Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Explains components, ranges, failure modes, and starting settings for granite/marble/quartz edge cutting.

TL;DR: The Engineering Principles

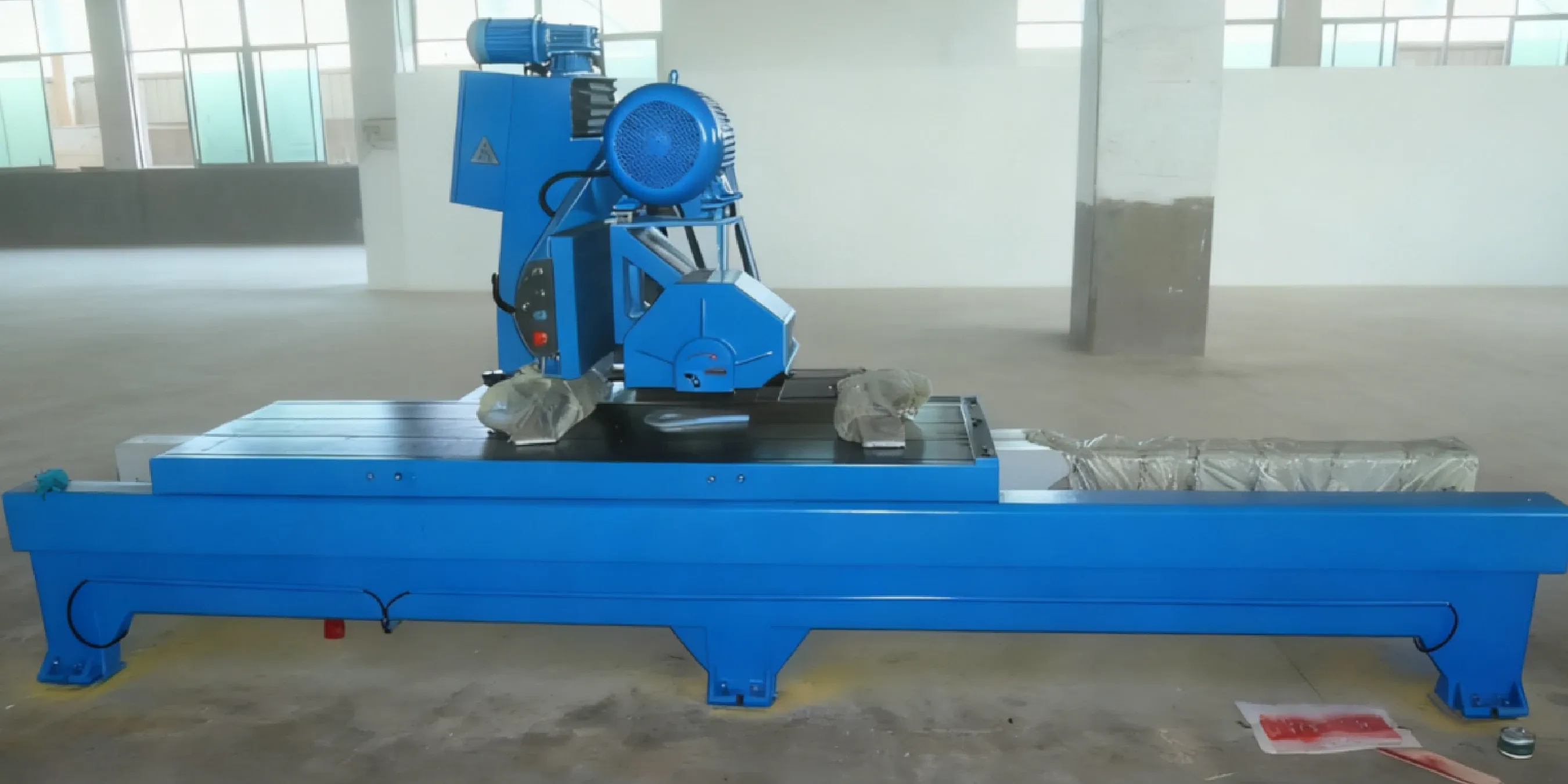

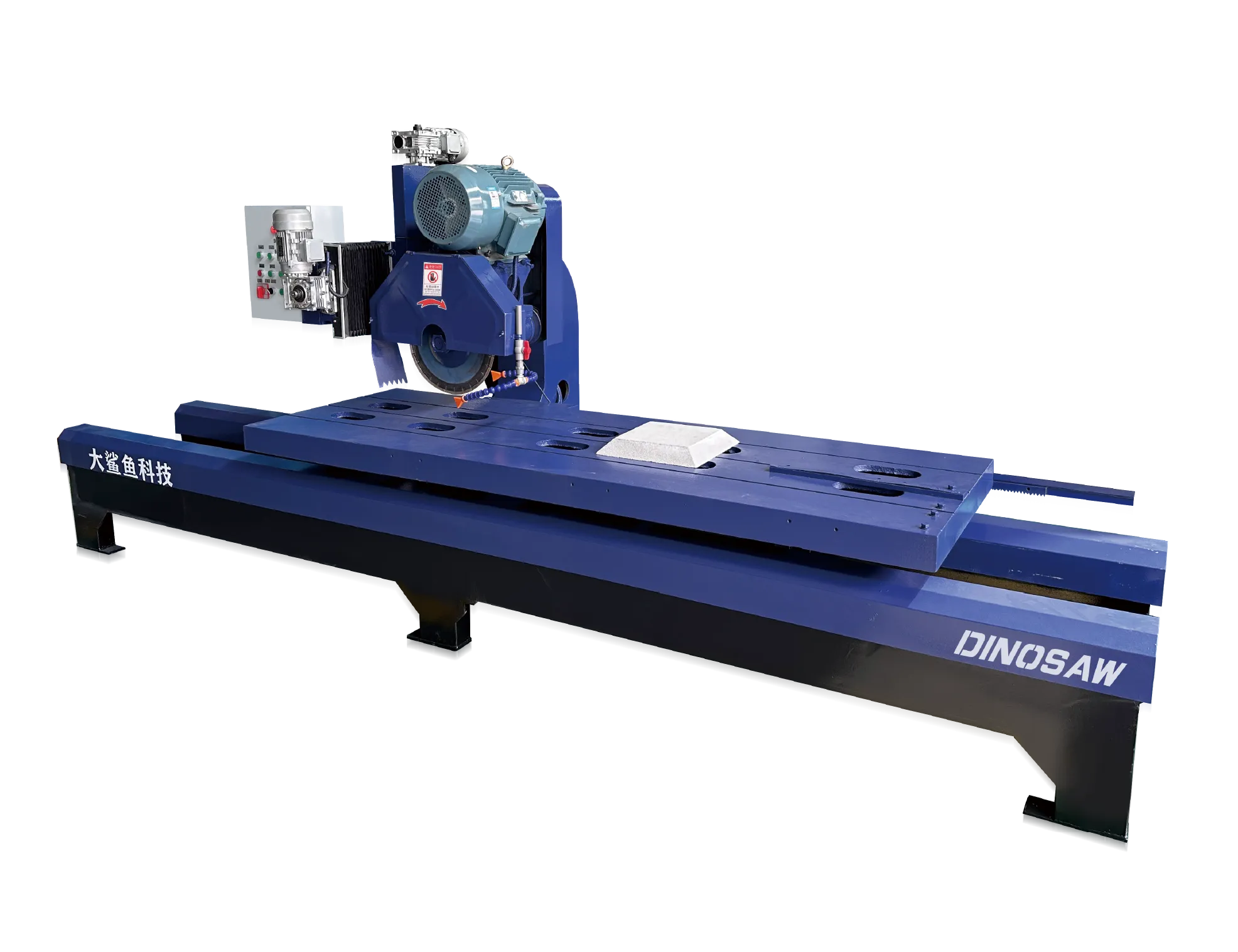

- What It Is: A manual industrial stone cutting machine built on a stable cast‑iron frame with oil‑immersed guide rails and a tilting head for 45° chamfers.

- Why It’s Better (for Standard Cuts): It offers faster deployment, lower maintenance, and repeatable edge quality compared to complex automated routes for standard jobs.

- Where It Fits (and Doesn't): Perfectly suited for small‑batch straight cuts and bevels. It is not the right tool for complex curves—use a CNC or a Automatic Bridge Saw (CNC/PLC) instead.

- How to Proceed: Start with a blade matched to the material, a moderate RPM appropriate to the material, and a water flow of 2–3 m³/h. Always validate the angle with a test cut before batch processing.

What Manual Industrial Stone Cutting Machine and Why Is It Better for Standard Geometries?

Principles & Architecture

- Power and Cutting Depth: The main motor drives the blade spindle, while the operator controls feed and depth. This manual control helps minimize blade deflection and ensures a clean cut by allowing real-time adjustments based on material feedback.

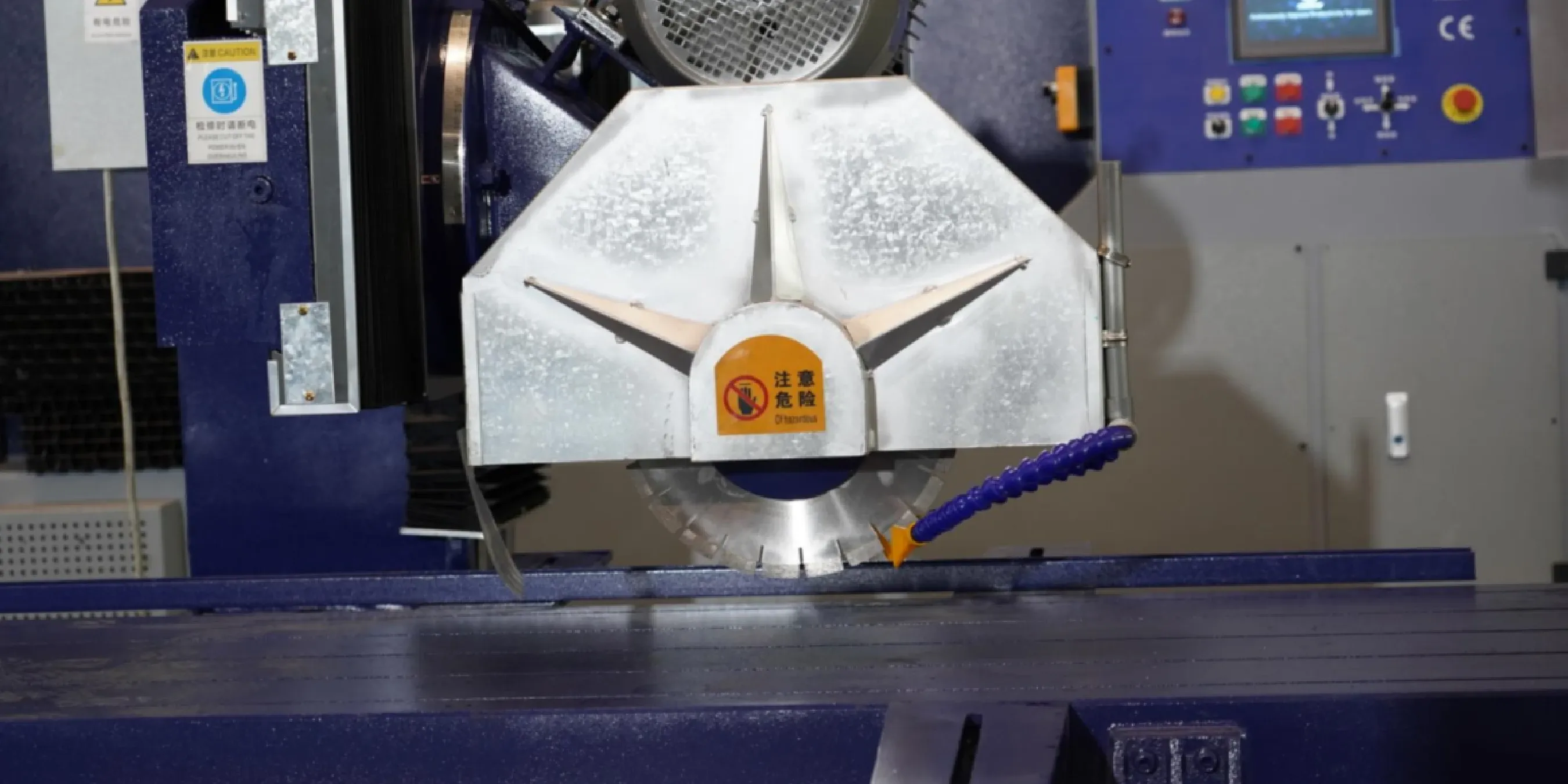

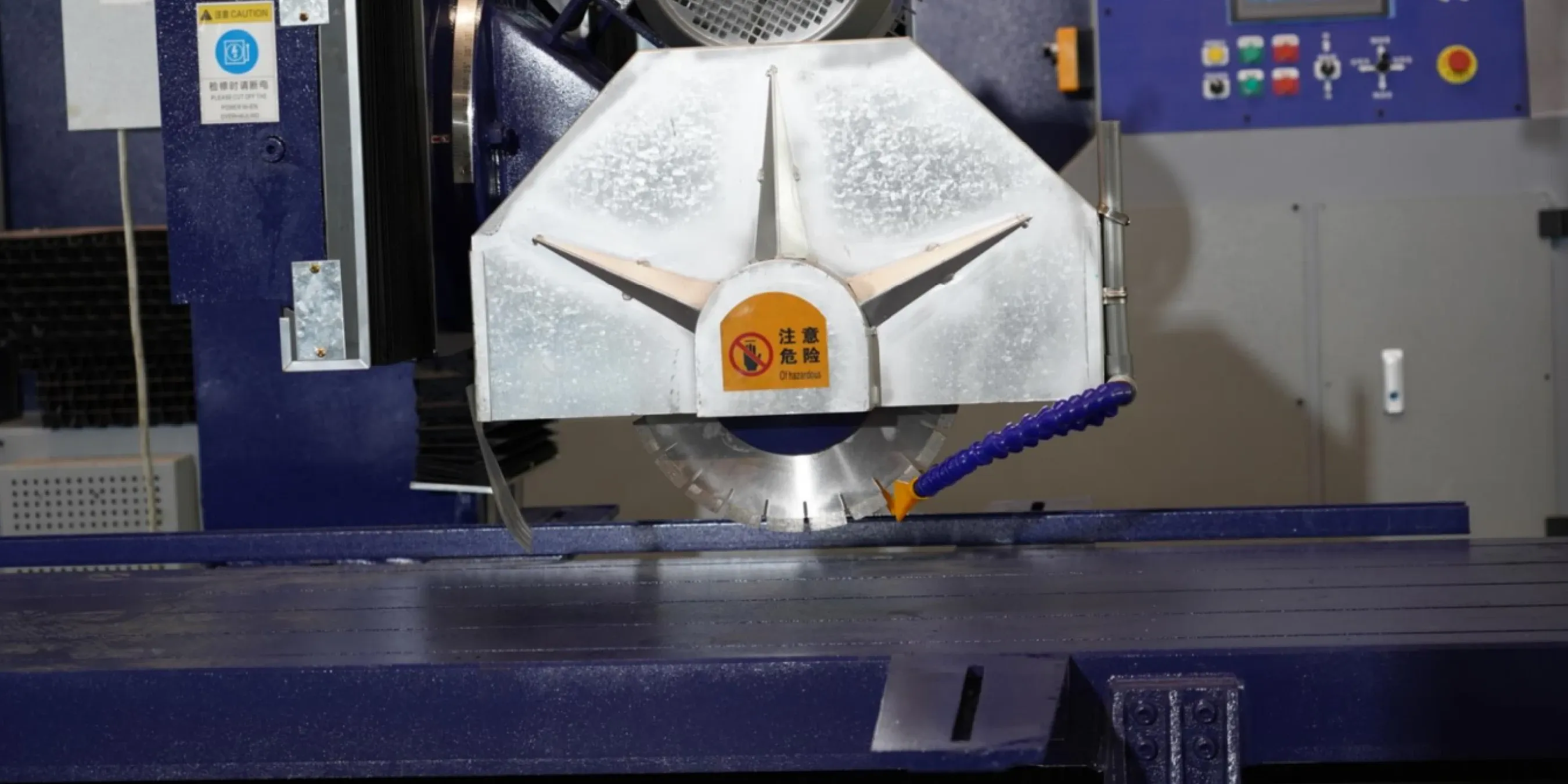

- Angle Control: The cutting head assembly tilts and locks securely at a 45° angle. Before starting a batch, this angle must be calibrated with a precision gauge or digital protractor to guarantee consistency across all pieces.

- Water Cooling and Dust Suppression: A continuous water circuit, delivering 2–3 m³/h, cools the blade to prevent thermal damage and suppresses respirable crystalline silica dust. This is critical for protecting both the operator and the quality of the cut edge.

- Data Flow: The operational data flow is straightforward: the operator sets the RPM, adjusts the feed rate, and monitors the cooling flow. These parameters are adjusted based on material hardness and slab thickness to optimize performance.

Manual Industrial Stone Cutting Machine Core Technical Advantages

Precision

Control

Deployment & O&M

Neutral Comparison: Manual vs. Other Technologies

Technology | When to Choose | When Not to Choose |

|---|---|---|

Manual Cutter (This Product) | Straight cuts & 45° chamfers on small-to-medium batches. Wins on speed, cost, and flexibility for simple jobs. | Complex curves, high-volume automation, or multi-axis patterns. |

Waterjet / Band Saw | Waterjets for intricate, custom shapes and multi-material cutting. Band saws can handle rough curves. | Standard straight edges and chamfers, where the manual cutter delivers a superior surface finish more efficiently. |

Waterjet / Band Saw | Waterjets are for intricate, custom shapes and multi-material cutting. Band saws can handle rough curves. | Standard straight edges and chamfers, where the manual cutter delivers a superior surface finish more efficiently. |

Automatic Bridge Saw (CNC/PLC) | High-volume production, intricate designs, and perfect repeatability. Ideal for nested cutting to maximize slab yield. | Quick, one-off straight cuts where programming time and higher operating costs are not justified. |

Components & Parameter Ranges

Main Motor Power | 7.5–11 / 15 / 18.5 kW (manufacturer-reported) |

Blade Diameter | Φ350–Φ600 mm |

Worktable Size | 2700×800 / 3000×800 mm (approx. 106×31 / 118×31 in) |

Max Cutting Size | 2500×1200×180 / 3000×1200×180 mm (approx. 98×47×7 / 118×47×7 in) |

Water Consumption | 2–3 m³/h |

Approximate Weight | 1.8–2.5 t |

Voltage | Three-phase, configurable per region and customer requirements (e.g., 380V/440V) |

Manual Industrial Stone Cutting Machine Common Failures & Mitigation Strategies

- Edge Chipping : - Symptom: Micro-cracks and notches along the cut edge. - Cause: Dull blade, excessive feed rate, or workpiece vibration. - Diagnosis: Inspect the blade for wear and check that the worktable is level. - Resolution: Replace the blade with a fine-tooth or appropriate grit model, reduce the feed rate, securely clamp the workpiece, and increase water flow.

- Angle Deviation : - Symptom: Inconsistent chamfer angles. - Cause: Insufficiently tightened angle lock or contaminated guide rails. - Resolution: Re-calibrate and securely tighten the 45° lock. Clean and lubricate the guide rails. Always perform a test cut before starting a new batch.

- Thermal Cracking : - Symptom: Fine cracks appearing at the cut line. - Cause: Insufficient cooling or attempting to cut dry. - Resolution: Ensure a continuous water flow of 2–3 m³/h covers the cutting zone. For very hard materials, reduce the cutting speed and use multiple shallow passes.

- Special Case - Slate: Due to its high brittleness, slate requires a fine-grit blade, a slow feed rate, and a perfectly level, securely clamped setup. If chipping persists, an infrared bridge saw may be a better alternative.

Compatibility & Starting Parameters

- Interfaces: Basic status-monitoring with workshop PLC/drives/safety circuits is possible (e.g., via OPC UA/Profinet, where applicable). Contact our team for details.

- Clamping/Fixtures: Using positioning jigs and mechanical clamps significantly improves repeatability. For batch chamfering, mechanical limit stops and angle gauges are highly recommended.

Starting Settings by Work Condition

Soft Stone

Hard Stone

Thin Slabs

Frequently Asked Questions (FAQ)

Why is 45° chamfer control easier on this machine?

- Context: Angle lock at 45° with gauge/digital‑protractor calibration; oil‑immersed rails reduce vibration.

- Benefits: Higher repeatability, faster batch setup, less rework on chamfered edges.

When should I use a Φ600 mm blade?

- Context: Thicker sections and high‑hardness materials increase cutting load; blade size extends cutting depth.

- Benefits: Achieves required depth while maintaining cut quality when paired with slower feed and ample water.

How often should I lubricate the guide rails?

- Context: Oil‑immersed rails are critical for smooth motion and precision.

- Benefits: Maintains repeatability, lowers wear, and prevents stick‑slip.

What are the electrical wiring & safety basics?

- Context: Industrial circuits must meet local codes; periodic cable/terminal inspections.

- Benefits: Stable power, safer operation, fewer outages.

Can you provide parameter starting points?

- Context: Match blade/feed/water to material hardness and thickness; validate with trial cuts.

- Benefits: Cleaner edges, fewer defects, and consistent finishing across batches.

- Next Step: Get material‑specific starting settings on the Manual Industrial Stone Cutting Machine page.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский