. The core cutting principle remains the same.

- Procedure: To switch between materials, you would simply change the cutting parameters (e.g., lower the feed rate for the more fragile ceramic) and potentially switch to a different diamond wire specification (e.g., a finer grit).

- Next Step: Maintain a parameter sheet for each material you cut to make changeovers quick and repeatable.

What is the typical ROI for a CNC wire saw in a ceramic fabrication shop?

- Context: ROI is driven by direct cost savings (reduced material waste from minimized kerf loss), increased profit margin (ability to produce high-value complex parts), and labor savings from automation.

- Procedure: To calculate your potential ROI, quantify your current annual spending on wasted material, the value of complex jobs you currently turn down, and the labor hours spent on manual cutting processes.

- Next Step: Contact us for a consultation. We can help you build a business case and estimate the ROI for your specific operation.

What are the key differences between ATC and Multi-head CNC machines?

- Context: As explained in our ATC vs. Multi-Head comparison, ATC (Automatic Tool Changer) routers provide flexibility for complex jobs, while Multi-Head routers are for mass-producing identical items.

- Procedure: For wire saws, the equivalent choice is between a single-wire machine, which offers maximum flexibility for unique, complex shapes, and a multi-wire machine, which is designed for mass-slicing large blocks into uniform slabs.

- Next Step: Choose a single-wire saw for prototyping and custom fabrication. Choose a multi-wire saw if your business is focused on high-volume slab production.

How do I arrange a test cut of my material?

- Context: A test cut provides definitive proof that the machine can meet your quality and precision standards on your specific material.

- Procedure: Provide our sales engineering team with your material specifications and a design file (DXF or DWG) of the part. We will then coordinate the logistics to process your sample.

- Next Step: Contact us today to begin the process. We will return the finished part and a detailed report for your evaluation.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский